In modern CNC machining, the choice of tool material directly affects machining efficiency, surface quality, and production costs. The comparison between carbide and HSS end mills has long been a core topic among engineers and machining companies. Carbide end mills are renowned for their high hardness, wear resistance, and high-speed cutting capabilities, making them suitable for difficult-to-machine materials such as stainless steel, hardened steel, and titanium alloys. Meanwhile, HSS end mills maintain their market share in low-speed cutting, mold finishing, and non-ferrous metal machining due to their toughness, impact resistance, and cost-effectiveness.

Whether performing roughing or finishing, selecting the appropriate tool material influences cutting speeds, feed rates, tool life, and workpiece surface finish. For example, choosing between a carbide and an HSS end mill for aluminum significantly impacts chip evacuation and surface quality. When machining stainless steel, carbide tools often maintain stable cutting performance at high speeds, reducing tool wear.

For CNC engineers, understanding the differences between HSS milling cutters and carbide end mills in terms of hardness, heat resistance, cost, and material compatibility is key to developing efficient machining solutions. This article provides an in-depth analysis of carbide vs HSS end mills, focusing on tool performance comparison, material compatibility, economic analysis, and application scenarios. It will help you make informed tool choices for your CNC projects.

What Is an End Mill? Basic Concepts and Classification

End mills are among the most commonly used tools in CNC milling, primarily used for cutting metals, plastics, and wood. Unlike drills, end mills can feed both axially and radially, enabling various processes such as slotting, side milling, pocketing, and finishing. Based on tool material, flute count, flute profile, and coating, end mills are categorized into various types, including high-speed steel (HSS) end mills and carbide end mills.

In CNC machining, tool material selection is closely linked to workpiece material, cutting speed, feed rate, and machining accuracy. For example, in aluminum milling, appropriate tool geometry and material can greatly improve chip evacuation and surface finish; similarly, in stainless steel milling, tool wear and heat resistance are critical to machining efficiency.

Below, we introduce the two most common tool materials: high-speed steel end mills and carbide end mills, along with common end mill structures and geometric parameters.

Definition and Characteristics of End Mill HSS

End mills HSS are made from high-carbon steel alloyed with elements such as molybdenum, tungsten, and vanadium. They offer high toughness and impact resistance. In low-speed and intermittent cutting, HSS tools reduce the risk of chipping, making them ideal for mold finishing, small-batch production, and cost-sensitive machining projects.

Key Features:

-

High toughness: Suitable for intermittent cutting and complex shapes, with minimal chipping risk.

-

Low cost: Significantly less expensive than carbide tools, ideal for budget-conscious operations.

-

Resharpenable: Tool life can be extended through regrinding.

-

Low heat resistance: Not suitable for ultra-high-speed cutting or machining very hard materials.

HSS end mills are more appropriate for machining soft metals such as aluminum alloys and copper, as well as non-metallic materials like wood and plastic.

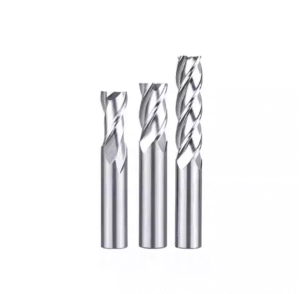

Definition and Characteristics of Carbide End Mills

Carbide end mills are made from tungsten carbide and cobalt, offering much higher hardness and wear resistance than HSS. Their superior strength and heat resistance allow stable cutting at high speeds and feeds, making them ideal for difficult-to-machine materials like stainless steel, titanium alloys, and hardened steel.

Key Features:

-

High hardness and wear resistance: Extends tool life and reduces tool changes.

-

Excellent high-temperature resistance: Maintains hardness at elevated cutting temperatures.

-

High machining efficiency: Suited for high-volume, high-precision production.

-

High clamping rigidity requirements: Machine spindle and toolholding must be rigid to prevent vibration.

Carbide end mills excel in stainless steel and titanium machining, significantly boosting productivity while maintaining precision.

Common End Mill Structures and Geometric Parameters

End mill design and geometry directly affect cutting performance and surface quality. Key parameters include:

-

Number of flutes: Typically 2, 3, 4, or more. More flutes improve surface finish but reduce chip evacuation.

-

Helix angle: Commonly 30° or 45°. Higher angles offer smoother cuts but lower rigidity.

-

Tip shape: Square, ball nose, corner radius — each suited for specific machining needs.

-

Coatings: TiAlN, AlTiN, DLC, etc., enhance wear and heat resistance, reduce cutting forces.

When selecting tools, consider differences in geometry and edge sharpness between carbide and HSS, as these impact chip evacuation, stability, and surface finish.

Carbide vs HSS End Mill Performance Comparison

Tool performance impacts cutting efficiency, surface quality, and production costs. Choosing between carbide and HSS end mills depends on hardness, wear resistance, cutting speed, feed rate, heat resistance, and machining accuracy.

Hardness and Wear Resistance Comparison

Carbide end mills typically have hardness around 90 HRA (above 65 HRC), significantly higher than HSS. This high hardness reduces plastic deformation and maintains sharpness when cutting hardened steels, titanium, and composites. Carbide tools sustain stable wear resistance during high-speed or long continuous cuts, especially under dry or MQL conditions.

HSS end mills, though less hard, provide sufficient wear resistance for softer materials and resist chipping better during interrupted cuts.

Cutting Speed and Feed Rate Comparison

Carbide end mills support higher cutting speeds—several times faster than HSS—boosting production efficiency. High cutting speeds reduce cycle times, making carbide ideal for high-volume, precise machining.

HSS tools require lower speeds due to lower heat resistance, suited for finishing or intermittent cutting. Carbide tools also allow higher feed rates thanks to their rigidity.

Tool Life and Heat Resistance Comparison

Carbide tools tolerate cutting temperatures above 800°C without softening, crucial for machining stainless steel and high-temperature alloys.

HSS tools withstand about 600°C; prolonged high-speed cutting leads to softening and shorter tool life.

Machined Surface Quality Comparison

Carbide end mills deliver lower surface roughness (Ra) at high speeds and low vibration, ideal for mold finishing and mirror surfaces.

HSS tools have sharp edges and smooth chip evacuation at low speeds, suitable for soft metals like aluminum and copper.

Tool choice for surface finish should consider material, machine rigidity, and cutting parameters.

Material Compatibility Comparison: HSS Milling Cutter vs Carbide End Mill Cutter

Choosing tool material depends on workpiece characteristics. Different materials demand varying hardness, toughness, wear resistance, and chip evacuation.

Tool Selection for Aluminum Alloy Machining

Aluminum’s moderate hardness and long chip formation require good chip evacuation.

End mills hss, with toughness and sharp edges, suit low-speed, interrupted aluminum cutting and small batches. Carbide end mill cutters support higher speeds, better wear resistance, and improved surface finish. Coated carbide (e.g., TiB2) further improves wear and anti-stick.

Performance in Machining Stainless Steel and High-Hardness Steel

Stainless and hardened steels require high hardness and heat resistance.

Carbide end mill cutters provide stable high-speed cutting, reducing wear and extending tool life.

HSS tools are suitable for low-speed finishing but soften at high temperatures.

Proper cutting parameters and cooling enhance carbide tool performance.

Tool Advantages for Plastic and Non-Ferrous Metal Machining

Plastics and non-ferrous metals need toughness and anti-stick.

HSS end mills prevent chipping and chip adhesion effectively, good for intermittent and small batch work.

Carbide tools risk sticking without proper parameters but coated versions (DLC) improve performance.

Cost and Economic Analysis

In CNC machining, tool costs are not limited to the initial purchase price; they also encompass tool life, maintenance, and machining efficiency, all of which influence overall production expenses. When comparing the economics of carbide vs HSS end mills, manufacturers must assess both short-term investment and long-term operational costs to choose tooling solutions that balance machining quality and cost-effectiveness.

Initial Purchase Cost Comparison

HSS end mills have simpler manufacturing processes and lower material costs, resulting in significantly lower market prices compared to carbide tools. This makes HSS tools ideal for budget-sensitive projects or small-batch production.

In contrast, carbide end mill cutters come with a higher upfront cost due to expensive raw materials and tight machining tolerances, especially for premium versions featuring multi-layer coatings and specialized geometries. While initial cost is an important factor, it should not be the sole consideration when choosing between carbide vs HSS end mills.

Long-Term Costs (Tool Life and Replacement Frequency)

Tool life and replacement frequency directly affect production continuity and maintenance costs.

Carbide end mills offer superior hardness and wear resistance, resulting in longer tool life—especially when machining stainless steel and other hard materials—thus reducing downtime and minimizing the risk of instability from frequent tool changes.

HSS end mills, despite lower purchase prices, tend to wear faster under high-intensity, high-temperature conditions, necessitating more frequent replacements that increase overall operational costs.

Therefore, evaluating tool life and replacement cycles based on specific machining processes and materials is essential to balance tool expenses with production efficiency.

Impact of Machining Efficiency on Cost

Machining efficiency significantly influences unit production cost. Carbide tools support higher cutting speeds and feed rates, shortening cycle times and boosting throughput, particularly in high-volume environments.

Due to lower heat resistance and toughness, HSS tools require conservative cutting parameters, leading to longer machining times and higher labor and equipment costs. Moreover, the high rigidity and stability of carbide tools improve machining accuracy and surface finish, reduce rework, and further lower overall costs.

In many cases, the gains in speed and productivity with carbide tools offset their higher initial price, delivering better economic value over time.

Usage Scenario and Application Recommendations

Choosing the right end mill involves considering material, performance, and the specific machining scenario. The application strategies for carbide vs HSS end mills vary based on production scale, accuracy demands, and workpiece materials. Proper tooling alignment with process conditions enhances efficiency, ensures quality, and reduces costs.

Selection Recommendations for High-Precision Mold Machining

High-precision mold machining demands high tool rigidity, surface finish, and dimensional stability.

Carbide end mills, with their hardness and wear resistance, maintain sharp edges at high speeds and feeds, enabling fine surface detail and reducing dimensional errors caused by wear.

HSS end mills are suitable for mold finishing, grinding, and low-speed detail work. Their toughness helps prevent chipping on complex curves and intermittent cuts.

Typically, carbide tools serve as primary cutters in mold making, supplemented by HSS tools for detailed finishing.

Tooling Strategies for Mass Production and Small-Batch Trial Production

Production volume heavily influences tool selection.

Mass production prioritizes stable efficiency and long tool life, favoring carbide end mills for continuous high-speed cutting.

Small-batch or prototype production often uses cost-effective, versatile HSS tools to reduce upfront investment and accommodate varied processes.

Companies should tailor procurement and tool management based on production demands and budgets, balancing carbide and HSS tool use accordingly.

Differences in Tool Selection for Roughing and Finishing

Roughing and finishing have distinct tool requirements.

Carbide tools are typically used in roughing for high material removal rates and process stability, shortening cycle times.

Finishing requires surface quality and dimensional accuracy; here, HSS tools—with sharp edges and toughness—are suitable for detailed and delicate work.

Combining carbide tools for roughing with HSS tools for finishing balances productivity with quality.

By strategically pairing carbide and HSS end mills according to process needs, manufacturers can maximize tool benefits and overall machining efficiency.

Considerations for Upgrading from HSS Milling Cutters to Carbide End Mills

As machining demands rise, many CNC engineers upgrade from HSS to carbide end mills. While carbide offers superior hardness, wear resistance, and efficiency, the upgrade necessitates systematic adjustments in cutting parameters, machine rigidity, and cooling methods to maintain quality and avoid tool damage.

Cutting Parameter Adjustment (Speed, Feed, Depth of Cut)

Adjusting cutting parameters is critical after switching to carbide tools.

-

Spindle Speed: Carbide tools tolerate significantly higher speeds but must be matched to machine rigidity and material.

-

Feed Rate: Higher feed rates improve efficiency but must be optimized by tool size, flute count, and machining process.

-

Cutting Depth: Increasing depth per pass can boost productivity but requires stable machine setup to prevent vibration and tool breakage.

Consulting guidelines on carbide end mill parameters and comparisons with HSS helps optimize performance and tool life.

Tool Clamping and Rigidity Requirements

Carbide tools’ brittleness and high cutting forces demand rigid clamping.

Precision toolholders and collets must prevent tool deflection or loosening.

Machine spindle and bed rigidity are equally important; minimizing vibration extends tool life and improves accuracy.

Optimizing clamping during upgrade prevents premature tool failure.

Optimizing Cooling and Lubrication Methods

Proper cooling and lubrication enhance carbide tool performance by reducing heat and wear.

Compared to HSS, carbide end mills benefit from high-pressure cooling or minimum quantity lubrication (MQL) to lower cutting zone temperatures and prevent chip clogging.

In dry machining, selecting the right coatings and coolant strategies is vital.

Adjusting coolant flow and nozzle position when upgrading from HSS to carbide tools improves stability and tool life.

Upgrading involves holistic process optimization beyond simply switching tool materials.

How to Choose the Best Carbide vs HSS End Mill

Selecting the right end mill impacts machining efficiency, product quality, and overall competitiveness. Choosing between carbide and HSS end mills requires evaluating tool performance, material compatibility, and cost.

Summary of Comprehensive Factors: Performance, Material Compatibility, and Cost

-

Performance: Carbide end mills offer higher hardness, wear and heat resistance, enabling high-speed, high-feed machining of hard materials and large volumes. HSS excels in low-speed, intermittent cutting and soft material machining due to toughness.

-

Material Compatibility: Carbide tools suit stainless steel, hardened steel, titanium alloys, and high-speed aluminum machining. HSS tools are better for aluminum alloys, non-ferrous metals, plastics, and mold finishing.

-

Cost: Carbide tools have higher initial costs but longer life and efficiency reduce long-term expenses. HSS tools are cost-effective for small batches and prototypes but require frequent replacement, increasing indirect costs.

Recommended Solutions for Different Processing Needs

-

For high-precision mold making and hard-to-machine materials, carbide end mills combined with optimized cutting parameters and cooling are ideal.

-

For high-speed aluminum and soft material machining, coated carbide tools enhance speed and tool life while maintaining finish.

-

For small-batch trials and intermittent cuts, HSS end mills provide economical toughness and versatility.

-

For combined roughing and finishing, carbide tools serve roughing needs, while HSS tools handle fine finishing, balancing speed and quality.

Through scientific evaluation and tailored use of carbide and HSS end mills based on machining requirements and equipment conditions, manufacturers can maximize tool benefits and optimize CNC production efficiency.