Tungsten carbide cutting tools are widely used in metal cutting and precision manufacturing due to their exceptional hardness, wear resistance, and thermal stability. For every tungsten carbide cutting tool manufacturer, stringent quality control standards not only determine the product’s lifespan and machining performance but also directly influence the company’s competitiveness in the global market.

High-quality tungsten carbide tools rely on accurate raw material ratios, advanced sintering technology, precision grinding equipment, and systematic testing procedures. Together, these factors form the foundation of a manufacturer’s quality assurance system.

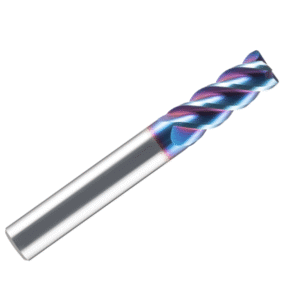

As modern manufacturing evolves, the demand for higher tool performance continues to rise. Whether in high-speed cutting, hard material machining, or automated CNC production lines, tungsten carbide tools must meet strict precision and stability requirements. Compared to traditional high-speed steel (HSS) cutting tools, tungsten carbide tools outperform HSS in hardness, wear resistance, and thermal strength, making them the preferred choice in modern manufacturing. In the comparison of tungsten carbide vs HSS cutting tools, carbide tools offer longer tool life, faster cutting speeds, and superior surface finishes.

For professional tungsten carbide tool manufacturers, the sophistication of their quality control systems reflects both technological depth and management capability. From raw material inspection and sintering density control to coating adhesion testing and dimensional accuracy verification, every process step must comply with international standards such as ISO 9001 or other industry-specific norms. Only through rigorous inspection and full process traceability can each tungsten carbide tool deliver consistent performance before leaving the factory—providing users with reliable and efficient cutting solutions.

In summary, quality control for tungsten carbide cutting tools is not just a production step but a long-term industrial discipline. Manufacturers with comprehensive testing systems and strict standards can consistently supply high-performance tungsten carbide tools for CNC machining, maintaining a strong competitive edge in the global market.

Why Quality Control Is Crucial for Tungsten Carbide Cutting Tool Manufacturers

The performance stability of tungsten carbide cutting tools is directly tied to manufacturing precision, and quality control is the key to ensuring consistent and reliable performance. For any professional tungsten carbide cutting tool manufacturer, a robust quality system is essential not only for product yield but also for brand reputation and customer trust.

The manufacturing of high-performance tools involves complex processes requiring precise control at every stage—from tungsten carbide powder composition and sintering density to precision grinding and coating. Deviations at any point can lead to uneven hardness, edge chipping, or unstable cutting behavior, all of which reduce machining efficiency. Only comprehensive testing and continuous monitoring ensure that tungsten carbide tools for CNC machining maintain optimal performance under diverse working conditions.

Meanwhile, global customers increasingly emphasize quality certifications such as ISO 9001 and the use of advanced inspection technologies like coordinate measuring machines (CMMs) and microstructure analyzers to verify consistency. These standards not only define technical requirements but also represent the manufacturer’s credibility and competitive strength in the international market.

The High Precision Requirements of Tungsten Carbide Material Properties

Tungsten carbide is a hard alloy produced by sintering tungsten carbide powder with a metallic binder—typically cobalt—at high temperatures. Its extremely high hardness and wear resistance also make it brittle, which demands exceptional precision throughout the manufacturing process.

From powder preparation and granulation to sintering and grinding, every step must maintain tight control over temperature, pressure, and duration. Even slight variations can cause grain coarsening, internal porosity, or weak bonding, ultimately compromising tool strength and cutting performance. Particularly for tungsten carbide tools used in CNC machining, geometric accuracy and cutting edge integrity directly determine surface finish and tool longevity.

To ensure precision, leading manufacturers employ automated sintering furnaces, high-precision CNC grinders, and in-line inspection systems. Through digital monitoring and process traceability, they guarantee consistent quality across all batches—an essential distinction between standard tool makers and high-end carbide tool manufacturers.

The Relationship Between Quality Control and Customer Trust

In the cutting tool industry, customer trust is built on the foundation of consistent product quality. A strict quality control system not only optimizes production management but also serves as the cornerstone for maintaining long-term partnerships.

When manufacturers implement comprehensive quality tracking—from raw material testing and dimensional tolerance checks to hardness and coating adhesion testing—customers gain visibility into product reliability. This transparency reduces machining risks, minimizes downtime, and lowers total tooling costs.

In the comparison of tungsten carbide vs HSS cutting tools, although carbide tools have a higher upfront cost, their superior durability and stable performance deliver significantly greater cost efficiency over time. Choosing a manufacturer with a proven quality management system ensures consistent machining results and confidence in long-term collaboration.

By continuously enhancing inspection standards and adopting advanced quality management practices, top-tier tungsten carbide cutting tool manufacturers strengthen their brand reputation and establish themselves as trusted global partners.

Core Quality Inspection Items for Tungsten Carbide Cutting Tools

The performance stability and durability of tungsten carbide cutting tools depend on the precision of every manufacturing stage—from raw materials to final inspection. For professional tungsten carbide cutting tool manufacturers, establishing a complete and systematic quality inspection framework is essential to guarantee consistent product quality.

High-performance tungsten carbide tools undergo multiple key tests, including powder purity, sintering hardness, microstructure evaluation, dimensional tolerance verification, and coating adhesion testing. These inspections reflect not only the sophistication of the production process but also the tool’s reliability in demanding CNC machining applications.

The following are five essential inspection stages that define the quality standards of tungsten carbide cutting tools:

Raw Material Inspection

High-quality tungsten carbide powder is the cornerstone of superior cutting tool performance. The ratio, purity, and particle size distribution of tungsten carbide and cobalt binders directly determine hardness, toughness, and wear resistance. Manufacturers perform chemical composition analysis and particle size distribution testing (using laser particle analyzers) to ensure purity above 99.5%, with uniform and consistent granularity.

Cobalt content typically ranges from 6% to 12%, influencing the tool’s balance between hardness and toughness. Uneven particle distribution can lead to microstructural voids or reduced strength after sintering, negatively impacting cutting performance. Rigorous raw material testing ensures microstructural stability and lays the foundation for consistent downstream processing.

Sintering and Hardness Testing

Sintering determines the density and mechanical integrity of tungsten carbide cutting tools. The sintering temperature, typically between 1400°C and 1500°C, must be tightly controlled—too high leads to grain coarsening, while too low results in poor bonding. Manufacturers use vacuum or atmosphere sintering furnaces with precise temperature profiling to maintain consistency.

Post-sintering, Rockwell hardness (HRA) testing is performed. Tungsten carbide tools typically exhibit a hardness range of HRA 89–94. Higher hardness indicates better wear resistance but lower toughness, so hardness testing verifies both material quality and process optimization. It remains one of the most critical stages in carbide tool quality control.

Microstructure and Grain Size Analysis

Microstructure analysis evaluates the uniformity and density of the carbide’s internal structure. Using metallographic microscopes or scanning electron microscopes (SEM), manufacturers assess grain size, porosity, and phase distribution. A fine, dense, and uniform structure enhances toughness and minimizes chipping.

In advanced production, grain size control is key to balancing wear resistance and impact toughness. Fine-grained tungsten carbide is ideal for high-speed, high-precision machining, while coarser grains are suited for heavy-duty or interrupted cutting. This microscopic evaluation ensures consistent sintering quality and prevents early tool failure.

Dimensional and Geometric Tolerance Inspection

Geometric accuracy directly affects tool performance and surface quality. Manufacturers use high-precision CNC grinding machines to shape the tool, followed by dimensional and geometric inspections with CMMs, optical micrometers, and laser scanners.

Critical parameters include tool diameter, cutting edge angle, runout accuracy, and edge radius. Even minimal deviations can lead to cutting vibration, poor surface finish, or premature wear—particularly in tungsten carbide tools for CNC machining, where micron-level precision is vital.

Coating Quality and Adhesion Testing

High-performance tungsten carbide tools often use PVD or CVD coatings to enhance wear and oxidation resistance. Coating quality inspection focuses on thickness, uniformity, adhesion strength, and surface finish.

Testing methods include scratch tests, film thickness measurements, and microscopic evaluation. Premium coatings such as TiAlN, AlCrN, and TiCN significantly extend tool life and cutting performance. Through strict coating inspection and process control, manufacturers ensure every batch meets consistent international performance standards.

Quality Differences Between Tungsten Carbide and High-Speed Steel Cutting Tools

Tungsten carbide cutting tools and HSS cutting tools are two of the most widely used tool materials in modern metal cutting. They differ greatly in hardness, wear resistance, thermal stability, and overall cost-effectiveness. As manufacturing continues to move toward high-efficiency and precision machining, choosing the right tool for each application has become increasingly critical.

Tungsten carbide tools are recognized for their exceptional hardness and wear resistance, making them ideal for high-speed machining and cutting of difficult materials such as stainless steel, titanium alloys, and hardened steels. High-speed steel tools, by contrast, offer better toughness and affordability, making them suitable for medium- and low-speed machining. For tungsten carbide cutting tool manufacturers, understanding these differences helps improve production standards, enhance process optimization, and meet a wide range of customer requirements.

The comparison below analyzes the two materials across three key dimensions: hardness and wear resistance, tool life and cost-effectiveness, and quality control standards.

Hardness and Wear Resistance Comparison

The primary advantage of tungsten carbide cutting tools lies in their extreme hardness and superior wear resistance. Tungsten carbide typically measures between HRA 89–94, while HSS tools range from HRA 65–70. This higher hardness allows carbide tools to maintain sharp cutting edges under high temperatures and heavy loads, minimizing plastic deformation.

Under high-speed cutting conditions, tungsten carbide can withstand temperatures up to 800°C–1000°C, whereas HSS retains its “red hardness” only below 600°C. This means tungsten carbide tools can run at higher cutting speeds and feed rates while maintaining dimensional accuracy and surface finish.

Their wear resistance also makes tungsten carbide tools the preferred choice for mass production and CNC automation, as they reduce tool changes and machine downtime. For manufacturers focused on productivity, carbide cutting tools offer unmatched stability and longevity.

Service Life and Cost-Effectiveness Analysis

In terms of durability, tungsten carbide tools generally last 3 to 10 times longer than high-speed steel tools. Their hardness and thermal stability ensure consistent cutting performance in both continuous and heavy-duty operations. This longer lifespan translates directly into lower cost per part and higher overall efficiency.

While carbide tools have a higher upfront cost, their long-term economic benefits are significant. In automated production lines or CNC batch machining, extended tool life reduces changeovers, minimizes inventory, and maximizes spindle uptime.

HSS tools, although cheaper, wear out faster and require frequent replacement—adding indirect costs and production delays. For high-precision or high-volume applications, tungsten carbide cutting tools clearly deliver better return on investment.

Different Requirements of Quality Control Standards

Quality control requirements differ significantly between tungsten carbide and high-speed steel cutting tools. Tungsten carbide manufacturing involves stricter testing and process control standards, including ISO 513, ISO 4957, and GB/T 2075, which define requirements for carbide powder purity, sintering density, hardness, microstructure, and coating adhesion.

High-speed steel tools, on the other hand, focus more on chemical composition and heat treatment consistency, ensuring proper hardness and impact toughness. While HSS manufacturing is based on forging and heat treatment, it still adheres to standards like ISO 4957 or GB/T 9943.

Modern tungsten carbide tool manufacturers often integrate ISO 9001-certified quality systems and employ advanced measurement technologies such as coordinate measuring machines (CMMs) and laser scanning to guarantee precision and repeatability. In contrast, HSS tool production relies more heavily on manual inspection and heat treatment expertise, leading to greater variability.

Special Requirements for Tungsten Carbide Tools in CNC Machining

CNC machining places far higher demands on tool performance than conventional machining. Due to their hardness, wear resistance, and heat stability, tungsten carbide cutting tools have become the top choice for high-speed, high-precision CNC applications. However, maintaining consistent performance under these extreme conditions requires strict control of geometric accuracy, batch consistency, and tool life management.

Even minor deviations in geometry can cause dimensional errors or poor surface finishes. Thus, the quality of tungsten carbide tools depends not only on material properties but also on precise manufacturing and rigorous quality assurance throughout the production cycle.

Below are the three core quality requirements for tungsten carbide tools in CNC machining environments.

High Precision and Stability Requirements

The essence of CNC machining is repeatability and consistency. Tool geometry directly affects cutting path stability, surface finish, and dimensional accuracy. Even a small error in edge angle or alignment can lead to vibration or poor part quality.

Top-tier tungsten carbide tools are produced using high-precision CNC grinders to maintain cutting edge radii, rake angles, and dimensional tolerances within 0.002 mm. Proper dynamic balance is equally important—imbalance can cause tool wear and spindle vibration.

Reputable manufacturers use laser measurement systems and CMM inspections to verify geometric accuracy and ensure stable, predictable performance in every machining operation.

Tool Consistency and Batch Stability

In CNC batch production, tool-to-tool consistency directly impacts product quality and productivity. Any variation in hardness, geometry, or coating quality can lead to uneven performance or dimensional fluctuation.

Manufacturers achieve batch stability through Statistical Process Control (SPC) and comprehensive traceability systems. Automated inspection tools like vision sensors and laser scanners detect minor deviations in real time, ensuring every batch of tungsten carbide cutting tools meets the same precision standards.

For facilities operating continuous CNC production, consistent tool quality means reduced adjustments, shorter cycle times, and higher yield rates—key advantages in competitive manufacturing environments.

Tool Life and Management Systems

Effective tool life management is vital for reducing costs and maximizing productivity. Even with tungsten carbide’s superior durability, wear and chipping can occur during prolonged or high-load operations.

Factories use tool inspection instruments to monitor wear and determine optimal regrinding intervals. Proper regrinding restores cutting geometry and can extend tool life by 30–50%. Implementing digital tool coding and tracking systems allows real-time monitoring of usage, wear, and performance history.

A well-structured tool management system helps minimize downtime, optimize replacement schedules, and maintain consistent machining quality—critical factors in large-scale CNC operations.

Application of International Quality Standards and Certification Systems

Global manufacturing now emphasizes both precision and sustainability. For tungsten carbide cutting tool manufacturers, quality assurance extends beyond internal testing—it requires full compliance with international certification systems such as ISO 9001, ISO 14001, and regional standards like EN, JIS, and GB/T.

These standards govern every stage—from raw material sourcing and process control to environmental management and final inspection—ensuring that products meet global requirements for performance, traceability, and sustainability. Certified manufacturers demonstrate reliability, consistency, and environmental responsibility—key attributes for global CNC machining clients.

Implementation of ISO 9001 in Tool Manufacturing

ISO 9001 emphasizes process control and continuous improvement. Within tungsten carbide tool manufacturing, it ensures traceability and documentation across all stages—powder preparation, sintering, grinding, and final inspection.

Manufacturers adhering to ISO 9001 maintain comprehensive SOPs, digital quality records, and batch traceability, allowing any product to be linked to its process data. The standard also promotes regular audits and feedback loops, helping companies optimize design and process efficiency. For end users, ISO 9001-certified tools guarantee performance consistency and reliability.

ISO 14001 and Environmental Management

As manufacturing moves toward sustainability, ISO 14001 plays a vital role in tungsten carbide production. It focuses on reducing emissions, energy consumption, and waste.

Since tungsten and cobalt are valuable and finite resources, certified manufacturers implement closed-loop recycling systems, reclaiming materials from worn tools through crushing, chemical separation, and regeneration into high-purity tungsten powder. Environmentally friendly PVD/CVD coating and high-efficiency sintering equipment further reduce pollution and energy usage.

These measures improve both environmental performance and production efficiency, enhancing a manufacturer’s reputation as a responsible global supplier.

Comparison of Major Industry Standards in Europe and Asia

Regional standards differ slightly in testing methods and tolerance control but share the same goal: ensuring consistent, high-performance cutting tools.

-

EN Standards (Europe): Focus on safety, consistency, and mechanical testing—used widely in automotive and aerospace sectors.

-

JIS Standards (Japan): Emphasize precision and surface finish, suitable for ultra-fine CNC machining and mold manufacturing.

-

GB Standards (China): Align with international norms while adapting to local production needs, defining hardness, microstructure, and wear resistance tests for carbide tools.

Leading manufacturers often test and certify products according to their clients’ regional standards—providing EN ISO-compliant or JIS-certified reports for export. This multi-standard approach enhances global competitiveness and ensures reliable performance across industries.

Key Criteria for Choosing a Reliable Tungsten Carbide Cutting Tool Manufacturer

In today’s highly competitive manufacturing industry, selecting a reliable tungsten carbide cutting tool manufacturer directly affects machining efficiency, cost control, and product quality consistency. High-quality tungsten carbide cutting tools rely not only on premium materials but also on the manufacturer’s comprehensive strength in equipment configuration, technical expertise, quality systems, and after-sales support.

Reputable manufacturers typically operate with advanced testing and production systems, strong R&D capabilities, international certifications, and a stable customer base. They can provide customized tungsten carbide cutting tools for CNC machining to suit various materials and applications—such as stainless steel, titanium alloys, and aluminum alloys—while ensuring consistent tool performance across mass production through rigorous quality management.

The following sections outline three key criteria for identifying a trustworthy tungsten carbide cutting tool supplier:

-

Testing equipment and R&D capabilities

-

Process experience and technical support

-

Customer case studies and export certifications

Manufacturer’s Testing Equipment and R&D Capabilities

Leading tungsten carbide cutting tool manufacturers are equipped with high-precision five-axis CNC grinders, coordinate measuring machines (CMMs), microstructure analyzers, Rockwell hardness testers (HRA), and coating thickness testers. This advanced equipment ensures that every tool meets strict international standards for geometric accuracy, hardness distribution, and surface quality.

For example:

-

CNC grinding machines ensure uniform edge geometry and surface finish.

-

Microstructure analyzers evaluate tungsten carbide grain size and sintering density.

-

Hardness testers verify that sintered tools consistently achieve HRA 92 or higher.

Manufacturers with in-house R&D centers often design and optimize tool geometries and coatings to match different CNC machining environments. This capability to innovate and tailor solutions to specific materials distinguishes professional suppliers from generic tool producers.

Process Experience and Technical Support Capabilities

The performance of tungsten carbide cutting tools depends not only on equipment but also on the manufacturer’s process experience and engineering expertise. Manufacturers with over a decade of experience typically have in-depth knowledge of tool design, sintering process control, and grinding optimization—ensuring long-term product stability and precision.

Professional manufacturers also offer comprehensive technical support, including:

-

Optimization of cutting parameters

-

Tool regrinding and life extension solutions

-

Wear monitoring and performance assessment

-

Data-driven recommendations for improving machining efficiency

Through tool monitoring systems and digital management platforms, experienced suppliers can analyze wear behavior in real time and propose practical, cost-saving improvements. Their ability to integrate process optimization helps customers reduce tool change frequency, extend tool life, and lower unit machining costs—key benefits of partnering with an industrial-grade manufacturer.

Customer Case Studies and Export Certifications

When evaluating a tungsten carbide cutting tool manufacturer, customer case studies and international certifications are critical indicators of reliability. A manufacturer with long-term partnerships demonstrates proven product quality and service consistency validated by the market.

Manufacturers certified under ISO 9001 (quality management) and ISO 14001 (environmental management), as well as those holding export qualifications such as CE, RoHS, or SGS, are better positioned to meet global performance and safety standards. Some leading producers also hold EN or JIS compliance reports to satisfy regional customer requirements in Europe and Japan.

Customer portfolios also reflect the manufacturer’s industry coverage and technical depth. Companies capable of delivering a complete range of high-performance tungsten carbide end mills, drills, and inserts—and offering on-site optimization support—typically demonstrate superior engineering capability and production stability.

Quality Control Is the Core Competency of Tungsten Carbide Cutting Tool Manufacturers

In high-end manufacturing, quality control defines the core competitiveness of tungsten carbide cutting tool manufacturers. From raw material purity and sintering density to geometric precision, coating adhesion, and tool life, every aspect of performance depends on a rigorous quality management system and precise testing procedures.

A high-performance tungsten carbide cutting tool undergoes multiple verification stages:

-

Raw material inspection

-

Microstructure analysis

-

Hardness testing

-

Dimensional and tolerance measurement

These processes ensure stable cutting performance under high-temperature and high-speed conditions, directly impacting CNC machining accuracy and surface finish. Only manufacturers with complete, traceable quality systems can consistently guarantee tool performance and reliability.

Compared with HSS cutting tools, tungsten carbide tools have a far more complex production process and stricter quality requirements. Their superior performance depends on precise control of every stage—from powder metallurgy sintering to CNC grinding, PVD/CVD coating, and final inspection. Continuous process monitoring is the foundation for achieving high hardness, excellent wear resistance, and long tool life.

The adoption of international quality standards such as ISO 9001 and ISO 14001 has also made tungsten carbide tool manufacturing more traceable, quantifiable, and sustainable. Certified manufacturers not only demonstrate technical strength but also reinforce their credibility and professionalism in the global CNC machining market.

For end users, choosing a tungsten carbide cutting tool manufacturer with robust quality systems and reliable testing capabilities is essential for achieving consistent machining performance and long-term cost-effectiveness. Only manufacturers who integrate quality control throughout the entire production cycle—from raw materials to final delivery—can provide truly high-precision, durable, and consistent tungsten carbide cutting tools for modern CNC machining applications.