In the world of CNC routing, accuracy and quality are everything. This piece drills down into flat compression end mills – the finest precision compression router bits. We want to touch on every detail that makes these tools necessary for better finishes and increased performance in woodworking, among other materials. We will cover everything, including design considerations as well as benefits over alternative types of endmills, hence providing you with all-around information that is essential for decision-making in your CNC machine operation, such as tool path selection and step-over setting. Whether this is not your first time using a CNC machine or you have been using it for years, this manual will give insights on how you can best choose compression router bits while working on different projects with the machine.

What does a compression end mill do?

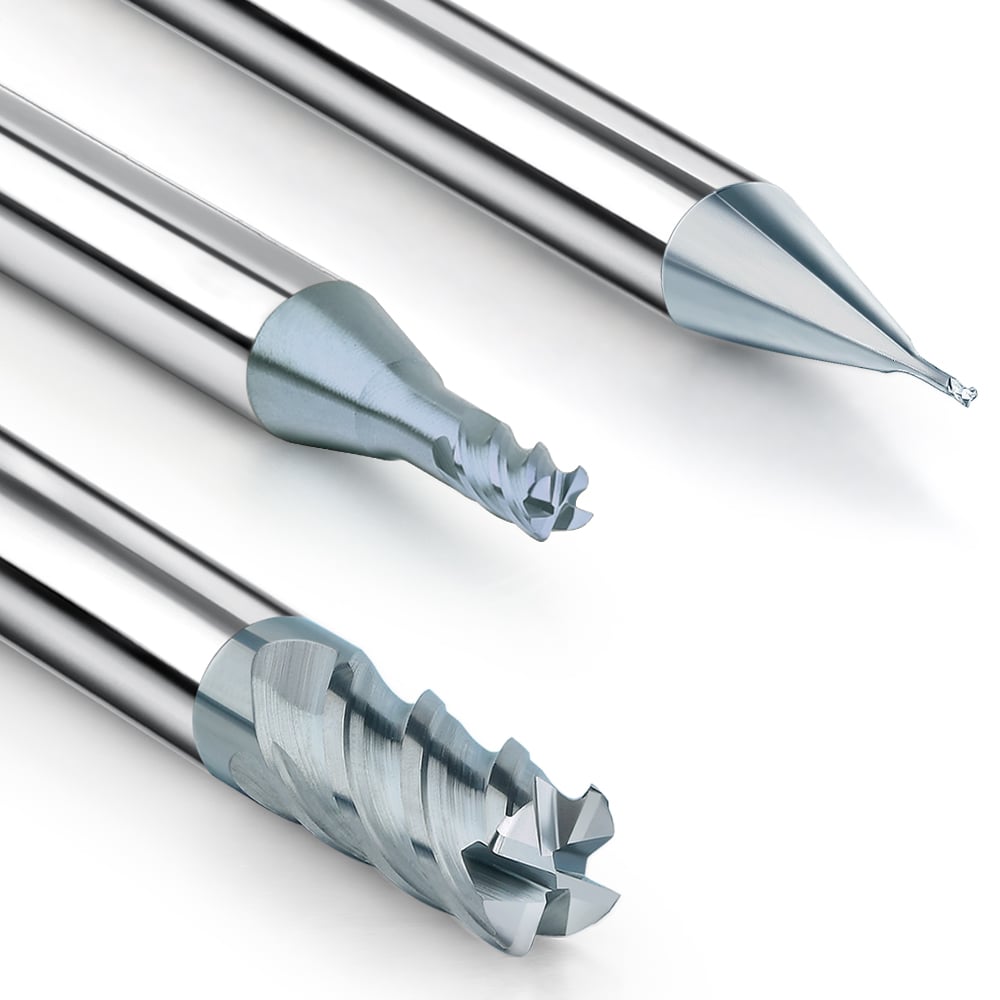

Knowing Compression End Mill Technology

A router bit of this kind is just one that can deal with both the top and bottom surfaces of materials effectively in one pass. It does this by having an upcut and downcut flute pattern which actually compresses the material as it cuts; thus giving clean edges on both sides. The two flutes reduce tear-out and improve finish quality especially in plywood, laminates, and fiberboard. Such accuracy, coupled with speediness, makes these bits very important for good CNC routing results.

Compression Bits versus Traditional End Mills

To know the difference between them, let’s see how they are used. First off, compression bits use both up-cutting and down-cutting flutes to compress materials, thereby creating cleaner edges with minimal tear-out on each surface. On the other hand, traditional end mills typically only have the single-directional cutting capability, meaning they can either excel at up-cutting or excel at down-cutting but not both, which often leads to more pronounced tear-outs as well as less desirable edge finishes. Moreover, compression bits stabilize better and finish better due to their dual-flute design, while traditional mills might need multiple passes or finishing steps before achieving comparable results.

Applications & Advantages of Using Compression End Mills

Mainly used during spoil board machining operations done by CNC routers onto such materials like plywood, laminates, or fiberboards – so-called spoil board materials; this type of end mill is great for jobs that require clean edges without tearing, such as cabinet making, furniture production, or sign making among others. In addition to reducing time spent on finishing because of superior cuts made possible by using these tools, they also provide better stability when cutting through different types of substances since both sides are dealt with simultaneously during one pass, thus minimizing chances for vibrations, which could affect quality adversely. This is what makes them perfect choices whenever high-quality surface finishes are needed in many woodworking projects involving composite materials, too.

How to Pick the Best Compression End Mill?

Points to Consider: Diameter, Shank and Cutting Lengths

- Diameter – The size of the diameter affects the speed of cutting as well as the capacity for making complicated cuts. Small diameters are ideal for detailed work while larger ones remove material faster.

- Shank – This part should match with the collet size of your CNC machine. A good fit ensures stability thereby reducing chances of breaking tools.

- Cutting Length – It should correspond to the thickness of the material being worked on. When planning tool paths especially, an appropriately matched cutting length prevents one from making multiple passes through and ensures clean cuts across entire thicknesses of materials used in this case.

Comparing Solid Carbide versus Coated Solid Carbide shank router bits options enhance durability

Solid Carbide:

- Pros: High hardness level; strong; good at cutting hard stuffs

- Cons: More expensive than coated versions; may wear off quickly in particular applications

Coated Solid Carbide:

- Pros: More resistant to wear and tear; lasts longer; performs better when exposed to heat generation during operation

- Cons: Initial cost is higher than that of solid carbides; coating wears away after being used for some time consecutively

- Whether you choose solid carbides or coated ones will mainly depend on specific requirements for cutting materials’ properties.

Finest Woodworking Compression Spiral Router Bits

Several important factors must be considered when choosing the finest compression spiral router bits for woodworking. The kind of wood, desired finish and specific project requirements are all part of this. Some of the best shank router bits available typically include:

- Whiteside Compression Spiral Bits – Whiteside bits are known for being long-lasting and accurate in many applications on hardwoods or softwoods.

- Amana Tool Compression Router Bits – These bits feature an advanced carbide composition with unique geometries that provide higher edge quality and longer-lasting tools. They work well in industrial settings as well as professional woodworking shops.

- Freud Compression Router Bits offer the best of downcut and upcut flutes for clean cuts.: Freud’s balanced design is famous for smooth cuts and its anti-kickback safety feature also enhances operator safety.

- CMT Compression Spiral Bits – CMT tools are a perfect mix between durability and accuracy which makes them suitable for elaborate tasks in carpentry.

These brands ensure fast material removal, minimal tear out, and high-quality finish to your woodwork projects, among other things, hence making them some of the top choices on the market today.

Setting Up Your CNC Router for Compression End Mills

Why RPM and Feed Rate are Important

Proper RPM (rotations per minute) and feed rate are two of the most important considerations when using compression end mills. Right RPM is necessary because it makes the cutting edges engage with the material at an optimal speed, thereby preventing heat buildup, which would shorten tool life in turn. The right feed rate, on the other hand, guarantees efficient removal of materials while reducing the chances of damaging the workpiece or tool. These factors need to be adjusted correctly so that you can achieve accurate cuts, improve surface finish quality, and enhance productivity during any CNC routing operation.

Effective Procedures for Setting Up CNC Router Bits

- Choose the Appropriate Bit: Identify a compression end mill that suits both your project needs and the material type being worked on.

- Fit the Bit Firmly: Ensure that it is properly placed into collet chuck before tightening down firmly enough not to allow any movements when running.

- Determine Best Speed: Check what speed should be used according to manufacturer’s instructions depending on diameter of bit used together with kind or kinds being cut through at present .

- Consider Suitable Feedrate: Look for an ideal feed rate which can facilitate desired cut quality based upon calculations done from size of bit employed and nature of workpiece involved . Some adjustments might have to be made depending on various project parameters like hardness etcetera.

- Set Depth Cut Properly : This is done in order not overload both router & cutter thus causing breakage but rather start with shallower ones then increase gradually if need arises .

- Try Cutting Experiment: Always carry out some test cuts first using sample materials before settling down with certain settings; this will help validate them against performance standards expected .

- Keep Watch On Tool Wear: Periodically examine its condition visually so as determine whether there’s any wear evident or not plus take appropriate action such as replacing worn out bits promptly without delay; otherwise they may spoil precision achieved during cutting operation.

These steps are meant to ensure accuracy, efficiency and safety in CNC routing.

Tricks for Boosting the Performances of a Router

- Clean up Equipment: Routinely get rid of dust and debris that might impede the smooth running of routers.

- Utilize Bits with Sharp Edges: Always employ bits that have sharp edges to ensure cuts are neat and minimize the chances of ruining materials.

- Profound Maintenance of your shank router bit is paramount if you want it to function optimally.: Create a schedule for regularly inspecting and servicing the CNC machine so as to forestall possible mechanical problems.

- Clamping Materials Firmly: Clamp items securely lest they slip while being cut which affects accuracy as well as precision levels.

- Lubrication: Apply lubricants that are appropriate in order to reduce friction, thereby lengthening the life span of both bits and routers.

Spetool Compression Router Bits: A Thorough Review

Product Range and Features Overview of Spetool’s

Compression router bits meant for different applications, such as spoilboard flattening, are among the many types of compression router bits provided by Spetool. These products are made out of high-quality carbide, which guarantees their durability and precision. Here are some features:

- Dual-Compression Design – The one-of-a-kind dual-compression design reduces tear-out on both the top and bottom faces of material; hence they work well with laminates and veneer plywood.

- Wide Diameter Range – They have a variety of sizes that can handle anything from fine intricate details to large cuts as needed for various projects.

- Optimized Flute Geometry – Superior flute geometry allows for better chip evacuation thereby reducing heat buildup while enhancing cutting speed altogether.

- Coating Options – Some bits are coated like TiAlN among others so as to give them longer life span plus improved cutting performance.

- Compatibility with various router bit diameters x ensures flexibility for different applications.: These bits were designed to work with most CNC routers thereby making them usable in industries and with hobbyists alike.

Evaluation of Cutting Capability and Longevity

Spetool compression spiral router bits give unparalleled cutting performances by having two compressions that restrict breakout effectively and make clean cuts on either side of the stock. Built using high-quality carbide with optimized flute geometry, it helps to remove chips quickly while reducing heat buildup which leads to more efficient overall cuts. Even when used on hardwood or laminated surfaces, these bits keep their sharpness for long periods, according to tests carried out so far. In addition, if desired, an optional coating – titanium aluminum nitride- can be applied as this provides extra protection against wear, especially in areas where there is exposure to higher temperatures, thus extending the tool’s life span further. Ultimately, what makes Spetool compression spiral router a bit worth having around any CNC machine is its reliability, which is backed up by longevity.

Testimonials & Case Studies

Many users have shared their satisfaction with how well these bits worked for them, sharing success stories that underline both efficiency and durability. One such example comes from a cabinet maker who noted significant improvements in terms of edge quality along with faster finishing times when working with harder woods; similarly, another person said less material wastage occurred during sign-making due to better accuracy achieved on laminates thanks to the continuous, reliable performance shown by these cutters even after they were extensively used over time. There was also someone else involved in the hobby use case study who appreciated the versatility demonstrated by such tools, which enabled him to undertake various projects ranging from intricate designs right down to larger pieces, stating, “It doesn’t tear out anymore”. All these examples show people agree that nothing beats Spetool compression spiral router bit as far as reliability coupled with long service life are concerned.

Sophisticated Approaches for Utilizing Compression End Mills

Cutting End Grain and Plywood Efficiently

To cut end grain and plywood efficiently with compression end mills, it is necessary to use the correct settings and methods. According to the density and thickness of the material, set a suitable feed rate as well as spindle speed for better results. Keep the constant depth of cut so that the bit does not become overloaded and cuts smoothly. By using a good quality vacuum or dust extraction system, you can take away waste material, which would otherwise cause heat build up along the tool path, resulting in burns on materials. For plywood, align grain direction properly and employ backing boards to reduce tear-out.

Minimizing Tear-out on Wood and Composites

Several strategies can be employed to minimize tear-out on woods and composites, such as using the best bits between downcut and upcut bits. One important thing is to ensure that sharp, high-quality compression endmills are used because blunt or low-quality ones will increase tearouts. Additionally, adjusting feed rates and spindle speeds according to different types of materials may lead to cleaner cuts. A climb-cutting technique where the tool cuts in the direction of the router’s rotation should also be applied since it reduces tear-outs. Proper work holding like clamps/vacuum tables should be utilized so as to hold securely the material, hence preventing any movement that might result in blemishes being formed during the machining operation. In case tearing out frequently occurs in some materials, pre-scoring the cut line with a shallow pass before final cutting could further enhance, thus giving cleaner edges/surfaces.

Downcut versus Upcut Bits: Achieving the Perfect Finish

The surface finish of a workpiece can be improved by either using down-cut or upcut bits, where each has its own purpose depending on what kind of finish is desired on top/bottom edges, respectively. Downward cutting rotates downwards, pushing chips away from the top surface, thus reducing splintering along the upper edge while ensuring a clean appearance. This makes them ideal tools for laminated surfaces, especially plywood, where a top-edge finish is essential. Upwards pulling clears chips efficiently, preventing overheating of bits during deep cuts, which leads to better quality bottom edge . A downcut bit will give you a cleaner surface on the top of your workpiece, while an upcut bit will give you cleaner edges on the bottom of your workpiece.

Common Questions about Bits for Compression Cutters

What is the Best Diameter for Different Projects?

The best diameter for different projects depends on many things, such as the thickness of the material and the type of cut being made. A 1/4 inch (6.35 mm) compression end mill should work well for most woodworking projects that involve working with thin materials. However, if you are going to be cutting through thicker materials or need more aggressive cuts, then using a bit with a 1/2 inch (12.7 mm) diameter will provide better stability and faster cutting speeds. Always choose a bit size that balances between being able to remove material quickly enough and still being able to create the necessary detail required by the specific project being worked on.

How to Keep Up and Extend the Life of Your End Mills

If you want to prolong the lifespan of your end mill, it is necessary that you perform proper maintenance and handling. Here are some of the best practices:

- Frequent Cleaning: Clean after every use to remove accumulated materials and prevent clogging.

- Safekeeping: Protect them from other tools by storing them in a case or any other safe place.

- Proper usage of shank router bit improves performance and increases longevity.: Always use the right feed rate together with spindle speed so as not to overheat or wear out unnecessarily.

- Sharpening: Inspect regularly for dullness and sharpen when necessary in order to maintain sharpness which lead to efficient cutting.

- Application of Coolant: During cutting operations, heat is generated due to friction; hence, coolants should be employed accordingly.

Following these practices will keep your end mills at their peak performance levels thus ensuring longer life span as well as better quality cuts achieved through stepover control.

Which materials are compression end mills most suitable for?

Laminated materials like plywood, MDF, and melamine are best for compression end mills. They work very well in composites where neither the top nor bottom surface can chip or tear out. Furthermore, these tools provide clean, accurate cuts on both sides of hard and soft woods, too.

Reference Sources

Frequently Asked Questions (FAQs)

Q: Definition of precision compression router bits?

A: Precision compression router bits are specialized tools that can be used with CNC routers. These tools help to create neat edges and surfaces on materials such as plywood and pine. To provide a smooth finish on both sides of the cut material, these bits combine downcut and upcut flutes.

Q: What are 2 flute compression end mills?

A: Two-flute compression end mills have two cutting edges, which helps balance chip clearance and cutting performance. These end mills are suitable for roughing and finishing cuts in wood, plastics, and other materials.

Q: What is “dia x shank x overall length” mean?

A: “Dia x shank x overall length” refers to the dimensions of the router bit. The cutting diameter is known as “dia,” shank means part that fits into a router whereas overall length refers to total length.

Q: Why use carbide end mills for my CNC router?

A: In comparison with other materials, carbide end mills last long due to their durability, lifespan, and high precision capabilities. They can also handle tougher materials without dulling quickly, making them perfect for professional use.

Q: Are these mill bits good for cutting plywood and pine?

A: Yes, these mill bits work great when it comes to cutting plywood or pine too! With compression end mills having both downcut and upcut flutes will ensure clean cuts on both sides of the material leaving smooth finish behind.

Q: How many items per package?

A : The number of items per package may vary depending on the specific product as well as manufacturer so always refer back to product description for more details regarding contents/quantities etc..

Q: Can you explain more about how well they cut?

A: These bits are built to be very precise and make clean cuts. They have downcut and upcut flutes combined in a compression end mill for the best cutting performance that they can achieve, which means it won’t tear out any material and will leave smooth edges instead, also known as the features of both downcuts and upcuts.

Q: What does a spiral cutting do in these router bits?

A: The reason why there is a spiral cutting on router bits is because it helps remove chips faster while ensuring smoother cuts at the same time. It also aids in finishing material with a prolonged bit of life.

Q: Why are specific dimensions like dia x shank x overall length important for CNC routers?

A: Specific details such as diameter by shank size by overall length matter when choosing tools for use with CNC machines on certain materials. This ensures accurate fitting so that they can work properly without causing any harm to either side of them – bits or machines being used as well as giving optimal cuts.

Q: Where can I buy the best compression router bits?

A: Some of the places where top-quality compression router bits can be bought from include Sienci Labs and Spetool EU among others who deal specifically in this line of products. Always check through customer reviews plus ratings alongside product specifications before making any payments to ensure you end up with what suits your needs most.