Drilling hardened steel is one of the most demanding operations in metalworking. Due to its extreme wear resistance and deformation resistance—especially in materials reaching HRC65 standard drill bits are likely to become dull, chip, or even break during operation. For this reason, choosing the right drill bits for hardened steel is essential for improving drilling efficiency and extending tool life.

In practice, successful drilling of hardened steel requires proper selection of drill bit material, coating, cutting speed, feed rate, and cooling method. For extremely hard workpieces, using a dedicated HRC65 drill bit or custom drill bits for hardened steel from a reliable supplier is often necessary to ensure stable and precise machining.

In addition, mastering the correct drilling techniques is equally important. Pre-drilling pilot holes, using step drilling, and maintaining adequate cooling can significantly reduce heat generation and friction, helping prevent tool damage and ensuring stable hole quality.

Core Challenges When Drilling Hardened Steel

Machining hardened steel is far more difficult than working with carbon steel or low-alloy steel. Its high wear resistance and strength increase cutting resistance, making the drilling process more prone to heat buildup, friction, and accelerated tool wear. Because hardened steel requires greater cutting force, improper drilling parameters may lead to reduced stability or even catastrophic drill bit failure. To maintain accuracy and extend tool life, selecting the right tool material and coating—combined with optimized rotational speed and feed rate—is crucial for efficient drilling.

The High Hardness and Machining Difficulties of Hardened Steel Materials

Hardened steel commonly reaches a hardness level of HRC50 and above, with certain tool steels achieving HRC65. High hardness makes chip formation more difficult, increasing the likelihood of chip packing, heat accumulation, and cutting instability. When the drill bit engages a hard surface, it must withstand significantly higher axial and radial forces. If the drill bit geometry or material is not suitable, chipping or edge deformation can occur, reducing machining accuracy. Using carbide or coated drill bits—combined with pilot drilling and segmented drilling—can effectively reduce cutting difficulty.

The Impact of High Temperature on Drill Bit Life

Excessive heat during drilling is one of the main causes of tool wear. The higher cutting resistance of hardened steel leads to rapid temperature rise, which can soften the cutting edge, cause abrasive wear, or even create microcracks. Adequate cooling, controlled cutting speeds, and avoiding prolonged friction can significantly extend tool life and maintain drilling stability.

Common Failure Modes of Ordinary Drill Bits in Drilling Hardened Steel

Standard high-speed steel or uncoated drill bits typically fail quickly when drilling hardened steel. Common failures include cutting-edge chipping, uneven tip wear, flute clogging, and thermal softening. These issues not only reduce efficiency but can also cause poor surface finish and unstable hole diameters. For high-hardness steel, drill bits with specialized heat treatment or advanced coatings—and in some cases, fully customized drill bits—are required to ensure safe, consistent drilling.

Choosing the Right Drill Bit Type

When drilling high-hardness steel, the drill bit’s material and geometry directly influence machining efficiency and hole accuracy. Different drill bit materials and coatings vary widely in wear resistance, heat resistance, and cutting performance. Selecting the right drill bit helps minimize tool wear, maintain dimensional accuracy, and improve productivity while reducing tooling costs. In real applications, the choice should be based on steel hardness, hole size, production volume, and cooling capability.

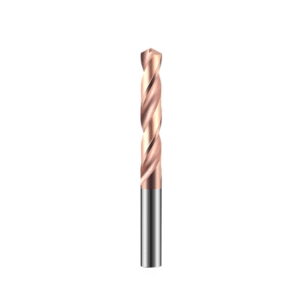

Advantages and Precautions for Using Carbide Drill Bits in Hardened Steel

Carbide drill bits excel in hardened steel applications due to their high hardness and wear resistance. They maintain a sharp cutting edge under high-temperature conditions, helping reduce hole size deviation and improve surface finish. However, they are also more brittle than other materials. Proper cooling, moderate cutting speeds, and controlled feed rates are essential to prevent thermal cracking. When drilling deep holes or using high-speed drilling, pilot holes and segmented feed are highly recommended for optimal performance.

Applicability and Cost-Effectiveness of Cobalt Steel Drill Bits

Cobalt drill bits provide a cost-effective option for drilling medium-hard hardened steel, particularly in small- to medium-batch production. They offer higher toughness and can withstand more vibration without chipping. However, they may not perform well in extremely hard materials such as HRC65 steel. Adjusting cutting speeds, using proper lubrication, and monitoring wear can significantly improve performance and extend tool life.

Performance of HRC65 Drill Bits in Machining Extremely Hard Materials

For extremely hard materials, HRC65 grade drill bits deliver superior wear resistance and cutting stability. They maintain sharp edges even under heavy loads, helping control drilling deviation and maintain accurate hole diameters. However, precise control of drilling speed, feed rate, and cooling is critical. These drill bits are widely used in aerospace components, mold manufacturing, and precision tooling industries.

When to Choose Custom Drill Bits for Hardened Steel Suppliers

When standard drill bits fail to meet the required accuracy, depth, or material hardness, custom drill bits become the best solution. A specialized supplier can design drill bits tailored to the workpiece material, drilling depth, hole tolerance, and cutting environment. Custom tools often include advanced carbide blends and multilayer coatings that provide exceptional performance in extreme conditions—especially when drilling steel at HRC65 or above.

Key Machining Parameters Affecting Drilling of Hardened Steel

Cutting parameters play a crucial role in determining drilling accuracy, efficiency, and tool life. Cutting force, heat generation, and chip evacuation are closely tied to rotational speed, feed rate, and drilling depth. Improper parameter settings may lead to rapid tool wear, chipping, poor surface finish, or oversized holes. Optimizing these parameters—especially when using HRC65 or custom drill bits—can significantly reduce machining difficulty and improve overall efficiency.

Controlling Rotational Speed to Avoid Burning

Excessive rotational speed increases frictional heat, raising the temperature of the cutting edge and causing burning, softening, or micro-cracks. This is particularly critical for carbide and HRC65 drill bits. Maintaining a controlled cutting speed and applying sufficient cutting fluid helps reduce heat generation, preserve edge sharpness, and improve hole quality.

The Impact of Feed Rate Settings on Cutting Stability

Feed rate strongly affects cutting stability and chip evacuation. Too low a feed rate increases rubbing and heat, accelerating edge wear; too high a feed rate increases cutting load and may cause tool deflection or chipping. Selecting the appropriate feed rate based on tool material and hole size—and using segmented feeding for deep holes—can improve machining stability and ensure consistent performance.

Selecting the Appropriate Cutting Depth and Segmented Drilling Method

Excessive cutting depth increases heat and cutting resistance, which can lead to tool breakage or unstable hole diameters, especially in hardened steel. Segmented drilling reduces load by removing material gradually, improving chip evacuation and reducing heat buildup. Choosing a suitable cutting depth based on tool capability and material hardness helps maintain tool life and ensure accurate hole geometry.

Cooling and Lubrication Strategies

Heat management is critical when drilling hardened steel. Proper cooling reduces cutting temperature, minimizes edge wear, improves chip evacuation, and stabilizes hole dimensions. Different cooling and lubrication methods—liquid, high-pressure, spray, or gas—offer different performance characteristics. Selecting the appropriate method based on material hardness, drill bit material, and hole depth is essential for consistent performance.

How to Choose a Cooling Method for Drilling Hardened Steel

The cooling method must align with drilling depth, material hardness, and heat generation. Liquid coolant offers efficient heat removal, while air or mist cooling is suitable for shallow holes or light-duty operations. For HRC65 and similar materials, concentrated liquid cooling or high-pressure coolant is often necessary to control temperature and prevent thermal cracking.

Differences Between Oil-Based Coolants and High-Pressure Cooling

Oil-based coolants provide excellent lubrication, helping reduce friction and cutting load, making them suitable for small to medium hole sizes. However, they dissipate heat more slowly. High-pressure coolant systems deliver strong jet flow that improves heat removal and chip evacuation, making them highly effective for deep holes or extremely hard materials.

Techniques for Reducing High Temperatures and Increasing Drill Bit Life

Temperature control is essential for extending tool life when drilling hardened steel. Key strategies include segmented drilling, reducing cutting speed, optimizing feed rate, and ensuring continuous coolant flow. Regular inspection of tool wear and timely resharpening help prevent edge deterioration. Combining these techniques with high-performance HRC65 or custom drill bits ensures consistent drilling quality and long tool life in high-hardness applications

Techniques for Ensuring Drill Bit Stability

Stability has a decisive impact on hole accuracy, surface finish, and tool life when machining high-hardness steel. Even when using high-performance HRC65 drill bits or custom-designed tools, issues such as vibration, runout, or insufficient rigidity can lead to hole deviation, accelerated wear, and workpiece damage. By optimizing clamping methods, controlling drilling conditions, and applying effective pre-positioning techniques, drilling stability can be significantly improved, ensuring both machining efficiency and consistency.

How to Reduce Runout to Improve Drilling Accuracy

Runout increases cutting resistance, reduces dimensional accuracy, and accelerates edge wear. To minimize runout, use a high-rigidity drill chuck system and ensure proper radial concentricity before drilling. It is also important to check for drill wear and replace damaged tools before starting the operation. When machining hardened steel at HRC65 and above, segmented drilling and pre-drilling techniques help distribute cutting forces more evenly, improving straightness and overall hole stability.

The Importance of Fixture and Workpiece Clamping Methods

Proper clamping dramatically reduces vibration and helps maintain drilling accuracy. When machining high-hardness steel, fixtures must provide adequate rigidity and should support the workpiece as close as possible to the drilling point. This prevents displacement caused by uneven forces. Auxiliary supports and positioning devices further enhance stability, especially when using HRC65 drill bits or custom drills for deep holes or complex workpiece geometries.

The Necessity of Pre-positioning or Spotting Before Machining

Pre-positioning—such as center drilling or spotting—provides a stable entry point for the drill bit, reducing sliding and eccentricity. This is particularly important when using precision custom drills or high-performance tools for HRC65 steel. Proper pre-positioning minimizes the risk of edge chipping caused by concentrated cutting forces. Combined with suitable cutting parameters and effective cooling and lubrication, this step plays a crucial role in ensuring high-accuracy hole machining.

Practical Steps for Drilling High-Hardness Steel

Drilling high-hardness steel is a demanding process that involves multiple stages, including workpiece preparation, drill bit selection, parameter adjustment, and cooling management. Even with HRC65 drill bits or custom-made tools, improper steps can lead to accelerated wear, dimensional deviations, or poor surface quality. Following a systematic drilling procedure reduces machining risks, improves efficiency, and extends tool life.

Preparation and Surface Treatment Before Drilling

Proper surface preparation ensures a stable start to the drilling process. Cleaning the workpiece to remove scale, burrs, and oil improves drill engagement and minimizes vibration. Selecting a pre-drilled guide hole or marking the drilling position according to the material hardness helps establish an accurate entry point, particularly when machining steel rated at HRC65 or higher. Proper fixturing and checking the drill bit’s edge condition are also essential to ensure smooth and precise machining.

Operating Procedures to Follow When Drilling Hardened Steel

Begin drilling with a low-speed pilot hole, then gradually increase the cutting depth using a segmented drilling method. This prevents excessive heat buildup and reduces the risk of edge chipping. Cutting speed and feed rate must be carefully controlled, and oil-based or high-pressure coolant should be used to maintain thermal stability. Smooth chip evacuation and periodic cleaning of debris around the hole are crucial. Monitoring drill wear throughout the process ensures reliable performance from both HRC65 drill bits and custom-made tools.

Adjustment Methods for Different Hardness Levels

Cutting parameters must be adjusted based on the hardness of the material.

-

For moderately hardened steel, cutting speed and feed rate can be increased to enhance productivity.

-

For extremely hard materials (HRC65+), spindle speed should be reduced, cutting depth minimized, and segmented drilling used to reduce heat accumulation and cutting force.

Selecting the right drill bit material and coating based on hardness requirements helps extend tool life and maintain hole accuracy and consistent surface finish.

Common Problems and Troubleshooting During High-Hardness Steel Machining

Even when using high-quality HRC65 drill bits or custom-designed tools, issues such as rapid wear, diameter inconsistencies, and poor surface finish may arise. These problems are often linked to improper parameters, insufficient cooling, tool instability, or operator error. With systematic troubleshooting and targeted adjustments, these issues can be resolved effectively, ensuring stable machining performance.

Treatment Methods for Drill Bit Blackening, Smoking, and Overheating

Blackening or smoke indicates excessive heat in the cutting zone, usually caused by high spindle speed, insufficient coolant flow, or forced cutting. Solutions include reducing rotational speed, appropriately increasing feed rate, or switching to a high-efficiency oil-based coolant with high-pressure delivery. Segmented drilling and regular chip clearing help further prevent thermal overload. These measures extend tool life while maintaining stable drilling accuracy.

Causes of Drill Bit Chipping and Breakage and Corresponding Solutions

Chipping or breakage typically results from excessive cutting force, misaligned drilling, or using tools unsuitable for ultra-hard materials. When machining steel at HRC65 or higher, excessive depth per pass or off-center drilling can easily damage the cutting edge. Solutions include selecting high-performance carbide or custom drill bits, optimizing cutting parameters, using segmented drilling, and ensuring stable clamping of both the drill bit and the workpiece to prevent tool failure.

Troubleshooting Methods for Unstable Hole Diameter or Poor Surface Quality

Hole diameter instability or rough surface finish often stems from drill runout, incorrect parameters, inadequate coolant supply, or chip packing. Troubleshooting steps include checking drill sharpness and concentricity, verifying spindle speed and feed settings, and ensuring proper coolant delivery. Improving chip evacuation and monitoring drill wear help restore hole accuracy and surface quality, ensuring stable tool performance when drilling high-hardness steel.

How to Extend the Lifespan of Drill Bits for Hardened Steel

Drilling hardened steel requires exceptional wear resistance and thermal stability from the tool. Even advanced HRC65 or custom drill bits can experience rapid degradation if not properly maintained. Through correct sharpening, proper storage practices, and timely replacement or upgrading, tool lifespan can be significantly improved, reducing machining costs and ensuring consistent performance.

Correct Sharpening and Maintenance Methods

Maintaining a sharp cutting edge is critical for preserving drill bit performance. For hardened steel applications, sharpening should be done using precision grinding equipment to maintain accurate geometry and edge angles. Regular inspection for micro-cracks, burns, or coating damage allows for timely corrective action. Combined with well-controlled cutting parameters and proper cooling, these practices help delay tool degradation and ensure stable machining of high-hardness steel.

Appropriate Storage and Cleaning Procedures

Cleaning and storing drill bits correctly has a direct impact on tool longevity and machining results. After machining, chips, oil, and coolant residues must be thoroughly removed to prevent corrosion or oxidation. Drill bits should be stored in a dry, temperature-stable environment, and protected from contact that may cause edge damage. For tools used across multiple production cycles, individual compartments or protective cases ensure that carbide or custom drill bits retain their precision and sharpness for future use.

When to Replace or Upgrade Drill Bits

Despite proper maintenance, drill bits showing severe wear, chipped edges, increased dimensional deviation, or reduced drilling efficiency should be replaced or upgraded. For extremely hard materials such as HRC65 steel, custom high-performance drills often provide superior durability and stability compared with standard tools. Regular evaluation of tool condition and establishing replacement intervals based on production volume and part requirements help minimize downtime and maintain consistent hole quality.

Choosing a Reliable Supplier of Custom Drill Bits for Hardened Steel

Selecting a dependable supplier is critical when machining high-hardness steel, especially materials rated at HRC65 and above. Even with optimized procedures and careful parameter control, poor-quality tools can still lead to chipping, wear, and hole instability. Working with a professional supplier ensures access to high-performance drills designed specifically for hardened steel, along with technical support and customized solutions that improve machining safety and efficiency.

Supplier’s Expertise in Drilling Hardened Steel

A qualified supplier provides drill bit materials, geometries, and coatings tailored to hardened steel applications. They understand the cutting characteristics of ultra-hard materials and can recommend suitable solutions based on hole size, tolerance requirements, and production volume. Their expertise helps prevent common machining problems such as overheating, chipping, and diameter variation, improving overall tool stability and service life.

Advantages of Custom Drill Bits in Difficult Machining Applications

Custom drill bits offer advantages in wear resistance, thermal stability, chip evacuation, and resistance to chipping, especially for deep-hole or special geometry applications. Designed to meet specific hardness levels and machining challenges, custom tools outperform standard drills when machining high-hardness steel. When combined with optimized parameters, effective cooling strategies, and proper fixturing, they ensure stable hole dimensions, improved surface quality, and increased productivity.

How to Evaluate a Supplier’s Product Quality and Stability

When evaluating a supplier, focus on drill material quality, heat-treatment consistency, and coating technology. Assess their customization capabilities for materials rated at HRC65 or above, and examine their quality management system, delivery reliability, and technical support resources. Conducting small-batch trials or reviewing real machining cases helps verify whether the drills maintain precision, efficiency, and long service life under demanding machining conditions. A reliable supplier ensures consistent tool performance while reducing overall machining risks.