Machining deep and difficult-to-access cavities often faces a major challenge: tool deflection. Due to their long length and relatively small diameter, long reach end mills are prone to insufficient rigidity and vibration, which can reduce machining accuracy, compromise surface finish, and shorten tool life.

This issue becomes especially significant when cutting different materials. For instance:

-

Long reach end mills for steel face high cutting resistance and concentrated forces.

-

Long reach end mills for stainless steel often experience tool vibration due to thermal hardening and high cutting heat.

-

Long reach end mills for aluminum can suffer from poor chip evacuation, leading to built-up edge and unstable toolpaths.

-

Long reach end mills for titanium require strict control of tool rigidity and cooling due to low thermal conductivity and high viscosity.

-

Long reach end mills for plastics need to avoid material melting and runout caused by high-speed friction.

Effectively reducing runout in long reach end mills during deep cavity machining is critical not only for tool life and workpiece precision but also for overall process stability. This article analyzes practical methods for minimizing runout from the perspectives of tool structure, material properties, cutting parameters, clamping, and cooling strategies. It also provides optimization recommendations for different materials to help CNC engineers achieve stable and efficient machining in production.

What Are Long Reach End Mills? Why Is Runout Common During Deep Cavity Machining?

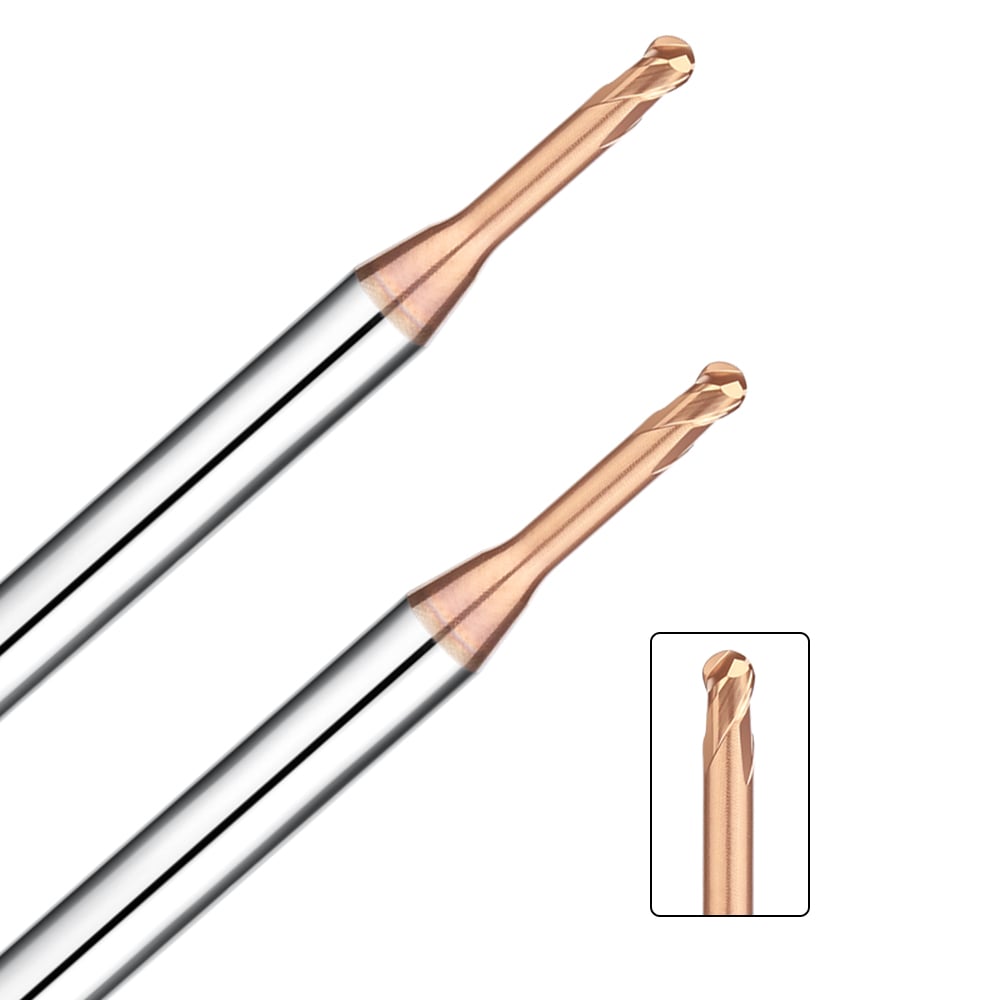

Long reach end mills are designed with extended cutting edges to reach deep cavities, grooves, and hard-to-access features. They are widely used in aerospace, mold manufacturing, automotive parts, and precision components. Examples include long reach end mills for steel mold cavities and long reach end mills for aluminum lightweight parts.

However, their long length relative to diameter (high L/D ratio) makes them less rigid. This can lead to runout, especially when machining difficult materials like stainless steel and titanium. Understanding their design, applications, and causes of runout is essential for improving machining accuracy and tool life.

Design Features and Applications of Long-Reach End Mills

Long-reach end mills are usually made from ultrafine-grain carbide or coated carbide for wear resistance and chipping resistance. Their cutting edges are often sharper to handle the high forces encountered in deep cavity cutting.

-

Steel: Requires a balance of strength and wear resistance to maintain a stable path in mold steel machining.

-

Aluminum: High-speed cutting benefits from polished flutes and high helix angles for smooth chip evacuation.

-

Titanium & Stainless Steel: Coatings like TiAlN or AlCrN improve heat and wear resistance.

-

Plastics: Sharp cutting edges reduce frictional heat and prevent melting.

These designs enable long-reach end mills to machine deep cavities in diverse materials but also present rigidity challenges.

Special Challenges of Deep Cavity Machining: Insufficient Rigidity Due to Slender Tools

Deep cavities require extended tools, which can amplify minor fluctuations in cutting resistance as runout and vibration.

-

Stainless steel: Tends to harden, increasing cutting forces and tool deflection.

-

Titanium: Low thermal conductivity concentrates heat, causing thermal deformation.

-

Aluminum: Poor chip evacuation can create uneven forces and slight runout.

Thus, deep cavity machining challenges tool design, machine rigidity, fixture stability, and cutting parameter optimization.

Impact of Tool Runout on Machining Accuracy and Surface Quality

Tool runout directly affects dimensional accuracy and surface finish:

-

Excessive runout can cause over-tolerance machining and prevent mold cavity compliance.

-

Prolonged vibration may fracture the tool edge, shortening life.

-

In plastics, vibration can leave melt marks or burrs.

-

Severe runout can increase spindle load and reduce machine stability.

Controlling runout is key to improving machining quality and reducing costs.

Main Factors Affecting Runout in Long Reach End Mills

Runout depends on tool length, material, cutting parameters, clamping, and machine rigidity. Understanding these factors helps engineers select the right tool, optimize parameters, and achieve precision and efficiency in deep cavity machining.

Tool Length-to-Diameter Ratio

A higher L/D ratio decreases bending rigidity, making the tool more prone to vibration and runout.

-

For long reach end mills for steel, high cutting resistance worsens tool deflection.

-

For long reach end mills for aluminum, high-speed cutting may cause tool marks even on soft material.

Selecting the proper diameter and flute length is critical.

Workpiece Material Characteristics

Material properties significantly affect runout:

-

Steel: High hardness increases tool deflection.

-

Stainless steel: Thermal hardening exacerbates vibration.

-

Aluminum: Poor chip evacuation creates uneven forces.

-

Titanium: Low thermal conductivity and viscosity increase thermal deformation.

-

Plastics: Frictional heat can cause melting and surface defects.

Matching tool material, coating, and geometry mitigates runout risks.

Cutting Parameters

Depth of cut, feed rate, and spindle speed influence runout:

-

Excessive depth or volume increases bending and vibration.

-

Mismatched spindle speed and feed rate lead to instability.

-

Layered cutting reduces load and improves stability for long reach end mills for titanium and stainless steel.

Clamping Rigidity and Machine Tool Stability

-

Loose or long tool holders increase vibration.

-

Low spindle or table rigidity amplifies minor deflections.

-

High-rigidity toolholders (shrink-fit, hydraulic) and stable fixtures reduce runout risk for steel, aluminum, and titanium.

Long Reach End Mill Runout Control Techniques for Machining Different Materials

During deep cavity machining, the mechanisms of tool runout and the methods to control it vary depending on the material. Mastering optimization strategies for each workpiece material can not only reduce tool runout but also improve machining stability, extend tool life, and enhance surface finish. The following sections provide practical runout control techniques for steel, stainless steel, aluminum, titanium, and plastics.

Long Reach End Mills for Steel: How to Improve Tool Rigidity and Life

When machining steel, high cutting resistance can easily cause tool deflection, reducing machining accuracy. Controlling runout is crucial to maintain precision.

-

Select a hard, wear-resistant tool material, such as ultrafine-grain carbide, combined with coatings like TiAlN or AlTiN to improve bending rigidity and heat resistance.

-

Control the L/D ratio, choose a coarser tool diameter, or perform segmented cutting to minimize deflection.

-

Adjust cutting parameters: reduce depth of cut and feed rate as needed. Segmenting the cutting process can significantly lower vibration.

-

Ensure a secure connection between the tool and the toolholder and verify machine rigidity to improve cutting stability.

Long Reach End Mills for Stainless Steel: Thermal Hardening and Cutting Heat Control

Stainless steel tends to harden during cutting, and high temperatures can exacerbate tool deflection. Controlling runout is critical for consistent machining results.

-

Use carbide tools with high-temperature-resistant coatings to improve tool rigidity and wear resistance.

-

Adopt a layered cutting strategy with low depth of cut, appropriate feed, and high spindle speed to reduce tool load.

-

Ensure efficient chip evacuation and cooling, such as oil mist or high-pressure coolant, to control cutting temperature and prevent thermal runout.

-

For deep cavities, use spiral or multi-segment toolpaths to maintain stable cutting forces.

Long Reach End Mills for Aluminum: High-Speed Cutting and Smooth Chip Evacuation

Aluminum has low cutting resistance, but high-speed cutting may cause tool vibration and built-up edge, affecting runout control.

-

Select tools with sharp, polished cutting edges to ensure smooth chip evacuation.

-

Increase helix angle or use a large spiral flute design to prevent chip clogging.

-

Combine high-speed cutting with proper feed rates to reduce cutting force fluctuations and improve tool stability.

-

Apply coolant or an air blast to evacuate chips efficiently and reduce frictional heat.

Long Reach End Mills for Titanium: Reducing Vibration and Preventing Tool Chipping

Titanium alloys have low thermal conductivity and high strength, which can increase tool stress and vibration. Controlling runout is essential for precision and tool life.

-

Use highly rigid tools with short flute lengths to enhance bending rigidity.

-

Adopt a light cutting strategy with low depth of cut, low feed, and higher spindle speed to control cutting forces.

-

Apply efficient cooling, such as high-pressure oil mist, to minimize thermal deformation.

-

Combine segmented cutting with optimized toolpaths to reduce the risk of vibration.

Long Reach End Mills for Plastics: Avoiding Melting and Surface Burrs

Plastics are sensitive to frictional heat, and tool vibration can cause material melting or burrs. Proper runout control ensures smooth surface finish.

-

Select tools with sharp, smooth cutting edges to minimize cutting friction.

-

Adjust cutting parameters: reduce spindle speed or adopt layered cutting to maintain stability.

-

Use air cooling or gas-assisted chip evacuation to control heat and prevent tool deflection.

-

Plan toolpaths to maintain smooth feed rates during deep cavity machining.

Engineering Solutions for Reducing Tool Runout in Long Reach End Mills

Even with properly designed long reach end mills for deep cavity machining, tool runout can occur due to material properties, fluctuating cutting forces, or inadequate clamping. Engineers can effectively reduce runout and improve machining accuracy and tool life through systematic optimization measures, focusing on tool selection, cutting paths, cutting parameters, toolholder rigidity, and cooling/lubrication strategies.

Proper Tool Selection

Tool selection is the first step in controlling runout:

-

Choose tool material and coating based on the workpiece.

-

Steel and stainless steel: coated carbide with high hardness and wear resistance.

-

Aluminum: sharp cutting edges with polished grooves for smooth chip evacuation.

-

-

Control the tool’s L/D ratio to maintain rigidity.

-

Optimize cutting edge geometry (e.g., large helix angle, chamfered edges) to distribute cutting forces and reduce vibration.

Optimize Cutting Paths

Cutting path design directly affects tool forces and runout:

-

Layered or spiral cutting reduces load on each cut.

-

Avoid long straight feeds and sudden directional changes to maintain stable forces.

-

For complex cavities, leverage CAM software to optimize toolpaths for titanium and plastics.

Adjust Cutting Parameters

Cutting parameters play a key role in runout control:

-

Reduce depth of cut and feed rate to minimize bending and vibration.

-

For high-hardness materials (steel, stainless steel, titanium), use a light cutting strategy with high speed and low feed.

-

Dynamically adjust parameters based on machining experience to match cutting forces with tool rigidity.

Selecting a Highly Rigid Toolholder

Toolholder rigidity is essential:

-

Use shrink-fit or hydraulic toolholders to improve spindle stability and reduce vibration.

-

Maintain a short and stable toolholder to reduce deflection.

-

In high-speed machining of aluminum or plastics, stable toolholders prevent surface scratches and burrs.

Optimizing Cooling and Lubrication

Proper cooling/lubrication reduces thermal deformation and runout:

-

High-pressure oil mist or liquid cooling controls temperature, especially for stainless steel and titanium.

-

Air or gas-assisted chip evacuation prevents chip jamming in aluminum and plastics.

-

Optimize coolant spray angle and flow to improve cutting stability and surface finish while extending tool life.

Case Studies and Experience Sharing

Engineers have extensive experience with long reach end mills across different materials. By analyzing success and failure cases, we can understand runout causes and master optimization techniques in cutting parameters, tool selection, toolpath design, and cooling strategies, improving machining accuracy, surface finish, and tool life.

Successful Case Studies in Steel Deep Cavity Machining

-

Controlled L/D ratio and layered cutting with high-hardness coatings.

-

Workpiece accuracy: ±0.02mm; surface finish: Ra0.8.

-

Optimized clamping and spindle speed reduced runout.

-

Tool life increased by 30%, enhancing machining efficiency.

Common Failures and Optimization in Stainless Steel

-

Problems: tool overheating, chip hardening, increased runout.

-

Solutions: high-temperature coated carbide, layered cutting, reduced depth, high-pressure cooling.

-

Optimized toolpaths avoid sudden directional changes, reducing chipping risk.

High-Speed Machining Techniques for Aluminum

-

Challenges: built-up edge, vibration.

-

Solutions: sharp polished edges, large helix angle, air or gas-assisted cooling.

-

Benefits: improved chip evacuation, surface finish, and machining stability.

Process Improvements for Titanium Alloy Structures

-

Challenges: tool runout, vibration due to low thermal conductivity.

-

Solutions: high-rigidity tools, light cutting, layered toolpaths, high-pressure cooling.

-

Optimized clamping and toolholders ensure stability for complex structures.

Surface Quality Control in Plastics

-

Challenges: frictional heat, melting, burrs.

-

Solutions: sharp tools, smooth edges, layered cutting, optimized speeds, air cooling.

-

Benefits: improved surface finish and tool life.

Summary: How to Effectively Use Long Reach End Mills in CNC Deep Cavity Machining

Long-reach end mills are essential for machining complex cavities and hard-to-access areas. Factors like tool runout, vibration, cutting heat, and material properties affect accuracy, surface finish, and tool life. Systematic optimization in tool selection, cutting parameters, toolpaths, clamping, and cooling achieves balance between stability and efficiency.

Tool Selection and Process Matching

-

Steel & Stainless Steel: high hardness + coatings + layered cutting.

-

Aluminum: sharp polished edges + high-speed cutting.

-

Titanium: rigid tools + light cutting + high-pressure cooling.

-

Plastics: sharp edges, controlled speeds, layered cuts.

System Optimization Approach

-

Tooling: L/D ratio, coating, edge geometry for rigidity and wear resistance.

-

Machine & Fixtures: rigid machines, stable toolholders reduce vibration.

-

Cutting Technology: layered cuts, optimized toolpaths, parameter adjustment.

-

Cooling & Lubrication: high-pressure oil/gas-assisted removal stabilizes cutting and extends tool life.

Engineers’ Recommendations in Production

-

Select tools based on material and geometry.

-

Adjust cutting depth, feed rate, and speed to avoid overload/vibration.

-

Plan layered, optimized toolpaths.

-

Apply proper cooling and clamping to maximize tool life and surface quality.