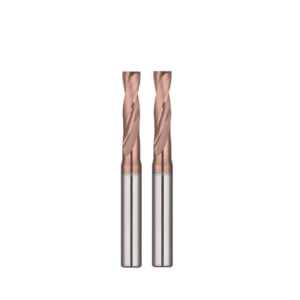

In the metalworking industry, identifying high-quality carbide bits for metal is essential for maximizing machining efficiency, achieving superior surface finish, and extending tool life. High-performance carbide tools not only maintain stable performance under heavy cutting conditions but also reduce wear, lower machining costs, and ensure consistency in large-scale production. Many manufacturers, when selecting metalworking carbide tools or carbide cutting tools for metal, often overlook critical factors such as base material quality, cutting edge geometry, coating integrity, and the expertise of the manufacturer, which can lead to suboptimal machining results.

Evaluating a tool’s performance requires attention to the carbide matrix quality, cutting edge design, coating uniformity, and real-world cutting results. Partnering with a reliable carbide tool factory for CNC machining is equally important, as professional manufacturers typically maintain rigorous quality control systems, advanced testing equipment, and refined production standards, ensuring tool consistency and durability. For applications requiring specialized solutions, choosing an experienced custom carbide drill bit manufacturer can provide tailored designs that significantly enhance wear resistance, chip evacuation, and overall machining efficiency.

A comprehensive assessment of the tool itself, its machining performance, and the supplier’s capabilities is key to identifying truly high-quality carbide bits for metal. Understanding these factors enables the selection of more reliable, durable, and stable carbide tools, forming a solid foundation for superior machining results.

Core Factors Affecting the Quality of Carbide Bits for Metal

The stability, wear resistance, and consistent performance of carbide tools largely depend on several critical factors. These factors influence not only cutting efficiency but also surface finish, tool life, and cost control. For operations involving high-hardness materials or long-term continuous machining, special attention should be given to the carbide matrix properties, geometric design, and coating quality. Below, we outline how to assess the overall quality of carbide cutting tools from three perspectives: material integrity, structural geometry, and surface coating performance, particularly for challenging tasks such as deep hole drilling, high-speed milling, and machining heat-resistant alloys.

Consistency of Base Material Purity and Hardness

The foundation of a high-quality cutting tool lies in its base material. A well-structured carbide matrix ensures that chipping and cracking are minimized during high-speed or heavy-load cutting. Uniform particle distribution, stable hardness, and precise alloying composition are key indicators of material performance. Insufficient material purity can lead to microcracks when machining stainless steel, carbon steel, or other high-hardness alloys, significantly shortening tool life. In mass production or extended machining, stable hardness ensures better process control, reduces tool changes, and supports high-efficiency metalworking operations.

The Influence of Tool Geometry on Machining Results

Tool geometry directly affects cutting smoothness, chip evacuation, and surface quality. Parameters such as rake angle, clearance angle, helix angle, and cutting edge structure determine the stress distribution on the tool. Optimized geometry reduces cutting resistance, allowing the tool to maintain stability when machining aluminum alloys, alloy steels, heat-resistant metals, or high-strength materials. Greater geometric accuracy reduces runout during high-speed operations or deep hole drilling, improving dimensional control and surface finish. Properly designed geometry also limits heat generation, prolonging tool life during continuous machining.

Coating Quality and Its Stability in Metal Cutting

Coatings play a critical role in tool performance, especially when cutting hard metals or heat-resistant alloys. Uniform, well-adhered, and thermally stable coatings improve wear resistance and reduce the risk of built-up edge formation. Poor or uneven coatings can peel under high-speed conditions, increasing friction and heat, and shortening tool life. High-quality coatings ensure consistent surface finish, even under heavy cutting loads, long production runs, or precision operations. Combining high-purity base materials with advanced coatings maximizes tool reliability in demanding environments.

Judging the Quality of Metalworking Carbide Tools Based on Machining Performance

Assessing machining performance is central to evaluating metalworking carbide tools. High-quality tools enhance cutting efficiency while ensuring surface finish and dimensional accuracy. Observing cutting force variations, chip shape, and tool wear during operations allows you to directly assess stability and lifespan. These evaluations are essential when selecting carbide cutting tools for metal and when sourcing from reputable carbide tool factories for CNC machining or custom carbide drill bit manufacturers.

Cutting Edge Sharpness and Surface Finish

Sharp cutting edges improve surface quality and reduce cutting resistance. Tools with precise geometry reduce vibration, extend tool life, and increase production efficiency. Surface roughness can be measured with standard instruments, while chip morphology provides visual confirmation of cutting stability. Regular evaluation helps ensure optimal performance of carbide bits for metal.

Evaluating Wear Resistance and Chipping Resistance

Wear resistance and chipping resistance are key indicators of durability. High-intensity cutting tests reveal the rate of edge wear and any chipping. Tools that show uniform wear and minimal chipping typically originate from skilled custom carbide drill bit manufacturers or high-standard carbide tool factories. Reliable wear resistance reduces downtime and ensures consistent quality in precision machining.

Stability and Heat Dissipation under High-Temperature Conditions

High-speed cutting generates significant heat, requiring tools with excellent thermal stability and heat dissipation. Observing cutting force changes, chip color, and edge wear during hot operations indicates tool suitability. Selecting carbide bits with premium coatings and high-purity matrices enhances stability, durability, and performance during complex metalworking tasks.

How to Identify High-Quality Carbide Cutting Tools by Inspecting Tool Details

In metalworking, the performance of high-quality cutting tools depends not only on the base material and coating but also on machining process details. By examining a tool’s microstructure, surface finish, and manufacturing precision, you can quickly assess its overall quality and stability. High-precision tools ensure uniform cutting forces, reduce vibration, and improve both part surface quality and machining efficiency. Whether evaluating the performance of carbide bits for metal or purchasing tools from CNC carbide tool factories or custom carbide drill bit manufacturers, thorough inspection is essential for identifying reliable tools.

Key Points for Inspecting Surface Finish and Dimensional Precision

The surface finish and dimensional precision of a tool directly reflect its manufacturing quality. Tools with smooth surfaces, free from scratches or burn marks, typically indicate tight control of grinding, polishing, and heat treatment processes. Using a magnifying glass or microscope to examine the cutting edge and tool body allows assessment of geometric accuracy and consistency. In precision milling or deep-hole machining, high-precision tools help minimize machining errors and enhance the overall performance of metalworking carbide tools.

Evaluating Process Quality: Welding, Edge Chamfering, and Cutting Edge Profile

Flat weld points, uniform edge chamfering, and smooth cutting edge profiles are key indicators of tool process quality. High-quality tools feature crack-free welds, consistent chamfer angles, and smooth edges, reducing cutting resistance and extending service life. Comparing machining records with actual cutting results provides a clear measure of a tool’s durability during high-speed or hard-metal machining, ensuring selection of reliable carbide cutting tools for metal.

Inspecting Tool Concentricity and Runout

Tool concentricity and runout directly affect machining accuracy and surface quality. High-precision measuring equipment, such as coordinate measuring machines or dynamic balancing tools, can detect eccentricity or vibration issues. Tools with minimal runout maintain stable cutting at high speeds, reduce chatter and burrs, and improve the reliability of carbide bits for complex parts. These inspection methods are also effective for identifying high-quality tools produced by experienced custom carbide drill bit manufacturers.

Evaluating CNC Carbide Tool Factory Capabilities for High-Quality Production

The performance of a carbide tool depends not only on materials and design but also on the professional capabilities of the production process. A top-tier factory ensures consistency and reliability across each batch through precision equipment, strict process flows, and comprehensive quality control. When selecting a supplier, assessing their expertise in machining carbide bits and carbide cutting tools for metal can reduce production risks and improve the accuracy and stability of machined parts. With increasing demand for customized tools, a reliable custom carbide drill bit manufacturer can meet complex machining requirements efficiently.

Assessing Production Equipment Stability and Machining Processes

Advanced production equipment and stable machining processes are the foundation for accurate and durable tools. High-precision grinding machines, automated heat treatment equipment, and precision coating systems ensure geometric consistency and performance stability. Reviewing a factory’s process management, equipment maintenance records, and production standardization provides insight into its ability to maintain high-quality output in mass production, helping select a dependable CNC carbide tool factory.

The Role of Tool Inspection Systems and Quality Standards

Comprehensive inspection systems and strict quality standards are key to ensuring tool performance. Coordinate measuring machines, edge measurement instruments, and wear resistance testing can evaluate dimensional accuracy, edge sharpness, and durability. Factories implementing standardized inspection throughout production can significantly reduce defects, improve machining stability, and enhance customer satisfaction.

Evaluating Customization Capabilities and Delivery Reliability

Custom tool requirements demand strong design, process, and production capabilities. Experienced custom carbide drill bit manufacturers provide tailor-made solutions based on material type, machining conditions, and precision requirements. Reliable delivery ensures smooth production schedules, avoiding delays and interruptions, demonstrating the manufacturer’s overall expertise and supporting complex machining operations.

How Professional Custom Carbide Drill Bit Manufacturers Improve Machining Quality

Tool performance directly affects efficiency, accuracy, and part surface finish. Choosing an experienced manufacturer ensures high-quality carbide bits while offering customized solutions for specific machining needs. Professional manufacturers optimize tool geometry and cutting edge parameters based on material properties, cutting conditions, and machining environment, improving tool durability and machining stability. Customization also ensures batch-to-batch consistency, enabling tools to perform reliably under high loads or complex processes.

Optimizing Drill Bit Structures for Different Metal Materials

Metals vary in hardness, ductility, and cutting characteristics. Top manufacturers adjust drill bit geometry, flute design, and cutting edge layout according to the workpiece, reducing cutting resistance, heat, and wear. This targeted design enhances efficiency and accuracy without requiring changes to existing machining equipment.

Designing Durable Tool Parameters for Actual Cutting Conditions

High-speed cutting, deep-hole drilling, and hard-metal machining place high demands on tools. Manufacturers select suitable base materials, coatings, and cutting edge angles for wear resistance and chipping prevention. These condition-specific designs ensure machining stability, extend tool life, reduce replacements, and increase production efficiency.

Benefits of Custom Services for Mass Production Consistency

For high-volume production, consistency and repeatability are critical. Professional manufacturers ensure each carbide bit maintains dimensional accuracy, edge sharpness, and coating quality. This reduces machining deviations and defect rates, allowing tools to perform stably under diverse conditions, improving overall production efficiency and product quality.

Key Considerations When Purchasing Carbide Bits for Metal

Appearance or brand reputation alone is insufficient. A systematic inspection process ensures purchased tools meet requirements for accuracy, durability, and cutting stability. Focus on testing data, actual machining performance, and supplier technical support to avoid rework and ensure optimal performance under high-load or complex conditions. Comparing reports and samples from multiple manufacturers helps make informed purchasing decisions.

Reviewing Tool Reports, Testing Data, and Standardized Parameters

Carefully examine technical reports for dimensional accuracy, edge sharpness, coating thickness, and material hardness. Confirming standardized parameters ensures tools meet machining requirements and maintains consistency across machines or batches. Comparing test data with actual cutting results reduces errors and scrap caused by tool quality variations.

Evaluating Actual Sample Machining Performance

Performance cannot be judged by data alone. Assess cutting forces, surface roughness, and wear resistance through sample machining. Machining metal samples of different hardness and thickness provides insight into cutting efficiency, chipping resistance, and high-temperature stability, helping select the most suitable carbide tools for production.

Auditing Supplier After-Sales and Technical Support

Reliable suppliers offer after-sales services, cutting parameter optimization, and troubleshooting guidance. Assessing technical support, delivery reliability, and customization capabilities ensures production continuity. Long-term cooperation with experienced manufacturers provides a stable supply of high-performance carbide cutting tools, reducing production risks.

Choosing Reliable Metalworking Carbide Tools

High-performance tools require evaluation across materials, design, machining performance, and manufacturer capabilities. Quality depends on base material purity, tool geometry, coating, and actual performance, including edge sharpness, wear resistance, chipping resistance, and high-temperature stability. Tool inspection, concentricity, and runout are crucial for machining accuracy.

Selecting a CNC carbide tool factory with complete equipment, stable processes, and rigorous quality control, along with a custom drill bit manufacturer offering customized services, ensures consistency and reliability in mass production. Combining inspection reports, sample machining data, and supplier support enables users to identify the most suitable tools, reducing machining risks and improving efficiency.

Comprehensive Assessment Based on Needs, Tool Performance, and Manufacturer Expertise

Consider workpiece material, machining conditions, cutting performance, and supplier capabilities. Multi-dimensional evaluation allows selection of carbide bits that provide efficient, stable, and high-quality machining results.

Establishing a Long-Term Reliable Tool Supply Chain

A stable supply chain ensures production continuity and reduces downtime risks. Choosing a manufacturer with customization capabilities and reliable delivery supports diverse machining needs while accumulating long-term data and experience. High-quality tools combined with a reliable supply chain are essential for improving machining quality and efficiency.