In CNC precision machining, threading demands extremely high dimensional accuracy, excellent surface finish, and stable process control. Selecting the right carbide threading insert not only directly affects thread quality but also impacts overall machining efficiency and tool life. With the wide variety of thread insert tools available—from traditional turning inserts to modern thread mill cutter inserts—choosing the optimal tool has become a key concern for CNC engineers and purchasing specialists alike.

This article provides a comprehensive analysis of key factors including threading insert types, material properties, and compatible machining methods and materials. It aims to help you optimally match tool types and machining parameters for both thread turning and thread milling. For example, when machining chip-prone materials such as aluminum alloys, selecting thread inserts designed specifically for aluminum to prevent built-up edge (BUE) is critical for improving thread quality. For small-batch, high-precision internal threading, thread milling inserts offer greater flexibility and advantages.

Whether you are involved in mass production turning or precision mold machining, this guide offers a systematic and practical approach to thread tool selection, empowering you to make more efficient and reliable decisions in complex and ever-changing applications.

Why Is Precise Insert Selection Crucial for Thread Machining?

Thread machining is a critical step in the CNC metal cutting process, affecting not only dimensional accuracy and fit tolerances but also assembly quality and part service life. Whether machining internal or external threads across various materials and thread standards (ISO, UN, NPT, BSP, etc.), the tooling must be precisely matched to process requirements. Selecting the right thread insert tool is therefore essential for success.

Precision Requirements and Process Challenges in CNC Thread Machining

Unlike general contour machining, thread cutting demands stringent control of pitch accuracy, thread profile consistency, and thread start and end positions. In high-precision applications such as aerospace or mold manufacturing, even minor geometric deviations can cause poor thread fit or assembly failure. Additionally, challenges such as chip control, tool vibration, and thermal deformation must be managed effectively.

Because threading involves complex multi-axis interpolation, the choice of carbide threading inserts directly impacts thread quality, process stability, and tool life. Clearly defining parameters like insert geometry, material compatibility, and cooling strategy is key to stable and repeatable mass production.

The Role and Definition of a Thread Insert Tool

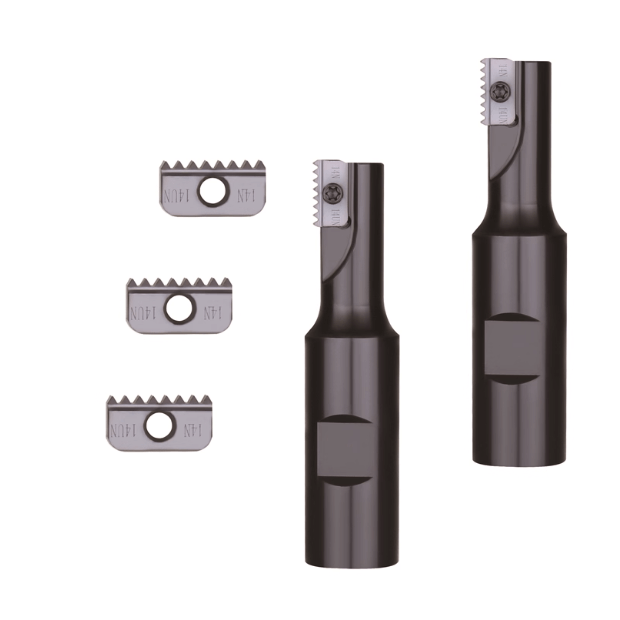

A thread insert tool generally refers to a tool system used for thread turning or milling. It consists of a toolholder (or cutter head) and an indexable threading insert. Depending on machining needs, thread insert tools can be categorized as turning inserts for lathes and thread mill cutter inserts for milling machines or machining centers.

The tool’s core function is to generate a thread with a standardized profile on the workpiece, ensuring tight tolerances and consistent quality across multiple parts. Practical selection involves considering workpiece material (e.g., stainless steel, carbon steel, aluminum), thread type (internal or external), tool rigidity, and machine characteristics.

Additionally, selecting inserts tailored to the workpiece material is critical. For example, aluminum threading requires inserts designed to prevent chip adhesion and improve surface finish.

Impact of Common Threading Methods on Tools (Turning vs. Milling)

CNC threading primarily employs two methods: thread turning and thread milling. While both produce threads, they require distinctly different insert designs, cutting paths, and feed strategies.

Thread Turning: Typically performed on lathes, thread turning is ideal for medium to large batch production of uniform thread specifications. It offers high efficiency but poses challenges in chip control and high tool load, especially with hard materials or short threads. Carbide threading inserts with highly wear-resistant coatings are recommended to withstand these demanding conditions.

Thread Milling: Common in machining centers, thread milling excels in small-batch, multi-specification, and high-precision threading. Using helical interpolation, it can cut internal and external threads gently and allows multiple thread sizes to be produced in one setup. Thread mill cutter inserts are required for this method, along with precise programming and toolpath planning.

Understanding these differences helps CNC engineers select the most appropriate insert design and material to achieve efficient and accurate threading.

Classification and Application Scenarios of Carbide Threading Inserts

Carbide threading inserts have become mainstream in CNC threading due to their excellent wear resistance, toughness, and thermal stability. Based on machining method, material, and process requirements, insert types and applications are diverse. Correctly identifying insert types and selecting the best product for each scenario is essential for maximizing machining efficiency, ensuring thread accuracy, and controlling tool costs.

Forming vs. Cutting Threading Carbide Inserts

Carbide threading inserts generally fall into two categories based on machining principle:

-

Forming Inserts: These inserts form the complete thread profile in a single pass without secondary finishing. Suitable for high-volume, consistent threading of standard metric, imperial, or NPT threads, they improve process consistency and throughput.

-

Cutting Inserts: These inserts machine only the thread flank profile, requiring finishing passes to complete thread roots and crests. Their adaptability allows usage across various pitches and profiles, ideal for small batches or non-standard threads. They also constitute a major portion of multifunctional threading inserts.

Selection should consider machine capabilities, batch size, thread type, and tolerance requirements. Forming inserts favor consistent production; cutting inserts provide flexibility and cost control.

Insert Types Suitable for Different Materials (Steel, Stainless Steel, Aluminum, etc.)

Workpiece materials impose specific demands on insert geometry, substrate hardness, and coating:

-

Carbon and Alloy Steels: Require inserts with high wear and fracture resistance. CVD-coated carbide inserts (e.g., TiCN + Al₂O₃) effectively manage heat and load during machining of medium-to-high strength steels.

-

Stainless Steel: Prone to work hardening and tool sticking. Select sharp-edged inserts with ample chip clearance and PVD coatings (e.g., TiAlN) to improve chip evacuation and reduce adhesion.

-

Aluminum: Features high thermal conductivity but tends to cause BUE. Use ultra-sharp, mirror-finished, uncoated or specialized coated inserts designed for aluminum. Advanced geometries improve surface finish and dimensional stability.

Selecting inserts matched to material characteristics reduces wear, stabilizes machining, and extends tool life—key to enhancing shop efficiency.

Applications in Special Scenarios: Precision Microthreading and Special-Shaped Threads

High-end industries like medical devices, optics, and aerospace often require machining microthreads, fine pitches, and complex thread profiles (e.g., trapezoidal, serrated). These demand ultra-precise inserts with:

-

Very small nose radii and accurate contours for microthreads

-

Highly rigid designs to prevent deflection on small parts

-

Indexable mechanisms for repeatability

-

Compatibility with specialty alloys (titanium, nickel-based)

For deep or blind hole threading, thread mill cutter inserts excel by enabling interpolation in restricted spaces. Their flexibility also benefits low-volume, high-mix production.

How to Select the Appropriate Thread Insert Based on Workpiece Material?

In CNC threading, material properties dictate tooling requirements. Insert substrate, geometry, and coating must align with material characteristics to ensure forming accuracy, tool longevity, and cutting stability. Matching thread insert tools to specific materials improves efficiency and lowers rework and costs.

Recommended Inserts for Carbon Steel and Stainless Steel Machining

Carbon steel and alloy steels generate high cutting forces and heat. Use carbide threading inserts with wear-resistant substrates and CVD coatings to withstand thermal stress and maintain long tool life—ideal for long continuous cuts in mass production.

Stainless steel’s work-hardening and stickiness call for sharp geometry and generous chip clearance. PVD-coated inserts (e.g., TiAlN) improve edge sharpness and reduce built-up edge, ensuring stable thread quality.

Key Points for Selecting Threading Inserts for Aluminum

Aluminum’s low strength, low melting point, and high thermal conductivity cause challenges like tool sticking and BUE during threading. To counter these:

-

Use ultra-fine grain carbide inserts with polished or mirror-finished edges to reduce cutting resistance and chip adhesion.

-

Select inserts with positive rake angles, large chip flutes, and sharp geometry for smooth chip flow and reduced heat.

-

Avoid conventional coatings that raise cutting zone temperatures; if coating is needed, choose low-friction aluminum-specific coatings.

Dedicated thread inserts for aluminum prevent sticking and improve thread finish and dimensional stability—essential for high-quality aluminum threading.

How to Prevent BUE and Tool Sticking?

BUE leads to tool damage, surface roughness, and dimensional errors. Effective prevention includes:

-

Using sharp, polished thread inserts to minimize chip adhesion

-

Optimizing spindle speed and feed to dissipate heat and avoid material softening

-

Applying appropriate cooling methods such as high-pressure oil mist or MQL for materials prone to sticking

-

Employing low-friction surface treatments (e.g., DLC coatings, mirror finishes) to reduce affinity with aluminum

Selecting specialized thread inserts for sticky materials like aluminum and stainless steel reduces tool changes and scrap rates, enhancing production line efficiency.

How to Choose the Right Carbide Threading Inserts for Your CNC Machine

In CNC machining, thread manufacturing methods mainly fall into two categories: thread turning and thread milling. The optimal choice depends not only on the machine type but also on factors such as workpiece material, thread specifications, production volume, and requirements for accuracy and surface finish. Different machining approaches require distinct insert designs—such as lathe-style threading inserts and thread mill cutter inserts—each with its unique application scenarios and benefits.

Advantages and Disadvantages of Using Lathe-Style Carbide Threading Inserts

Thread turning inserts are ideal for machining internal and external threads on lathes, especially suited for large batches, symmetric workpieces, and deep threads. For common thread types like ISO and UN, carbide threading inserts designed for CNC lathes enable efficient continuous cutting.

Advantages:

-

High machining speeds, making them well-suited for high-volume production.

-

A broad selection of inserts compatible with many standard thread types.

-

Facilitate integrated roughing and finishing in a single setup.

Disadvantages:

-

Limited to certain workpiece geometries; unsuitable for asymmetric or complex shapes.

-

Precision heavily influenced by tool wear and machine rigidity.

-

Risk of vibration and deformation on thin-walled or hard-to-machine materials.

Advantages and Typical Applications of Thread Mill Cutter Inserts

Thread mill cutter inserts, used primarily for thread milling on CNC machining centers, offer exceptional flexibility. They adapt to a wide range of thread sizes, pitches, and materials, excelling in small-batch, multi-specification, and high-precision applications.

Typical use cases include:

-

High-precision internal threads under M3 diameter.

-

Asymmetric or complex parts with interference structures.

-

Applications demanding tight thread base tolerance control.

-

Milling internal and external threads in difficult-to-machine, sticky materials such as aluminum and titanium alloys.

Moreover, indexable thread mill inserts enable reusable cutter bodies with replaceable inserts, reducing long-term tooling costs. They are favored in industries like medical devices, aerospace, and mold making for their high precision and adaptability.

When Is a Thread Mill Cutter Insert More Cost-Effective?

Though initial investment for thread mill cutter inserts tends to be higher than traditional turning inserts, they become cost-effective in scenarios such as:

-

Irregular-shaped parts or hard-to-clamp workpieces where thread milling mitigates clamping risks.

-

Diverse thread standards, since a universal thread mill cutter accommodates multiple pitches and diameters, reducing tool change frequency.

-

High precision and surface finish requirements, as multi-axis coordinated feed provides superior accuracy and stability.

-

Difficult-to-machine materials, where optimized cutting paths lower cutting forces and prolong tool life, particularly in machining centers.

Indexable thread mill cutter inserts support flexible programming and parameter tuning, making them vital for modern, high-end thread machining.

Five Key Parameters to Consider When Selecting a Threading Insert

Selecting CNC threading inserts, such as carbide threading inserts, requires considering multiple parameters to balance machining efficiency, thread accuracy, and tool life. These five key factors are essential for every CNC engineer when choosing thread inserts.

Pitch and Thread Profile

Pitch and thread profile (e.g., 60° American thread, 55° British Standard, 30° trapezoidal thread) determine the insert geometry compatibility. Ensure the insert matches the target thread standard to avoid profile errors. For non-standard pitches or shapes, choose specialized profile inserts to maintain accuracy and repeatability.

Insert Material and Coating (CVD/PVD)

The insert substrate and coating technology critically impact performance.

-

CVD coatings provide excellent wear and heat resistance, ideal for continuous cutting and medium-strength steels.

-

PVD coatings enhance adhesion and chip resistance, suitable for intermittent cutting or challenging materials.

For example, threading high-temperature alloys or stainless steel typically benefits from carbide inserts with PVD TiAlN coatings to extend tool life and minimize chipping.

Matching Feed Rate with Spindle Speed

Proper coordination between spindle speed (RPM) and feed rate is vital for thread stability. Excessive speeds accelerate insert wear; insufficient feed can cause thread collapse or rough surface finishes.

For thread mill cutter inserts, optimal toolpaths should be designed based on insert diameter, pitch, and cut depth to avoid excessive cutting per pass or thermal distortion.

Support for Indexable Insert Systems

Indexable threading inserts provide flexibility and cost efficiency in batch production.

-

Multiple cutting edges per insert extend usable tool life.

-

Toolholders can be swapped easily to switch between internal and external threads.

-

Modular, interchangeable insert tips further reduce maintenance and improve production uptime.

Recommendations for Selecting Insert Brands and Quality Stability

High-precision or heavy-duty machining demands consistent, high-quality inserts. Leading brands such as Sandvik, Walter, Seco, Mitsubishi, and SAMHO offer stringent quality control and extensive technical documentation.

For factories requiring OEM customization, reputable domestic brands or specialized toolmakers with reliable supply and technical support are viable for cost-effective, long-term partnerships.

FAQ: How to Avoid Thread Machining Failures?

Thread machining’s tight dimensional and surface finish tolerances make it sensitive to tool condition, cutting parameters, and machine rigidity. Understanding causes and remedies for common thread issues ensures stable production.

Why Do Blade Gnawing, Thread Slipping, or Thread Forming Fail?

Common causes include:

-

Tool wear or chipping: Leads to uneven cutting and thread profile distortion.

-

Improper cutting parameters: Excessive feed or incorrect spindle speed can cause slipping or form errors.

-

Insufficient machine rigidity or vibration: Compromises tool stability, causing profile deviation.

-

Material inconsistencies: Variations in hardness or heat treatment increase machining difficulty.

Using appropriate carbide threading inserts matched to material and adjusting parameters reduces these issues.

How to Determine Insert Wear?

Timely wear detection prevents quality decline. Signs include:

-

Visible chipping, dull or rounded cutting edges.

-

Increased surface roughness or dimensional deviations.

-

Audible changes or increased vibration during cutting.

-

Fluctuating machining parameters or longer machining times.

Implementing a comprehensive wear monitoring system coupled with production experience extends tool life and ensures process stability.

Tool Life Management and Replacement Strategy

Effective tool management ensures continuous quality and productivity:

-

Set tool life standards based on material, complexity, and batch size.

-

Inspect inserts regularly and replace promptly to prevent quality loss.

-

Use indexable inserts to maximize tool utilization.

-

Optimize cutting parameters and cooling to reduce tool load and thermal damage.

-

Leverage digital monitoring and tool management software for real-time status and intelligent replacement.

Scientific tool life strategies combined with quality inserts improve thread machining reliability and throughput.

Select the Most Appropriate Threading Tool Solution Based on Application Scenario

Choosing the right thread insert tool in CNC threading directly impacts machining efficiency, product quality, production cost, and tool life. This article’s comprehensive analysis of carbide insert classifications, material compatibility, machining method selection, and key parameters highlights the importance of tailoring tools to specific applications and materials.

Different threading demands require scientifically matched tooling based on process and material characteristics to achieve optimal results.

Summarizing the Applicability of Different Tool Combinations

-

Forming inserts: Best for high-volume, standard threads ensuring consistency and efficiency.

-

Cutting inserts: Provide flexibility for multi-specification, small-batch, or non-standard threads.

-

Thread turning inserts: Suitable for traditional lathe machining, efficient but limited by workpiece geometry.

-

Thread mill cutter inserts: Offer flexible paths and adaptability, excelling in complex and high-precision applications.

Selecting the right combination based on real conditions balances machining stability and cost efficiency.

Recommending the Use of Thread Insert Tools to Improve Efficiency and Quality

Modern CNC machining demands increasing thread precision and surface quality. High-performance thread insert tools—featuring premium carbide grades and advanced coatings—combined with optimized cutting parameters significantly reduce wear and defects.

Especially for materials prone to chip adhesion (aluminum) or difficult to machine (stainless steel), dedicated thread inserts improve surface finish, prevent built-up edge, and reduce thread stripping.

Introducing efficient tooling systems boosts automation, productivity, and lowers manual intervention and maintenance costs for sustainable manufacturing.

Balancing Empirical Judgment with Manufacturer Recommendations

While manufacturers provide detailed product specs and cutting guidelines, real-world experience and field feedback are crucial for optimal results. Variations in machine rigidity, fixtures, and material batches affect best practices.

Combining manufacturer data with on-site testing and dynamic parameter adjustment achieves theory-practice integration. Modern digital tool management further quantifies tool status and optimizes replacement, enhancing quality and efficiency.