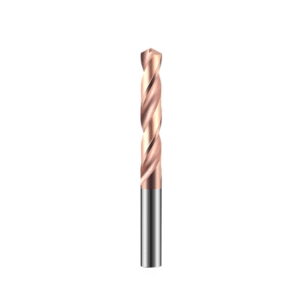

When performing lateral cutting with side cutting drill bits in metal machining, burrs frequently appear along edges, affecting dimensional accuracy, surface finish, and subsequent assembly. This is especially true during combined drilling and milling of materials such as steel, stainless steel, and aluminum alloys. The cutting force distribution and chip evacuation path of side cutting drill bits are often complex. Without proper control, significant edge tearing and micro-deformations can occur, making burr reduction a critical goal for many manufacturers.

With the increasing use of precise metal side cutting tools, manufacturers are demanding more from the geometric structure, coating type, and flute design of side cutting drill bits for metal. Side milling drill bits offer excellent stability and provide superior edge control in operations such as side milling, hole enlargement, and groove machining. Achieving optimal results requires proper parameter settings, tool selection, and process planning. Different metal materials exhibit varying heat generation, plastic deformation, and chip flow characteristics. If rotational speed, feed rate, and cutting depth are not adjusted accordingly, burr formation is almost inevitable.

Customized tools from OEM side cutting drill bit manufacturers are also becoming a crucial option for burr reduction. By optimizing cutting edge angles, improving tool rigidity, and tailoring tool designs for specific materials, manufacturers can significantly enhance stability and consistency in mass production. Choosing cutting drill bits with high-quality coatings further reduces cutting resistance and edge tearing, suppressing burr formation at its source.

Analysis of the Main Causes of Burr Formation in Metal Processing

Burrs have long been a critical factor affecting machining quality and subsequent processing efficiency. Especially when using high-precision cutting tools for lateral operations, improper handling or ignoring material characteristics can easily result in irregular burrs. These burrs compromise assembly accuracy and surface finish. Analyzing stress concentration, heat distribution, and chip evacuation during metal cutting helps identify the core causes of burr formation, enabling targeted process strategies to improve machining quality and extend tool life.

Stress and Deformation Issues During Side Cutting

During side cutting, metal experiences combined lateral and vertical stresses. Uneven cutting force distribution or insufficient tool rigidity can cause localized micro-deformation, leading to edge tearing. This is particularly common in high-speed cutting or machining hard alloys. By optimizing cutting parameters, selecting suitable metal side cutting tools, and employing proper feed strategies, stress concentration can be reduced, minimizing burr formation.

Edge Tearing Caused by Cutting Heat Accumulation

Machining generates significant heat at the tool-workpiece interface. If this heat is not dissipated efficiently, the metal surface softens and undergoes plastic flow, causing edge tearing and burr formation. This effect is most pronounced when working with high-strength steel or thick-walled components. Controlling cutting speed, applying effective coolant, and choosing an appropriate cooling strategy for metal side cutting drill bits help alleviate heat buildup, ensuring a clean and smooth cutting edge.

Material Accumulation Due to Insufficient Chip Evacuation

Inefficient chip evacuation is another major source of burrs. In side milling or lateral cutting, chips that are not removed promptly can accumulate between the tool and the workpiece, interfering with the cutting process and generating burrs. Adjusting cutting angles, optimizing flute design, and using OEM side cutting drill bits for metal help ensure smooth chip flow and improve surface finish.

Optimizing Side Cutting Drill Bit Machining Parameters to Reduce Burrs

To achieve high-quality surfaces and minimize burr formation, machining parameters must be carefully optimized. Spindle speed, feed rate, and cutting depth directly affect cutting forces, heat generation, and chip evacuation. By balancing these factors, material deformation and plastic flow can be controlled, significantly reducing edge burrs. Tailoring parameters for different metal types and thicknesses improves machining efficiency and extends the life of metal side cutting tools. Integrating process design with parameter optimization is especially important when using OEM side cutting drill bits for stable and consistent results.

Rational Combination of Spindle Speed, Feed Rate, and Cutting Depth

Excessively high spindle speeds can rapidly increase cutting zone temperature, softening the metal and causing burrs. Too low speeds increase cutting forces and promote tearing. Feed rate and cutting depth are equally critical; values that are too high increase tool load and surface roughness, while too low reduce efficiency. Adjusting the speed and feed of the side milling drill bit to balance cutting force and heat ensures clean, smooth edges.

Parameter Adjustment Strategies for Different Metal Materials

Metal hardness, toughness, and thermal conductivity vary widely. Aluminum, with low heat resistance, performs best with higher spindle speeds and lower feed rates. Stainless steel and titanium alloys require slower cutting, increased tool rigidity, and adequate cooling and lubrication. Optimizing parameters based on material characteristics reduces burrs and extends the life of metal side cutting tools.

The Importance of Maintaining a Stable Tool Path During Side Cutting

Tool path stability directly affects surface quality. Tool vibration or path deviation causes uneven cutting depth and edge burrs. Planning cutting sequences, securing the workpiece, and using high-precision side cutting drill bits maintain consistent paths. Combining parameter optimization with superior tool performance effectively reduces burr formation while maintaining efficient machining.

Choosing the Right Side Cutting Drill Bit for Metal

Selecting the appropriate side cutting drill bit is critical for smooth surfaces and burr reduction. Tool material, structure, and coating affect cutting forces, chip evacuation, and wear resistance, determining both surface quality and tool life. High-performance metal side cutting tools withstand heavy cutting loads while maintaining stability during high-speed and complex side milling operations. Using OEM side cutting drill bit manufacturers’ tools, along with optimized parameters, achieves high-precision edge finishing on various metal materials.

Influence of Tool Substrate and Structure on Burr Control

Tool substrate hardness and toughness determine wear resistance and deformation control. Carbide tools maintain sharp edges and reduce material plastic flow, lowering burr probability. High-speed steel tools suit ductile metals like aluminum or copper. Geometric features like rake angles, helix grooves, and tip shapes affect cutting force and chip evacuation, crucial for smooth edges.

Differences in Performance of Coating Types in Metal Machining

Coating types vary in wear resistance, anti-adhesion, and thermal stability. TiAlN reduces temperature during high-speed cutting of hard metals, minimizing edge tearing. TiN and TiCN perform well on aluminum and softer steels, reducing adhesion and burrs. Selecting coatings based on workpiece material enhances surface finish and extends tool life.

Advantages of Side Milling Drill Bits in Side Milling and Edge Finishing

Side milling drill bits provide stable cutting force distribution and efficient chip evacuation during side milling and edge finishing. They reduce material buildup and edge tearing, especially on precision parts or thin-walled workpieces. With proper parameters and high-performance tools, burrs are effectively controlled, achieving consistent and efficient metal machining.

Methods to Improve Chip Evacuation Performance of Metal Side Cutting Tools

Efficient chip evacuation directly affects surface quality and burr formation in metal machining. Chips that remain on the workpiece or flow back can cause edge tearing and localized burrs. Improving chip evacuation performance is essential for stable processing and smooth surfaces. Optimizing flute design, guiding chip flow, and using cutting fluids or oil reduce clogging and friction. This ensures smooth material removal and extends the life of side cutting drill bits for metal and side milling drill bits, resulting in efficient edge finishing.

Flute Design and Chip Evacuation Direction Optimization

The flute design plays a crucial role in chip removal. A proper helix angle, flute width, and depth reduce cutting force fluctuations and prevent material accumulation. Optimizing the chip evacuation direction enhances processing efficiency and minimizes burrs. When selecting tools from OEM side cutting drill bit manufacturers, consider the chip evacuation structure for the best results across different metals and workpiece thicknesses.

Full Use of Coolant or Cutting Oil During Processing

Cutting fluid or oil removes heat efficiently, reducing plastic deformation caused by temperature rise and minimizing burr formation. Lubrication also lowers friction between the tool and workpiece, facilitating smooth chip flow. For high-speed side cutting or hard metals, proper use of coolant is critical for maximizing the performance of metal side cutting tools.

Avoiding Secondary Chip Scratching of the Machined Surface

Accumulated or returning chips can scratch already machined surfaces, creating new burrs. Optimizing tool paths, controlling feed rate and cutting depth, and using high-efficiency chip evacuation tools ensure prompt chip removal. Side milling drill bits designed for lateral cutting further support clean and smooth edges, achieving high-precision finishes.

Process Improvement Strategies to Reduce Cutting Edge Burrs

To enhance surface quality and minimize burrs during metal machining, the machining process must be optimized. Methods such as incremental cutting, pre-treatment operations, reverse machining, and chamfering can effectively reduce stress concentration and edge tearing. Maintaining a stable tool path and minimizing vibration are also key to high-precision machining and extending the service life of side cutting drill bits. Proper process flow and tool strategy improve efficiency while lowering the risk of burr formation, ensuring reliable results for precision parts machining.

Application of Incremental Cutting and Pre-treatment Processes

Incremental cutting gradually removes material, reducing single-pass cutting loads and minimizing plastic deformation. For high-hardness or thick-walled workpieces, pre-treatment operations like rough milling or semi-finishing remove stress concentration areas, preparing ideal conditions for finishing. This approach not only reduces burrs but also improves efficiency and extends the life of side milling drill bits.

Combined Use of Reverse Machining and Chamfering

Reverse machining effectively controls burrs by changing the cutting direction, reducing material tearing along edges. Chamfering removes small burrs and improves surface flatness. Combining reverse machining with chamfering enhances surface quality while maintaining efficient processing, leveraging the advantages of tools from OEM side cutting drill bit manufacturers.

Reducing Tool Vibration to Improve Cutting Path Stability

Tool vibration causes uneven cutting depth, burr accumulation, and rough surfaces. Maintaining tool rigidity, optimizing fixture clamping, and adjusting cutting parameters reduce vibration and improve tool path stability. Using precision metal side cutting tools with a stable trajectory minimizes burrs and enhances machining accuracy, ensuring high-quality finishes for precision parts.

The Importance of Equipment and Fixture Stability in Burr Control

Equipment and fixture stability are critical for accurate side cutting. Even with high-performance side cutting drill bits for metal, insufficient spindle accuracy, unstable clamping, or inadequate auxiliary tooling can cause vibrations and minor material deformation, increasing burr formation. Ensuring machine rigidity, proper clamping, and vibration-damping configurations improves stability, surface quality, and tool life.

The Critical Role of Machine Spindle Accuracy in Side Cutting

Spindle runout or instability can create uneven cutting depth and localized burrs. High-speed or hard metal machining amplifies cutting force fluctuations, intensifying edge tearing. Maintaining precise spindle accuracy is essential for reducing burrs and achieving high-quality results.

The Impact of Workpiece Clamping Method on Edge Deformation and Burrs

Unstable clamping can lead to minor workpiece movement or elastic deformation, creating burrs or scratches. Selecting appropriate fixture types and positions distributes cutting forces effectively. Combined with OEM tools, this reduces burr formation while ensuring machining accuracy and efficiency.

Auxiliary Tooling Configuration for Vibration Reduction

Vibration contributes significantly to cutting instability and burrs. Configuring damping bases, supports, or vibration absorption devices reduces resonance, ensuring a stable trajectory for side cutting drill bits for metal. Along with optimized parameters and tool selection, auxiliary tooling enhances surface quality and extends tool life.

Purchasing Advice from an OEM Side Cutting Drill Bit Manufacturer

Choosing a reliable OEM tool manufacturer is vital for high-precision metal machining. Quality manufacturers offer high-performance side cutting drill bits and metal side cutting tools, along with customized solutions for different metals and requirements. Evaluating processing capabilities, testing standards, and mass production stability reduces burrs, extends tool life, and ensures consistent machining performance.

How to Assess the Processing and Testing Capabilities of an OEM Tool Manufacturer

Focus on tool material selection, heat treatment, machining accuracy, and quality control procedures. High-precision machining and rigorous testing ensure side milling drill bits maintain sharp edges and minimize burrs. Manufacturer expertise and process optimization experience provide effective solutions for diverse metal applications.

Advantages of Custom Tools in Reducing Burrs in Specific Metal Applications

Custom tools can optimize geometry, edge design, and coatings to balance cutting forces and improve chip evacuation, reducing burrs. OEM custom tools enable precision cutting for cemented carbide, stainless steel, or titanium alloys, enhancing surface finish and machining quality.

Considerations for Tool Stability and Lifespan in Batch Processing

In mass production, tool stability and lifespan affect efficiency and consistency. Using rigorously tested metal side cutting tools with optimized parameters ensures sustained cutting performance, reducing burrs and secondary processing. Evaluating OEM supply capacity, tool consistency, and durability supports efficient, high-quality machining.

Practical Case Studies and Burr Reduction Results with Side Cutting Drill Bits

Optimizing tool selection, cutting parameters, and processes can significantly reduce burrs, improve surface quality, and boost production efficiency. Using precision metal side cutting tools or customized side cutting drill bits for metal achieves ideal results in complex side cutting and precision parts machining.

Case Study of Burr Control in Aluminum Machining

Using a side milling drill bit with optimized geometry, proper spindle speed, and feed rate reduces edge tearing. Incremental cutting and proper use of cutting fluid evacuate chips smoothly, resulting in flat, smooth surfaces. Burr generation decreased significantly, while machining efficiency improved by approximately 15%.

Optimization Experience in Machining Stainless Steel or High-Hardness Steel

High-hardness steel often forms burrs and microcracks. Wear-resistant, coated side cutting drill bits, combined with reduced cutting speed, increased tool rigidity, and optimized fixture clamping, effectively control cutting forces and heat. Burrs were reduced by over 50%, cutting stability improved, and surface quality enhanced.

Examples of Reducing Rework Rates Through Tool and Parameter Adjustment

In mass production, optimized high-precision tools and adjusted parameters—feed rate, cutting depth, and tool path—reduce burrs and secondary scratches. Rework rates dropped approximately 30%, tool life increased, and overall production efficiency improved, achieving both quality and cost optimization.