In CNC machining, selecting the right flute end mill cutter is a key factor that directly affects machining efficiency, tool life, and surface finish. One of the most frequently asked questions among engineers and CNC programmers is: When should I use a 2-flute end mill versus a 4-flute end mill?

While 2-flute end mills are often associated with high-speed machining of soft materials, 4-flute cutters are preferred for harder metals and finishing tasks. But the choice isn’t always that straightforward. Material type, cutting strategy, chip evacuation needs, and machine tool characteristics all play a role.

What Is a Flute End Mill Cutter?

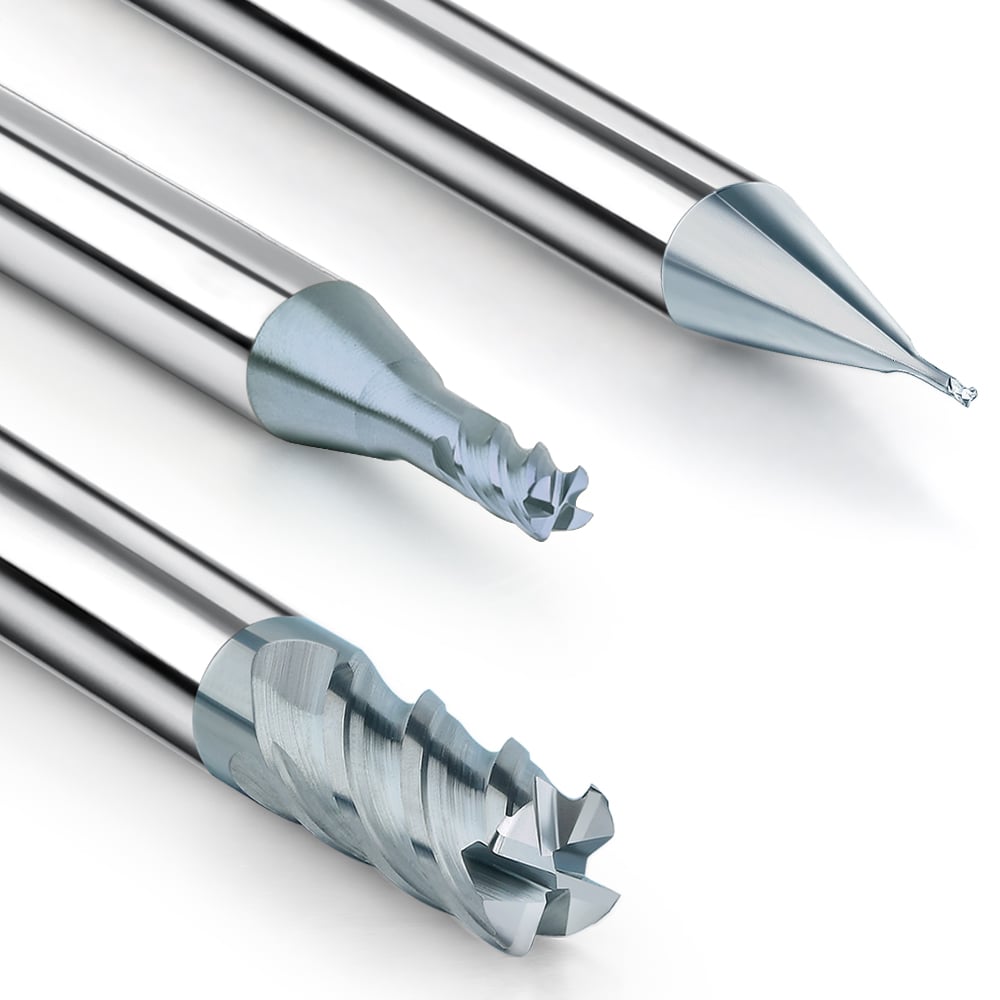

Flute end mill cutter is one of the most commonly used tools in CNC machining, mainly used for milling of various metal or non-metal materials. It consists of a tool holder, a tool body and multiple spiral cutting edges. The cutting edges are spirally distributed along the tool axis, which helps to achieve continuous cutting and chip removal.

These cutting edges are not only responsible for physically cutting the workpiece, but also directly affect key performances such as chip removal efficiency, cutting force distribution, vibration control and surface finish of the machined surface. Therefore, choosing a milling cutter with different numbers of flutes (such as 2 flute end mill cutter or 4 flute end mill cutter) is essentially choosing a suitable tool strategy for different processing needs.

The Key Influence of the Number of Flutes on Milling Cutter Performance

The number of flutes of a milling cutter is one of the core parameters that affect processing performance. The fewer the number of flutes, the greater the cutting load on a single flute, but the chip removal space is also relatively larger. This makes the 2-flute end mill cutter have good chip evacuation performance and high-speed feed capability when processing soft materials such as aluminum alloy, copper, and plastic.

On the contrary, the 4-flute end mill cutter has more cutting edges, which can achieve higher cutting efficiency at the same speed and significantly improve the surface quality of the workpiece. It is very suitable for side milling and finishing operations of hard materials such as steel and stainless steel.

In other words, the choice of the number of blades directly affects the cutting load, chip evacuation ability, processing stability and service life of the tool. When formulating tool paths and cutting parameters, engineers must comprehensively consider the number of blades to achieve the best processing effect.

Basic Difference Between 2-flute End Mill Cutter and 4-flute End Mill Cutter

Among CNC tools, 2-flute and 4-flute end mill cutter are the two most common types, and there are obvious differences between the two in structure and application characteristics:

2-flute end mill cutter has a larger chip groove, which is suitable for slotting and fast cutting of soft materials, especially in high-speed processing. In addition, it is also conducive to better entry of coolant or compressed gas into the cutting area, effectively reducing the cutting temperature.

4-flute end mill cutter provides more cutting edges, which helps to share the load under the same feed conditions, improve cutting stability and surface roughness level. However, its chip space is relatively small, so care should be taken to avoid chip blockage when processing soft materials or deep grooves.

Therefore, in the choice of 2-flute vs 4-flute end mill, a comprehensive judgment should be made based on factors such as workpiece material, cutting depth, and feed strategy to achieve a balance between efficiency and quality.

Advantages and Aapplication Scenarios of 2 Flute End Mill Cutter

In the field of CNC machining, 2 flute end mill cutter is an ideal choice for machining soft materials such as aluminum alloy, plastic, copper and other non-ferrous metals due to its excellent chip removal ability and high feed efficiency. Compared with milling cutters with higher number of blades, it has wider chip removal grooves and fewer cutting edges. This structural advantage enables it to have stable cutting performance under high speed and high feed conditions.

In addition, under working conditions where the cutting path needs to be cleaned and chip accumulation needs to be effectively controlled, the 2-edge milling cutter can better cooperate with cutting fluid or compressed air for heat dissipation and chip removal with its open chip removal path, greatly reducing tool overheating and sticking.

Stronger Chip Removal Capability, Suitable for Soft Materials Such as Aluminum and Plastic

The 2 flute end mill cutter is designed to retain a large chip removal space, which is especially important for processing materials with low melting points and easy chip blocking (such as aluminum, PVC, acrylic and other engineering plastics). Since these materials are prone to sticky chips and high temperatures during the cutting process, if the chip removal is not smooth, it is very easy to cause scratches on the workpiece surface, increased tool wear or tool breakage.

By using a 2-edge milling cutter, chip accumulation can be effectively reduced, making the processing process smoother and the heat dissipation effect better, thereby improving the overall processing efficiency and tool life. This is also one of the reasons why many CNC milling machines are almost equipped with a 2 flute end mill cutter by default when cutting aluminum alloys at high speed.

The Tool of Choice for Slotting

Slotting is a form of processing that requires high axial and radial loads on the tool. The tool needs to feed the full width and remove chips at the same time. Compared with 4-edge or 6-edge milling cutters, 2 flute end mill cutters have significant advantages in slot milling: it not only has smoother chip removal, but also has less cutting resistance, and is more suitable for maintaining good processing stability when cutting into the full slot.

Especially when processing through slots or blind slots on structural parts such as aluminum parts, plastic shells or copper parts, 2-edge milling cutters can run at higher speeds and feed rates, reduce vibration and tool marks, and obtain neater slot bottoms and side walls.

Typical Application Cases and Recommended Speed/Feed Parameters

The following are the actual parameter recommendations for 2 flute end mill cutter in typical applications, for reference only (specific parameters should be determined according to the actual conditions such as tool diameter, tool material, machine tool rigidity and cooling conditions):

| Material | Cutting Speed (SFM) | Feed per Tooth (IPT) |

|---|---|---|

| Aluminum 6061 | 600–1200 | 0.003–0.012 |

| Acrylic/Plastic | 200–400 | 0.002–0.008 |

| Copper | 300–800 | 0.002–0.010 |

Advantages and Application Fields of 4 flute End Mill

Compared with 2-edge milling cutters, 4 flute end mill cutters have significant advantages in multi-edge cutting and overall tool strength, and are often used in precision machining of high-hardness metal materials such as steel, stainless steel, and titanium alloys. Because it has more cutting edges, the cutting load per edge is smaller, which is conducive to improving the surface quality and dimensional stability of the machining. It is especially suitable for use in high-load and high-precision scenarios such as side milling and fine milling.

In addition, the 4-edge structure also improves the rigidity of the tool, reduces vibration and offset during machining, making it an optimal solution for high-intensity cutting, deep cavity milling or contour finishing. Whether it is mold manufacturing, part forming or multi-axis linkage machining of complex contours, 4 flute end mill cutters can demonstrate excellent cutting control capabilities and long life performance.

More Cutting Edges Lead to Higher Surface Finish

One of the main advantages of 4 flute end mill cutter is that it has more cutting edges, which increases the cutting contact points per unit speed. This means that under the same processing conditions, 4-flute milling cutters can achieve more uniform material removal and finer cutting textures. This effectively improves the surface finish and processing accuracy of the workpiece.

Especially when finishing mold cavities, curved contours, and tooling parts, 4-flute milling cutters can significantly reduce surface roughness (Ra value) and reduce the need for subsequent secondary processes such as polishing and grinding. For high-end manufacturing applications that pursue high surface quality and geometric accuracy, such as aviation structural parts and precision medical devices, 4-flute end mills are undoubtedly a more reliable choice.

Suitable for Hard Materials sSuch as Steel and Stainless Steel

When processing materials such as 45# steel, die steel, and stainless steel (such as 304, 316), the cutting resistance that the tool needs to withstand increases significantly, so higher requirements are placed on the tool rigidity and wear resistance. 4 flute end mill cutter has a larger cross-sectional area of the blade, strong rigidity, and good shock resistance, which can achieve a more stable cutting path and longer tool life on hard materials.

In addition, the edge strength of the 4-flute milling cutter is higher, and it can maintain good processing performance even under no or little cooling conditions. Combined with high-performance tool coatings (such as TiAlN, AlCrN), it can further improve its heat resistance and wear resistance in high-hardness materials, and is an indispensable tool in the daily “hard material processing strategy” of CNC workshops.

Suitable for High-load Conditions Such as Side Milling and Finishing

Unlike 2-flute cutters that are more suitable for slotting, 4 flute end mill cutters are better at side milling, semi-finishing and finishing. Due to its evenly distributed cutting edges and multiple contact points, it can keep the tool stable during heavy cutting and long path processing, avoiding dimensional errors caused by vibration or offset.

In the processing of complex parts, such as mold contours, feature boundaries, and the finishing stage of the inner wall of the cavity, the 4-flute milling cutter can provide more stable cutting force control. It is suitable for small step finishing to help process high-quality surfaces with consistent size and no burrs.

It is worth noting that it is necessary to be cautious when using a 4-flute end mill cutter for full groove processing, because the chip removal space is small, which is easy to cause chip accumulation and tool overheating. Therefore, when the groove width is more than 50% greater than the tool diameter, it is recommended to give priority to a 2-flute milling cutter or use a 4-flute milling cutter for layered cutting.

2 Flute vs 4 Flute End Mill: How to Choose According to Working Conditions?

In CNC machining, choosing the right flute end mill cutter is crucial to improving machining efficiency and workpiece quality. In actual production, one of the common comparison questions is: Which one is more suitable for my working conditions, 2 flute end mill cutter or 4 flute end mill cutter?

This is not a “one size fits all” question, but requires comprehensive consideration of multiple factors such as the material being processed, the processing method, and the performance of the machine tool to make a choice.

From the Perspective of Material Type: Aluminum Alloy vs Alloy Steel

When milling different materials, the number of tool edges has a critical impact on chip removal space and cutting stability. For soft materials such as aluminum alloy, brass, and plastic, the chip volume is large during processing and is easy to clog the cutting groove. At this time, the 2-flute end mill cutter should be preferred, which has a wider chip groove, can efficiently remove chips, reduce the risk of chip adhesion, and improve cutting efficiency and workpiece surface quality.

On the contrary, when processing high-hardness materials such as alloy steel, stainless steel, and titanium alloy, more cutting edges help to share the cutting load and improve tool rigidity and wear resistance. At this time, the 4-flute end mill cutter is more competent, especially in dry cutting or small cutting depth processing scenarios, with more stable performance and longer life.

From the Perspective of Processing Methods: Roughing vs Finishing

Different processing stages have different requirements for tools. In roughing, large feed, large cutting depth, and rapid material removal are usually required. 2 flute end mill cutter is more advantageous in this scenario because it has a large chip removal space, is not easy to block chips, and has more concentrated cutting force, which helps to improve processing efficiency and cutting depth.

In finishing or semi-finishing, higher surface finish and dimensional accuracy are pursued. At this time, the multi-edge structure of 4 flute end mill cutter is more ideal, which can reduce the cutting load per edge and improve surface quality. It is especially suitable for high-precision processing tasks such as mold finishing and part edge trimming.

In addition, if the working condition is full slot milling, that is, the tool is buried in the material as a whole for processing, it is recommended to use 2-edge end mills first, because 4-edge milling cutters have limited chip removal and are prone to problems such as sticking and overheating.

From the Perspective of Equipment Capabilities: High-speed Machine vs Ordinary Machining Center

Machine tool performance also affects tool selection. If you are using a high-speed machining center with a high-speed, high-rigidity spindle system, you can give full play to the advantages of the 4-flute end mill cutter to achieve efficient finishing with small step distance, high speed and high surface quality at high spindle speed.

For ordinary machining centers, especially small and medium-sized CNC equipment, due to limited spindle power and rigidity, too many flutes may lead to excessive cutting resistance and the machine tool cannot be eaten. At this time, the 2-flute end mill cutter is easier to control the cutting force, suitable for rough machining tasks with large feeds, and easier to avoid problems caused by poor chip removal.

In addition, whether the machine tool has a coolant system (oil mist or spray cooling) will also affect the tool selection strategy. In the absence of cooling, 2-flute milling cutters are safer when processing aluminum and other materials that are easy to stick to the tool. Under high-performance cooling conditions, 4-flute milling cutters can better maintain cutting stability and tool life.

Choosing the right flute end mill cutter is not only related to machining quality, but also directly affects production efficiency and tool costs. Understanding the characteristics of different numbers of blades and combining them with one’s own equipment and working conditions are basic skills that every CNC engineer or processing plant manager must master.

| Feature | 2-Flute End Mill | 4-Flute End Mill |

|---|---|---|

| Chip Space | Large—better chip evacuation | Smaller—may cause chip packing |

| Cutting Load per Flute | Higher | Lower—shared across more cutting edges |

| Material Suitability | Aluminum, copper, plastic | Steel, stainless steel, titanium |

| Applications | Slotting, plunging, roughing | Side milling, semi-finishing, finishing |

| Coolant Access | Excellent | Moderate |

| Surface Finish | Good for roughing | Excellent for finishing |

Common Misunderstandings and Selection Suggestions

When choosing a flute end mill cutter, many processing personnel are prone to some cognitive misunderstandings, which affect the use of tools and processing efficiency. Whether it is a 2-flute end mill cutter or a 4-flute end mill cutter, its scope of application and performance are not fixed. Instead, it should be comprehensively evaluated according to the actual working conditions, material types, processing methods and equipment capabilities. The following clarifies common misunderstandings and provides professional selection suggestions.

2-flute is not Only for Aluminum

In many factories, 2-flute end mills are often regarded as “for aluminum only”, which is actually an oversimplified understanding. Indeed, the 2-flute structure is particularly suitable for processing soft materials such as aluminum alloys, copper, and plastics due to its large chip removal space, sharp cutting, and concentrated cutting load, but this does not mean that it cannot be used for other materials.

In fact, in the roughing or slotting of hard materials such as steel, if the appropriate cutting parameters and cooling methods are used, 2-flute end mills can also perform well. For example, for shallow cutting at high speeds, or for roughing on carbon steel or pre-hardened mold steel with moderate hardness, 2 flute end mill cutters are still a cost-effective choice.

Long-tail keywords such as 2 flute end mill for steel or 2 flute cutter for stainless roughing point to this diversified application trend.

Can 4 Flutes Also be Used for Slotting? It Depends on the Cutting Conditions

Another common misunderstanding is: “4-flute end mills cannot be used for slotting.” This is true under certain conditions, especially in working conditions where the material is highly viscous, there is no coolant assistance, and the chips are not easy to be discharged. Using a 4-flute milling cutter for full slot milling is indeed prone to problems such as sticking, chip blocking, overheating, and even chipping.

But in fact, if the following conditions are met, the 4 flute end mill cutter can still be competent for some slotting tasks:

- The processed material is a short-chip metal (such as medium carbon steel, cast iron).

- The processing parameters adopt a shallow cutting depth and fast feed strategy.

- Use high-pressure cooling or tool center water discharge design.

- Or choose a 4-flute slot cutter with core thickness optimization and improved chip groove structure.

Many modern high-performance 4-flute end mill designs have optimized chip grooves and blade shapes in structure, giving them a certain slot milling capability. As long as the parameters are adjusted according to the specific working conditions and the processing load is controlled, it is completely feasible to use 4 flutes for shallow slot milling.

Therefore, long-tail keywords such as can 4 flute end mill slot or 4 flute slotting cutter parameters reflect the flexibility and development trend of this field.

Number of Flutes ≠ Efficiency, Reasonable Matching is the Key

When selecting a tool, some processors have the misunderstanding that “the more blades, the higher the efficiency”. In fact, more blades means a smaller cutting thickness per blade and more dispersed cutting force, which is indeed beneficial to improving surface finish and tool life, but it does not necessarily improve overall processing efficiency.

Processing efficiency depends on the coordination of multiple variables, including:

- Matching of spindle speed and feed rate.

- Matching of machine tool rigidity and tool material.

- Control of cutting depth and feed per blade.

- Smoothness of chip removal in the cutting area.

In practical applications, if your goal is to remove material quickly (such as rough machining or initial machining of batch products), it is more efficient to choose a tool with a low number of blades and high sharpness. In the scenario of pursuing dimensional accuracy and surface quality, the advantages of multi-blade tools should be considered.

Therefore, “the more blades, the better” or “only choose the sharpest knife” are not professional selection logic. Reasonable matching should be carried out according to specific working conditions and equipment conditions to achieve a balance between tool life, processing efficiency and workpiece quality.

Choosing the right tool is not just “selecting a model”, but also a comprehensive reflection of technology and experience. Only by understanding the applicable scenarios and design logic of end mill cutters with different numbers of flutes and combining their own process conditions can the optimal solution for processing efficiency be achieved.

Choose a Suitable Flute End Mill Cutter to Make Processing More Efficient

2 Flute and 4 Flute End Mill have Their Own Advantages

In the selection process of end mills, 2 flute end mill cutters and 4 flute end mill cutters each have clear structural characteristics and usage advantages, and show differentiated performance for different working conditions.

- 2-flute milling cutters are widely used in the processing of soft materials such as aluminum alloys, copper, and plastics due to their strong chip removal ability and sharp cutting edge. They perform well in grooving, rough machining, and light-load high-speed cutting scenarios.

- 4-edge milling cutters are more suitable for side milling, finishing or continuous cutting under high load conditions of hard materials such as steel, alloy steel and stainless steel, thanks to the advantages of multiple blades sharing the load and good cutting stability.

It can be said that there is no absolute difference between end mill cutters with different numbers of blades. The key lies in the reasonable matching of processing requirements and working conditions.

Comprehensive Judgment Based on Workpiece Material, Processing Strategy and Equipment Capacity

In actual processing, there are often more than one factor affecting tool selection:

- The workpiece material determines the chip removal ability, rigidity and edge wear resistance of the required tool.

For example: 2 flutes are recommended for aluminum to improve chip removal efficiency, while 4 blades are more suitable for steel parts to enhance cutting stability.

- The processing strategy affects the adaptability of the tool type, such as slotting, side milling, roughing or finishing.

Finishing tends to use 4 flutes to improve surface quality, while roughing needs to consider the tool chip space and feed capacity.

- Equipment capabilities directly determine whether the tool can perform its designed performance.

Using 2 flutes for light milling on high-speed machine tools can achieve extremely high efficiency; and a machining center with strong rigidity can give full play to the feed and precision potential of 4-flute tools.

Therefore, when selecting a flute end mill cutter, you should avoid mechanically applying the simple logic of “2 flutes for aluminum and 4 flutes for steel”. Instead, you need to develop the best optimization plan based on a comprehensive evaluation of the overall machining system.

Summary suggestions:

- Clear machining goals: Is it to pursue machining efficiency, or to emphasize surface quality and precision?

- Analyze material properties: Is chip removal the priority, or is tool wear resistance more important?

- Consider equipment conditions: Does it have high speed, good rigidity, or cooling assistance?

Ultimately, choosing the right number of flutes and parameters can truly achieve “high-efficiency machining with half the effort”.