Avoiding chip welding during aluminum cutting is critical for improving the stability and quality of CNC aluminum cutting. Due to aluminum’s high ductility and low melting point, high-speed CNC cutting of aluminum is more prone to chip adhesion, which can result from heat concentration, poor chip evacuation, or improper tool selection. This adhesion can negatively affect dimensional accuracy, surface finish, and tool life. Therefore, in practical production, reducing the risk of chip welding through proper selection of aluminum cutting tools, optimizing cutting parameters, improving cooling and lubrication, and maintaining machine and fixture stability is essential for smoother and more efficient aluminum part processing.

For industrial buyers or overseas purchasers seeking consistent production capacity, choosing a CNC aluminum cutting supplier with proven process experience is also important. Professional suppliers can provide parameter guidance tailored to different aluminum alloys and offer effective chip evacuation strategies along with tool recommendations based on long-term practice. This ensures a more controllable machining process while minimizing rework and downtime. By comprehensively optimizing machining conditions and leveraging industry-proven expertise, stable quality and high-efficiency production of aluminum parts can be achieved.

Core Factors Influencing Chip Welding Problems in Aluminum Processing

During aluminum cutting, high-speed friction and rapid heat buildup occur between the tool and the material. Insufficient heat dissipation or blocked chip evacuation paths can lead to chip adhesion. This not only reduces surface finish but can also destabilize equipment operation and even lead to premature tool failure. Slight deviations in tool geometry, insufficient chip groove design, or imbalance between cutting speed and feed rate can cause chips to accumulate on the cutting edge, forming an adhesive layer. Understanding these key factors is critical for establishing a stable, controllable aluminum machining process, especially for high-speed operations, mass production, or long-duration cutting.

Adhesion Caused by Aluminum Properties and Heat Accumulation

Aluminum’s softness, high ductility, and rapid heat conductivity make it seemingly easy to machine. However, under high feed rates or heavy material removal, local temperatures can rise quickly. If the cutting edge is not sharp or heat dissipation is inadequate, chips can stick to the tool, forming a secondary cutting edge that alters the tool geometry. This leads to scratches, burrs, or dimensional errors on the workpiece surface. High-speed aluminum machining of thin-walled parts, deep cavities, or precision components is particularly susceptible to these issues.

Tool Geometry and Insufficient Chip Evacuation

Tool geometry—rake angle, relief angle, chip groove depth, and edge sharpness—directly impacts chip removal efficiency. Poor chip evacuation can cause chips to rub repeatedly against the cutting edge, increasing temperature and promoting adhesion. This is especially true for general-purpose tools or tools with narrow chip grooves, which struggle to handle aluminum’s light, sticky chips. As the tool wears, cutting forces rise, further increasing the likelihood of chip buildup, which can severely affect machining efficiency and surface quality.

Chip Accumulation from Improper Cutting Parameters

Cutting speed, feed rate, and depth of cut significantly influence chip flow. Low speed can create incomplete cuts, causing chips to clump near the tool edge; low feed rate produces sticky, poorly formed chips; excessive cutting depth increases friction and local heat. In high-efficiency operations, such as continuous or high-speed aluminum removal, improper parameter settings can lead to curled chips adhering to the tool, destabilizing machining results. Proper tool paths and parameter matching reduce chip accumulation and improve cutting smoothness.

Reducing Tool Adhesion Risk by Optimizing Cutting Parameters

Cutting parameter settings critically affect chip evacuation and tool stability. Imbalanced spindle speed, feed rate, or cutting load can quickly lead to heat buildup and chip adhesion. By carefully adjusting spindle speed, feed rate, depth of cut, and side cutting amount, adhesion risk is minimized, surface quality improves, and tool life is extended. Accurate parameter tuning is particularly important for high-speed, high-volume, or continuous operations, enhancing stability and reducing rework.

Matching Spindle Speed and Feed Rate

Balancing spindle speed and feed rate is crucial. Excessive speed with low feed generates fine, sticky chips; high feed with low speed increases cutting load, destabilizing chip flow. Moderate feed at higher spindle speeds typically produces continuous, easily evacuated chips. Thin-walled parts, deep cavities, and precision components especially benefit from synchronized parameter adjustments to maintain stable cutting forces and prevent localized overheating.

Impact of Cutting Depth and Side Cutting Amount

Depth and side cutting amount determine load per tool path and affect chip volume and pressure in the evacuation zone. Excessive depth or side cutting width can trap chips, creating local high temperatures and promoting adhesion. Multi-pass strategies and controlled cutting loads facilitate smooth chip evacuation, particularly for long cavities or narrow grooves.

Stable Strategies for High-Speed CNC Aluminum Cutting

In high-speed aluminum cutting, stability is key. Slight parameter imbalances can accelerate chip buildup near the cutting edge. Ensuring tool sharpness, adequate chip flute volume, and effective lubrication, while maintaining efficient spindle speed and feed, reduces the risk of adhesion. Optimized tool paths balance cutting forces and prevent localized overheating, supporting high surface quality and smooth chip evacuation even under continuous, high-speed conditions.

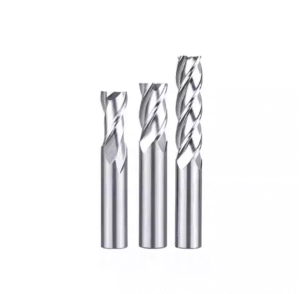

Improving Machining Stability with Suitable Aluminum Cutting Tools

In high-precision aluminum machining, selecting the right tools directly affects cutting performance and overall machining efficiency. A well-designed tool not only reduces chip welding but also improves surface finish and maintains stability throughout the process. Sharp cutting edges and tools with large rake angles lower cutting resistance, allowing chips to evacuate smoothly and preventing accumulation or overheating. In addition, matching the tool material and coating with the aluminum alloy is critical. High-speed CNC aluminum cutting requires tools with high wear resistance and anti-adhesion properties. Using the right coating extends tool life while maintaining cutting accuracy. Furthermore, specialized tools with optimized chip flute designs and carefully planned tool paths ensure continuous and stable machining, particularly under long-term or high-load conditions. These measures effectively minimize chip welding risk and improve overall production efficiency.

The Importance of Choosing Sharp Cutting Edges and Tools with Large Rake Angles

In CNC aluminum cutting, sharp cutting edges significantly reduce cutting resistance and heat buildup, which helps prevent chip welding. Tools with large rake angles improve chip evacuation and reduce cutting forces, maintaining surface quality and dimensional accuracy. This combination is particularly beneficial for high-speed operations and machining complex-shaped aluminum parts. As a result, machining defects are minimized, and the consistency of CNC aluminum cutting processes is enhanced.

Considerations for Tool Material, Coating, and Compatibility with Aluminum

Different aluminum alloys have unique requirements for tool hardness, wear resistance, and anti-adhesion performance. When using high-speed steel, carbide, or coated tools, it is essential to select the appropriate coating based on the material’s characteristics. Coatings like TiAlN or DLC can reduce cutting heat and prevent chip welding, extending tool life and improving machining stability. This is especially important in long-term, high-volume CNC aluminum cutting operations, ensuring smooth and efficient production.

Tool Path and Chip Flute Design Specifically for CNC Aluminum Cutting

Optimized tool paths combined with properly designed chip flutes significantly improve chip flow and prevent entanglement or blockage. Strategies such as helical cutting or multi-directional feeds, along with the flute design of specialized aluminum cutting tools, ensure smooth chip evacuation and reduce tool temperature buildup. This not only minimizes chip welding but also maintains machining accuracy and surface finish during high-speed CNC aluminum cutting. As a result, overall production efficiency and reliability are enhanced.

Improving Heat Dissipation and Lubrication to Reduce Tool Adhesion

In high-precision aluminum machining, excessive temperatures in the cutting zone are a key factor leading to tool adhesion and chip accumulation. By implementing effective heat dissipation and lubrication strategies, frictional heat between the tool and the workpiece can be significantly reduced. This helps maintain machining stability and ensures consistent surface quality. Selecting suitable cooling methods, optimizing coolant spray position and flow rate, and combining these with proper lubrication techniques not only extend tool life but also enhance machining efficiency and safety. Particularly in high-speed CNC aluminum cutting or mass production, managing heat dissipation and lubrication is crucial for keeping the process stable.

Coolant Spray Method and Flow Rate Control

The angle and flow rate of coolant sprays directly affect the temperature distribution in the cutting zone. Precisely directing the coolant to the tool tip and chip evacuation area reduces heat accumulation, minimizing chip welding. Proper flow rate control prevents excessive coolant waste or insufficient cooling, maintaining a stable temperature for continuous aluminum CNC cutting.

Application of Lubrication Methods such as MQL, Air Cooling, and Oil Mist

Different lubrication methods offer unique advantages. MQL provides localized lubrication without excessive coolant accumulation. Air cooling is ideal for high-speed or thin-walled part machining, quickly removing cutting heat. Oil mist lubrication reduces friction on the tool surface and helps chips evacuate smoothly. Selecting the appropriate method based on part geometry, cutting depth, and CNC aluminum cutting speed ensures stable and efficient machining.

Practical Measures to Reduce Temperature Fluctuations

Beyond optimizing cooling and lubrication, cutting parameter adjustments can stabilize the temperature. Distributing the cutting load evenly, avoiding sudden changes in feed rate or cutting depth, and optimizing tool paths all help maintain smooth operations. Regularly clearing chips to prevent obstruction in the cutting zone also helps keep temperatures uniform. Combined with high-performance tools and precise control strategies, these measures minimize chip welding and improve reliability in CNC aluminum cutting.

Influence of Workpiece Clamping and Equipment Condition on Chip Evacuation

The stability of the workpiece and machine condition directly determines the efficiency of chip evacuation. Unstable clamping or machine vibration can cause force fluctuations, leading to chip accumulation and higher risk of tool adhesion. Optimizing fixture design, ensuring machine rigidity, and regularly maintaining key components enhances chip removal efficiency and reduces secondary cutting or recutting. In high-speed or complex CNC aluminum cutting, reliable fixturing and machine condition are essential for maintaining dimensional accuracy, surface finish, and overall production efficiency.

The Stabilizing Role of Rigid Clamping Systems

High-rigidity clamping minimizes vibrations and micro-movements, keeping the tool on its intended path. Stable clamping supports smooth chip evacuation, improves surface finish, and prevents premature tool wear or adhesion. Multi-point or custom fixtures are particularly effective for thin-walled or complex parts, enhancing continuous CNC aluminum cutting reliability.

Maintenance Essentials for Machine Guides, Spindle, and Chip Evacuation Systems

Maintaining guide and spindle accuracy is critical for stable cutting. Wear or poor lubrication can cause uneven cutting forces, impairing chip removal. Regular inspection and cleaning of chip evacuation channels prevent accumulation and reduce tool adhesion. Maintaining spindle lubrication and controlling temperature further supports consistent CNC aluminum cutting performance.

Tool Path Design Optimization to Avoid Secondary Chip Cutting

Suboptimal tool paths can cause repeated chip cutting, increasing friction, temperature, and adhesion risk. Optimizing feed direction, cutting sequence, and using helical or segmented strategies allows efficient chip removal. Tailoring tool paths to CNC aluminum cutting conditions improves efficiency, surface quality, and extends tool life.

Optimizing Aluminum Cutting Processes from a Factory Operations Perspective

In actual production, the efficiency and stability of aluminum machining depend not only on equipment and tools but also on process management and operating procedures. By scientifically planning processing sequences, optimizing transitions, and monitoring cutting conditions, chip adhesion can be effectively minimized. This ensures improved dimensional accuracy and surface finish. In mass production, rationally arranging tool usage and reducing downtime and tool change time further enhances overall productivity. For CNC aluminum cutting, closely integrating process optimization with practical operations is key to achieving stable and efficient machining while minimizing tool wear.

The Importance of Surface Cleaning and Pre-treatment of Aluminum

If the aluminum surface contains oil, oxide films, or other impurities, it can directly affect cutting smoothness and tool life. Cleaning the surface, removing oxide layers, or lightly sanding before machining ensures smooth tool entry, easy chip removal, and prevents localized heat accumulation. This pre-treatment is especially important for high-precision parts and high-speed CNC aluminum cutting, significantly improving processing consistency and surface quality.

Monitoring Strategies for Batch Processing and Long-Term Cutting

During continuous or mass production, tool wear, machine temperature fluctuations, and chip accumulation are common issues. Real-time monitoring of spindle load, cutting temperature, and chip evacuation allows timely adjustment of parameters or tool replacement. Establishing a standardized monitoring protocol ensures stable CNC aluminum cutting and improves overall production efficiency.

Process Adjustment Methods to Reduce Downtime and Tool Changes

Optimizing process transitions, rational tool arrangements, and presetting tool parameters can greatly reduce downtime and minimize the impact of frequent tool changes. Multi-station fixtures or automatic tool changers enable rapid tool swaps without halting production. Combining this with optimized tool paths and tool life management enhances continuous machining performance and reduces factory operating costs in CNC aluminum cutting.

Key Points for Choosing a Professional CNC Aluminum Cutting Supplier in B2B Procurement

Selecting a reliable supplier is critical for B2B aluminum part procurement, impacting product quality, production efficiency, and cost control. Professional suppliers typically offer comprehensive processing capabilities, mature chip removal and anti-adhesion strategies, and a robust quality management system. Evaluating a supplier’s expertise in tool application, parameter optimization, and technical support ensures efficient and stable aluminum cutting. A supplier’s delivery reliability and mass production experience are also crucial, guaranteeing a continuous supply of high-quality CNC aluminum parts, reducing production interruptions, and lowering additional costs.

Supplier’s Capabilities in Preventing Tool Adhesion

Experienced suppliers can develop tailored tool selection, cutting parameters, and chip removal strategies for different aluminum alloys. Through scientific process design and equipment calibration, they reduce the risk of tool adhesion, chip accumulation, and excessive heat. This capability is vital for high-speed CNC aluminum cutting and complex part machining, ensuring consistent dimensional accuracy and surface quality.

Technical Support and Parameter Guidance from Suppliers

Professional CNC aluminum cutting suppliers provide high-performance tools along with detailed guidance on tool parameters, processing strategies, and path optimization. This support allows customers to achieve optimal cutting conditions, reduce tool wear, and maintain continuous efficient machining. Such technical guidance is particularly valuable in mass CNC aluminum cutting or custom part production, minimizing trial-and-error costs and improving overall productivity.

Evaluating Consistent Delivery of High-Quality CNC Aluminum Parts

Reliable delivery is a core indicator of supplier trustworthiness, encompassing equipment condition, process maturity, and quality management. Standardized workflows, parameter optimization, and real-time monitoring ensure dimensional accuracy, surface finish, and material consistency in each batch. For B2B companies, long-term partnerships with such suppliers secure a consistent, high-quality supply of CNC aluminum parts, supporting downstream production stability and overall operational efficiency.

Comprehensive Practical Suggestions for Preventing Tool Adhesion

Tool adhesion significantly impacts machining efficiency and part quality. By optimizing tool selection, cutting parameters, lubrication methods, and on-site processing management, adhesion risk can be greatly reduced, enabling efficient and stable CNC aluminum cutting. Sharp cutting edges, large rake angle tools, and appropriate wear-resistant coatings ensure smooth cutting and extended tool life. Coordinated spindle speed, feed rate, cutting depth, and side cutting, combined with lubrication methods such as coolant or oil mist, help control cutting zone temperature and facilitate chip evacuation. Ensuring workpiece clamping stability, regular machine maintenance, optimized tool paths, and batch monitoring further improves continuous machining performance and product consistency. Partnering with professional suppliers with mature processes and technical support guarantees long-term access to high-quality CNC aluminum parts. Together, these strategies form a systematic anti-adhesion approach that improves machining efficiency, reduces production costs, and ensures part accuracy.

Coordinated Optimization of Tools, Parameters, and Lubrication

Maximizing cutting stability requires combining sharp, large rake angle tools with optimized speed, feed, and cutting depth. MQL, oil mist, or air cooling further reduce cutting temperature and minimize adhesion between the tool and aluminum material. This coordinated approach ensures continuous, high-quality CNC aluminum cutting.

Troubleshooting Common Machining Problems

Tool wear, chip accumulation, machine vibration, and insufficient cooling are frequent causes of tool adhesion. Systematically inspecting workpiece clamping, machine condition, coolant spray, and tool paths helps identify root causes. Regular maintenance and timely chip removal maintain stable cutting zone temperatures, enhancing CNC aluminum cutting reliability.

Parameter Adjustment for Different Aluminum Alloys

Different aluminum alloys require tailored cutting parameters, tool selection, and lubrication strategies. Harder or more adhesive alloys benefit from reduced feed rates, higher spindle speeds, and anti-adhesion coated tools. Softer alloys allow deeper cuts and higher feed rates. Adjusting parameters by alloy grade maximizes tool life, improves surface quality, and reduces adhesion, achieving efficient and stable CNC aluminum cutting.