High-speed machining places extremely high demands on tool performance. The choice of an end milling cutter directly impacts machining efficiency, surface finish, and workpiece accuracy. End mills made from different materials and with various structures behave differently under high-speed cutting. For instance, solid carbide end milling cutters, with their high hardness and wear resistance, excel in machining challenging materials such as aluminum alloys, stainless steel, and titanium alloys.

Different types of end milling cutters, such as flat-end mills, ball-end mills, and tapered mills, vary in suitability for cutting depths, machining strategies, and complex curved surfaces. Special materials require even more refined planning: end milling cutters for hardened steel must balance wear resistance and thermal cracking resistance; end milling cutters for stainless steel emphasize cutting stability and anti-sticking properties; and end milling cutters for titanium require optimized thermal management and careful coating selection. Selecting the right end milling cutter manufacturers ensures tool quality, machining stability, and significantly extends tool life during high-speed, precision operations.

In summary, successful high-speed machining depends on properly matching tool material, type, and machining process. Rational selection and optimization of end milling cutters can greatly improve productivity and surface quality while maintaining dimensional accuracy.

What is an End Milling Cutter?

End milling cutters are essential tools in CNC milling and are widely used to cut metals and high-performance materials. They typically feature a cylindrical cutter body with multi-edged teeth, removing material through rotary cutting. End mills can machine flat surfaces, slots, grooves, contours, and also complex 3D surfaces. In high-speed CNC operations, choosing a solid carbide end mill or coated end mill is crucial for improving cutting efficiency, extending tool life, and ensuring surface finish quality.

Basic Definition and Structural Characteristics of End Milling Cutters

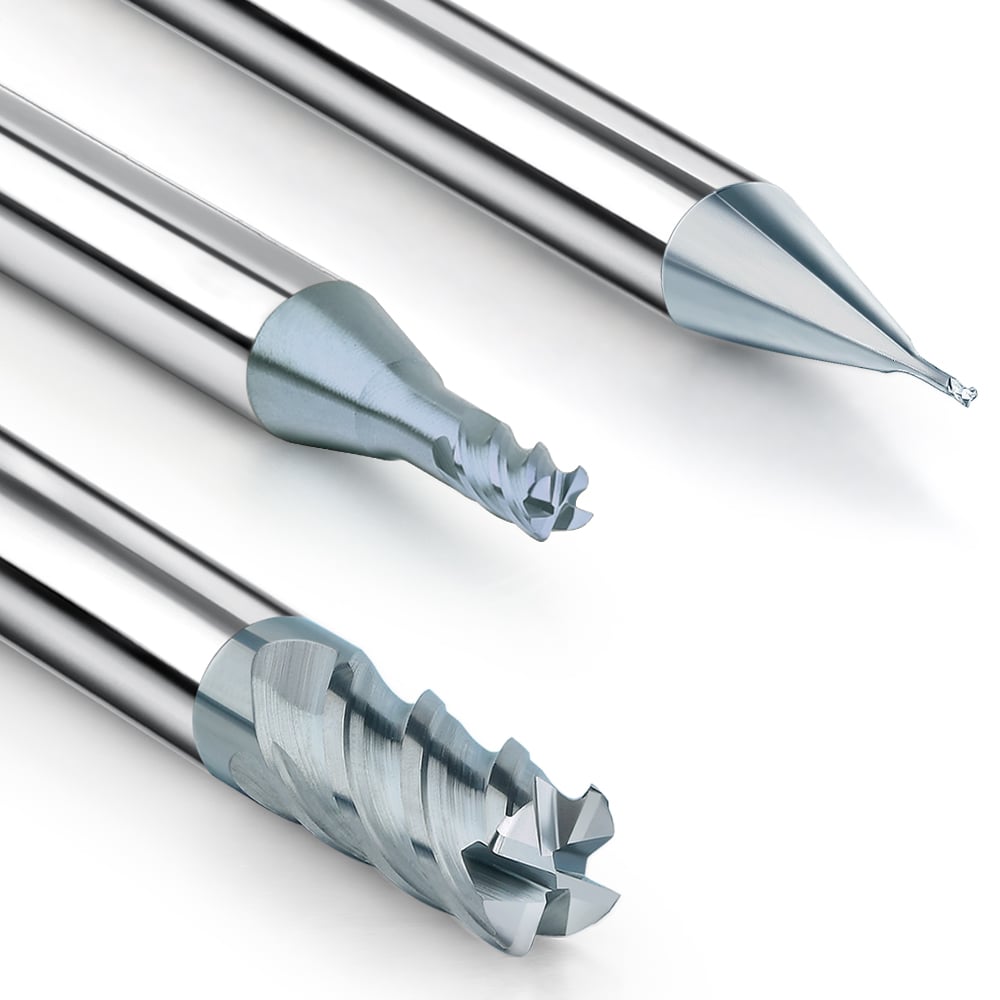

End mills typically consist of a cutter body, cutting edges, and spiral flutes. Materials include HSS, carbide, and some coated or composite materials. Solid carbide end milling cutters are preferred for high-speed cutting, machining hard materials (e.g., end milling cutters for hardened steel), and high-precision components due to their high hardness and excellent wear resistance. Cutting edge designs may be straight, helical, or ball-nose. The number of cutting edges and helix angle influence cutting forces, chip evacuation, and surface finish. Structural optimization ensures high-speed cutting stability and machining accuracy.

Common Classification of End Milling Cutters

End mills can be categorized based on shape and application:

-

Flat End Mills: For flat surface machining and grooving.

-

Ball Nose End Mills: For 3D surface machining and mold manufacturing.

-

Corner Radius End Mills: Improve tool strength and reduce stress concentration.

-

Tapered End Mills: For mold and precision contour machining.

Different types of end milling cutters exhibit significant differences in cutting performance and tool life when machining hardened steel, stainless steel, or titanium alloys. Selecting the right tool type is critical for high-speed CNC machining efficiency and quality.

Why High-Speed Machining Places Special Demands on Tools

High-speed machining involves high spindle speeds and feed rates, subjecting tools to forces and temperatures far beyond conventional operations. To maintain accuracy and surface finish, end milling cutters must have high wear resistance, thermal stability, and vibration resistance. For materials like hardened steel, stainless steel, or titanium, tool coatings, material selection (e.g., carbide or coated mills), helix angle, and cutting edges directly affect machining efficiency and tool life. Properly matching high-performance tools from end milling cutter manufacturers is crucial for successful high-speed, precision machining.

The Core Challenges of High-Speed Machining for End Milling Cutters

High-speed machining significantly increases material removal rates and productivity, but it also intensifies demands on end milling cutters. High speeds and feeds generate greater cutting forces and heat, which can lead to blade wear or fracture. Different materials—such as hardened steel, stainless steel, or titanium alloys—pose distinct challenges. Understanding these core challenges and selecting the right solid carbide end milling cutter or coated end mill, combined with appropriate cutting strategies and parameters, is essential to achieving accuracy, prolonging tool life, and ensuring superior surface finish.

Cutting Speed and Heat Management

Friction during high-speed cutting generates significant heat, impacting tool life and surface quality. When using end milling cutters for hardened steel or titanium, excessive heat can accelerate edge wear or coating failure. Optimizing spindle speed, feed rate, and depth of cut, along with efficient coolant or gas cooling, is essential. High-temperature-resistant and thermally stable tools minimize thermal deformation and wear during high-speed operations.

Tool Wear and Tool Life Issues

Tool wear is a common challenge in high-speed CNC operations, directly affecting productivity and part accuracy. Tool material and construction are key to wear resistance, with solid carbide end milling cutters excelling in machining hard materials. Different types of end milling cutters distribute cutting forces and evacuate chips differently, influencing wear rates. Choosing high-performance tools from trusted end milling cutter manufacturers, optimizing parameters, and selecting proper coatings can significantly extend tool life.

Impact of Surface Quality and Dimensional Accuracy

Even with high-speed machining, severe tool wear or improper conditions can result in rough surfaces and reduced contour accuracy, particularly for stainless steel or titanium. Tool geometry, cutting edges, helix angles, and material hardness directly affect surface finish and accuracy. Selecting the right type of end mill, combined with a high-performance solid carbide end milling cutter and optimized parameters, ensures superior surface quality and dimensional control.

Advantages of Solid Carbide End Milling Cutters in High-Speed Machining

In high-speed operations, tools must withstand high rotational speeds, cutting forces, and heat. Solid carbide end milling cutters outperform HSS or other materials due to superior hardness, wear resistance, and thermal stability. Whether machining hardened steel, stainless steel, or titanium, carbide mills improve cutting efficiency, extend tool life, and maintain surface quality and dimensional accuracy.

Hardness and Wear Resistance

Carbide end mills maintain sharp edges at high speeds, reducing wear and chipping. For high-hardness materials such as end milling cutters for hardened steel or high-temperature stainless steel, choosing appropriate coatings further enhances wear resistance, improving machining stability and efficiency.

Stability in High-Speed Cutting

High rigidity and thermal stability allow solid carbide end milling cutters to maintain cutting edge geometry under high-speed conditions, reducing vibration and force fluctuations. Different types of end milling cutters have unique cutting force distributions and chip evacuation efficiencies, which, when combined with carbide, improve stability and surface quality.

Applicable Processing Scenarios and Case Studies

Carbide end mills are widely used in mold making, aerospace parts, automotive components, and high-speed machining of challenging alloys. When machining titanium, carbide tools control heat and prevent premature wear. For hardened steel or stainless steel, selecting the right diameter, flute count, and helix angle ensures high-precision, efficient operations. Purchasing tools from reputable end milling cutter manufacturers ensures consistency and performance reliability.

End Milling Cutter Selection and Application for Different Materials

Different materials place varying demands on the cutting performance and tool life of end milling cutters. For hardened steel, stainless steel, and titanium alloys, the tool material, number of flutes, geometry, and coating type must be carefully selected. Properly matching a solid carbide end milling cutter or other high-performance tool improves machining efficiency, extends tool life, and ensures surface finish and dimensional accuracy. Additionally, choosing tools from reliable end milling cutter manufacturers helps maintain material consistency and machining stability.

End Milling Cutters for Hardened Steel

Hardened steel, due to its high hardness and strength, is challenging to machine, demanding high tool wear resistance and thermal stability. Solid carbide end milling cutters are widely used for hardened steel, as their hardness and wear resistance reduce tool chipping. Optimizing spindle speed, feed rate, and depth of cut, while selecting the proper flute count and helix angle, minimizes cutting forces and improves chip evacuation. Scientific tool selection and parameter optimization can significantly extend tool life and maintain high surface quality.

End Milling Cutters for Stainless Steel

Stainless steel machining is prone to tool sticking and chip clogging, requiring sharp cutting edges and high-performance coatings. Using a solid carbide end milling cutter or coated milling cutter reduces friction and sticking. Different types of end milling cutters, such as flat-end and ball-end mills, perform differently on grooves and curved surfaces. Proper cutting parameters and efficient cooling improve machining stability, ensuring dimensional accuracy and surface finish.

End Milling Cutters for Titanium

Titanium alloys have low thermal conductivity and generate high cutting temperatures, leading to rapid tool wear. End milling cutters for titanium are typically carbide with heat-resistant coatings such as TiAlN or DLC. Optimizing cutting parameters, feed rate, and depth of cut, combined with high-efficiency cooling, helps control cutting heat. Selecting high-performance tools from trusted end milling cutter manufacturers ensures long tool life and consistent quality when machining complex parts and precision curved surfaces.

How to Evaluate and Select a High-Performance End Milling Cutter

Selecting a high-performance end milling cutter is essential for high-speed, high-precision machining. Tool material, geometry, coating, and machining parameters directly affect cutting efficiency, surface finish, and tool life. Evaluating types of end milling cutters, appropriate coatings, and cutting parameters, along with selecting high-quality tools from reliable end milling cutter manufacturers, improves productivity, reduces costs, and ensures machining accuracy.

Principles for Selecting Different Types of End Milling Cutters

Choose tool types based on workpiece material, surface finish, and machining depth. Flat-end mills are suitable for flat surfaces and grooves; ball-end mills excel at complex 3D surfaces; corner radius mills enhance strength and reduce stress concentration; tapered mills are ideal for precise contour machining. Selecting the right tool type for end milling cutters for hardened steel, stainless steel, or titanium ensures optimal cutting efficiency and tool longevity.

The Importance of Tool Coatings

Coatings improve wear resistance, thermal stability, and adhesion resistance. TiAlN and AlCrN coatings are suitable for high-temperature machining and hardened steel. DLC coatings reduce friction and enhance surface finish. PCD tools excel in high-speed cutting of hard materials and non-ferrous alloys. Matching coatings with solid carbide end milling cutters extends tool life, reduces costs, and maintains accuracy.

Optimizing Tool Parameters

Cutting speed, feed rate, and depth of cut significantly influence tool performance. For materials such as stainless steel or titanium, parameters should be adjusted based on tool material, type, and coating. Optimized parameters reduce cutting forces, minimize wear, control heat, and improve surface finish. Proper parameter management ensures stable, high-precision results during high-speed machining.

Global End Milling Cutter Manufacturers and Market Trends

Selecting the right end milling cutter manufacturers is vital for high-speed machining efficiency, tool life, and precision. Global competition is intense, and manufacturers differ in materials, coatings, manufacturing processes, and product lines. Understanding brand strengths, procurement criteria, and future trends helps companies make informed decisions for machining complex parts and challenging materials.

Major International Brands and Advantages

European and American manufacturers lead in materials, coating technologies, and precision, suitable for molds and aerospace parts. Japanese brands excel in high-hardness carbide and advanced coatings for high-speed and complex surface machining. Chinese manufacturers offer competitive price/performance ratios and broad product lines of solid carbide end milling cutters and other types of end milling cutters, ideal for mass production and general machining. Selection should consider material, process complexity, and cost.

Key Indicators for Business-End Procurement

Procurement should focus on tool life, cost, and delivery reliability. High-performance solid carbide end milling cutters reduce downtime when machining hardened steel, stainless steel, or titanium. Stable lead times and manufacturer support are critical for uninterrupted production.

Future Trends: Intelligent Tools and Sustainable Manufacturing

The industry is moving toward intelligent, high-performance, and sustainable tools. End mills with tool condition monitoring, life prediction, and automated parameter optimization enable smart machining. Eco-friendly coatings, wear-resistant materials, and energy-saving cooling improve tool efficiency, reduce energy consumption, and minimize environmental impact. Companies should consider these technologies when selecting end milling cutters to maintain competitiveness and quality.

The Key to Improving High-Speed Machining Efficiency Lies in the Right End Milling Cutter

High-speed machining efficiency and quality depend on selecting and applying the right end milling cutter. Tool material, type, coating, and machining parameters influence cutting forces, tool wear, surface finish, and accuracy. Proper selection of a solid carbide end milling cutter, combined with the advantages of different types of end milling cutters, and optimized cutting parameters, achieves high efficiency, precision, and long tool life. Choosing high-performance tools from reliable end milling cutter manufacturers ensures stable production and superior machining quality.

Balancing Materials, Tools, and Processes

Material hardness, tool performance, and machining processes are tightly linked. End milling cutters for hardened steel require wear-resistant carbide; stainless steel end mills emphasize anti-sticking; titanium mills focus on thermal management and coating. Matching tool type, material, and process maximizes tool life and productivity while maintaining accuracy and surface finish.

How to Improve Productivity and Processing Quality Through Tool Selection

Selecting high-performance solid carbide end milling cutters and optimizing tool geometry, flutes, helix angle, and coating reduces cutting force fluctuations and tool wear while improving surface quality. Properly setting speed, feed, and depth, and sourcing from reliable end milling cutter manufacturers, enhances production stability and overall efficiency. In high-speed machining, tool selection and parameter optimization are key to maximizing machining capability and competitiveness.