In modern manufacturing, graphite electrode processing has become an indispensable process in mold manufacturing, aerospace, and the production of new energy vehicles. Graphite materials have unique properties such as light weight, high strength, and high temperature resistance. However, they are also brittle, produce severe powder loss, and wear out quickly, which makes their processing challenging. This is especially true for high-speed milling and complex contour finishing, where the choice of tools is directly related to surface finish, machining accuracy, and production efficiency.

Compared to ordinary metal processing tools, graphite electrode processing needs to handle extremely high material wear rates and large amounts of fine dust. This places higher demands on the tool’s wear resistance, chip removal performance, and edge design. Traditional milling cutters often suffer from short tool life, edge cracking, and rough surface finishes during graphite processing. This not only increases tool replacement frequency but also directly affects the consistency and service life of the electrode.

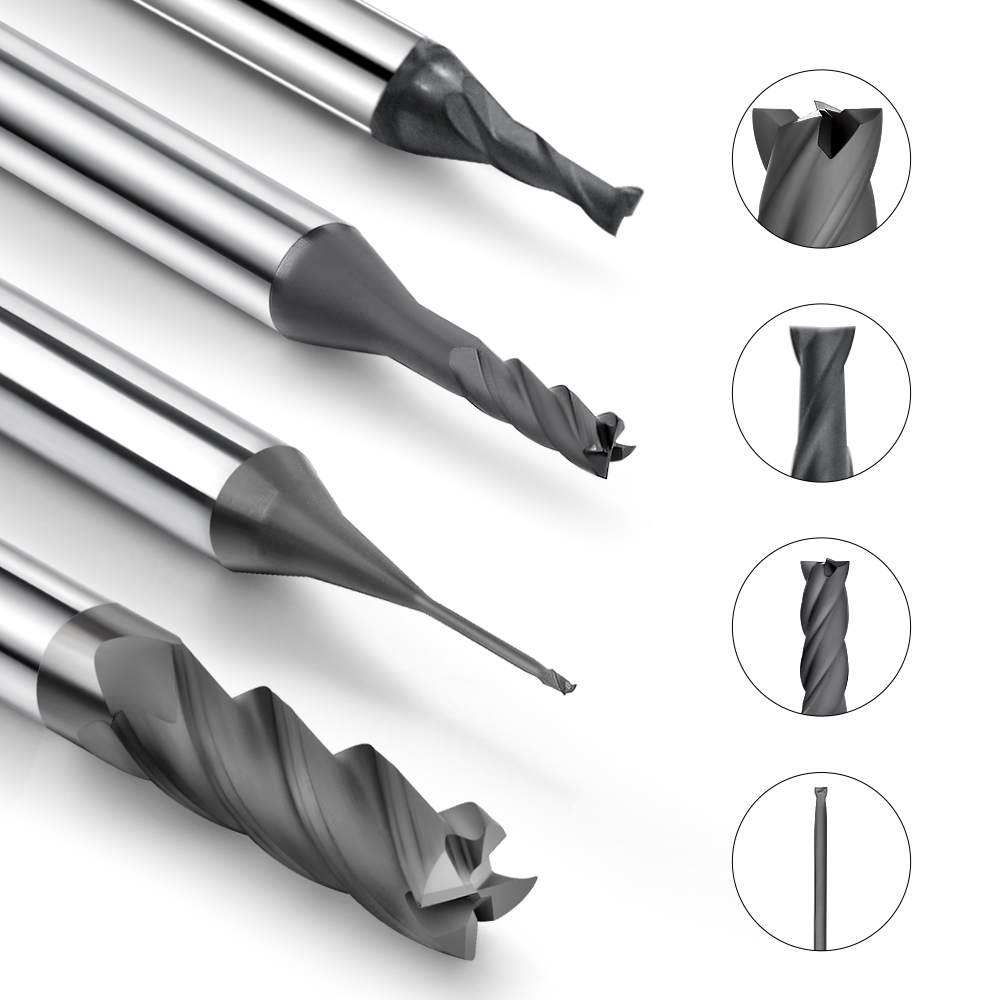

As a result, special graphite milling cutters designed specifically for graphite came into being. Graphite end mills made of materials such as CVD diamond coatings, PCD materials, or ultra-fine particle carbide significantly improve wear resistance and anti-chipping performance. Moreover, optimizing tool groove design and edge treatment can effectively reduce the erosion caused by graphite dust and significantly improve processing surface quality, extending tool life.

This article will analyze in-depth why special graphite milling cutters are essential for graphite electrode processing, and provide guidance on proper selection and usage to help improve efficiency, reduce costs, and achieve better processing results.

Characteristics and Challenges of Graphite Electrode Processing

Introduction to the Physical Properties of Graphite Materials

Graphite, a typical non-metallic material, is widely used in electrode manufacturing, mold processing, and aerospace applications. Graphite materials have excellent high-temperature resistance, electrical conductivity, and machinability, with a light texture and natural self-lubricating properties. However, the flaky crystal structure of graphite makes it brittle, and it easily disintegrates into fine dust under external forces. This unique physical property poses special requirements for tool performance. Ordinary milling cutters struggle to balance processing efficiency and surface quality. As a result, specially designed graphite end mills are typically required to ensure processing consistency and high precision when manufacturing graphite electrodes.

Common Problems in the Processing Process

In actual graphite electrode processing, common issues include excessive powder loss, tool edge chipping, and rapid wear due to the material’s brittleness and high abrasiveness. Graphite generates a large amount of fine dust during milling, which not only accelerates tool wear but also disrupts the cleanliness and stability of the machine tool system. Ordinary carbide milling cutters often suffer from short tool life, frequent chipping of the cutting edge, and rough surface finishes during graphite processing. In severe cases, tools may need frequent replacement, leading to decreased production efficiency. To overcome these challenges, many manufacturers have turned to high-performance graphite end mills, particularly CVD diamond-coated cutters, to improve wear resistance and extend tool life.

Analysis of the Disadvantages of Traditional Milling Cutters in Graphite Processing

Traditional milling cutters, designed for metal processing, have significant limitations when processing graphite. Firstly, the cutting edge of ordinary milling cutters is typically optimized for tough materials like steel and aluminum alloys. However, when working with graphite, a brittle and highly abrasive material, the cutting edge lacks sufficient sharpness and toughness, making it prone to chipping. Secondly, traditional tool coatings, such as TiN and TiAlN, cannot resist the long-term erosion of graphite dust, leading to accelerated tool wear. Additionally, traditional milling cutters’ chip grooves are not optimized for handling fine dust, which can result in chip blockage and affect both surface quality and tool life. For professional graphite processing, it is recommended to use tools specifically designed for graphite, such as best graphite end mills for EDM electrodes, to achieve better surface finishes, longer tool life, and lower processing costs.

Core Advantages of Special Graphite Milling Cutters

Ultra-High Wear-Resistant Materials and Special Coatings

In graphite electrode processing, the wear resistance of the tool directly influences processing efficiency and cost control. Special graphite milling cutters typically use ultra-fine particle carbide as the substrate, which offers higher strength and toughness, maintaining stable performance during high-speed milling of graphite. Diamond coatings have become the standard for high-end graphite milling cutters. By applying a hard, high-purity diamond film to the tool’s surface, wear resistance is significantly improved.

For example, Samho’s graphite end mills utilize high-quality diamond coatings that can extend tool life by 5-10 times compared to ordinary coated cutters in continuous dry processing environments, significantly reducing the frequency of tool replacements.

For users seeking high-precision and high-efficiency processing, selecting diamond-coated graphite end mills can greatly improve the stability and consistency of the overall process.

Optimized Design of Cutting Edge and Chip Groove

The design of the cutting edge and chip groove of graphite milling cutters directly affects cutting smoothness and surface quality. Specialized graphite processing tools are designed with sophisticated edge treatments, such as tiny arc blades or sharp edge designs, to reduce cutting resistance and prevent graphite particles from causing cracks during processing.

Samho’s graphite end mills are optimized for micro-edge chamfering and deep groove chip removal, addressing the brittle nature of graphite. These tools deliver excellent chip removal performance, from roughing to finishing, minimizing the risk of chip sticking and clogging. Using graphite roughing end mills for graphite roughing can improve efficiency while keeping tool wear rates low.

Structural Optimization for Graphite Dust

Fine dust produced during graphite processing accelerates tool wear and damages machine tools. As a result, top graphite milling cutter designs are optimized for the cutter body structure. Samho Tool’s graphite end mills feature a special anti-adhesion treatment on the cutter body surface. Additionally, increased chip removal groove volume and an open chip removal angle effectively prevent graphite dust accumulation on the tool surface. This design extends tool life during continuous processing, reduces the risk of surface scratches, and minimizes secondary wear caused by dust buildup. For customers requiring long-term stable operation, selecting long-life graphite cutters can significantly improve machine uptime and reduce downtime due to tool issues.

Performance Comparison Between Special Graphite Milling Cutters and Ordinary Milling Cutters

Tool Life Comparison

In graphite processing, tool life is a key indicator of processing costs and production efficiency. When using ordinary milling cutters, due to insufficient wear resistance, the cutting edge often wears and cracks quickly, leading to reduced processing stability and frequent tool replacements.

In contrast, special graphite end mills, particularly those with diamond coatings or ultra-fine grain carbide substrates, exhibit exceptional wear resistance and anti-chipping performance during dry high-speed milling of graphite.

Data from real-world processing shows that high-quality premium graphite end mills can last 3-5 times longer than traditional cutters, reducing the frequency of tool changes and minimizing the risk of dimensional deviation and rework caused by tool wear.

Comparison of Surface Finish and Processing Accuracy

The surface finish and dimensional accuracy of graphite electrodes directly impact the quality and efficiency of subsequent electrical discharge machining (EDM). Ordinary milling cutters often cause surface scratches, burrs, and dimensional errors due to insufficient cutting edge sharpness and poor chip removal.

Specially designed graphite milling cutters feature sharp, specially treated cutting edges, optimized chip grooves, and tool body geometry, which maintain a stable cutting state during both roughing and finishing.

Using high-precision graphite cutting tools can achieve lower surface roughness (Ra value), significantly improve electrode surface quality, reduce subsequent grinding and correction, and enhance mold manufacturing consistency.

Processing Efficiency and Cost-Effectiveness Analysis

While special graphite milling cutters typically come at a higher unit price than ordinary cutters, their extended tool life, improved processing quality, and faster production cycle offer a more favorable overall cost. Ordinary milling cutters require frequent changes, have high failure rates, and often necessitate more post-processing, all of which add hidden costs.

Choosing cost-effective graphite end mills, such as those in Samho Tool’s graphite series, enables longer continuous and stable cutting, improving workpiece qualification rates within the same processing time, reducing overall manufacturing costs, and significantly improving production efficiency—especially in large-scale graphite electrode manufacturing.

How to Correctly Choose a Special Milling Cutter for Graphite Electrode Processing

Look at the Tool Material

When choosing a special milling cutter for graphite processing, the first factor to consider is the tool material. Due to the high abrasiveness of graphite materials, ordinary carbide tools are difficult to meet the long-term stable processing requirements. The current mainstream graphite milling cutter materials include:

- Ultra-fine particle carbide: Basic graphite end mills mostly use high-hardness particle carbide, taking into account toughness and wear resistance, suitable for general precision and mass production requirements.

- PCD tools: Suitable for ultra-long life and extremely high precision requirements, excellent processing performance, but high cost, suitable for high-end graphite mold manufacturing, such as PCD graphite end mills.

- CVD diamond coated tools: A good balance between wear resistance and economy, such as CVD diamond coated graphite cutters launched by samhotool.com, can significantly extend tool life, while ensuring the consistency and high surface quality of graphite electrode processing.

Correctly selecting graphite tools of suitable materials is the first step to ensure processing efficiency and cost control.

Focus on Cutting Edge Design

The geometric design of the tool directly determines the cutting efficiency, surface finish and chip removal performance. In graphite processing, it is usually recommended to use a milling cutter with a 2-edge or 3-edge structure to achieve good chip removal and reduce cutting load.

In terms of edge treatment, high-quality graphite tools will be slightly chamfered or mirror-polished to enhance the ability to resist chipping while keeping the edge sharp to ensure a smooth cutting process.

In terms of groove design, the use of wide chip grooves and large helix angles can effectively reduce graphite dust blockage and improve processing stability.

Samho’s graphite milling cutter series has specially optimized the blade shape and groove design for graphite characteristics, making the tool perform well in dry high-speed cutting, and is an ideal solution for high precision graphite end mills.

Consider Chip Removal Performance

The requirements for tools in different processing stages are obviously different. Reasonable matching of tool models is the key to improving overall process efficiency.

Rough machining: Graphite rough machining is mainly aimed at efficient material removal. It is recommended to use a coarse-toothed graphite rough machining milling cutter with a more open blade shape and stronger impact resistance, which is suitable for large cutting depth and high feed rate machining.

Finishing: Graphite finishing pursues high surface finish and dimensional accuracy. You should choose a special graphite finishing milling cutter with sharp cutting edge, smooth chip removal and good vibration control to ensure fine surface and stable size.

Precautions in the Use of Graphite Milling Cutters

Reasonable Setting of Processing Parameters

The processing parameters of graphite milling cutters (such as speed, feed and cutting depth) are key factors affecting processing efficiency, tool life and workpiece surface quality. Reasonable parameter settings can not only improve cutting efficiency, but also extend tool life and reduce unstable factors generated during processing.

- Speed: Graphite milling cutters usually require a higher spindle speed to ensure a higher cutting speed. It is recommended to use a medium-high speed range to avoid tool vibration or workpiece damage due to excessive cutting force.

- Feed speed: For graphite end mills, it is recommended to increase the feed speed appropriately, but the cutting stability must be maintained. Excessive feed may cause uneven cutting and rough surface.

- Cutting depth: For the roughing stage, a larger cutting depth can be selected, but the cutting depth should be controlled during fine processing to ensure surface finish and detail accuracy.

By reasonably adjusting these parameters, the processing efficiency and stability of graphite milling tools can be greatly improved, while reducing production costs.

Importance of Dry Machining and Air Blowing Assistance

During graphite machining, the impact of dust on tool wear and machining accuracy cannot be ignored. Dry machining and air blowing assistance are effective means to control graphite dust accumulation and increase tool life.

- Dry machining: When using graphite end mills for dry machining, due to the strong friction of graphite material itself, appropriate speed and feed must be used to avoid overheating and tool damage. Dry machining can reduce the contamination of graphite material by coolant and ensure the surface quality of workpiece.

- Air blowing assistance: In dry machining, the use of air blowing device can effectively clean graphite dust in the cutting area, keep the cutting area clean, prevent dust from accumulating on the tool surface, thereby reducing tool wear and improving cutting stability.

In the process of graphite electrode manufacturing, the combination of air blowing assistance technology can effectively improve the machining accuracy of graphite cutters and reduce the maintenance requirements of tools.

Tips for Extending Tool Life

To extend the service life of graphite end mills, it is necessary not only to select high-quality tool materials, but also to use the correct operation method and daily maintenance. Here are some tips for extending the service life of graphite end mills:

- Maintain proper cutting temperature: Graphite materials are very sensitive to temperature. Excessive cutting temperature will cause damage to the tool surface coating, so control the rotation speed and feed speed to maintain proper cutting temperature.

- Clean the tool regularly: After processing, clean the tool surface in time to prevent graphite dust accumulation from causing tool sticking or wear.

- Reasonable feed rate: Choosing a reasonable feed rate can not only improve cutting efficiency, but also effectively reduce tool wear. Too high feed will increase tool load, while too low feed may cause uneven chips and reduce processing effect.

- Check tool status regularly: Check the sharpness and wear of the tool regularly, and perform maintenance or replacement in time to avoid the quality of processing being reduced due to long-term use of the tool.