In metal cutting, choosing the right tool directly affects both production efficiency and cost control. When comparing end mills vs face mills, engineers and purchasing teams need to understand the difference between end mills and face mills as well as consider tool cost and tool life to evaluate overall production economics.

Which is an end mill cutter and which is a face mill? While these may seem basic, these questions are critical. End mills are typically used for pocket machining, surface cutting, and high-precision detail work, whereas face mills are designed for efficiently removing large, flat surfaces. Differences in tool geometry, cutting methods, and maintenance result in significant variations in tool life and cost.

In practice, deciding when to use an end mill vs a face mill depends on factors such as workpiece material, machining stage (roughing or finishing), tool coating, chip evacuation, and cooling. Choosing the wrong tool can cause premature wear, increased costs, and reduced surface quality.

From a production economics perspective, tool purchasing decisions should account for more than unit price. Consider tool life, unit machining cost, insert replacement frequency, and overall productivity. Only a systematic comparison of end mills vs face mills allows engineers to find the optimal solution, achieving lower costs and greater production stability.

Introduction: Why Compare End Mills vs Face Mills?

Tool selection affects cutting efficiency, surface quality, and production costs. For engineers and purchasers, understanding end mill vs face mill is critical for tool ROI and overall production economics.

In mold manufacturing or mass production, companies face a familiar choice: use an end mill for complex cavities and curved surfaces, or a face mill for rapid large-area material removal. Tool geometry and cutting methods lead to significant differences in tool life, unit costs, and replacement frequency. A systematic analysis helps compare the practical applications of an end mill cutter and a face mill.

The Importance of Cutting Tools in CNC Machining Costs

Tool costs can make up a large portion of CNC machining expenses, particularly when working with hard materials or requiring high precision. Tool life impacts efficiency and profitability. For instance, end mills excel at fine-cavity machining but often need more frequent replacement. Face mills may have higher initial costs but, with replaceable inserts, provide lower long-term costs.

Cutting tools are not just tools—they are key drivers of machining efficiency, maintenance costs, and unit cost of production.

The Core Significance of the Difference Between End Mills and Face Mills

Understanding the difference between end mills and face mills is essential for optimal tool application. End mills suit 3D surfaces, grooves, and small-area finishing, while face mills excel at roughing large surfaces and high-efficiency cutting. Using the wrong tool increases wear, replacements, and downtime, reducing production economics. Comparing these tools from a cost and life perspective is therefore essential.

Article Objective: Analyze Tool Selection from an Economic Perspective

This article explores how to balance tool cost, tool life, cutting efficiency, and productivity from both business and engineering perspectives. We will examine when to use end mills vs face mills for roughing and finishing, low- and high-volume production, and different materials, helping readers make the most economical tool selection.

What is an End Mill Cutter?

End mills are among the most common milling tools. Understanding what an end mill cutter is helps analyze end mill vs face mill differences and guides tool selection and cost control. End mills remove material while enabling machining of complex geometries, making them essential in mold manufacturing, part machining, and 3D surface work.

Definition and Structural Features

End mills are multi-edge cutting tools with a cutter body, cutting edges, spiral flutes, and a shank. Unlike face mills, end mills have cutting edges on both the perimeter and the bottom, allowing simultaneous side and face cutting.

Key factors include:

-

Tool diameter and flute length: determine cutting depth and capacity.

-

Helix angle and number of flutes: influence cutting efficiency, chip evacuation, and surface finish.

-

Coating materials (TiAlN, CVD, PCD): extend tool life significantly.

End mills are ideal for detailed machining and small-area cutting, offering high accuracy and surface quality.

Common Types and Applications

-

Two-flute end mills: Large chip clearance, suitable for high-speed cutting of soft materials like aluminum.

-

Four-flute end mills: Smooth cutting, good for finishing steel.

-

Ball-nose end mills: Used in 3D surfaces and mold machining for precise contouring.

-

Coarse-tooth end mills: For roughing with large depths and high feed rates, providing rigidity and wear resistance.

Selecting the right end mill type affects cost control for both roughing and finishing, balancing efficiency, surface quality, and tool life.

Typical Cost and Lifespan Characteristics of End Mills

-

Low initial cost: Generally cheaper than face mill bodies but require full replacement.

-

Tool life: Highly dependent on material, speed, and cutting conditions.

-

High unit workpiece cost: Shorter lifespan may reduce cost-effectiveness in high-volume production.

-

Flexibility: Can handle grooves, cavities, and curved surfaces, reducing inventory pressure.

End mills suit small-batch, diversified, high-precision work but may be less cost-effective for high-volume roughing.

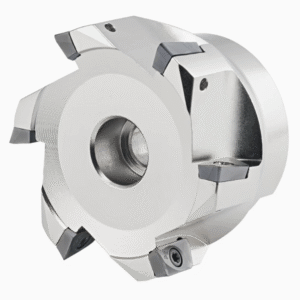

What is a Face Mill?

Face mills are designed for high-efficiency, large-area machining. Knowing what a face mill is is critical for distinguishing it from end mills and optimizing tool investment. Face mills are commonly used on CNC mills or machining centers. Their stable cutting performance and long tool life make them indispensable for flat surfaces and high-volume production.

Definition and Structural Features

A face mill consists of a cutter body and replaceable inserts:

-

Cutter body: Made from high-strength alloy or carbide.

-

Replaceable inserts: Carbide, CVD, or PCD; only worn inserts need replacement.

-

Cutting edge distribution: Inserts positioned around the periphery for efficient face cutting.

This design reduces replacement costs and improves face mill tool life and cost efficiency.

Common Insert Configurations and Applications

-

Roughing inserts: Large edge angles, high toughness for rapid material removal.

-

Finishing inserts: Sharp edges, high-quality coatings for low surface roughness.

Applications: large flat surface milling, mold finishing, and high-volume material removal from steel, aluminum, or cast iron. Face mills provide better stability, surface finish, and productivity compared to end mills.

Typical Cost and Lifespan Performance of Face Mills

-

Higher initial investment: Cutter body is expensive but reusable.

-

Low replacement cost: Replace worn inserts only.

-

Long tool life: Outperforms end mills in high-volume or stable cutting.

-

Lower unit cost per workpiece: Especially for large, flat surfaces.

Face mills are ideal for large-scale, standardized production where efficiency, lifespan, and cost-effectiveness are priorities.

End Mill vs Face Mill: Core Difference Comparison

Understanding the differences is critical for tool optimization and cost reduction. Differences include geometry, cutting method, machining range, material suitability, and tool life, all affecting efficiency, surface quality, and production economics.

Difference Between End Mills and Face Mills

-

End mills: Cutting edges on the periphery and base, suitable for cavities, grooves, and curved surfaces; flexible for roughing to finishing.

-

Face mills: Inserts along the periphery, optimized for large-surface removal; replaceable inserts reduce long-term costs.

End mills are more flexible for detailed, small-area work, while face mills are more efficient for large, flat surfaces.

Comparison of Machining Scope and Material Applicability

-

End mills: 3D surfaces, grooves, cavities, small areas; materials include steel, aluminum, copper, composites; ideal for precision work.

-

Face mills: Large flat surfaces, datum surfaces, mass production; suitable for steel, aluminum, cast iron; emphasize efficiency and lower unit cost.

Differences in Tool Life and Replacement Cycle

-

End mills: Lifespan affected by material hardness, speed, feed, and cooling; frequent replacement may be needed.

-

Face mills: Only worn inserts replaced, resulting in longer life and lower unit cost.

In high-volume or large-area production, face mills offer superior ROI and lower tool investment per workpiece.

Tool Cost Analysis: End Mill vs Face Mill

In CNC machining, tool costs include not only the initial purchase price but also lifecycle costs, replacement frequency, and maintenance. Comparing end mill vs face mill cost reveals major differences in initial investment, unit workpiece cost, and maintenance strategies, which directly affect production economics.

Tool Unit Price vs Initial Investment Comparison

-

End mills: Sold as a complete unit, relatively low initial price, but short tool life under high-hardness or high-speed conditions, requiring frequent replacement.

-

Face mills: Consist of a cutter body plus replaceable inserts. Higher initial investment, but inserts reduce long-term costs. Face mills are more economical for high-volume or high-cutting applications.

Analyzing these costs allows companies to understand both short-term expenses and long-term benefits of tool purchases.

Tool Life and Unit Cost

Unit cost = (Total tool cost + Tool maintenance cost) / Total number of workpieces

-

End mills: Frequent replacements increase unit cost; flexible for complex cavities but less economical in high-volume production.

-

Face mills: Replaceable inserts extend tool life and reduce unit cost, especially in large-area or mass-production scenarios.

Repair and Replacement Costs

-

End mills: Worn or damaged tools require full replacement, increasing downtime and procurement costs.

-

Face mills: Only worn inserts need replacement, reducing maintenance costs and production interruptions.

Face mills are ideal for high-volume, long-run production; end mills fit small-batch, diverse machining but require careful planning to control replacement costs.

Tool Life Analysis and End Mill vs. Face Mill Comparison

In CNC machining, tool life directly affects machining costs, production efficiency, and product quality. Comparing end mills vs face mills not only helps engineers select the right tool but also improves production scheduling, reducing downtime and maintenance costs. Tool life depends on several factors, including tool material and coating, cutting parameters, cooling methods, and operating environment.

The Impact of Tool Material and Coating

Tool material and surface coating are key factors in tool life:

-

End mill material: Typically carbide or PCD, suitable for precision and surface machining.

-

Face mill material: The cutter body is usually high-strength alloy steel, while the inserts are carbide or CVD/PCD coated, capable of withstanding high cutting loads.

-

Coating effect: Coatings reduce friction, increase wear resistance, and improve heat resistance, extending tool life and lowering replacement frequency.

Different combinations of material and coating can lead to significant differences in end mill vs face mill tool life under identical machining conditions. Engineers should select tools based on workpiece material and machining requirements.

Impact of Cutting Speed, Feed Rate, and Cooling Method

Tool life is also affected by cutting parameters:

-

Cutting speed: Too high accelerates wear; too low reduces productivity.

-

Feed rate: Excessive feed increases tool load; too low underutilizes the tool.

-

Cooling method: Liquid or spray cooling reduces tool temperature, extends life, and ensures cutting stability.

Key takeaway: Optimizing these parameters extends tool life and lowers unit workpiece costs while maintaining machining efficiency and surface quality.

End Mill vs Face Mill Tool Life in High-Volume Operations

-

End mills: Best for complex cavities and curved surfaces, but wear rapidly under continuous high loads. Frequent replacements increase downtime and maintenance costs.

-

Face mills: Replaceable inserts and stable cutting structure allow long tool life and consistent performance, even in high-volume flat machining.

Production economics: Face mills reduce tool cost per workpiece and improve machining efficiency in high-volume production.

Proper selection of tool materials, coatings, cutting parameters, and tool types can extend tool life, improve efficiency, and enhance production stability, optimizing end mill vs face mill performance.

When to Use an End Mill vs a Face Mill

Choosing the right tool is key to improving cutting efficiency, tool life, and production economics. Analyzing end mill vs face mill applications helps engineers make informed decisions based on machining requirements, reducing unit costs and improving quality.

Optimal Choice for Roughing vs Finishing

-

Roughing: Face mills allow deep cuts and high feed rates, enabling rapid material removal. Replaceable inserts lower tool change costs, ideal for mass production.

-

Finishing: End mills excel in high-precision detail work, machining cavities, grooves, and complex 3D surfaces, delivering high accuracy and excellent surface finish.

Properly distinguishing roughing from finishing maximizes cost efficiency and extends tool life.

Selection Logic for Small Workpieces vs Large Area Cutting

-

Small or complex parts: End mills are flexible with multi-edge cutting, ideal for fine machining and curved surfaces.

-

Large flat surfaces: Face mills with stable structure and replaceable inserts offer higher efficiency and lower unit costs.

Summary: Use end mills for small, complex parts; face mills for large, flat surfaces to ensure accuracy and reduce costs.

Special Applications: Hard Materials, High-Speed Cutting, and Mold Machining

-

Hard materials: Face mills handle high cutting loads; end mills should use highly wear-resistant or PCD tools.

-

High-speed cutting: Face mills are suitable for large-volume flat machining; end mills for high-speed precision cavities.

-

Mold machining: End mills are essential for 3D surfaces and complex cavities; face mills efficiently rough mold base surfaces.

Choosing the right tool type balances efficiency, tool life, and production economics.

Selection Recommendations from a Production Economics Perspective

Ignoring production economics can lead to waste. A thorough end mill vs face mill cost analysis helps companies maximize ROI.

Tool Combination for Maximizing Cost Efficiency

-

Roughing: Face mills for large-area material removal.

-

Finishing: End mills for cavities, curved surfaces, or small details.

Combining tools effectively maintains efficiency, extends tool life, and reduces production costs, showing economic advantages in high-volume production.

Tool Selection Strategies for Enterprises of Different Sizes

-

Small enterprises: Use end mills for diverse, small-batch work for flexibility.

-

Medium to large enterprises: Use face mills for large-volume flat work and end mills for complex cavities or 3D surfaces.

Quantifying tool life, unit cost, and replacement frequency helps optimize investments and long-term economic benefits.

Case Analysis: Reducing Overall Costs Through Tool Selection

Example: A mold company used:

-

Face mills for large-area roughing, reducing tool changes and improving stability.

-

End mills for complex cavities and fine surfaces, ensuring high precision.

Result: 15–20% reduction in production costs and improved tool utilization. Proper tool selection optimizes unit cost, tool life, and machining efficiency.

Conclusion: Achieving Optimal Cost-Effectiveness

Optimal tool selection in CNC machining requires balancing cost, tool life, efficiency, and process requirements.

Overall Comparison

-

End mills: Flexible, precise, excellent surface quality, but shorter tool life and higher unit cost.

-

Face mills: Efficient for large-scale machining, replaceable inserts, longer life, lower unit cost.

Face mills suit large-scale production; end mills suit diversified, high-precision machining.

Key Considerations

-

Processing stage: Face mills for roughing; end mills for high-precision or 3D surfaces.

-

Workpiece size/type: End mills for small, complex parts; face mills for large flat surfaces.

-

Material & parameters: Consider tool material, coating, and cooling for special applications.

-

Production economics: Calculate unit cost, tool life, and replacement cycles to optimize tool combination.

Future Trends: High-Performance Tools and Production Economics

-

Wear-resistant tool materials and coatings extend life and reduce replacement frequency.

-

High-performance inserts improve cutting stability and unit workpiece efficiency.

-

Intelligent tool monitoring optimizes cutting parameters in real time, reducing waste and improving production ROI.

These trends allow more precise end mill vs face mill application optimization, maximizing cost-effectiveness and competitive advantage.