In precision machining, controlling drilling depth is a core factor in ensuring part quality. Spot drilling depth control directly impacts the positioning accuracy and stability of subsequent drilling or milling operations. Using appropriate spot drilling tools combined with precise machining parameters effectively reduces hole position deviations and material deformation, improving production efficiency.

For complex parts or multi-hole machining, center spot drilling is often used for pre-positioning, ensuring consistent depth and center alignment for each hole. Tool wear, variations in material hardness, and machine tool rigidity can all affect spot drilling depth. Therefore, proper tool selection and depth compensation strategies are essential.

Working with a reliable spot drilling tools supplier provides access to high-precision tools and technical support, enabling repeatable and stable depth control. By combining tool geometry, coating technology, and optimized cutting parameters, spot drilling can ensure accurate hole positioning, extend tool life, and reduce production costs.

The Importance of Spot Drilling Depth in Machining

Precise control of drilling depth is critical for overall machining quality and assembly accuracy. Depth deviations can affect subsequent drilling or milling, potentially leading to uneven surface morphology or assembly gaps that fail to meet design specifications. For multi-hole machining or high-precision parts, depth control directly impacts repeatability and production efficiency. Selecting suitable tools, optimizing cutting parameters, and adjusting feed rates appropriately significantly improve drilling stability while reducing material stress and deformation risks.

Relationship Between Machining Accuracy and Subsequent Drilling

The initial positioning and depth of a drilled hole establish the accuracy foundation for subsequent operations. Deviations in the initial drilling depth cannot be fully corrected later, even with high-precision tools, potentially affecting hole coaxiality and flatness. Using proper tool geometry and cutting speeds reduces drilling eccentricity and vibration, ensuring each hole meets design requirements. In multi-step drilling, depth compensation and continuous measurement help keep each operation within tolerance, improving final part consistency and accuracy.

Differences in Spot Drilling Depth Requirements for Different Materials

Material hardness, toughness, and thermal conductivity significantly influence depth control. Hard alloys or stainless steel are prone to tool rebound and wear, while soft materials like aluminum and copper may experience depth deviations due to excessive cutting forces. Adjusting cutting speed, feed rate, and tool type for the specific material effectively controls depth and reduces burrs and edge damage. Pre-drilling or center drilling for pre-positioning is especially beneficial for thin-walled parts or high-precision molds, ensuring consistent hole depth.

Impact of Depth Errors on Part Quality in CNC Machining

Depth errors directly affect assembly accuracy, functionality, and part lifespan. Shallow holes may result in insecure threads or pins, while overly deep holes waste material and weaken structural integrity. Common causes include insufficient machine rigidity, unstable fixtures, and tool wear. Real-time monitoring of cutting forces, tool compensation adjustments, and high-precision measurement equipment can effectively reduce depth deviations, ensuring each hole meets process requirements and improving overall part quality and machining reliability.

Key Factors Affecting Spot Drilling Depth

Drilling depth stability is influenced by several factors. Even minor deviations can lead to hole position errors, affecting subsequent machining accuracy and part assembly quality. By optimizing tool design, adjusting cutting parameters, improving machine rigidity, and adopting material-specific processing strategies, depth deviations can be significantly reduced. This ensures high-precision and highly repeatable drilling. For high-precision parts or multi-hole machining, understanding these factors and implementing targeted control measures is essential for reliable processing and production efficiency.

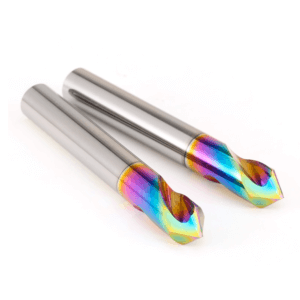

Spot Drilling Tool Types and Tool Tip Geometry

The type and geometric design of a tool directly determine its depth control capability. Tools with varying diameters, cutting edge lengths, and tip angles exhibit different levels of cutting stability. An appropriate tip angle reduces initial drilling offset and minimizes vibrations. For deep holes or hard materials, selecting wear-resistant coated tools improves depth accuracy, extends tool life, and reduces errors caused by tool wear. Additionally, a proper tool layout and the use of multi-step drilling techniques help maintain stability during continuous hole machining.

Optimal Cutting Parameters

Cutting speed, feed rate, and single-pass depth are crucial for controlling hole depth. Excessive speed or feed can cause vibrations and result in hole depths exceeding design specifications, while insufficient depth increases processing time and tool wear. Adjusting cutting parameters to match tool characteristics for different materials and hole diameters reduces cutting force fluctuations, ensuring each drilling operation reaches the target depth. Moreover, depth compensation and multi-stage feed strategies further improve stability and repeatability.

CNC Machine Rigidity and Fixture Stability

Machine tool rigidity and fixture stability are fundamental to maintaining consistent hole depth. Low rigidity can cause micro-vibrations under cutting forces, resulting in depth deviations. Unstable or vibrating fixtures affect tool-workpiece contact accuracy, leading to inconsistent hole positions. Using high-rigidity machines, optimizing fixture design, and distributing clamping points strategically reduce depth errors, while also enhancing processing efficiency and surface quality.

Influence of Material Hardness and Surface Treatment

Material hardness, toughness, and surface treatment significantly affect drilling depth. Hard materials may cause tool rebound and vibration, leading to uneven hole depths, while soft materials can collapse or over-drill due to excessive cutting forces. Selecting the appropriate tool type, adjusting cutting parameters, and using a center drill for pre-positioning effectively control depth. Surface treatments such as plating or heat treatment alter cutting resistance, making proper tool selection and processing strategy critical for achieving accurate and stable hole depths.

The Role of Center Spot Drilling in Depth Control

Accurate initial hole positioning is essential for consistent depth and diameter during subsequent drilling. Using a center drill (for pre-positioning) provides a reliable reference point for spot drilling and subsequent operations, significantly reducing depth deviations and machining errors. Proper use of a center drill ensures consistency in multi-hole machining, reduces tool vibration, and stabilizes cutting forces. Combining tool geometry, optimized cutting parameters, and pre-drilling strategies enables precise hole depth control in production.

Techniques for Combining Center Drilling and Spot Drilling

In multi-step drilling, a center drill creates a small locating indentation, providing a precise starting point for spot drilling. Selecting the correct center drill diameter to match the spot drill prevents initial offset and improves hole position accuracy. Adjusting cutting speed and feed ensures a stable pre-positioning indentation. Proper tool alignment and vibration control reduce depth errors during subsequent spot drilling. Coated or wear-resistant center drills further maintain consistent hole depth when machining hard materials.

Reducing Depth Deviation Through Center Drill Pre-positioning

Pre-positioning establishes a stable guide hole on the workpiece surface, helping the spot drill maintain the correct angle and depth during initial drilling. This reduces starting offset and controls cutting force fluctuations, minimizing hole depth variations. Utilizing machine tool compensation and depth monitoring further ensures that each hole meets design requirements, improving consistency and reliability in multi-hole machining.

Depth Control Strategies for Center Drilling in Multi-Step Drilling

Multi-step drilling typically uses a stepwise deepening method, combining center and spot drilling for precise depth control. Performing depth checks and applying compensation after each step prevents cumulative errors that could lead to deviations. Planning tool diameter, tip angle, and cutting sequence, along with center drill pre-positioning, reduces cutting vibration and material deformation. This approach ensures repeatable accuracy and overall part quality, especially for hard materials and thin-walled components, enhancing machining stability and extending tool life.

The Impact of Spot Drilling Tool Selection on Depth Control

Drilling depth stability largely depends on selecting the right cutting tool. Tools vary in materials, diameters, and flute lengths. These differences significantly affect cutting stability during processing. The proper tool maintains consistent drilling depth, reduces vibration and cutting force fluctuations, and improves repeatability in multi-hole part machining. Additionally, wear resistance and surface coatings directly impact depth control stability. Combining machine tool compensation with optimized processing parameters minimizes errors and enhances part quality and production efficiency.

The Impact of Different Tool Diameters and Flute Lengths on Depth Stability

Tool diameter and flute length directly affect drilling depth accuracy. Longer tool tips are prone to bending and vibration, which can lead to depth deviations, while shorter tips offer higher rigidity and stability but may limit deep hole machining. Matching the tool diameter to the workpiece hole and using gradual deepening or multi-step drilling strategies improves efficiency and hole position consistency. Optimizing tool geometry further reduces the impact of initial offset and cutting vibrations.

Advantages of Coated Tools in Deep Hole Machining

Coated tools, such as TiN and TiAlN, improve depth control stability in deep hole machining. These coatings provide excellent wear resistance and high-temperature hardness, reducing friction and tool wear while maintaining consistent hole depth. For high-hardness materials or high-speed machining, coated tools also reduce cutting force fluctuations and improve hole position repeatability. When combined with optimized cutting speed and feed rate, coated tools effectively extend tool life and reduce depth errors caused by wear.

Analysis of the Impact of Tool Wear on Processing Depth Deviation

Tool wear, especially at the tip, increases over processing time and directly affects depth stability. Wear can cause hole position deviations and burrs. Regular tool inspection, implementing tool life management, and adjusting depth compensation parameters effectively control these errors. Using wear-resistant coatings and optimizing cutting parameters further reduces tool wear, enhancing consistency and repeatability in deep hole machining, ensuring parts meet design specifications.

Spot Drilling Depth Detection and Adjustment Methods

Precise drilling depth control requires systematic detection and adjustment. Even with high-precision tools and optimized parameters, small deviations may occur due to machine vibration, tool wear, or material variations. Advanced measurement techniques, tool compensation, and processing data feedback help control depth errors, improving repeatability and part quality. For high-precision or multi-hole machining, these methods ensure each hole meets design requirements while reducing rework and material waste.

Using Triggered Measurement and Machine Tool Automatic Measurement Technology

Triggered measurement uses a tool or probe to contact the workpiece, enabling real-time depth detection. It quickly captures initial deviations. Combined with machine tool automatic measurement, it monitors each hole’s depth during machining, allowing timely adjustments to cutting parameters or tool position. This improves accuracy and multi-hole consistency, especially for high-hardness materials or deep holes. Recording and analyzing measurement data further optimizes subsequent processing strategies.

Depth Correction Method Based on Tool Length Compensation

Small variations in tool length directly affect depth stability. Depth compensation based on tool length allows correction of machine parameters before machining, ensuring consistent starting position and depth. Monitoring tool wear and cutting force feedback enables dynamic adjustment, reducing cumulative errors. In multi-step or high-precision drilling, pre-machining compensation improves depth consistency and repeatability, ensuring parts meet tight tolerances.

Pre- and Post-Machining Part Depth Detection and Data Feedback

Pre-machining inspection determines the initial workpiece surface and hole positions, providing a reference baseline. Post-machining re-measurement verifies accuracy and records data. Establishing a feedback mechanism allows adjustments to tool parameters, cutting speed, or feed rate, achieving closed-loop control. Accumulated data helps analyze depth deviation causes, optimize tool usage, and improve overall production efficiency and part quality stability.

Optimizing Depth Control with a Spot Drilling Tools Supplier

In high-precision drilling operations, stable depth control depends not only on machine capability and machining strategy but also on tool quality and supplier support. Establishing a long-term partnership with a reliable spot drilling tool supplier ensures access to high-precision, wear-resistant tools while enabling process optimization through professional technical assistance. This collaboration helps minimize hole depth variation caused by tool inconsistencies and significantly improves machining repeatability and overall part quality. In multi-hole applications or when machining high-hardness materials, supplier expertise and customized services often play a decisive role in achieving consistent and reliable depth control.

How to Choose a Reliable Supplier to Ensure Tool Accuracy

When selecting a tool supplier, key considerations include tool manufacturing accuracy, production consistency, and the robustness of the supplier’s quality management system. High-precision tools help maintain consistent drilling depth across all operations, reducing variation and material waste. In addition, evaluating delivery reliability and technical service responsiveness ensures timely support during tool changes or process adjustments. A supplier with a stable supply chain and strict quality control enables consistent tool performance in high-precision machining environments, ensuring drilling depth consistently meets design specifications.

The Role of Customized Spot Drills or Tool Debugging Services in Depth Control

Customized tools can be designed to match specific hole diameters, target depths, and material characteristics, directly improving depth control accuracy. Tool debugging services—such as optimizing tip geometry, adjusting cutting edge length, and selecting appropriate coatings—address potential deviation issues before production begins. Through customization and pre-process optimization, cutting stability and wear resistance are enhanced. This reduces depth variation during machining and minimizes the effects of tool wear and machine vibration, improving consistency and efficiency in multi-hole machining applications.

The Impact of Supplier Technical Support on Processing Stability

Supplier technical support provides valuable guidance on tool selection, cutting parameter optimization, and depth compensation strategies. Support services may include recommended cutting data, tool life management programs, and on-site or remote process troubleshooting. When combined with machine monitoring and measurement systems, supplier recommendations help achieve highly repeatable and precise drilling results. This integrated approach not only improves production efficiency and yield but also provides reliable process stability when machining complex components or high-hardness materials.

Spot Drilling Depth Control Practical Case Studies

In real-world machining environments, drilling depth stability directly affects dimensional accuracy, assembly performance, and overall production efficiency. By integrating proper tool selection, optimized cutting parameters, center drill pre-positioning, and supplier technical support, consistent depth control can be achieved across a wide range of materials and machining conditions. Practical case studies demonstrate that systematic depth control methods effectively reduce machining errors, improve part quality, and enhance productivity for both high-hardness stainless steel and lightweight aluminum alloy components.

Multi-Hole Spot Drilling of Stainless Steel Parts: A Case Study

When machining multi-hole stainless steel components, high material hardness and elevated cutting forces often lead to depth variation and hole position errors. By applying wear-resistant coated tools and center drill pre-positioning, along with a gradual multi-step drilling strategy, drilling depth can be effectively controlled while reducing vibration. Optimized cutting speeds and feed rates ensure consistent performance at each hole location. Continuous tool wear monitoring and depth compensation further ensure that all drilled holes meet design requirements, significantly improving overall part accuracy.

High-Speed Spot Drilling Depth Optimization for Aluminum Alloy Parts

In high-speed machining of aluminum alloys, effective depth control focuses on minimizing cutting force fluctuations and preventing hole deformation. Selecting the appropriate tool diameter and cutting edge length, combined with optimized cutting speed and feed rate, supports stable depth control at elevated spindle speeds. Center drill pre-positioning enables accurate tool engagement, while coated tools and tool length compensation enhance repeatability. These measures ensure that multi-hole aluminum alloy parts maintain high precision and stable depth consistency even under high-speed machining conditions.

Sharing Experience in Solving Common Depth Deviation Problems in Machining

Common depth deviation issues in daily machining typically result from tool wear, machine vibration, unstable fixturing, and material property variation. Effective solutions include selecting high-precision, wear-resistant tools and leveraging supplier customization or debugging services; using center drills for accurate pre-positioning combined with multi-step drilling strategies; and implementing closed-loop control through tool length compensation, depth monitoring, and pre- and post-machining inspection feedback. Applying these practices systematically improves drilling depth consistency, enhances machining stability, ensures compliance with design requirements, and increases overall production efficiency.