What is an End Mill?

An end mill is a tool that can be used on a CNC or conventional milling machine, or on a lathe with a universal tool holder. When milling, the tool rotates and the workpiece moves with the milling machine. It moves horizontally or laterally, not vertically. The spindle moves vertically, and the tool is fixed, cutting the workpiece with the milling cutter’s cutting edge. Different tool geometries are designed to determine what tool is used where and when.

What is an End Milling Cutter?

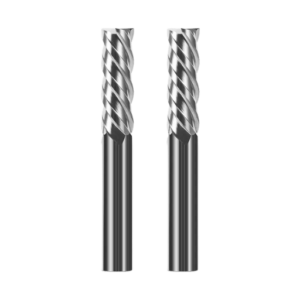

An end milling cutter is a type of end mill bit that can perform a variety of applications, including facing, plunging, slotting, contouring, and shoulder milling. End mills cut in the direction of rotation in horizontal, lateral, and vertical motions on a transverse plane. This makes them versatile and allows them to perform many different applications. End mills range from 2-6 flutes by the number of flutes, but we don’t call a 2-flute milling cutter an end mill, but a slot mill.

What is Slot Milling?

A slot mill is a milling cutter with two flutes. The two-flute geometry allows for better chip evacuation. But they are usually designed as tools with two cutting edges, specifically for making slots or holes in a material. Slot mills are designed to be more efficient when making slots. Using a slot mill first, followed by a 3-4 flute end mill, makes the process faster. However, having only two flutes can prevent higher feed rates than a multi-flute mill.

What are the Differences Between Slot Mills and End Mills?

A slot mill is a combination of a drill and an end mill, which means it cuts like a drill and then cuts like an end mill. In contrast, an end mill will mainly make lateral and horizontal cuts. One flute of a slot drill is slightly longer than the other, which helps with centering and cutting.

How does the Number of Flutes Affect the Tool?

The number of flutes can affect the tool specifications and application. For example, non-ferrous materials often require a two-flute mill to help with chip evacuation. However, when cutting harder materials, such as stainless steel, it may be better to use a 3 or 4 flute tool for added strength. The greater the number of flutes, the shallower each flute is, which creates a stronger core (the center of the tool).

What is the Difference Between Ggeneral Purpose and High Performance Tools?

General performance tools can be found in the high speed steel, powder metal and solid carbide tool ranges. These ranges perform well on low to medium hardness steels, stainless steels and cast irons.

High performance tools are designed for higher metal removal rates (sometimes ultra-high). There are various different geometries designed to help with high chip removal rates.

These include a variable helix, which breaks up the tool harmonics, helping to prevent vibration and extend tool life. Uneven spacing of grooves can reduce friction between the tool and the workpiece, thereby reducing heat generation and burns on the workpiece surface, further improving surface finish.

The “Double Core” design mentioned is an innovative technology used in high performance milling cutters. The main advantage of this design is the ability to enhance the strength and durability of the tool while pushing metal removal rates to the limit. Now the double core design means that the milling tool has two cores or center supports, which helps to increase the rigidity and stability of the tool, especially when cutting at great depths or high loads. This design improves the tool’s resistance to bending and reduces vibration, which results in longer tool life and more efficient machining.

What’s the Difference?

High-speed steel is best suited for manual or semi-automatic machining, where the equipment is unstable. Due to its toughness and durability, high-speed steel does not chip easily and is not affected by vibration like carbide. In addition, the cost of high-speed steel is generally much more economical than powdered metal and carbide in general machining applications.

Powdered metal is the bridge between high-speed steel and carbide. It is perfect for use in manual or CNC machines where there is vibration or certain constraints, such as unstable equipment. The atomic structure of powdered metal means it is as durable and tough as high-speed steel, helping to reduce the effects of vibration. But with the wear resistance and tool life of carbide.

Carbide substrates can be found in different “grains”, which indicate the level of performance, including micrograins, ultra-fine grains, and nanograins (the finest and highest performance carbide types). These all affect performance, as the smaller the grain, the tighter the atomic structure, which improves performance. To fully exploit the benefits of carbide, a sturdy unit with a hydraulic mount or precision collet chuck is required. There is little vibration and it can withstand high speeds and feed rates. This will prevent the tool from backing out and extend tool life.

Why Choose a Replaceable Head Milling Cutter?

The initial cost of purchasing a toolholder and replaceable head may seem expensive. But it is an effective way to save money in the long run. This is because after the initial investment, you only need to purchase a new replaceable head at a later time. This saves money in the long run, not having to purchase a new tool each time. This method also saves potential downtime because the toolholder is already in the toolholder. Therefore, you do not need to reset the tool every time the cutting edge wears. Because it has very high repeatability.

Sharp Angles vs. Chamfer Milling Cutters

The geometry of a chamfer end mill helps strengthen the cutting edge and is highly recommended when machining difficult materials. You prevent the tool from chipping, which can easily happen when using a standard sharp edge. It creates a more stable cutting edge because it has more consistency if the edge does not break. It can greatly reduce cycle times because you can push the tool harder with less chance of chipping or breaking.

What are the Different Types of Milling Cutters?

Due to the wide range of applications for end mill cutters, the shape, size, and characteristics of each milling cutter must be determined based on its defined purpose. Most commonly, the differences between milling cutter models will be found in the cutting edge, which is the most important part of the tool. This is because it is the part that makes direct contact with the workpiece. Below are the most common types of milling cutters.

Square shoulder milling cutter: The most common milling cutter variation, it features a 90° cutting edge and is suitable for general machining operations.

Chamfer milling cutter: Chamfer end mills will utilize an angled cutting tip (e.g. 30°, 45°) to strengthen the cutting edge, prevent tool backout, and allow the tool to run faster and harder than a traditional square end mill.

Roughing end mill cutter: Also known as a roughing cutter, this type of cutter features multiple ridges throughout the depth of cut, giving it a “rough” appearance. Due to these ridges, you can push it to be harder core than a finishing milling cutter and is ideal for cutting large amounts of material quickly.

Ball nose milling cutter: Named for the shape of its cutting edge, ball nose milling cutters have a hemispherical end that can be used to cut curved shapes in a workpiece. This could be slotting, contouring, and end milling.

Fillet milling cutter: Similar to chamfer preparation, tool manufacturers add fillet radii to milling cutters, where the cutting edge or tip portion of the cutter has one or more fillet radii. This is to strengthen the cutting tip and prevent the tip from breaking off in more demanding machining conditions.

Tapered milling cutter: Characterized by a tapered cutting edge, this type of milling cutter has a diameter that tapers from the shank end to the cutting end. The design of this type of milling cutter makes them particularly suitable for milling in tight spaces or complex designs. The taper of a tapered milling cutter can be gradual or at a specific angle, depending on the machining requirements.

Finishing milling cutter: Typically, a finishing milling cutter will have 6 or more flutes (but sometimes a 4-5 flute milling cutter can perform finishing operations). Finishing cutters have shallower flutes, which means the core of the tool is stronger. Not only does a stronger core mean you can push the cutter further, but the shallower grooves allow a better finish to be formed on the workpiece.

Advantages of Solid Carbide Milling vs. Indexable Milling

Indexable milling cutters allow users to machine much larger diameters than standard milling cutters. Indexable cutters have a cutter body and multiple inserts, allowing for flexibility by changing inserts. Therefore, the tool life of an indexable cutter will be much longer than a solid carbide cutter.

However, there are some benefits to using a solid carbide milling cutter over an indexable milling cutter. For smaller diameters (e.g. under 20mm), a solid carbide milling cutter is often more cost-effective than investing in an unnecessarily large indexable system. Due to their smaller size, solid carbide cutters also put less stress on the user’s machine tool. This means that solid carbide cutters can be used at higher feed rates without requiring higher machine tool capacity.

In addition, the insert design of an indexable system means that it is impossible to achieve the same level of finishing with an indexable milling cutter as with a solid carbide milling cutter. Especially in 4-6 flute cutters, a solid carbide milling cutter will always provide a smoother surface finish.

How to Choose the Right End Mill?

There is no one exact way to choose the right milling cutter, as there are many variables that may influence your choice during the decision-making process. However, over time, we have compiled a series of general criteria and questions that we use to determine the type of milling cutter required for a specific job. Here is an explanation of these detailed questions:

The first, and perhaps most obvious question, is what diameter milling cutter is required? This not only greatly narrows the range of milling cutter choices, but in some cases it can also allow you to determine whether a solid carbide milling cutter or an indexable milling cutter is more appropriate. For example, when you need a diameter of up to 25mm, it may be more cost-effective to invest in an indexable system with replaceable inserts rather than purchasing a large solid milling cutter.

Next, we ask whether a high-speed steel or solid carbide milling cutter is required to complete the job. This will depend on the machine tool setup, budget, and the material being machined. If it is on a manual machine, it is likely that a high-speed steel milling cutter will be used. Depending on the budget, a powder metallurgy milling cutter, which acts as a bridge between high-speed steel and carbide. Can be used in unstable machine conditions and may also be recommended for manual machining.

Similarly, if the budget is limited, high-speed steel may be the first choice. Although if it is operated using a CNC machine, there are many cost-effective carbide milling cutters to choose from. In fact, carbide milling cutters can achieve higher cutting speeds and feeds. If conditions permit, choosing a carbide milling cutter may be more cost-effective in the long run.

The workpiece material will most likely be the next consideration in deciding which milling cutter to use. Cutting tool manufacturers will always provide cutting data for the materials they recommend for use with a specific milling cutter, and this data should always be referenced before use.

If the manufacturer does not provide cutting data for the material, it should be assumed that the milling cutter is not suitable for that material. In terms of the construction of the milling cutter itself, manufacturers use a series of characteristics that make the milling cutter work best on certain materials. For example, aluminum will adhere to the grooves of coated milling cutters, so manufacturers create special uncoated, ground and polished grooves to prevent chip flute clogging. And to ensure the best surface finish in non-ferrous metal milling. Other dimensional characteristics may also play a role in the decision process.