Achieving a mirror-finish surface on molds requires precise control over cutting stability, tool geometry, and material removal methods, all of which depend heavily on high-performance mold cutting tools. Whether machining deep cavities, inclined surfaces, or high-hardness steel mold parts, the sharpness of the cutting edge, wear resistance of the coating, and cutting path strategy directly influence the final surface quality. Choosing the right mold milling cutters, mold milling tools, and steel mold cutting tools is crucial for producing a smooth surface, reducing polishing time, and improving overall mold efficiency.

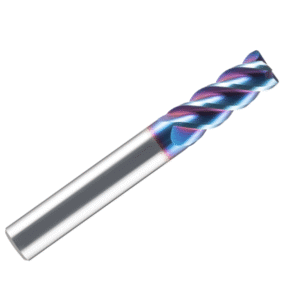

Mirror-finish results are not achieved through a single action but through the combination of tool material, tool structure, processing parameters, and machine tool dynamics. High-quality carbide tools excel in heat resistance, edge stability, and resistance to micro-chipping. They are commonly used during the finishing stages of high-precision molds. Partnering with a reliable custom carbide mold cutting tools supplier ensures access to customized tools tailored to mold material, machining area, and surface finish requirements, helping maintain stability and consistency throughout the cutting process.

As mold quality requirements rise, mirror-finish machining has become standard in industries such as plastic molds, optical molds, and automotive exterior parts molds. To achieve these high standards, tools must minimize machining marks, control heat buildup, and prevent surface fatigue layers. Geometric accuracy, tool runout control, coating adhesion, and machining rigidity are core factors influencing the mirror finish.

Core Requirements for Tool Performance in Mirror-Finish Mold Machining

High-gloss mold surfaces demand exceptional tool performance, particularly when cutting high-hardness steel or hardened workpieces. Tool structure, edge integrity, wear resistance, and stability directly affect surface brightness and uniformity. To achieve a mirror-like finish, minimal vibration, consistent cutting forces, and predictable tool wear are critical, especially during finishing. Fine grinding tools for mold steel, reinforced milling cutters, and highly stable micro-edge tools are essential for machining deep cavities, small radius, and narrow grooves, helping reduce surface irregularities and polishing time.

Stable Cutting and Edge Strength Control in Hard Material Machining

High-hardness steel and heat-treated workpieces impose heavy loads on cutting edges. Tools must have sufficient edge rigidity and chipping resistance. Small-diameter tools or long overhangs can lead to micro-chipping, uneven marks, and localized burning if edges are weak. Using high-strength composite structures, enhanced edge treatments, and precision-ground micro-radius edges improves tool reliability while maintaining sharpness. Heat-resistant tool materials and wear-resistant coatings reduce the impact of cutting heat and ensure consistent machining, producing a high-reflectivity surface.

The Critical Role of Tool Geometry in Mirror Finish Machining

Tool geometry—including rake angle, relief angle, edge radius, and transition structure—determines cutting load distribution and material separation, affecting surface smoothness. An overly large rake angle may weaken the edge, while a small one increases friction. Optimized geometry reduces cutting resistance while maintaining edge stability. Fine edge radii minimize cutting marks and enhance wear resistance, ensuring consistent cutting during prolonged mirror-finish operations. On complex curved and inclined surfaces, well-designed tool geometry reduces step marks, approaching polished-quality results.

The Influence of Tool Material and Microstructure on Surface Quality

Highly reflective surfaces require tools with excellent hardness, toughness, and wear resistance. Cemented carbide materials offer heat resistance and resist plastic deformation, reducing edge blunting and maintaining cutting stability. Finishing tools with high-adhesion, wear-resistant coatings suppress microscopic damage caused by cutting heat, reduce built-up edge formation, and maintain uniform brightness. Fine-grained, high-density sintered materials produce sharper cutting edges, ideal for deep cavities, hard steels, and high-gloss mold finishes.

The Key Contribution of Mold Cutting Tools in Achieving Mirror Finishing

Microscopic textures formed during machining largely determine mirror quality. Stable cutting, uniform material removal, and smooth transitions rely on high-precision tools. Tools with high edge integrity, minimal runout, and enhanced surface treatments reduce roughness in deep cavities, complex curves, and hard steels. High-wear-resistant milling cutters, micro-edge grinding tools, and stable finishing tools minimize overcutting and scratches while maintaining consistent gloss, providing a strong foundation for improved mold quality and reduced polishing steps.

Low Roughness Achieved Through Precise Edge Treatment

Micron-level surface roughness requires precise edge treatments. Edge rounding and micro-chamfering reduce cutting marks and ensure smooth material separation. Precision-ground cutting edges maintain consistent trajectories under stable cutting loads, producing uniform gloss. Fine edge structures lower cutting resistance, reduce micro-vibrations, and prevent white layer formation, making them ideal for hardened steel, mold steel, and optical molds. This precision reduces manual polishing time and improves overall efficiency.

Vibration Suppression and Stability Enhancement Mechanisms in Machining

Machining vibrations can cause uneven textures and distorted reflection. High-rigidity tool designs—including optimized body shape, chip flute design, and rotational balance—minimize force fluctuations, resulting in smoother cutting. In deep cavities, long overhangs, and complex angled areas, stable tools reduce surface textures and improve edge continuity, producing consistent brightness. Controlling tool runout and cutting force variations prevents localized darkening, drag marks, and micro-step patterns.

Synergistic Effect of Edge Sharpness and Wear Resistance on Mirror Finish

A sharp edge enables finer material removal with low cutting load, reducing surface texture depth. However, sharpness alone cannot maintain long-term stability, making wear-resistant coatings essential. High-adhesion coatings enhance heat resistance and chipping resistance, keeping the tool geometry stable during extended machining. Combining sharp edges with high-performance coatings maintains low roughness, suitable for hardened steel, large curved molds, and high-transparency plastic molds.

Process Optimization Strategies Using Mold Milling Cutters and Tools

In high-precision mold machining, the selection and use strategies of cutting tools at different stages directly influence the final mold surface finish. Properly planning the division of labor for roughing, semi-finishing, and finishing tools improves processing efficiency. It also significantly enhances surface texture and mirror finish. By optimizing step size, feed rate, and tool posture, step marks can be minimized and uniform gloss improved, especially in five-axis mold finishing. Using high-performance mold milling cutters and precision mold milling tools from custom carbide or coated tool suppliers ensures cutting stability, extends tool life, and achieves efficient and consistent mirror-surface machining.

Tool Division and Strategy Matching in Roughing, Semi-finishing, and Finishing Stages

During roughing, large-diameter, high-rigidity tools are used for efficient material removal and uniform machining allowance, laying a solid foundation for finishing. In semi-finishing, medium-diameter, high-wear-resistant tools control cutting allowance while reducing tool marks and vibrations, creating ideal conditions for mirror polishing. Finishing employs small-diameter, high-precision mold milling tools with minimal cutting depth to achieve smooth surfaces and uniform texture. Throughout all stages, tool rigidity, edge accuracy, and wear resistance are critical factors in maintaining high-quality surface results.

Influence of Step Size and Feed Method on Mirror Surface Texture

Step size and feed method directly determine surface uniformity and gloss. Smaller step sizes effectively reduce step marks, while optimized feed rates limit heat buildup and vibration impact. In multi-channel machining, helical or staggered feed paths smooth tool marks and enhance mirror gloss. Matching the tool’s rotation direction, cutting direction, and material characteristics further improves surface flatness and visual quality at the microscopic level.

Influence of Tool Posture on Mirror Surface Quality in Five-Axis Machining

In five-axis machining, the tilt and swing posture of the tool significantly affect mirror surface quality. Properly adjusting the tool inclination angle reduces pressure concentration at the contact point, minimizing step marks and surface micro-undulations. Dynamic adjustment of tool posture ensures uniform cutting on complex curved surfaces and maintains high-quality surface finish. Combining high-precision mold milling cutters with advanced path-planning software enables exceptionally consistent mirror-like results while maintaining cutting efficiency.

Advantages and Application Points of Steel Mold Cutting Tools in Steel Mold Machining

In high-hardness steel mold machining, selecting the right cutting tool is critical for maintaining surface finish and machining efficiency. High-performance steel mold cutting tools maintain edge stability during high-speed cutting and high-temperature environments. They prevent surface scratches and microcracks while extending tool life. Through wear-resistant coatings and precision edge design, steel mold machining can significantly reduce manual polishing steps, achieving efficient and high-precision mirror-finish results. For complex curved surfaces or deep cavities, tool rigidity and thermal stability ensure uniform cutting, improve surface consistency, and provide reliable support for mold forming and downstream processing.

Thermal Stability Requirements in High-Hardness Steel Mold Machining

Hardened steel mold machining generates high temperatures that can lead to edge wear or deformation, affecting surface finish. High-rigidity steel mold cutting tools resist thermal deformation, maintaining a stable cutting state and producing flat, mirror-like surfaces even in deep cavities or complex curves. Combined with optimized cutting parameters and feed strategies, heat concentration is minimized, protecting the cutting edge and reducing vibrations that could degrade surface quality.

The Essential Role of Tool Heat Resistance and Wear Resistance in Steel Mold Mirror Machining

Wear-resistant coatings and high-performance carbide tools are key for steel mold machining. High wear resistance preserves edge sharpness during continuous cutting, reducing tool changes and maintaining machining consistency. Heat resistance keeps the cutting edge strong at elevated temperatures, preventing microcracks or burns from affecting the mold surface. By optimizing tool material and coatings, low roughness and high mirror gloss can be consistently achieved, providing reliable surface quality for mold forming.

Performance of Steel Mold-Specific Tools in Reducing Secondary Polishing

Steel mold-specific tools minimize tool marks and surface defects during machining, greatly reducing the need for manual polishing and secondary grinding. High-precision cutting tools, combined with optimized step sizes and feed rates, can complete most mirror-finish machining in a single pass, achieving uniform surface finish. In complex cavities and narrow grooves, the high rigidity and wear resistance of specialized tools maintain stability, shorten processing cycles, and improve production efficiency, while ensuring mirror-grade surface quality.

Customized Solutions Provided by Custom Carbide Mold Cutting Tool Suppliers

Standard tools often cannot meet the requirements of complex cavities or special mold materials. Customized carbide cutting tools are optimized for specific mold materials and precision requirements, improving efficiency and surface quality. Custom tools enhance geometric structure, edge treatment, and coating selection while improving cutting stability, reducing tool changes, and minimizing secondary processing steps. In mirror-grade mold machining, using customized tools shortens production cycles, reduces costs, and ensures consistent surface finish and dimensional accuracy, providing reliable support for high-end mold manufacturing.

Designing Tool Geometry Based on Mold Material and Accuracy Requirements

Different mold materials—steel, copper, aluminum—have varying hardness, toughness, and thermal conductivity, requiring tailored tool geometry. Adjusting rake angle, relief angle, edge radius, and tip shape reduces burrs and scratches while maintaining cutting stability. For high-precision machining, optimizing tool length and shank rigidity prevents vibration or deformation during deep cavity machining, improving mirror finish and surface consistency.

Tool Tolerance and Dynamic Balancing Control for Ultra-Precision Machining

In ultra-precision machining, tool tolerance and dynamic balance directly impact surface quality and cutting stability. Customized tools achieve smaller vibration amplitudes and uniform cutting force distribution through precision grinding, dynamic balance adjustment, and optimized coatings. This improves tool path consistency and surface flatness. In five-axis or multi-axis machining, this optimization reduces step marks and machining defects, achieving mirror-grade surfaces.

Advantages of Custom Tools in Mirror Surface Machining: Cycle Time and Cost Savings

Custom carbide cutting tools optimize edge wear resistance and cutting efficiency, reducing tool changes and preparation time, shortening the machining cycle. Compared to standard tools, custom tools are more stable and reliable for complex curves, deep cavities, and high-hardness materials, reducing secondary polishing and manual finishing costs. Longer tool life and higher machining accuracy allow manufacturers to optimize both production costs and time while maintaining mirror-quality surfaces.

Machining Parameters and Operational Key Points for Achieving Mirror Surface Effects

Besides selecting proper tools, machining parameters and operational strategies are decisive for final surface quality. Proper spindle speed, feed rate, and tool path planning reduce surface roughness, while cooling and lubrication control cutting heat and prevent microcracks and tool marks. Tool wear monitoring and timely replacement are essential for maintaining consistent quality. Optimizing these operational points ensures uniform mirror-like gloss while maintaining machining efficiency.

Coordinated Control of Spindle Speed, Feed Rate, and Tool Path

Spindle speed, feed rate, and tool path must be coordinated for high-gloss surfaces. Higher spindle speeds reduce force fluctuations but must match feed rates to prevent tool marks and vibrations. Helical or parallel tool paths evenly remove material, minimizing step marks. In complex surfaces, five-axis linkage can adjust tool posture, optimizing cutting angles and achieving smooth transitions with uniform gloss.

The Impact of Cooling Methods and Lubrication Strategies on Surface Brightness

Cutting heat and friction affect surface finish. Appropriate cooling and lubrication methods are essential. Oil mist, minimum quantity lubrication, or water-soluble coolants are selected based on material and stage. Proper lubrication reduces cutting temperature, prevents tool wear, and avoids micro-scratches, improving mirror consistency. In deep cavities or high-hardness steel, precise coolant flow and spray angles further enhance surface flatness and gloss.

The Necessity of Tool Life Monitoring and Timely Replacement

Tools wear over time, and dull or microcracked edges can cause defects and increased roughness. Regular monitoring, parameter adjustments, and timely tool replacement ensure stable machining. High-wear-resistant tools’ condition directly affects surface consistency and gloss, reducing rework and improving efficiency in precision mirror-surface machining.

Common Problems and Solutions in Mirror-Grade Mold Machining

In high-precision mold machining, even when using high-quality tools and optimized machining parameters, issues such as insufficient surface finish, localized whitening, or burning may still occur. These problems often stem from tool wear, poor tool path planning, machining vibrations, excessive cutting heat, or difficulties in machining special areas.

By systematically analyzing the machining process—including tool selection, geometry, coating performance, machining parameters, cooling, lubrication, and five-axis tool posture—these common problems can be effectively resolved. This approach ensures uniform mirror gloss and stable machining quality. For challenging areas such as steel molds, hardened molds, complex curved surfaces, and deep cavities, combining custom carbide tools with precise tool management can significantly reduce secondary polishing, improve efficiency, and enhance reliability.

Causes and Solutions for Uneven Surface Texture

Uneven surface texture usually results from tool wear, insufficient or excessive cutting path overlap, vibrations, and inadequate tool rigidity. To address these issues, select wear-resistant coated tools, optimize tool geometry, and adjust the five-axis machining posture. Reasonably plan the tool path and fine-tune step size and feed rate to achieve even material removal and reduced surface roughness. In complex curves or deep cavities, using custom tools with optimized cutting strategies effectively eliminates uneven textures, producing mirror-grade surfaces with consistent gloss.

Key Parameter Adjustments for Surface Whitening and Burning

Surface whitening or burning is often caused by excessive cutting heat or insufficient cooling and lubrication. Adjusting spindle speed, feed rate, and cutting depth, combined with the use of oil mist, minimum quantity lubrication, or water-soluble coolant, can reduce cutting temperatures and prevent microcracks or material oxidation. In high-hardness steel molds or hardened molds, combining heat-resistant and wear-resistant tools with properly tuned cutting parameters improves surface brightness and consistency while maintaining stable machining.

Causes of Poor Mirror Finish in Corner Areas and Tool Selection

Corners, tight radius, and deep cavities often show poor mirror finish due to insufficient tool diameter, low rigidity, or improper cutting posture. Solutions include selecting precision tools suited to the specific geometry, adjusting tool shape and edge rounding, optimizing five-axis machining angles, and using custom tools designed for special machining positions. Implementing these strategies improves corner flatness, reduces manual polishing, and achieves an overall uniform mirror finish.