In aerospace manufacturing, the machining accuracy and surface quality of metal structural components directly impact the overall safety and performance of aircraft. When working with aerospace-grade metals such as titanium alloys, nickel-based superalloys, and aluminum-lithium alloys, selecting efficient and stable face milling tools for aerospace grade metals becomes critical to achieving precision and reliability.

As modern manufacturing technology advances, companies not only pursue higher cutting efficiency but also focus on tool durability, dimensional accuracy, and consistent surface finish. Optimized CNC face milling tools for metal—featuring improved tool body structures and advanced insert geometries—offer greater cutting stability and heat dissipation when machining high-strength alloys. The use of multi-flute face mills, multilayer coatings, and indexable insert systems makes machining more economical and sustainable.

Additionally, side and face cutters play an essential complementary role when machining shoulders, grooves, and complex outer contours. They can operate in tandem with face mills to enable multi-surface cutting in a single setup, significantly improving production cycle times and machining consistency.

To meet the stringent quality control standards of aerospace components, tool manufacturers continuously develop more advanced CNC face milling tool solutions. These include diverse insert materials such as carbide, ceramic, and CBN, along with coatings optimized for specific metals. These innovations not only reduce tool wear and replacement frequency but also improve energy efficiency and process flow during machining.

Choosing the right CNC face mill supplier is equally critical. Reliable suppliers provide not only consistent, high-quality tooling but also customized solutions and application support based on specific material and process requirements—helping manufacturers achieve greater productivity, precision, and cost control in aerospace metal machining.

Challenges and Cutting Requirements of Aerospace-Grade Metal Machining

Aerospace-grade materials are renowned for their high strength-to-weight ratio and excellent heat resistance. While these properties enhance aircraft performance, they also make machining far more challenging. Traditional tools often struggle with excessive cutting forces, high temperatures, and accelerated wear when processing titanium and nickel-based alloys.

Modern aerospace production demands both high surface quality and dimensional accuracy, requiring manufacturers to balance machining efficiency and tool life. High-performance CNC face milling tools for metal, combined with optimized cutting strategies, are key to maintaining that balance. Tool geometry optimization, advanced wear-resistant coatings, and precise control of feed rate and spindle speed all contribute to improved stability in metal cutting.

With the growing use of composite materials and metal laminates, tool geometry, insert design, and cooling strategies must be carefully matched. Partnering with a capable CNC face mill supplier allows companies to access tailored tool solutions that ensure machining consistency and high production efficiency across complex materials.

Machining Challenges of High-Strength and Heat-Resistant Materials

Titanium and nickel-based alloys exhibit high strength and low thermal conductivity, causing heat buildup and rapid tool wear during cutting. Standard face milling tools are often insufficient in such high-heat environments. Using carbide inserts with advanced coatings—or ceramic and CBN inserts—can significantly improve wear resistance and thermal stability.

These materials are also prone to chip adhesion and built-up edges, which degrade surface quality. By adopting CNC face milling tools for metal with positive rake angles and optimized coolant delivery, cutting forces and temperature rise can be minimized, extending tool life and improving surface finish.

The Importance of Cutting Stability and Tool Life

Cutting stability is a decisive factor in aerospace part machining, directly influencing dimensional accuracy and equipment uptime. Variations in cutting force, vibration, and tool wear can compromise surface integrity. Using side and face cutters with high-rigidity tool bodies and multi-point support structures helps maintain stability under deep cuts and high feed rates.

Integrating tool wear monitoring and life prediction systems is also essential for reliable aerospace production. CNC face milling tools with quick-change inserts and high-precision clamping mechanisms reduce downtime and control overall tooling costs effectively.

Face Milling Process Optimization: Balancing Efficiency and Precision

Aerospace structural components are large and geometrically complex, requiring a delicate balance between cutting efficiency and precision. Excessive cutting speed may cause heat distortion and surface defects, while overemphasizing precision can reduce throughput.

CNC face milling tools for metal with indexable multi-blade designs improve feed rates while maintaining smooth cutting action. Using intelligent CNC systems to dynamically adjust cutting parameters enables seamless integration of roughing and finishing, achieving both accuracy and productivity.

For long-term stability, partnering with professional CNC face mill suppliers for process optimization and customized tool matching is essential to maintain competitiveness in aerospace manufacturing.

High Performance Face Milling Tool Types for Aerospace Metals

As aerospace manufacturing increasingly relies on lightweight, high-strength materials, face milling cutter designs have evolved toward higher efficiency, precision, and longevity. Modern face milling tools for aerospace grade metals are engineered to deliver superior stability and surface finish through optimized tool structures, insert materials, and coatings.

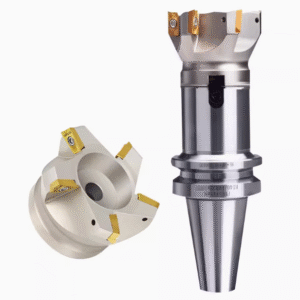

High-performance CNC face milling tools for metal typically feature indexable multi-edge designs, modular tool heads, and secure insert clamping systems. These enable high-speed, stable cutting under heavy loads. Compared with traditional solid cutters, modular tools offer greater flexibility, easier maintenance, and lower long-term costs—making them ideal for both small-batch and large-scale aerospace production.

Integrating side and face cutters for modular machining allows for multi-plane cutting in a single setup, improving surface consistency and dimensional accuracy. Selecting the right tool type according to material and process objectives ensures maximum machining performance and tool utilization.

Design Features of Heavy-Duty and High-Feed Face Milling Cutters

Heavy-duty and high-feed face milling cutters are commonly used for roughing large aerospace components or thick-walled workpieces. These CNC face milling cutters use rigid tool bodies and large positive rake angles, allowing deep cuts and high feed rates while maintaining stability.

High-feed face mills typically have small tip radii and optimized cutting angles for efficient axial force transfer, reducing vibration and tool deflection. When machining titanium or nickel alloys, this design lowers cutting temperatures and extends tool life. Advanced CNC face milling tools for metal also feature internal coolant channels that improve heat dissipation and chip evacuation.

Tool Geometry and Coating Strategies for Titanium and Nickel-Based Alloys

Due to poor thermal conductivity and high strength, titanium and nickel-based alloys demand precise tool geometry and coating solutions. Effective face milling tools for aerospace grade metals use large helix angles and positive rake angles to minimize cutting resistance and heat concentration.

Multilayer coatings such as AlTiN, AlCrN, and TiSiN improve heat resistance and oxidation protection. For extreme temperature applications, nanostructured or PVD coatings offer superior stability. Sharp cutting edges and fine grinding processes further reduce chip adhesion and built-up edge issues, enhancing tool life and surface finish quality.

Advantages of CNC Face Milling Tools for Metal in Aerospace Structural Components

Aerospace structural components like wing spars, landing gear supports, and engine housings demand high rigidity and machining precision. Advanced CNC face milling tools for metal ensure stable performance and excellent surface finish in large-area machining operations.

Compared with conventional tools, modern face mills deliver greater efficiency and repeatability in high-speed CNC machining. When used alongside side and face cutters, they enable simultaneous face and edge cutting on complex geometries, reducing setup times and improving throughput.

Replaceable insert systems offer flexible maintenance and cost control, while collaboration with experienced CNC face mill suppliers ensures continuous process optimization and tool performance improvement. As a result, this tooling approach has become a leading trend in aerospace machining, enhancing productivity, surface consistency, and overall manufacturing economy.

The Cooperative Role of Side and Face Cutters in Complex Workpieces

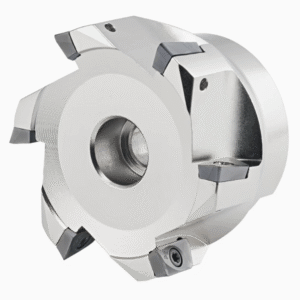

In aerospace component manufacturing, machining complex geometries and multi-curved surfaces remains a significant challenge. Conventional face milling tools alone often cannot complete all machining surfaces in one setup. Therefore, side and face cutters play a vital role in the process layout. These tools combine the capabilities of face and side milling, enabling high-precision machining of planes, grooves, and shoulder structures—significantly improving production efficiency and part consistency.

Within modern CNC face milling tools for metal machining systems, side and face cutters are typically used in coordination with multi-axis CNC machines. This integration allows simultaneous cutting from multiple angles, minimizing re-clamping errors. Especially when machining aerospace materials such as titanium alloys, nickel-based superalloys, and high-strength aluminum alloys, tool rigidity and heat dissipation performance become key factors for efficient and stable machining. With well-planned cutting paths and optimized parameters, manufacturers can enhance machining stability and effectively extend tool life.

Combined Machining Path of Face Milling and Side Milling in Multi-Axis CNC Systems

The integration of multi-axis CNC systems has made combined face and side milling an effective strategy for machining complex parts. For aerospace structural components featuring multiple planes and contours, combining CNC face milling tools for metal with side and face cutters allows different regions—such as upper surfaces, sidewalls, and grooves—to be machined in a single setup.

This combined process layout shortens machining time, reduces repositioning, and minimizes potential sources of error. By optimizing feed direction, spindle tilt, and depth of cut, operators can achieve high material removal rates without compromising accuracy. Advanced tooling designs, such as variable helix angles and internal coolant channels, further improve heat control and cutting stability, ensuring consistent surface finishes.

The main advantage of this hybrid path lies in process integration—achieving superior efficiency and consistency with fewer setups. This represents a critical optimization direction for aerospace manufacturers seeking to streamline their machining workflows.

High-Precision Performance of Side Milling Cutters in Groove, Shoulder, and Profile Machining

Grooves and shoulders in aerospace parts often determine assembly precision and structural integrity. High-rigidity side and face cutters provide outstanding dimensional accuracy and surface finish in these critical regions. Unlike conventional end mills, these cutters feature broader cutting edges and reinforced tool bodies, effectively suppressing vibration and deformation during deep-groove and wide-shoulder machining.

When paired with high-performance face milling tools for aerospace-grade metals, these cutters deliver seamless transitions between complex curved and straight surfaces. Coated carbide or CBN inserts offer superior wear resistance and anti-adhesion properties for difficult materials such as titanium and nickel alloys, ensuring long-term cutting stability.

By carefully managing tool entry/exit trajectories and minimizing overhang, surface distortion and ripple formation are reduced—achieving the precision required in aerospace manufacturing.

Improving Surface Consistency and Efficiency with Side and Face Cutters

Achieving consistent surface quality while maintaining efficiency is a central goal in aerospace machining. Side and face cutters ensure continuity in toolpaths during face and side milling, minimizing tool marks and achieving smoother, more uniform surfaces.

When combined with CNC face milling tools for metal, roughing and finishing operations can be strategically divided for maximum efficiency. For instance, using a high-feed face mill for roughing followed by a precision side mill for finishing dramatically shortens machining cycles while preserving surface integrity.

Furthermore, the integration of tool compensation systems, automatic tool length measurement, and optimization support from CNC face mill suppliers ensures stable surface consistency and dimensional repeatability in large-scale production. For aerospace-grade metals, this hybrid approach not only enhances surface quality but also reduces setup costs and downtime—strengthening overall production competitiveness.

Key Tooling Technologies for Improving Face Milling Efficiency in Aerospace Manufacturing

Aerospace components are typically made from high-strength, heat-resistant materials such as titanium alloys, nickel-based superalloys, and hardened aluminum alloys. These materials pose unique challenges for traditional milling processes. To overcome these, manufacturers increasingly rely on advanced CNC face milling tools for aerospace-grade metals, leveraging innovations in tool geometry, materials, and cooling systems to achieve higher cutting stability and tool longevity.

Modern CNC face milling tools for metal are designed with enhanced rigidity, precision, and adaptability. Advances such as indexable insert systems, multi-edge milling heads, and high-performance coatings enable these tools to maintain superior performance across a range of demanding conditions. Partnering with an experienced CNC face mill supplier is essential for accessing customized tooling solutions that balance performance, cost, and durability.

Advantages of Indexable Insert Systems and Multi-Insert Face Milling Heads

Most modern face milling systems now feature indexable inserts instead of traditional solid cutters. This design allows worn inserts to be replaced or rotated quickly, dramatically reducing downtime and overall tool costs. Each insert provides multiple cutting edges, ensuring continuous productivity and high utilization rates.

Multi-insert face milling heads are particularly advantageous for aerospace parts. Their distributed cutting edges support higher feed rates and better stability while evenly distributing cutting loads. Combined with precise insert clamping and spindle alignment, they deliver excellent surface finish and dimensional accuracy on materials like titanium and nickel alloys.

Performance of Advanced Tool Materials in High-Temperature Alloys

The choice of tool material plays a decisive role in machining aerospace alloys. Coated carbide inserts—with coatings such as AlTiN, AlCrN, or TiAlSiN—are the most widely used, offering superior hardness, oxidation resistance, and heat stability. They help maintain sharp cutting edges even under high thermal loads.

For more demanding conditions, ceramic and CBN inserts excel. These materials can endure extremely high cutting temperatures, making them ideal for high-speed machining of nickel-based superalloys such as Inconel and Hastelloy. Many aerospace manufacturers achieve optimal performance by combining different insert materials for roughing and finishing operations within the same CNC face milling tool.

Selecting the right coating and material combination for each workpiece and cutting condition is critical for maximizing tool life and maintaining consistent performance.

Cutting Fluid, Cooling Strategies, and Tool Vibration Control

Heat accumulation is the primary factor limiting tool life in high-temperature alloy machining. Advanced cooling strategies—such as internal coolant channels and high-pressure fluid delivery—directly target the cutting edge, minimizing wear and surface burns.

Equally important is vibration control. Optimized tool geometry and high-damping toolholders significantly reduce chatter, ensuring smoother surface finishes. Some CNC face mill suppliers now offer intelligent tool systems equipped with embedded sensors that monitor vibration and cutting loads in real time, enabling automatic parameter optimization and enhanced process reliability.

Selection and Cooperation Strategies for CNC Face Mill Suppliers

Choosing the right CNC face mill supplier is crucial for maintaining precision, efficiency, and cost-effectiveness in aerospace manufacturing. A reliable supplier provides not only high-performance face milling tools for aerospace-grade metals but also engineering support, process optimization, and customized tool design to meet complex machining demands.

When evaluating suppliers, manufacturers should consider product stability, technical innovation, responsiveness, and after-sales service. The most competitive CNC face milling tool suppliers for metal combine advanced R&D capabilities with stringent quality control and proven field experience. Beyond procurement, collaboration should evolve toward long-term technological partnerships that drive process innovation and sustainable productivity gains.

Assessing Technical Strength and Product Stability

Evaluating a supplier begins with verifying its technical expertise and product consistency. This includes assessing tool geometry precision, coating quality, and proven performance under high-load aerospace machining conditions. A reputable supplier should be able to provide cutting data, case studies, and verification reports demonstrating consistent results across production runs.

Key assessment criteria include:

-

Geometric precision and repeatability

-

Coating stability and wear resistance

-

Performance under thermal and mechanical stress

-

Quality inspection and testing capabilities

-

Responsiveness and technical support availability

Suppliers that actively participate in process testing and offer application-based recommendations typically deliver higher long-term value.

Competitive Advantages of Customized Tooling Solutions

In modern aerospace manufacturing, customized CNC face milling tools provide a significant competitive advantage. Tailored designs can optimize cutter diameter, insert count, rake angle, and cooling structure based on workpiece geometry and production cycle requirements. This customization ensures better chip evacuation, reduced cutting forces, and enhanced tool life.

For example, in machining titanium spars or engine housings, co-developing tool geometry with suppliers can drastically reduce tool wear while maintaining stability at high removal rates. Although initial costs are higher, custom tooling minimizes per-part cost and boosts throughput in large-scale production.

Building Long-Term Strategic Partnerships

Establishing long-term partnerships with professional CNC face mill suppliers ensures a stable tooling supply chain and continuous technical improvement. Successful collaborations rely on open data sharing, joint process validation, and mutual commitment to performance optimization.

Best practices include:

-

Sharing real-time tool performance and wear data

-

Conducting joint trials for new materials or processes

-

Establishing inventory safety mechanisms and rapid restocking

-

Implementing on-site technical training and support programs

Through strategic partnerships, aerospace manufacturers gain access to ongoing innovations in CNC face milling tools for metal, maintaining a strong competitive edge in global aerospace production.

Application Case: Performance Optimization of Face Milling Cutters in Aerospace Structural Component Machining

In the aerospace manufacturing sector, structural components are typically made from high-strength, heat-resistant, and difficult-to-machine materials. To enhance production efficiency while maintaining accuracy and surface integrity, manufacturers continuously refine their face milling tools for aerospace-grade metals. Practical experience has shown that tool geometry design, cutting parameter optimization, and material upgrades are the three primary factors that determine machining performance.

By integrating advanced tool geometries, high-performance coatings, and optimized cooling strategies into modern CNC face milling tools for metal, companies can significantly reduce cutting resistance and tool wear, resulting in longer tool life, higher material removal rates, and superior surface finishes. Furthermore, through collaboration with professional CNC face mill suppliers, manufacturers have developed customized tool solutions tailored to specific aerospace components—greatly improving overall throughput and process consistency.

Real-World Case Study: Improving Cutting Efficiency Through Tool Upgrades

An aerospace manufacturer previously experienced excessive tool wear, high cutting temperatures, and long machining cycles when roughing titanium alloy wing spars with conventional carbide face milling cutters. In collaboration with a leading CNC face mill supplier, they adopted a new generation of CNC face milling tools for metal featuring a high thermal stability coating and optimized insert geometry for stable high-feed cutting.

The results were significant:

-

Cutting efficiency increased by approximately 35%;

-

Tool life extended by 60%;

-

Surface roughness improved from Ra 1.8 µm to Ra 0.9 µm;

-

Machine vibration decreased, resulting in more uniform tool wear.

This case demonstrates that strategic upgrades to tool geometry and coating systems can dramatically improve cutting efficiency for high-strength aerospace materials without compromising precision.

In another example, during the face milling of nickel-based alloy engine brackets, the manufacturer implemented a multi-blade CNC face mill equipped with internal coolant channels. By precisely controlling the coolant flow rate, heat accumulation during cutting was minimized, further improving tool durability and cutting stability.

Face Milling Cutter Replacement Cycle and Cost Optimization Strategies

In aerospace mass production, the replacement cycle and operating cost of face milling cutters have a direct impact on production planning and profitability. Manufacturers who focus solely on tool purchase price often overlook the importance of Tool Life Cycle Cost (TLC)—a more comprehensive metric of economic performance.

By implementing indexable insert systems and modular face milling tools with regrindable cutter bodies, per-part tooling costs can be substantially reduced. For example, replacing disposable cutters with indexable designs can save approximately 25%–40% in total tool system costs. When paired with online monitoring systems provided by advanced CNC face mill suppliers, predictive maintenance based on real-time wear data can identify optimal replacement intervals, preventing losses from premature or delayed tool changes.

A further step forward involves establishing a “tool health database.” By analyzing cutting force, temperature, and vibration feedback from the CNC system, manufacturers can dynamically assess tool wear trends for side and face cutters, improving tool-change timing accuracy and overall machine uptime. This ensures stable, repeatable machining of high-value aerospace components.

Surface Quality Improvement and Its Connection to Subsequent Finishing Processes

In aerospace structural machining, face milling typically serves as a roughing or semi-finishing stage, and its performance directly affects the precision of subsequent finishing, drilling, or assembly operations. By using high-performance CNC face milling tools for metal and optimizing cutting parameters, manufacturers can significantly enhance surface integrity and control residual stresses—reducing the need for rework and minimizing machining allowances in later stages.

For example, when machining engine housings or fuselage frames, applying micro-positive rake angle inserts and high-stability tool bodies ensures uniform cutting forces and low-vibration operation. This enables consistent surface roughness below Ra 0.8 µm, greatly reducing finishing requirements. Additionally, the use of high-pressure coolant systems and adaptive feed control technologies suppresses thermal deformation and chip adhesion, further improving surface consistency.

A reliable CNC face mill supplier can provide customized tool–process matching solutions based on specific workpiece materials and machining routes. For instance, in titanium alloy structural components, the use of micro-edge radius inserts and multi-layer heat-resistant coatings maintains high cutting speeds while ensuring geometric precision and surface accuracy—reducing or even eliminating the need for post-process polishing or grinding.

Through systematic optimization of tool design, cutting parameters, and maintenance strategies, face milling tools for aerospace-grade metals not only enable efficient and stable material removal but also play a vital role in improving surface integrity and reducing total production costs. These application cases clearly illustrate the importance of tooling innovation and supplier collaboration in advancing aerospace manufacturing efficiency and reliability.