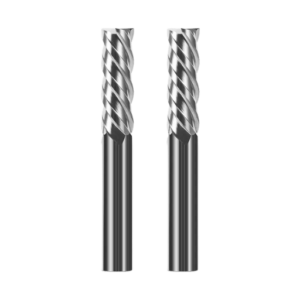

Common mistakes when selecting metal milling bits often arise from misjudging processing requirements, tool structure, and material characteristics. Many users, when choosing carbide mill bits, mill cutting bits, or other types of milling cutter bits, focus primarily on price or general specifications, overlooking key factors like tool coating, edge treatment, chip evacuation structure, and material compatibility. Furthermore, the market is flooded with CNC milling bits wholesale products of varying quality. Without systematic evaluation criteria, users may face issues such as shortened tool life, rough surface finishes, increased vibration, or even tool breakage.

The selection process for metal milling bits differs significantly depending on the type of metal, cutting strategy, and production mode. Whether it’s carbide tools that require stable performance for mass production or OEM metal milling bit manufacturers providing customized tools for specific working conditions, a comprehensive assessment based on processing parameters, tool geometry, and machine rigidity is essential. A lack of understanding of these crucial details can easily lead to common errors, such as choosing the wrong number of flutes, ignoring coating compatibility, or failing to select the proper tool material based on material hardness.

Therefore, understanding these typical errors and conducting a thorough analysis from the perspectives of tool compatibility, processing efficiency, and cost control is essential to avoid poor tool performance and unstable processing quality.

Neglecting Material Characteristics Leads to Incorrect Metal Milling Bit Selection

When selecting the right cutting tools, many manufacturers often overlook the characteristics of the processing material, leading to incorrect tool choices. This mistake not only impacts processing quality but can also shorten tool life and even cause equipment failure. Especially when working with metals of varying hardness, toughness, and thermal conductivity, choosing the appropriate tool material and design is critical. Selecting the right tool for a specific material ensures processing accuracy and efficiency.

Insufficient Matching of Tool Material and Edge Type Under Different Metal Hardnesses

The hardness of different metals directly impacts tool selection. For instance, harder metals like titanium alloys and tool steels require tools with high hardness and wear resistance, while softer metals like aluminum alloys can work with softer tools. If the tool edge type and material aren’t properly matched to the material’s hardness, it can lead to premature tool wear or poor processing results. Therefore, ensuring that the tool’s edge geometry and material match the metal’s hardness is crucial when selecting milling cutters.

Misusing Non-Carbide Mill Bits on Materials Like Stainless Steel and Titanium Alloys

High-hardness metals, such as stainless steel and titanium alloys, require milling cutters with high wear resistance and strength. However, many factories still use carbon steel or high-speed steel milling cutters for these materials, neglecting the advantages of carbide milling cutters. Carbide milling cutters not only offer superior cutting performance but also reduce thermal deformation and extend tool life. Choosing carbide milling cutters for these metals will significantly improve processing efficiency and accuracy.

Failure to Adjust Coating and Flute Design for Materials Like Aluminum and High-Hardness Steel

When milling materials like aluminum alloys or high-hardness steel, the coating and flute design of the tool need special attention. For aluminum alloys, tools with low friction coefficients and effective chip evacuation are often necessary, so coated milling cutters are commonly chosen. High-hardness steel, on the other hand, requires tools that can handle high temperatures and have excellent wear resistance, so coatings designed for thermal stability should be considered. Additionally, the flute design should be adjusted for specific materials to optimize cutting force and chip evacuation, ensuring smooth processing.

By making precise tool selections based on the characteristics of different metal materials, processing accuracy and efficiency can be significantly improved.

Focusing Only on Price and Ignoring the Key Performance of Milling Cutter Bits

Cost control is an important factor when making purchasing decisions. However, focusing solely on price and neglecting key tool performance features can lead to serious consequences, especially for high-precision and high-strength machining tasks. While low-priced tools might seem appealing, if they don’t meet the actual processing needs, they will inevitably result in lower machining efficiency, unstable product quality, and possibly even production delays due to tool failure.

Ignoring Tool Coating and Edge Treatment in Low-Priced Alternatives

The coating and edge treatment of a tool are directly related to its durability and cutting performance. High-quality tools typically use advanced coatings like TiN or TiAlN , which improve wear resistance, heat resistance, and corrosion resistance. On the other hand, low-cost tools often skimp on coating processes and edge treatment, leading to rapid wear during high-load, high-temperature, or high-intensity machining. This can negatively impact machining accuracy and production efficiency. Therefore, it’s important to consider both price and the quality of the coating and edge treatment when purchasing tools.

Tool Breakage or Poor Surface Quality Due to Insufficient Tool Strength in CNC Milling

Tool strength is critical in ensuring machining stability and surface quality in CNC machining. Using tools with insufficient strength can lead to tool breakage during high-load cutting, causing production downtime, delays, and increased scrap rates. Additionally, tools that lack the necessary strength often cannot handle prolonged high-intensity cutting, leading to rough surfaces and inaccurate dimensions. Thus, selecting strong, durable tools is essential for precision machining and should not be overlooked for the sake of saving costs.

Ignoring the Lifespan Difference Between Solid Carbide Tools and Standard Tools

Solid carbide tools have clear advantages over standard tools in terms of durability and stability. Their high hardness and wear resistance allow them to maintain good cutting performance under long-term, high-intensity machining, reducing the need for frequent tool changes. In contrast, standard tools, while cheaper, are often less durable, especially under high-load conditions, and require more frequent replacements. This can increase production downtime and costs. Choosing solid carbide tools can significantly enhance production efficiency and tool life, especially in high-precision machining tasks.

Inaccurate Tool Selection Due to Failure to Assess Machining Requirements

When selecting cutting tools, many machining plants make poor tool choices due to a failure to properly assess the machining requirements. This issue is particularly common in complex machining tasks. If the specific needs of the machining process are not accurately identified, using the wrong tool will negatively affect cutting performance and production efficiency. For example, rough machining and finish machining have very different tool requirements. Using the wrong tool for either can lead to reduced machining quality, shorter tool life, and higher production costs.

Using the Same Mill Cutting Bits for Both Rough and Finish Machining

The cutting conditions for rough and finish machining differ significantly. Rough machining requires tools with greater wear resistance and a larger cutting depth, while finish machining demands high surface finish and cutting accuracy. If the same tool is used for both, it can lead to poor surface quality in the finished product, and the tool will wear out too quickly, affecting efficiency. For rough machining, tools suitable for large cutting volumes should be selected, while for finish machining, tools with higher cutting accuracy and surface finish should be used. Ensuring the right tool is chosen for the right process will prevent unnecessary production problems.

Improper Flute Number Selection Leading to Chip Evacuation, Vibration, and Heat Issues

The number of flutes on a cutting tool affects the chip evacuation process. In high-speed or high-load machining, incorrect flute selection can result in poor chip removal, causing tool clogging, rough surfaces, and heat accumulation. Particularly in the machining of aluminum alloys and other soft materials, too few flutes can lead to chip accumulation, while too many flutes can increase tool vibration, reducing machining stability. Properly selecting the right number of flutes optimizes chip evacuation and minimizes vibration and heat, improving machining quality and tool life.

Ignoring the Matching of Tool Diameter, Cutting Edge Length, and Machine Tool Rigidity

The tool’s diameter and cutting edge length are closely related to the rigidity of the machine tool. Failure to match these elements correctly can cause vibration, increased tool wear, and even breakage. Larger tools require more rigid machine tools to avoid bending or vibration, which can affect machining accuracy and surface finish. Additionally, excessive blade length can lead to tool instability during machining, which can negatively affect results. Choosing the right tool diameter and edge length and matching them with the machine tool’s rigidity ensures stable machining and better quality.

Misunderstanding Machining Speed, Feed Rate, and Metal Cutting Mechanisms

In metal machining, the correct setting of cutting parameters is crucial for tool life, machining efficiency, and surface quality. The selection of machining speed, feed rate, and cutting mechanism must be precisely adjusted according to different materials and machining processes. However, many machining facilities fail to fully understand the significant impact that these parameters have on machining outcomes, often leading to issues such as excessive tool wear, insufficient machining accuracy, or even machining failure due to incorrect cutting conditions. Therefore, having a deep understanding of how each parameter influences the machining process, and setting appropriate cutting speed and feed rate, is key to improving production efficiency and reducing overall costs.

Using Excessively Low or High Cutting Parameters for Carbide Mill Bits

Carbide tools, such as carbide mill bits, are known for their excellent wear resistance and high-temperature tolerance. However, improper cutting parameters can still result in poor machining performance. Excessively low cutting speeds and feed rates can increase friction during the cutting process, leading to uneven wear on the tool surface and reduced cutting efficiency. On the other hand, using excessively high cutting parameters can cause tool overheating, breakage, increased surface roughness, or even accelerated tool damage. To fully maximize the performance of carbide tools, it’s essential to properly adjust the cutting speed and feed rate to suit the specific machining requirements and materials being processed.

Failure to Set Reasonable Cutting Speeds and Feed Rates for Different Metals

Different metal materials require different cutting parameters. For example, soft metals like aluminum alloys can typically handle higher cutting speeds and feed rates, while harder materials such as tool steel or titanium alloys require lower cutting speeds and smaller feed rates to ensure cutting stability and tool durability. If cutting parameters are not appropriately set based on the material’s characteristics, it can lead to excessive cutting temperatures, accelerated tool wear, or decreased machining accuracy. By correctly setting the cutting speed, feed rate, and cutting depth for different materials, machining efficiency can be improved, and tool life extended.

Neglecting the Impact of Chip Evacuation Direction and Cutting Depth on Tool Life

During the cutting process, the direction of chip evacuation and cutting depth have a direct impact on tool life and machining outcomes. Poor chip evacuation can cause chip accumulation, increasing friction on the tool and leading to accelerated wear, tool jamming, or breakage. This issue is especially problematic during deep-hole machining or when working with large cutting depths. A well-designed chip evacuation path and the proper cutting depth are essential to prevent chip clogging and maintain stable tool operation. Additionally, excessive cutting depth may exceed the tool’s load capacity, reducing its durability and cutting accuracy. Therefore, optimizing both cutting depth and chip evacuation direction is critical to ensuring that the tool operates effectively under high-load conditions and prolongs its service life.

The correct settings for cutting speed, feed rate, cutting depth, and chip evacuation direction not only improve machining efficiency but also extend tool life. Understanding the fundamental principles of metal cutting and adjusting parameters based on the needs of different materials is a fundamental skill that every machinist and engineer must master.

Neglecting Quality Differences and Testing Standards in Wholesale CNC Milling Bit Procurement

When purchasing cutting tools in bulk, many companies focus primarily on price, neglecting the quality differences and testing standards that can affect performance. While bulk purchasing may seem like a cost-effective strategy, overlooking the quality control of cutting tools can lead to problems such as poor product consistency, unstable processing quality, and even equipment damage. Therefore, when purchasing in bulk, it’s essential to focus on critical testing factors such as accuracy, concentricity, and dynamic balance to ensure that tools maintain consistent performance and stability.

Failure to Test Accuracy, Concentricity, and Dynamic Balance in Bulk Procurement

Accuracy, concentricity, and dynamic balance are essential factors affecting processing quality and tool longevity. When these quality indicators are neglected during the procurement process, it can lead to problems such as tool vibration, processing errors, and an increased risk of equipment failure during high-load machining. In precision machining, ensuring the concentricity and dynamic balance of cutting tools is crucial for maintaining processing accuracy. As a result, rigorous testing of these parameters before bulk procurement is essential to ensure smooth operations and avoid production delays and quality issues caused by poor tool quality.

Focusing Only on Price and Ignoring Batch Stability and Product Consistency

While opting for low-priced tools may provide some short-term savings, neglecting batch stability and product consistency can lead to significant long-term issues. Even the same model of tool can show performance discrepancies between batches due to differences in production processes, material batches, and other factors. This inconsistency can result in processing errors, increased downtime, and more frequent tool replacements. To avoid these issues, it is essential to consider batch stability and product consistency during procurement. Saving on upfront costs by ignoring these factors can ultimately lead to higher production costs and lower overall tool performance.

Lack of Established Tool Testing Standards Leading to Procurement Inconsistencies

Without clear and standardized tool testing protocols, there can be a lack of uniform quality control during the procurement process. This can result in fluctuations in the quality and performance of cutting tools, making it difficult to predict the outcome of each batch. To maintain production stability, clear testing standards should be established. This ensures that every batch of tools meets the required specifications for accuracy and durability. Without consistent testing standards, procurement results can vary, leading to unstable production quality, increased downtime, and higher tool replacement costs. Implementing a rigorous quality control system can help prevent these issues.

Blindly Selecting Carbide Mill Bits or Other Tools Without Clearly Defined Machining Tasks

Tool selection plays a crucial role in machining quality and efficiency. Blindly choosing carbide milling cutters or other types of tools without clearly defining the machining tasks and process requirements can lead to suboptimal results. Each tool is designed with specific performance characteristics that cater to particular machining tasks. Without a full understanding of the workpiece’s requirements, selecting tools based solely on material type or appearance may lead to underutilization of the tool’s capabilities, affecting both machining accuracy and tool life. Therefore, it is essential to clarify the specific machining tasks and conditions before tool selection to ensure a proper match.

Using Inappropriate Tool Structures Without Defining Groove Width, Angle, or Strategy

Groove width, cutting angle, and machining strategy are key factors influencing tool selection. For example, wider grooves typically require tools with larger cutting depths and widths, while narrower grooves demand tools with finer cutting abilities. If these factors are not defined clearly before tool selection, using an inappropriate tool structure can lead to issues such as chip accumulation, poor cutting performance, and premature tool wear. Each groove design requires a specific tool structure and edge shape to ensure efficient cutting. By matching the tool design to the machining requirements, machining efficiency and surface quality can be improved.

Failure to Distinguish Between High-Speed Machining and Low-Speed Deep Cutting

High-speed machining and low-speed deep cutting have distinct requirements. High-speed machining involves lower cutting temperatures and forces, necessitating tools with good heat dissipation and wear resistance. In contrast, low-speed, deep cutting requires tools with higher strength and stability to withstand greater loads and cutting depths. Using the same tool for both operations can lead to inefficiencies—either poor performance during high-speed machining or tool breakage during deep cutting. Therefore, it’s critical to differentiate the requirements for these two machining methods and choose the right tool material, geometry, and coating accordingly.

Confusing the Uses of End Mills, Ball End Mills, and Radius End Mills

Different types of milling cutters serve different purposes in the machining process. For instance, end mills are used for face milling and side milling, ball end mills are suited for complex surface machining, and radius end mills are ideal for internal grooves and fillets. Confusing these tools can compromise machining accuracy and results. Especially for complex parts, selecting the right tool based on the part’s shape, accuracy needs, and material characteristics is crucial. Choosing the wrong tool may not only lower machining efficiency but could also damage the workpiece. Understanding the specific applications of various milling cutters ensures a smooth and efficient machining process.

Ignoring the Differences in Capabilities of OEM Metal Milling Bit Manufacturers

When purchasing milling cutters, many companies overlook the differences in manufacturing capabilities between suppliers. Choosing the right supplier isn’t just about price—it’s about evaluating the manufacturer’s production technology, research and development (R&D) capabilities, and quality control. Variations in tool design, edge treatment, and coating technology across suppliers can significantly impact the tool’s cutting performance and lifespan. Failing to consider these differences can result in unstable tool performance and reduced tool life, ultimately affecting production efficiency. It’s crucial to assess the capabilities of potential OEM metal milling bit suppliers to ensure high-quality tools that meet your machining requirements.

Neglecting the Cutting Edge Treatment Technology and Coating Process of Tool Manufacturers

The cutting edge treatment and coating processes are vital for the performance and longevity of cutting tools. Advanced edge treatment technologies enhance the sharpness of the tool and reduce wear, while high-quality coatings improve high-temperature and oxidation resistance, ensuring stable performance even under extreme conditions. Neglecting these aspects when selecting a supplier may result in tools with uneven edge treatments or subpar coatings, which can degrade processing quality and reduce tool lifespan. By choosing a supplier with advanced edge treatment and coating processes, you can ensure your tools perform efficiently in demanding machining environments.

Failure to Evaluate the Manufacturer’s Precision Grinding Capabilities and Tool Design Experience

A manufacturer’s precision grinding capabilities and design experience are key factors in determining the accuracy and stability of the tools they produce. In high-precision machining, the geometric accuracy, dimensional consistency, and grinding process of a tool are critical. Manufacturers with strong grinding and design capabilities can create custom tools that meet specific material and process requirements. Neglecting to evaluate these aspects may lead to tools with poor geometry or dull edges, which can negatively impact processing quality and lead to equipment damage. By selecting a supplier with expertise in precision grinding and tool design, you can ensure that your tools meet the highest standards of quality and performance.

Failure to Select the Right OEM Supplier Based on Customization Needs and Machining Scenarios

Different machining tasks have unique requirements, especially when it comes to customization and specialized machining conditions. When selecting an OEM supplier, it’s essential to consider whether they can provide tailored solutions that meet specific needs. Suppliers who offer customization based on material types, cutting requirements, and process conditions are more likely to deliver tools that perform well under challenging scenarios. Failing to choose a supplier with the right customization capabilities can result in tools that are unsuitable for special tasks, compromising both machining accuracy and efficiency.

Incorrect Tool Usage and Maintenance Leading to Misjudgment of Metal Milling Bit Quality

In CNC machining, proper tool usage and maintenance are crucial for ensuring machining efficiency and extending tool life. In many cases, tool quality issues do not arise from manufacturer defects but from improper usage or lack of maintenance. For example, overuse, inadequate maintenance, or incorrect handling of tools can lead to decreased performance and even premature failure. Without proper care, it’s easy to mistakenly believe the tool itself is of poor quality, which can influence purchasing decisions and disrupt production plans. Therefore, correct tool usage and regular maintenance are essential for maintaining machining quality and extending tool life.

Failure to Replace Tools on Time Leading to Misconceptions About Tool Quality

Over time, cutting tools lose their cutting efficiency due to wear, edge dulling, and coating deterioration. Often, what seems like poor tool quality is actually the result of not replacing or repairing tools promptly. While extending tool life may save costs in the short term, overuse can lead to uneven cutting forces, rough surfaces, and even tool breakage. If tools are not inspected and replaced in a timely manner, it can lead to the incorrect conclusion that the tools are defective, resulting in unnecessary purchasing mistakes. Regularly monitoring tool condition and replacing or resharpening based on actual wear will prevent such issues.

Incorrect Clamping, Tool Holder Cleaning, or Mounting Methods Leading to Abnormal Wear

The method of clamping, cleanliness of the tool holder, and proper mounting of the tool directly impact its stability and service life. Improper clamping can cause the tool to vibrate or shift during machining, leading to abnormal wear. Additionally, the cleanliness of the tool holder is crucial as dirt or oil can affect the contact between the tool and the machine tool, causing unstable operation, increased cutting forces, and excessive wear. To prevent this, ensure that the fixture is properly installed, the tool holder is clean and free of impurities, and the tool is securely mounted. Proper setup will significantly reduce abnormal wear and maintain stable tool performance.

Improper Coolant Selection, Nozzle Direction, and Pressure Settings Reducing Cutting Performance

Proper coolant selection and usage are critical for optimizing tool performance. Coolant not only lowers the cutting temperature and reduces tool wear, but it also helps remove chips, preventing clogging or overheating. If the coolant is selected incorrectly—such as using coolant with too high viscosity or insufficient cooling capacity—or if the nozzle direction and pressure settings are off, cooling efficiency will suffer. Poor cooling can lead to high cutting temperatures, accelerating tool wear and reducing machining accuracy. Ensuring that the correct coolant is used, and the nozzle direction and pressure settings are properly adjusted, is key to maintaining tool performance and extending tool life.

By adhering to correct tool usage and maintenance practices, companies can maximize tool performance, extend service life, and avoid misjudging tool quality. Regularly checking tool conditions, optimizing operating conditions, and performing appropriate maintenance will help ensure the stability and efficiency of the machining process.

Neglecting Data Recording and Processing Feedback Leading to Long-Term Selection Errors

In efficient and precise metal processing, recording data and processing feedback are crucial for optimizing tool selection and improving production efficiency. Many factories neglect to document and analyze tool usage, which leads to uninformed decisions when selecting tools. Without data to support tool selection, companies often make errors that lead to frequent downtime and production instability. To avoid long-term selection mistakes, companies must establish a systematic data recording and feedback mechanism to identify patterns and trends, optimizing tool selection and improving overall production efficiency.

Failure to Record the Lifespan and Cutting Performance of Carbide Mill Bits

The lifespan and cutting performance of carbide mill bits change over time, depending on the processing task. Without timely recording of tool usage data, it’s difficult to assess whether a tool has performed as expected or whether it has worn to a point that negatively impacts processing quality. Recording data such as tool usage time, cutting volume, processed material, and machining accuracy allows engineers to assess whether the tool is still suitable for the task at hand, avoiding negative impacts on accuracy due to excessive wear. Additionally, accurate data logging can provide valuable insights for future tool selection, ensuring that only the most suitable tools are purchased.

Failure to Compare the Cost-Effectiveness of Different Milling Cutter Bits Using Data

Milling cutters come with varying costs and performance levels. Some tools, though more expensive upfront, may offer greater durability and higher processing efficiency, ultimately improving production efficiency and reducing overall costs. On the other hand, cheaper tools may result in higher long-term costs due to shorter lifespans and lower performance. Companies should compare the cost-effectiveness of different tools based on data analysis. By evaluating factors such as tool durability, machining accuracy, change frequency, and production efficiency, companies can make more informed decisions about which tools to invest in, rather than basing decisions solely on price.

Lack of Accumulated Processing Cases Leading to Continued Reliance on Incorrect Selection Judgments

Accumulating and analyzing past machining cases provides valuable experience that can inform future tool selection. Without systematically recording and analyzing previous tasks, companies may continue making the same mistakes when selecting tools for similar tasks. Each machining task has unique requirements, and tool selection should be adjusted based on factors like material type, machining accuracy, and processing conditions. By accumulating a database of machining cases, companies can improve their decision-making process and avoid relying on incorrect tool selection judgments. This ongoing process of learning from past cases will enhance machining efficiency and quality over time.

By effectively recording data and incorporating feedback from processing tasks, companies can make more informed tool selections, avoiding errors caused by subjective judgment or incomplete information. Establishing a robust data analysis system and continuously optimizing tool selection and management strategies will ultimately lead to increased production efficiency, reduced costs, and improved machining quality.