Face milling cutters are indispensable tools in CNC machining, and their performance directly affects machining efficiency, surface quality, and overall production costs. Different types of face milling cutters—such as carbide face milling cutters, roughing face milling cutters, and finishing face milling cutters—offer distinct advantages in tool life, cutting performance, and machining accuracy.

For engineers and buyers, selecting the right tool is not just about price. It requires a balanced evaluation of tool performance, machining adaptability, and long-term cost-effectiveness.

With many face milling cutter manufacturers available, from global brands to custom face milling cutter suppliers, options vary in material quality, specifications, and after-sales service. This article explores how to maximize cost-effectiveness when choosing face milling cutters, focusing on tool type, material, geometry, cutting strategies, and the price-performance trade-off.

What is a Face Milling Cutter? Basic Concepts and Types

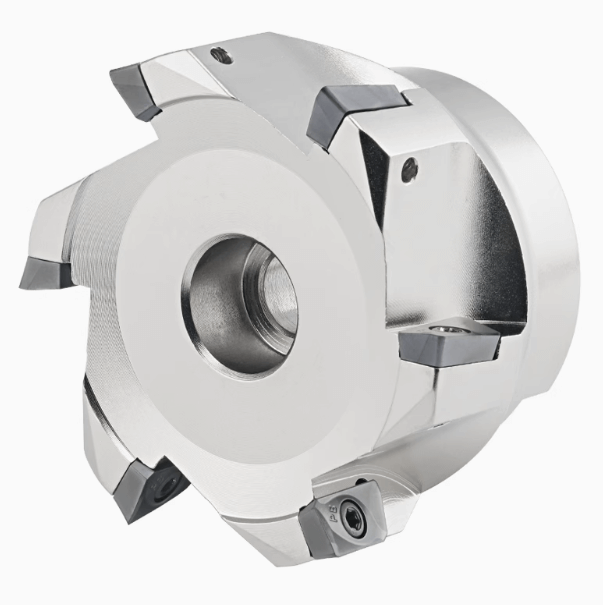

A face milling cutter is a rotary cutting tool designed for machining large or flat surfaces. It is one of the most efficient tools used in CNC machining, capable of removing material quickly while ensuring surface flatness and finish. Face milling cutters are widely used in automotive, aerospace, mold manufacturing, and general precision metalworking.

When selecting a face milling cutter, engineers must consider factors such as workpiece material, surface finish requirements, machining volume, and machine tool capability. By combining roughing and finishing cutters effectively, a complete process can be achieved—from heavy stock removal to high-precision finishing—thereby improving both productivity and cost-effectiveness.

Definition and Function of a Face Milling Cutter

Also called a face mill, this large-diameter tool rotates axially to machine surfaces. Its core functions include:

-

Efficient material removal: Ideal for roughing operations and flat surface machining on large parts.

-

Consistent surface quality: Optimized tooth profile and cutting parameters deliver smooth, flat finishes.

-

Extended tool life: Advanced materials like carbide and protective coatings help resist wear.

-

Higher machining efficiency: Properly combining roughing and finishing cutters reduces cutting time and costs.

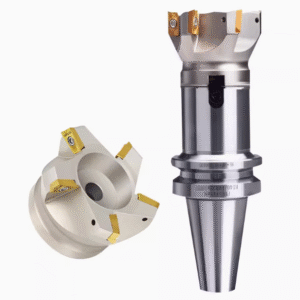

Common Types: Carbide, Roughing, and Finishing Face Milling Cutters

-

Carbide Face Milling Cutter

Hard and wear-resistant, carbide cutters are suited for high-speed, high-feed CNC machining. They are widely used for machining steel, stainless steel, and alloy materials, offering long tool life and fewer tool changes. -

Roughing Face Milling Cutter

Designed for rapid stock removal, roughing cutters have coarser teeth and withstand higher cutting forces. They are used for the initial machining of metal blanks and large workpieces. -

Finishing Face Milling Cutter

Used for the final machining step, these cutters provide excellent surface flatness and smoothness. Their fine-tooth design reduces vibration and ensures consistent surface finish, often paired with roughing cutters for complete machining cycles.

Key Factors Affecting Face Milling Cutter Performance

The performance of a face milling cutter depends not only on tool type but also on material selection, geometry, and machining strategies. Optimizing these factors improves efficiency, extends tool life, and ensures stable surface quality.

Tool Material and Coating Selection

Tool material is the foundation of performance. Carbide face milling cutters stand out for their hardness, wear resistance, and ability to handle high-speed cutting. Adding coatings such as TiN, TiAlN, or diamond coatings enhances heat resistance and oxidation resistance, especially in high-temperature or hard-material applications, reducing tool wear and overall costs.

Tool Geometry and Number of Teeth

Geometry affects cutting forces, vibration, and finish:

-

Roughing face milling cutters feature larger nose radii and coarser teeth for heavy-duty cutting.

-

Finishing face milling cutters have finer, evenly spaced teeth that minimize vibration and deliver smooth finishes.

Tooth count balance is critical: too few teeth may cause poor surface finish, while too many may generate excess heat and machine load. Optimized geometry ensures better efficiency and longer tool life.

Cutting Parameters and Machining Strategies

Cutting speed, feed rate, and depth of cut determine tool performance:

-

Roughing operations: High feed rates and deep cuts maximize material removal.

-

Finishing operations: Shallow cuts and controlled feed rates achieve superior surface quality.

Adjusting these parameters according to workpiece material (steel, stainless steel, aluminum alloys), machine rigidity, and cooling strategy ensures stable performance and cost-effective machining.

Price-Performance Trade-off Analysis

When evaluating face milling cutters, price is just one factor. True cost-effectiveness depends on a combination of tool performance, tool life, and long-term operating costs. Engineers must balance these elements to achieve optimal results in both roughing and finishing operations.

Comparison of Face Milling Cutters at Different Price Levels

-

High-End Tools

Made from premium carbide with advanced coatings, these tools excel in high-precision and high-speed machining. They offer excellent durability and reduced tool changes, though with higher upfront costs. -

Mid-Range Tools

Balanced in performance and cost, mid-range tools handle medium-duty machining efficiently. They are ideal for small to medium-sized manufacturers seeking both productivity and affordability. -

Low-End Tools

Inexpensive but less durable, these tools are suited for light-load or non-critical machining. While purchase costs are low, frequent replacements and inconsistent performance can increase long-term costs.

Cost-Effectiveness Evaluation Metrics

Key metrics for evaluating tool cost-effectiveness include:

-

Tool life: Longer life reduces downtime and tool replacement costs.

-

Machining efficiency: Higher removal rates improve throughput.

-

Surface quality: Smooth finishes reduce rework and secondary processing.

-

Maintenance cost: Includes resharpening, coating renewal, and tool handling.

Real-World Case Study

In steel machining:

-

A carbide face milling cutter used for roughing achieves faster removal rates and better durability.

-

A finishing face milling cutter delivers superior surface quality with reduced vibration.

Although low-end tools save on purchase price, they often wear faster and require more tool changes, ultimately increasing unit cost per workpiece. The case illustrates that the right combination of roughing and finishing cutters provides the best price-to-performance ratio.

How to Choose a Face Milling Cutter Manufacturer

Selecting the right face milling cutter manufacturer is critical for ensuring machining efficiency, tool reliability, and long-term cost control. A high-quality supplier not only delivers advanced carbide face milling cutters, roughing face milling cutters, and finishing face milling cutters, but also provides technical support, after-sales service, and consistent supply.

When evaluating manufacturers, engineers and buyers should look at key factors such as tool quality, manufacturing precision, brand reputation, supply chain stability, and the ability to provide custom face milling cutter solutions. These elements directly impact machining consistency, production costs, and overall productivity.

Recommendations for Well-Known Face Milling Cutter Manufacturers

The global market for face milling cutters includes both domestic and international brands, each offering different advantages in terms of performance, price, and service.

-

Domestic Brands

Typically more cost-effective, suitable for small- to medium-volume production and general-purpose metal cutting. Some premium domestic brands also provide carbide cutters with advanced wear-resistant coatings. -

International Brands

German, Japanese, and American manufacturers are widely recognized for superior tool geometry, wear resistance, and cutting efficiency. Their products are ideal for high-precision, high-load, and high-speed CNC machining where surface finish and tool life are critical.

By comparing specifications such as tool life, cutting performance, pricing, and technical support, buyers can make more informed decisions and find the best price-to-performance balance.

Advantages and Process of Custom Face Milling Cutter

For unique workpieces or non-standard machining, custom face milling cutters can significantly improve results.

Advantages include:

-

Tailored tool geometry for specific materials and machining accuracy;

-

Improved cutting efficiency and surface finish in both roughing and finishing operations;

-

Reduced need for secondary operations or rework.

Customization process typically involves:

-

Requirement Analysis – Define workpiece material, machining volume, and finish requirements.

-

Design Optimization – Adjust tooth geometry, number of inserts, and coating for best results.

-

Prototype Testing – Conduct trial runs to validate tool performance.

-

Mass Production – Finalize specifications for consistent, stable supply.

By partnering with a reliable manufacturer and leveraging custom tools, companies can maximize the efficiency of carbide face milling cutters and other cutter types while lowering total production costs.

Purchasing Recommendations and Practical Tips

Choosing a face milling cutter requires more than comparing price tags. Engineers must develop a well-rounded selection strategy based on machining type, tool material, coatings, and machine tool capability. At the same time, proper use and maintenance practices extend tool life and improve machining consistency, ensuring long-term cost-effectiveness.

Selecting Tools Based on Machining Type

Different stages of machining demand different cutters:

-

Roughing Face Milling Cutter

Designed for heavy stock removal, these cutters feature coarse tooth profiles and large tip angles. They withstand high cutting forces and are ideal for reducing workpiece volume quickly in high-speed CNC machining. -

Finishing Face Milling Cutter

Intended for surface finishing, these cutters have fine, evenly spaced teeth that reduce vibration and surface waviness, producing high-quality finishes.

By strategically combining roughing and finishing cutters, engineers can balance speed and surface accuracy, achieving better cost-effectiveness in CNC machining.

Maintenance and Usage Considerations

Proper care and use directly affect tool life and machining results:

-

Cooling Strategy

Apply coolant appropriately based on material and cutting conditions to reduce tool wear and improve surface quality. -

Tool Clamping and Installation

Ensure secure clamping to minimize vibration and misalignment, improving both accuracy and tool life. -

Tool Life Management

Regularly monitor wear and resharpen or replace tools before failure. This prevents poor finishes and unexpected tool breakage. -

Machining Strategy Optimization

Plan tool paths, depths of cut, and feed rates carefully. Proper sequencing of roughing and finishing operations minimizes wear and maximizes efficiency.

Through systematic selection and disciplined tool management, engineers can maximize the value of carbide face milling cutters and ensure stable machining performance.

Conclusion: Achieving the Optimal Cost-Effective Tool Performance

Selecting the right face milling cutter is not only about price—it requires evaluating tool material, geometry, coating, machining strategies, and long-term costs. A thoughtful balance ensures reliable machining performance and optimized production economics.

Practical Advice for Purchasing and Using Face Milling Cutters

-

Match Tools to Machining Requirements

Use roughing cutters for heavy stock removal and finishing cutters for precision surfaces. Combining both maximizes efficiency. -

Balance Price and Performance

-

High-end tools deliver precision and long life but involve higher upfront costs.

-

Mid-range tools strike a balance between durability and cost, suitable for mass production.

-

Low-end tools reduce purchase cost but may lead to higher replacement and downtime expenses.

-

-

Select Reliable Manufacturers or Custom Suppliers

Brand reputation, supply stability, and technical support are critical. For special applications, custom face milling cutters can provide significant performance improvements. -

Prioritize Maintenance and Optimization

Apply coolant correctly, ensure secure tool clamping, and monitor tool wear regularly. Optimize CNC cutting parameters to extend tool life and lower total production costs.

In summary, intelligent tool selection, proper maintenance, and optimized machining strategies enable engineers to achieve the best price-to-performance ratio for face milling cutters. This ensures machining efficiency, consistent surface quality, and cost savings in both roughing and finishing operations.