Selecting the correct drill diameter for flat bottom drill bits is critical for achieving high machining accuracy and operational efficiency. Material type, hole diameter, and machining depth all influence the optimal drill diameter. This is especially true when working with high-hardness steels or specialized alloys. The right drill diameter directly affects hole dimensional accuracy, tool wear, and overall production stability.

For engineers and production managers, selecting a flat bottom drill bit for CNC machining goes beyond choosing the drill material. Factors such as cutting parameters, feed rate, rotational speed, and cooling method must all be considered. Carbide flat bottom drill bits are widely used for high-precision holes and high-volume production due to their excellent wear resistance and stability. OEM flat bottom drill bits can be customized to meet specific process requirements, including special hole diameters or deep-hole machining needs.

Additionally, drill geometry, cutting edge angles, and center guide design play a significant role in machining performance. Choosing the correct diameter reduces hole deviation, minimizes tool wear, and enhances machining efficiency. By systematically evaluating material hardness, hole size requirements, and machining processes, companies can implement a scientific strategy for drill diameter selection, ensuring accuracy while extending tool life.

Key Factors Influencing Flat Bottom Drill Bit Diameter Selection

Selecting a flat-bottom drill diameter is influenced by multiple interrelated machining factors. The right diameter ensures not only hole dimensional accuracy but also cutting stability, vibration reduction, and lower tool wear. CNC engineers must consider material hardness, hole tolerance requirements, hole-to-depth ratio, and spindle rigidity. Balancing these factors allows the performance advantages of carbide flat-bottom drill bits to be fully realized, supporting efficient and stable holemaking.

Drill Diameter Requirements for Material Type and Hardness

Material type and hardness strongly influence the choice of drill diameter. For soft materials such as aluminum alloys or copper, selecting a drill diameter close to the design specification generally maximizes cutting efficiency.

When working with high-hardness steel or heat-treated mold steel, the approach changes. Flat bottom drill bits for hardened steel require careful consideration of tool wear resistance, cutting edge strength, and heat management. A too-small drill diameter increases cutting resistance, accelerating wear or causing chipping. Conversely, a too-large diameter may result in hole deviation or poor coolant penetration. In these cases, engineers often prefer carbide flat bottom drill bits, choosing diameters with a slight machining allowance to achieve final hole dimensions and surface quality after finishing.

Hole Diameter Accuracy and Machining Tolerance Considerations

Hole diameter accuracy and machining tolerance are critical indicators of quality in CNC applications. Flat bottom drill diameters should fall within specified drawing tolerances and align with the capabilities of CNC equipment. In practice, selecting a drill slightly smaller than the target diameter allows for finishing operations such as reaming or hole enlargement, ensuring consistent dimensional stability.

Drill edge geometry, cutting angles, and coatings also influence accuracy. Carbide flat-bottom drill bits that are precision-ground and coated can reduce thermal expansion-related errors. For OEM flat-bottom drill bits, manufacturers can customize tolerances to maintain consistency across large production batches.

Relationship between Hole Depth and Drilling Stability

Hole depth ratio significantly affects drilling stability. When the depth exceeds three times the drill diameter, chip evacuation and cooling efficiency decrease, causing higher drilling resistance, vibration, and potential tool deflection. Proper drill diameter selection and tool geometry are therefore essential.

Using carbide flat-bottom drill bits with reinforced cores and optimized chip flute design, combined with high-pressure coolant systems, ensures stable drilling. For deep holes or multi-layer workpieces, OEM-customized flat-bottom drills can optimize diameter and chip evacuation, reducing vibration and maintaining hole wall finish and dimensional accuracy.

Diameter Selection Strategies for Flat Bottom Drill Bits Made of Different Materials

Drill material impacts diameter selection. The properties of the tool, workpiece material, cutting speed, and machining method all influence the optimal diameter. Selecting the correct diameter improves hole accuracy, machining stability, reduces tool wear, and maximizes overall efficiency.

In CNC machining, whether using carbide, HSS, or coated composite flat-bottom drill bits, diameters must be tailored to process conditions. Standardization and precise control of drill diameters are critical in mass production and OEM-customized applications. Engineers analyze tool material properties and workpiece machinability to achieve a balance between accuracy and efficiency.

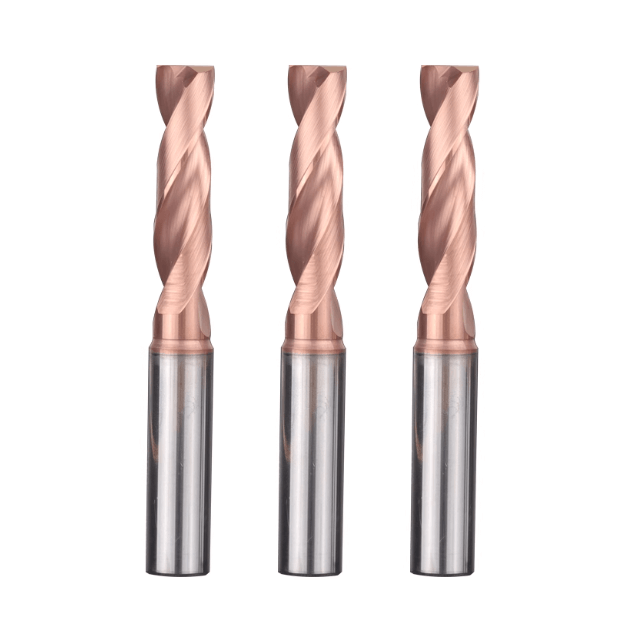

Tips for Selecting Carbide Flat-Bottom Drill Bit Diameter

Carbide flat-bottom drill bits are ideal for machining steel, stainless steel, and high-temperature alloys due to their hardness, wear resistance, and thermal stability. Diameter selection should consider material hardness and cutting parameters. For high-hardness steels (HRC 50+), slightly reducing the drill diameter tolerance minimizes cutting loads and prevents chipping.

Cutting edge sharpness and geometry also influence hole quality. Precision-ground, PVD-coated carbide drills improve surface finish and dimensional stability. OEM customization ensures perfect compatibility with CNC clamping systems, maintaining repeatability at high speeds.

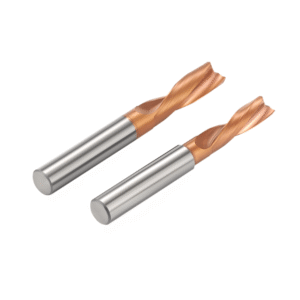

Diameter Matching Recommendations for High-Speed Steel and Coated Drill Bits

For medium-strength or lower-hardness materials, HSS flat-bottom drills provide cost-effective solutions. Their toughness and chipping resistance suit low to medium cutting speeds. Thermal expansion must be considered, and slight diameter allowances ensure finished hole stability.

Coated HSS drills enhance wear resistance and surface hardness, offering stable performance in medium-hard steels. For large-volume production, OEM flat-bottom drills standardize coating thickness and cutting edge geometry, ensuring consistent results.

Drill Diameter Optimization for Special Material Machining

Materials like titanium alloys, nickel-based superalloys, composites, or soft non-ferrous metals pose unique challenges. Poor thermal conductivity and machinability increase the risk of built-up edge and thermal deformation. Engineers must balance cutting resistance, cooling efficiency, and chip evacuation when choosing drill diameter.

For titanium alloys, a slightly eccentric cutting edge on a carbide flat-bottom drill reduces heat buildup. For aluminum or copper, polished grooves and slightly larger diameters ensure smooth chip flow and clean hole walls. OEM customization further optimizes cutting angles and diameters for high-end aerospace, mold, and precision electronics applications.

Diameter Selection Practice in CNC Machining

In CNC environments, selecting the correct flat-bottom drill diameter impacts hole accuracy, tool stress, chip evacuation, and tool life. Unlike manual drilling, CNC drilling involves complex conditions requiring consideration of spindle rigidity, fixture stability, cooling methods, and cutting parameters.

For automated or high-precision production, engineers must determine the optimal diameter range considering material properties, hole depth ratios, and tool geometry. Even minor deviations can cause out-of-tolerance holes or premature tool failure, especially in hard materials using carbide flat-bottom drills. Systematic analysis of diameter selection, parameter adjustment, and tool stability is essential for consistent and efficient drilling.

Steps for Choosing a Flat-Bottom Drill Bit for CNC Machining

To select the appropriate drill diameter:

-

Define the target hole diameter and tolerance based on design drawings.

-

Assess the hardness and machinability of the material. For mold steel or hardened steel, prefer carbide flat-bottom drills and allow finishing tolerance.

-

Preliminarily match drill diameter with CNC equipment performance (spindle speed, feed accuracy, coolant flow).

-

Perform test cuts to calibrate diameter deviation, ensuring dimensional stability and surface finish.

-

For high-volume or specialized production, consider OEM flat-bottom drills for perfect compatibility with toolholders and CNC systems.

Impact of Cutting Parameters on Diameter Selection

CNC cutting parameters significantly influence drill diameter selection. Variations in speed, feed rate, and cutting depth affect tool stress, heat distribution, and hole accuracy.

-

Excessive rotational speeds concentrate heat, causing drill expansion.

-

Too low feed rates increase friction and accelerate wear.

-

For hard or deep-hole machining, reduce cutting speed and use carbide drills with optimized chip flutes for thermal balance and smooth chip evacuation.

When the depth of cut exceeds three times the drill diameter, consider segmented drilling with high-pressure coolant to avoid chip clogging. Comparing hole diameter errors under different parameters helps establish a replicable drill diameter model for mass production.

Considering Diameter and Tool Stability in Multi-Hole/Deep Hole Machining

In multi-hole or deep-hole machining, drill diameter selection is crucial for stability and tool life. Long drilling paths and poor chip evacuation can cause hole deviation, scratches, or breakage.

-

Carbide flat-bottom drills with rigid cores and efficient chip evacuation are preferred.

-

Coated drills improve heat resistance for deep holes.

-

Maintain diameter tolerances within ±0.01 mm to ensure consistent hole sizes.

-

OEM customization allows optimization of diameter ratio and cutting angles for multi-layer composites or non-standard holes.

Excessive drill diameter or eccentricity can amplify spindle vibration, affecting hole spacing accuracy. Engineers can balance the toolholder system dynamically and adopt step-drilling strategies to distribute cutting loads, ensuring long-term machining stability.

OEM Flat Bottom Drill Bit Diameter Customization and Mass Production

In modern CNC machining, OEM flat bottom drill bit customization and mass production are critical for improving efficiency and consistency. This is especially true for high-volume hole machining, deep-hole drilling, or chamfering of special-shaped holes. Standard tools often fail to meet the precision, tolerance, and cost-control requirements of manufacturers. OEM solutions allow precise adjustments to drill diameter, cutting edge angles, and tool coatings based on hole design, tolerance grades, and workpiece materials—such as hardened steel, aluminum alloy, or titanium alloy—achieving optimal tool matching.

Partnering with a professional custom carbide flat-bottom drill bit manufacturer ensures tool consistency, stable mass production, and reduced unit processing costs. This approach provides a long-term, reliable tooling solution for production lines.

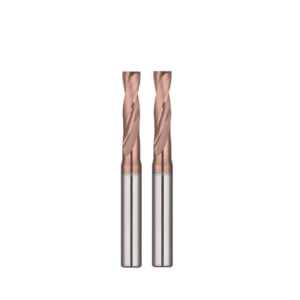

Advantages of Customized OEM Flat Bottom Drill Bits

OEM customization goes beyond simple dimensional adjustments; it involves optimizing tool geometry for specific applications. For instance, in mass production, modifying the drill point angle (135° or 145°), cutting edge length, and cutter body rigidity can greatly improve drilling stability and hole bottom flatness.

OEM solutions also offer various material combinations tailored to customer needs, including carbide flat-bottom drills, ultra-fine-grain tungsten carbide substrates, and CVD coatings for machining high-hardness materials.

These customized parameters enhance wear resistance and repeatability in applications such as CNC mass hole machining, mold and die production, and precision fixture manufacturing, significantly reducing tool change frequency and overall production costs.

Mass Production and Diameter Consistency Management

In mass production, tool diameter consistency is essential for maintaining hole accuracy and assembly interchangeability. Even minor deviations (±0.005 mm) can lead to misaligned holes or assembly clearance issues. OEM flat-bottom drills utilize CNC grinding and laser measurement systems to control diameter tolerances, ensuring each tool meets strict standards before leaving the factory.

Companies can also establish batch traceability with suppliers to maintain consistency in dimensions, materials, and coatings. This is particularly important in industries such as automotive, electronics, and hydraulic components.

Procurement Recommendations and Cost Optimization Strategies

When sourcing OEM flat-bottom drills, companies should evaluate cost-effectiveness considering batch size, tool life, coating type, and maintenance intervals. Long-term volume orders benefit from suppliers with OEM manufacturing capabilities and technical support to optimize unit pricing and after-sales service.

Standardizing toolholder sizes and modularizing drill dimensions can reduce inventory and tool change costs. For high-volume CNC production lines, regular performance evaluation and batch re-inspection extend tool life and optimize production investment.

Common Problems and Solutions

Flat-bottom drills are widely used for flat-bottom holes, blind holes, and chamfered holes. In practice, incorrect diameter selection, improper cutting parameters, or poor tool wear monitoring can reduce hole accuracy, cause premature tool failure, and lower machining efficiency.

This section provides practical solutions based on common application cases, focusing on hole accuracy, tool wear analysis, and efficiency improvement to ensure CNC drilling stability and extended tool life.

Hole Accuracy Issues Caused by Incorrect Diameter Selection

Drill diameter directly impacts hole geometry and surface finish. A too-large diameter can exceed tolerance, causing excessive assembly clearance or misfit. A too-small diameter may result in insufficient hole size, wall chatter, or surface burns.

High-precision hole machining requires attention to tool runout, spindle rigidity, cutting depth, and cooling methods. Using carbide flat-bottom drills combined with optimized CNC parameters can control feed rate and speed ratio, reducing drilling offset. In-process diameter monitoring systems or gauge pins enable dynamic accuracy checks, preventing rework or scrap.

Causes of Drill Wear and Premature Fracture

Excessive cutting loads, poor chip evacuation, and inadequate cooling are common causes of wear and premature fracture. Flat-bottom drills, lacking a center angle, are prone to chip accumulation and localized heat buildup. Without proper speed and feed adjustments for materials such as hardened steel, stainless steel, or cast iron, micro-chipping or flank wear may occur.

For hard materials, diamond-coated or nano-TiAlN-coated flat-bottom drills, combined with high-pressure coolant, improve heat dissipation and chip evacuation. Implementing tool life monitoring and wear curve tracking predicts failure points and prevents unexpected breakage.

Practical Tips for Improving Machining Efficiency and Tool Life

To enhance efficiency while maintaining accuracy:

-

Optimize cutting parameters: Adjust spindle speed, feed rate, and depth of cut based on material hardness.

-

Use advanced coatings: CVD diamond or TiAlN coatings increase wear resistance and thermal stability.

-

Manage tool change cycles: Track tool numbers and lifespan to standardize replacements.

-

Enhance cooling and chip removal: Use internal coolant or high-pressure systems.

-

Implement smart monitoring: Vibration and torque sensors detect abnormal wear in real time.

These measures improve efficiency, extend tool life, and reduce costs, ensuring stable CNC drilling in mass production.

Optimal Drill Bit Diameter Selection Strategy for CNC Machining

Selecting a flat-bottom drill diameter is a systematic engineering decision, not just a matter of dimensions. Factors include workpiece material, geometry, equipment performance, tool material, and cutting parameters. By evaluating drill diameter relative to process conditions, engineers can improve hole accuracy, stability, and tool life, increasing cost-effectiveness and production control.

Diameter Selection Based on Material, Process, and Equipment

Workpiece hardness and ductility are critical. Hard materials like hardened steel require tighter diameter tolerances to avoid over-tolerance or eccentric holes. Soft materials need appropriately sized drills to ensure smooth chip evacuation.

Machine spindle rigidity, fixture accuracy, and coolant system performance must also be considered to optimize diameter and hole depth ratios. Evaluating cutting stability, heat dissipation, and tolerance ensures reliable drilling results.

Effectively Using Carbide and OEM Drills to Improve Stability

Choosing appropriate carbide and OEM flat-bottom drills enhances machining stability. Carbide drills resist wear and heat, ideal for high-speed, high-hardness materials. OEM-customized drills match hole depth, geometry, or non-standard sizes, ensuring precise diameter and process alignment.

This combination of standardization and customization reduces tool change frequency, maintains batch consistency, and improves repeatability and process reliability.

Continuously Optimizing Cutting Parameters to Extend Drill Life

Tool life depends on material, diameter, and ongoing cutting parameter adjustments. Optimizing speed, feed rate, and depth of cut stabilizes cutting loads and heat dissipation, reducing wear and thermal fatigue.

Integrating smart monitoring systems and wear assessments provides real-time visibility, enabling data-driven tool replacement decisions. Continuous optimization preserves dimensional consistency, surface quality, and delivers sustained production advantages in high-precision CNC drilling.