Miniature carbide endmills are indispensable tools in precision manufacturing, offering unique advantages in small part machining and microstructure cutting. Compared to conventional carbide endmills, miniature endmills demand tighter control of tool diameter, sharper cutting edges, and greater cutting stability, making them ideal for industries such as moldmaking, electronics, medical devices, and aerospace.

Different materials require specific considerations when selecting mini carbide endmills. For instance, carbide endmills for hardened steel emphasize wear resistance and coating durability to handle high-hardness workpieces, while carbide endmills for stainless steel prioritize anti-sticking properties and cutting stability. In plastics machining, chip evacuation and melt prevention are critical. For graphite electrodes and molds, carbide endmills must balance wear resistance with accurate contour retention.

OEM carbide endmills provide customized solutions by tailoring tool geometry, coating type, and diameter specifications to meet customer requirements. This customization enhances tool life, improves cost-effectiveness in mass production, and ensures consistent high-precision machining. For CNC companies aiming to maximize efficiency and surface quality, selecting the right miniature carbide endmills is essential for improving overall machining performance and competitiveness.

What Are Miniature Carbide Endmills?

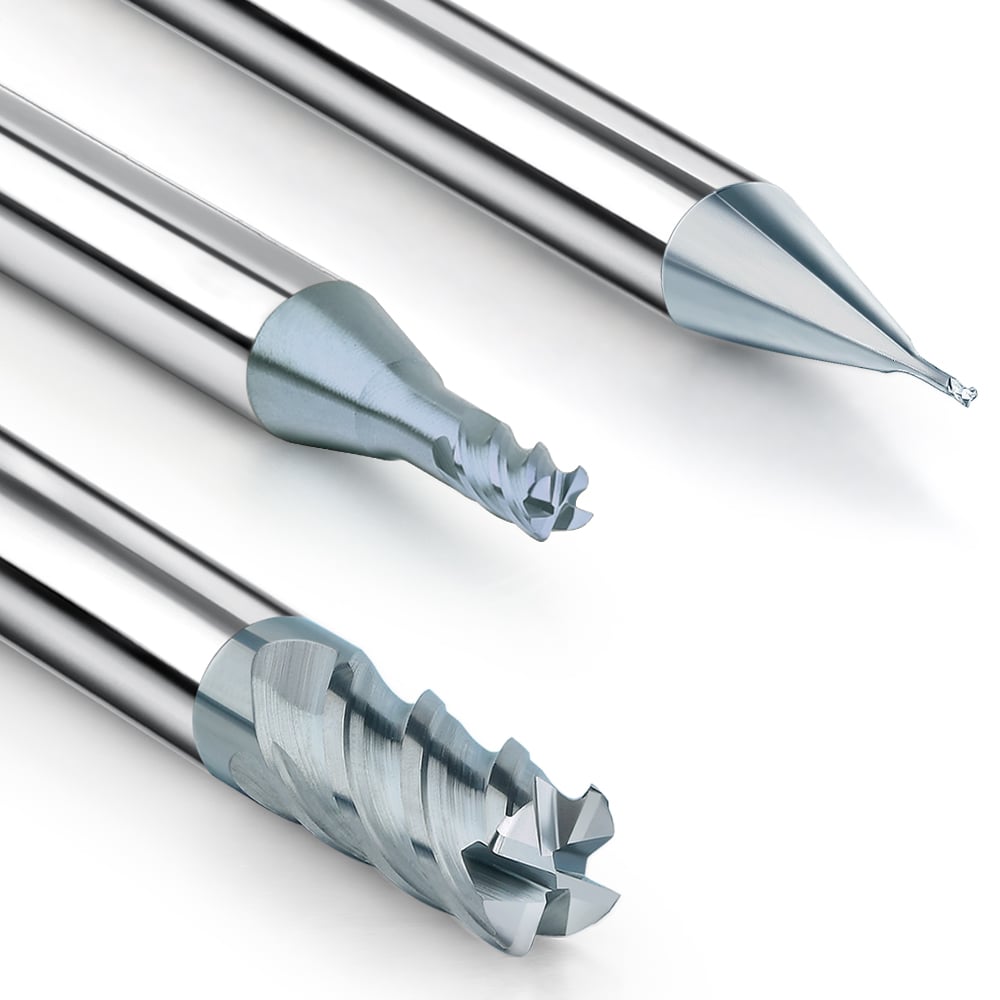

Miniature carbide endmills are specialized cutting tools designed for small part machining and precision manufacturing. Compared to standard carbide endmills, these tools typically have smaller diameters and sharper cutting edges, allowing micro-cutting and complex contour machining in confined spaces. Whether producing medical devices, electronic components, or high-precision molds, mini carbide endmills are favored for their dimensional accuracy and stable cutting performance.

Mini carbide endmills are optimized for a variety of materials: carbide endmills for hardened steel provide superior wear resistance; carbide endmills for stainless steel focus on anti-sticking and thermal stability; and carbide endmills for plastics and graphite emphasize chip evacuation and surface finish. They are not merely smaller versions of standard cutters—they are high-performance tools designed for precision micro-machining.

Basic Definition and Characteristics of Carbide Endmills

Carbide endmills are among the most common tools in CNC machining. Constructed from high-hardness tungsten carbide, they offer exceptional wear resistance and thermal stability. Compared to high-speed steel tools, carbide endmills maintain a sharp cutting edge at higher speeds, improving both efficiency and tool life. Various types of carbide endmills provide unique geometries tailored to specific machining requirements.

Mini carbide endmills, in particular, balance diameter control with tool strength, enabling high-precision small part machining while maintaining consistent cutting quality and excellent surface finish.

Differences Between Mini Carbide Endmills and Conventional Milling Cutters

Mini carbide endmills differ from standard endmills in several ways:

-

Smaller Diameter: Suitable for tight spaces and micro-details, with diameters reduced to microns.

-

Higher Cutting Precision: Designed to meet strict tolerances and surface finish requirements.

-

Specific Applications: Ideal for micro molds, medical components, electronics, and aerospace parts, whereas conventional endmills serve general machining of metals like steel and aluminum.

Thus, miniature carbide endmills are optimized tools for specialized precision machining, not just scaled-down versions of standard cutters.

Advantages of Using Mini Carbide Endmills in Small Part Machining

Mini carbide endmills offer the following advantages:

-

High Precision: Capable of achieving micron-level tolerances.

-

Excellent Surface Finish: Sharp edges reduce burrs and minimize secondary finishing.

-

Versatility: Suitable for hardened steel, stainless steel, plastics, and graphite, with coatings and geometry tailored for each material.

-

Long Tool Life: Maintains low wear rates at high speeds and shallow cuts.

-

OEM Customization: Customized diameters, cutting edge angles, and coatings improve productivity and competitiveness.

These advantages make miniature carbide endmills essential tools for precision micro-machining.

Types of Carbide Endmills – Common Types and Their Applications

Carbide endmills vary by geometry, cutting characteristics, and application. Selecting the right type improves cutting efficiency, extends tool life, and enhances surface finish. Common types include flat end mills, ball nose end mills, corner radius end mills, and mini endmills, each designed for specific machining needs.

Flat End Mills

Flat end mills feature straight cutting edges for efficient material removal and edge processing. Common in face milling, grooving, and contouring, they are suitable for roughing and semi-finishing hardened steel and stainless steel . Advantages include high rigidity, excellent geometric accuracy, and strong cutting efficiency. Complex surfaces often require additional specialized tools.

Ball Nose End Mills

Ball nose end mills are ideal for 3D surfaces and complex contours, producing smooth finishes for precision mold, aerospace, and medical components. For hardened steel and graphite, ball-nose designs achieve high-precision cavity and curved surface machining while reducing cutting forces at the tool tip, enhancing tool life and process stability.

Corner Radius End Mills

Corner radius end mills feature a rounded edge transition, reducing stress concentration and preventing chipping. They are suitable for stainless steel and high-strength materials, often used in aerospace and mold production. Compared to flat end mills, they offer better wear resistance, extended tool life, and improved corner machining performance.

Role of Miniature Carbide Endmills in Precision Machining

Mini carbide endmills excel in micro-cutting, forming micro-holes, grooves, and intricate details. In medical devices, electronics, and micro-molds, they provide dimensional accuracy and superior surface quality.

-

Carbide endmills for plastics: Smooth cutting, prevents material melting.

-

Carbide endmills for graphite: Maintain wear resistance and contour accuracy.

-

OEM carbide endmills: Customized diameters, coatings, and geometries enhance efficiency and competitiveness.

Miniature carbide endmills are thus critical tools for precision micro-machining.

Small Part Machining of Different Materials and Carbide Endmill Selection

Material properties dictate tool selection and cutting strategies. Carbide endmills excel across materials due to high hardness, wear resistance, and cutting stability. Tool geometry, coating, and cutting parameters must be adjusted for specific materials to improve accuracy, surface finish, and tool life.

Carbide Endmills for Hardened Steel

Hardened steel challenges small part machining due to high hardness, cutting forces, and heat generation. Carbide endmills for hardened steel feature ultrafine carbide substrates with TiAlN, AlTiN, or CVD coatings to improve wear and thermal resistance. Mini carbide endmills allow precise high-speed, low-depth cuts, preventing surface cracks or burns, crucial for mold cavities and precision components.

Carbide Endmills for Stainless Steel

Stainless steel’s toughness and low thermal conductivity increase tool sticking and heat buildup. Carbide endmills for stainless steel optimize flute design and anti-sticking properties, often combined with coatings to reduce built-up edge. Mini endmills maintain cutting stability via feed rate optimization and cooling, ensuring high surface quality for medical and precision parts.

Carbide Endmills for Plastics

Plastics are prone to melting and deformation, affecting small part precision. Carbide endmills for plastics feature sharp edges and large helix angles to reduce heat and improve chip evacuation. Miniature tools maintain high-speed cutting with low forces, preventing burrs or melt marks, improving surface finish and yield for electronic housings and medical parts.

Carbide Endmills for Graphite

Graphite’s brittleness and abrasiveness demand high wear resistance. Carbide endmills for graphite are uncoated or diamond-coated to maintain machining accuracy. Mini carbide endmills enable precise electrode and mold cavity machining, ensuring form accuracy, edge retention, and surface quality, critical for high-precision EDM electrodes.

Applications of Mini Carbide Endmills in Precision Manufacturing

Miniature carbide endmills, with ultra-small diameters, precise geometry, and excellent cutting stability, are indispensable in precision manufacturing. They efficiently machine micro molds, medical devices, electronic components, and aerospace parts, maintaining dimensional accuracy and excellent surface finish while minimizing tool wear.

When combined with OEM carbide endmill customization, tool geometry and coating types can be optimized for different materials—hardened steel, stainless steel, plastics, and graphite—significantly improving machining efficiency and tool longevity.

Micro Mold and Cavity Machining

Micro molds and precision cavities often feature complex curves and tiny details. Mini carbide endmills provide high precision, low vibration, and sharp cutting edges to machine microgrooves, microholes, and intricate contours within confined spaces.

For hardened steel or stainless steel molds, carbide endmills for hardened steel and carbide endmills for stainless steel offer the necessary wear and heat resistance. OEM carbide endmills can be tailored in diameter and cutting edge geometry to match specific mold designs, improving cutting efficiency and surface quality.

Medical Devices and Micro Components

Medical micro parts, including catheter connectors, micro gears, and surgical instruments, require extremely tight tolerances and smooth surfaces. Mini carbide endmills ensure precise cutting, low burr formation, and stable machining to meet stringent medical standards.

Material-specific tooling is critical: plastics require carbide endmills designed to prevent melting and deformation, while stainless steel components need wear-resistant, anti-sticking carbide endmills to maintain machining stability.

Electronic Components and Precision Connectors

Electronic parts are small, complex, and demand high surface finish and accuracy. Mini carbide endmills achieve low tool wear and high efficiency when machining micro holes, guide grooves, and precise contours.

PCB connectors, miniature plugs, and electronic housings benefit from tools with high rigidity, sharp cutting edges, and optimized chip evacuation. OEM customization further refines tool diameter, flute length, and helix angle for repeatable, high-volume production.

Aerospace and High-Precision Structural Parts

Aerospace components, often made of titanium alloys or hardened steel, require tools capable of maintaining dimensional tolerances and surface quality under challenging conditions. Mini carbide endmills provide extended tool life, stable cutting, and excellent finishes when machining micro fasteners, guide grooves, and support structures.

For high-hardness parts, carbide endmills offer wear resistance and thermal stability, while OEM carbide endmills enable customized geometry for efficient machining of complex, curved surfaces.

OEM Carbide Endmills – Advantages of Customized Mini Milling Cutters

While standard mini carbide endmills perform well, specialized parts often demand unique materials, geometries, and precision. OEM carbide endmills offer tailored solutions, adjusting diameter, cutting edge shape, coatings, and geometry to optimize cutting performance, tool life, and machining cost-efficiency.

Customized tools are suitable for a variety of materials, including hardened steel, stainless steel, plastics, and graphite, and excel in high-precision applications such as micro molds, medical devices, electronics, and aerospace parts.

Customizing Tool Diameter and Cutting Edge Shape

OEM carbide endmills can be tailored in diameter, cutting edge length, and helix angle based on part size, tolerance, and complexity. This ensures dimensional accuracy, stable machining, and optimized force distribution, reducing vibration and tool wear.

For micro molds, customized cutting edge shapes improve machining of deep grooves and complex contours. For stainless steel or hardened steel parts, helix angle and tip shape optimization enhances cutting stability and tool life.

Special Coatings and Wear-Resistant Designs

OEM carbide endmills can feature specialized coatings such as TiAlN, AlCrN, or diamond to enhance wear resistance, thermal stability, and cutting performance.

-

Carbide endmills for hardened steel: improved wear resistance and thermal durability

-

Carbide endmills for stainless steel: reduced sticking and improved surface finish

-

Carbide endmills for plastics/graphite: enhanced chip evacuation, reduced burrs, and minimized melting

These features ensure long tool life and high precision even under high-speed or heavy cutting loads.

Cost-Effectiveness and Competitiveness for B2B Customers

For B2B clients, OEM carbide endmills optimize machining efficiency, product quality, and production costs. Customization enables:

-

Reduced tool change frequency and downtime

-

Improved yield and reduced scrap

-

Optimized cutting parameters for mass production

-

Differentiation in the market through tailored tooling solutions

OEM carbide endmills combine durability, precision, and customization to enhance competitiveness and reduce costs in small part machining.

How to Extend the Life of Miniature Carbide Endmills

Mini carbide endmills, with their small diameters and sharp edges, are susceptible to wear or breakage. Optimizing cutting parameters, cooling, chip evacuation, and maintenance is essential to prolong tool life while ensuring accuracy and surface finish.

Effective tool life management reduces replacement frequency, machining costs, and improves yield for micro molds, medical devices, electronics, and aerospace components.

Optimizing Cutting Speed and Feed

Cutting speed and feed directly impact tool life. Material-specific recommendations include:

-

Hardened steel: lower cutting speed to reduce wear; maintain high feed for efficiency

-

Stainless steel: balanced speed/feed to prevent sticking and thermal damage

-

Plastics/graphite: higher speed allowed; control depth of cut to prevent melting or chipping

Optimized parameters reduce wear, enhance micro-cutting stability, and extend miniature carbide endmill life.

Cooling Method and Chip Evacuation Design

Mini carbide endmills are prone to high temperatures and chip clogging. Effective measures include:

-

Liquid or gas cooling to reduce tool temperature

-

Optimized helix angles and flute design for smooth chip removal

-

Enhanced chip evacuation for plastics and graphite to prevent burrs, melting, and surface defects

Proper cooling and evacuation ensure tool longevity and machining stability.

Tool Maintenance and Inspection

Regular maintenance is critical:

-

Inspect cutting edges for wear, chipping, or tip damage; replace or resharpen as needed

-

Clean and apply anti-corrosion treatment to prevent damage from chips and fluids

-

Adjust cutting speed, feed, and cooling according to material and part requirements

Maintenance ensures long-term efficiency, dimensional accuracy, and surface quality.

Why Mini Carbide Endmills Are the Best Choice for Small Part Machining

Mini carbide endmills provide high precision, wear resistance, and customization, making them essential for micro molds, medical devices, electronics, and high-precision aerospace components. They offer stable cutting, excellent surface finish, extended tool life, and reduced production costs.

OEM customization further enhances performance by optimizing diameter, cutting edge geometry, coatings, and chip evacuation for different materials, achieving high efficiency and long-term stability.

Comprehensive Advantages of Precision, Life, and Customization

-

High Precision: Ideal for micro holes, grooves, and complex contours

-

Long Tool Life: Optimized speeds, feeds, cooling, and chip management ensure durability

-

Customization: OEM carbide endmills tailored for geometry, coatings, and material requirements

These combined advantages make mini carbide endmills more reliable than standard tools for small part machining.

Value to Different Industries

-

Mold Manufacturing: Precise micro cavities and contours with smooth finish

-

Medical Devices: Micro components meeting strict tolerances

-

Electronics: Micro holes, guide grooves, and connectors with high repeatability

-

Aerospace: Micro-machining of high-strength structural parts with improved fatigue resistance

Strengthening B2B Customers’ Confidence in Choosing Carbide Endmills

Mini carbide endmills provide precision, durability, customization, and multi-material adaptability, giving B2B clients confidence in selecting tools, optimizing production, and controlling costs. OEM customization ensures tool performance is aligned with process needs, offering a technological advantage in a competitive market.

Summary: Miniature carbide endmills, with superior precision, wear resistance, cutting stability, and customization, are the optimal choice for small part machining, delivering efficient, reliable, and sustainable solutions across industries.