In the metalworking industry, selecting the right metal drill bit supplier is crucial for ensuring production efficiency and machining precision. Whether it is a twist drill bit for everyday workshop use or CNC metal drilling tools designed for high-strength materials, high-quality drill bits significantly improve cutting performance, extend tool life, and reduce downtime risks caused by tool failure. For companies purchasing in bulk, finding a reliable wholesale metal drill bit supplier ensures not only competitive pricing but also product variety and batch-to-batch consistency.

When evaluating suppliers, it is essential to consider material hardness, coating treatment, and wear resistance. Additionally, assessing a drill bit’s suitability for different metals—such as stainless steel, aluminum alloys, and copper—helps ensure optimal performance. Supplier service systems, logistical responsiveness, and technical support capabilities also directly impact production plans and operating costs. By considering these factors comprehensively, companies can select drill bits that meet their specific requirements, ensuring both machining quality and efficiency.

Key Assessment Points Before Wholesale Procurement of Metal Drill Bits

When purchasing drill bits in large quantities, a systematic evaluation process helps reduce risk and improve production efficiency. A high-quality drill bit must meet basic cutting requirements and be optimized for the materials and processing conditions to ensure tool life and machining precision. Assessment should focus on three main aspects: machining requirements, tool type matching, and adaptability to operating conditions. This ensures that each batch performs optimally in actual machining while minimizing production delays caused by wear or breakage.

Clarify Machining Requirements: Metal Material, Hole-Diameter Precision, and Batch Size

Before selecting drill bits, identify the type of metal to be machined, such as stainless steel, aluminum alloy, copper, or high-strength alloys. Different materials require varying hardness and cutting forces, affecting material selection, coating treatment, and drill bit geometry. Hole-diameter precision is also critical; high-precision holes require more stable and wear-resistant tools. Batch size further influences the balance between durability and cost-efficiency. For mass production, choose drill bits with long service life and high reusability to reduce overall procurement costs.

Matching Applicable Tool Types: Selection Criteria for CNC Metal Drilling Tools, Twist Drill Bits for Metal, etc.

Selecting the appropriate tool type based on machining methods is crucial. CNC machining typically requires high-precision CNC metal drilling tools that can withstand high-speed rotation and continuous cutting forces. For conventional or small-batch production, twist drill bits for metal offer a cost-effective solution. Tool helix angle, cutting-edge design, and coating treatment directly affect cutting efficiency and surface quality. Consider machine type, material hardness, and process requirements to ensure each tool performs optimally in actual conditions.

Confirming Machining Conditions: Requirements of Speed, Feed Rate, and Cooling Method on Tool Quality

Machining conditions significantly influence drill bit performance. Different materials and hole sizes require specific machine speeds and feed rates. High-speed operations are unsuitable for low-hardness or low-wear-resistance tools. Cooling methods, such as cutting fluids or gas cooling, reduce heat, extend tool life, and improve hole-wall finish. Vibration, chip removal, and drilling depth further affect wear and breakage risk. Evaluating these factors ensures the selected drill bit maintains stable performance during long-term use.

Assessing the Quality Control Capabilities of Wholesale Metal Drill Bit Suppliers

Bulk drill bit procurement relies heavily on supplier quality control systems to maintain machining stability and product consistency. Even identical drill bits can vary in wear resistance, accuracy, and tool life across batches. Assess suppliers’ material selection, heat treatment, machining precision, and coating processes. A robust quality control system ensures geometric accuracy, wear resistance, and consistent performance for each batch, reducing production interruptions and improving overall workshop efficiency.

Tool Material and Heat Treatment Stability

Drill bit performance depends primarily on material hardness and toughness. High-quality steel or cemented carbide, after rigorous heat treatment, maintains stable cutting performance and wear resistance, preventing edge chipping or breakage. Suppliers providing material composition reports and heat treatment records demonstrate strict control over material consistency and mechanical properties, ensuring reliable machining capabilities for each drill bit.

Drill Bit Geometric Accuracy and Consistency

Geometric design affects cutting efficiency, hole-diameter precision, and surface finish. Stable helix angles, cutting-edge angles, and center-tip geometry improve chip removal, reduce vibration, and extend tool life. Suppliers should follow standardized machining processes and conduct sampling inspections to ensure dimensional and geometric consistency across batches, guaranteeing stable machining performance.

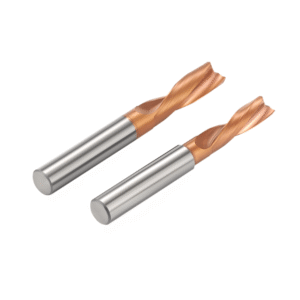

Coating Process and Quality Inspection Procedure

Coatings extend tool life and improve cutting performance. High-quality coatings, such as TiN, TiAlN, or composites, reduce friction, enhance wear resistance, and withstand high-speed or high-temperature operations. Suppliers must maintain a stable, controllable coating process and implement quality inspections, including thickness, adhesion, and uniformity tests, ensuring consistent performance and minimizing downtime.

Batch Consistency and Performance Verification of Metal Drill Bits for Metal

Ensuring batch-to-batch consistency is critical in bulk procurement. Differences in wear resistance, edge sharpness, and chip removal between batches affect machining efficiency and hole quality. Systematic verification identifies potential risks and confirms production stability, ensuring consistent long-term machining performance.

Comparative Testing of Drill Bit Life, Wear Resistance, and Chip Removal Performance Between Batches

Testing drill bit life and wear under simulated machining conditions reveals edge wear rates and heat accumulation. Evaluating chip removal efficiency ensures suitability for high-hardness or sticky materials. Batch-to-batch comparisons determine production stability and ensure each batch delivers reliable performance in large-scale operations.

Hole Quality Performance of Different Drill Bits in CNC Machining

In CNC machining, drill bit geometry, edge sharpness, and coating quality affect hole-wall finish, diameter accuracy, and coaxiality. Trial cuts under identical parameters allow direct comparison. Helix angle differences influence vibration and chip removal, impacting flatness and precision. These measurements provide essential data for selecting drill bits suitable for bulk procurement.

Supplier Sample Testing and Processing Test Records Evaluation

Reputable suppliers provide samples and processing records, such as tool life, wear resistance, and hole accuracy tests. Companies can evaluate actual performance, including cutting forces, chip removal, and service life. This ensures bulk drill bits meet processing needs while maintaining consistent performance, reducing production risks.

Supplier Production and Delivery Capacity Review

Supplier production and delivery capabilities directly affect production planning and inventory management. Long production cycles, insufficient inventory, or delayed shipments can disrupt operations. Evaluate production cycle, inventory levels, standard specification coverage, and custom processing ability to ensure timely, reliable delivery for bulk orders.

Production Cycle, Inventory Capacity, and Completeness of Standard Specifications

Efficient production and sufficient inventory shorten lead times and handle urgent or large orders. Standard drill bit coverage, including common diameters, helix angles, and cutting-edge types, reduces waiting time for custom processing and improves procurement efficiency. Evaluating these factors assesses supplier reliability for routine supply and urgent orders.

Custom Specification Drill Bit Processing Capability and Response Speed

Some companies require custom drill bits with unique diameters, materials, or coatings. Supplier capability and responsiveness determine flexibility in handling special orders. Advanced processing equipment, process control, and quality inspection ensure custom drill bits meet standards for size, geometry, and wear resistance.

Delivery Reliability for Large-Volume Wholesale Metal Drill Bits

Reliable delivery is essential for large-volume orders. Suppliers should maintain stable production plans and logistics systems to deliver on time, avoiding production delays or inventory issues. Historical delivery records provide reference for assessing reliability, ensuring continuous workshop operation and supporting production planning.

Price System and Cooperation Model Analysis

When purchasing drill bits in bulk, a reasonable price system is crucial for controlling costs. A flexible cooperation model is equally important for ensuring a long-term supply. Drill bit prices depend not only on the material, coating, and manufacturing process but also on order quantity, batch stability, and the supplier’s service level. Flexible cooperation models, including tiered wholesale prices, minimum order quantity (MOQ) settings, and long-term cooperation discount mechanisms, can further improve procurement efficiency. By analyzing both pricing and cooperation models comprehensively, companies can optimize procurement costs while ensuring product quality.

Price Composition Analysis Based on Tool Specifications, Coatings, and Processes

The price of drill bits is primarily determined by tool material, heat treatment, and coating type. For example, the cost difference between high-speed steel and cemented carbide is significant. Similarly, coatings such as TiN or TiAlN, which enhance wear resistance and cutting performance, also affect the price. Additionally, geometric requirements—including helix angle, cutting-edge design, and dimensional accuracy—can increase production complexity and cost. Companies should evaluate all these factors in combination with their machining needs to select drill bits that offer the best cost-to-performance ratio, ensuring both processing efficiency and hole-diameter accuracy.

Wholesale Price Tiers, MOQ, and Long-Term Cooperation Discount Mechanisms

Suppliers often provide tiered pricing based on order volume. Larger orders usually result in lower unit costs. Minimum Order Quantity (MOQ) requirements influence procurement strategy, balancing small-batch trials with large-scale production. Long-term cooperative customers may benefit from additional discounts, priority inventory, and flexible delivery options. These mechanisms not only reduce unit costs but also ensure a stable supply of drill bits purchased in bulk, supporting continuous production and effective inventory management.

Value of After-Sales Service and Technical Support

Efficient after-sales service and technical support are critical for ensuring long-term, reliable drill bit performance. Supplier-provided guidance on machining parameters, optimization suggestions, and rapid troubleshooting helps companies solve processing issues, minimize downtime, and maintain hole-diameter accuracy and surface finish. After-sales support may also include replacement or return services and maintenance advice for batch tools, providing added value and increased procurement security for long-term partnerships.

The Importance of Supplier Technical Support in Actual Machining

Even with high-quality drill bits and advanced machine tools, a lack of timely, professional technical support can reduce machining efficiency or result in substandard hole quality. Supplier technical support includes guidance on machining parameters, tool usage optimization, fault diagnosis, and handling machining anomalies. Strong technical support helps companies maximize drill bit performance, extend tool life, reduce downtime, and minimize scrap rates, ensuring stable workshop operations and consistent machining quality.

CNC Metal Drilling Tools Usage Parameter Recommendations and Actual Support Capabilities

During CNC machining, cutting speed, feed rate, spindle speed, and cooling methods directly affect hole accuracy and surface finish. Suppliers that provide detailed usage parameters for CNC metal drilling tools, along with optimization suggestions tailored to actual working conditions, help companies quickly determine the optimal machining solution. On-site or remote support, including trial cutting and parameter adjustment guidance, is particularly valuable when working with new materials or complex holes, reducing trial-and-error costs.

Machining Optimization Recommendations for Twist Drill Bits for Metal

The performance of twist drill bits for metal varies across different materials. For instance, tool wear and chip removal efficiency differ when machining high-hardness stainless steel versus aluminum alloys. Supplier-provided recommendations—such as selecting appropriate helix angles, cutting-edge angles, coating types, and feed/depth adjustments—can improve machining efficiency, reduce wear on the cutting edge, and extend drill life. This guidance ensures consistent hole-diameter accuracy and machining quality in mass production.

Technical Assistance for Machining Anomalies

Common machining issues include drill overheating, tool breakage, or rough hole walls, which can disrupt production and affect quality. Suppliers that provide rapid-response technical support—such as anomaly analysis, parameter adjustments, and tool improvement solutions—help minimize downtime and material waste. Long-term technical support also allows companies to accumulate machining experience and optimize processes, ensuring that metal drill bits for metal perform reliably under various conditions.

Evaluating the Supplier’s Packaging, Labeling, and Logistics Support

Packaging, labeling, and logistics support directly impact product integrity and traceability during transportation and storage. Even high-quality drill bits can be damaged or rusted if packaging or logistics are inadequate. Companies should evaluate supplier capabilities in packaging standards, batch management, and logistics to ensure that drill bits purchased in bulk arrive safely and on time.

Packaging Protection, Rust Prevention, and Batch Labeling Standardization for Wholesale Cutting Tools

Proper packaging protects the cutting edge and tool body, preventing collisions or deformation during transit. Rust prevention treatments and desiccants help protect metal surfaces from moisture. Standardized batch labeling—including production date, material, size, and coating type—facilitates inventory management and traceability. Suppliers who manage packaging and labeling rigorously help ensure stable, reliable use of bulk drill bits.

Logistics Methods, Transportation Time, and Loss Control Capabilities

Efficient logistics balance speed and safety. Suppliers should select appropriate transport methods, protection levels, and optimized routes. Loss control measures, such as extra protection for long-distance shipments or individual packaging for fragile tools, reduce the risk of edge wear or deformation. These measures ensure that drill bits purchased in bulk maintain their original performance upon delivery, supporting production reliability.

Final Judgment Criteria for Selecting Reliable Wholesale Metal Drill Bit Suppliers

Selecting a reliable metal drill bit supplier is key to ensuring machining efficiency, hole accuracy, and production stability. Evaluating processing requirements, tool types, working condition adaptability, quality control, batch consistency, production and delivery capabilities, pricing, technical support, and packaging/logistics provides a comprehensive view of supplier capabilities. Ultimately, stable performance, reasonable price, and reliable delivery should guide final decisions to guarantee consistent performance under diverse conditions and support long-term production.

Comprehensive Consideration of Three Key Factors: Stable Performance, Reasonable Price, and Reliable Delivery

Stable performance encompasses material hardness, heat treatment quality, geometric accuracy, coating process, and batch-to-batch consistency, affecting lifespan, wear resistance, chip removal, and hole quality. Reasonable pricing considers tool specifications, coating, manufacturing process, wholesale tiers, MOQ, and long-term discounts to optimize procurement costs. Reliable delivery relies on production capacity, inventory management, custom processing responsiveness, and logistics support, ensuring timely, intact delivery and uninterrupted production.

Long-Term Supplier Partnership Cases and Customer Feedback

Technical specifications and supply capabilities are not the only evaluation criteria. Long-term partnerships and customer feedback provide real-world insight into supplier reliability. Reviewing supplier experience across industries and customer evaluations on batch drill bit performance, on-time delivery, and after-sales support helps companies assess stability, sustainable supply, and service quality. This empirical information aids in risk reduction and building long-term reliable supplier relationships.

-白底主图3.jpg)