Stainless steel, a high-strength, corrosion-resistant material, is widely used in mechanical manufacturing, mold making, and industrial equipment. Due to its high hardness and machining difficulty, selecting the right drill bit is crucial for ensuring efficient drilling and high hole quality. In 2025, the market will feature a range of high-performance drill bits, including high-speed steel (HSS), cobalt alloy (Cobalt), and carbide, each offering advantages in wear resistance, cutting speed, and tool life.

For engineers and procurement professionals, understanding the performance differences between cobalt alloy and carbide drill bits for stainless steel, mastering practical stainless steel drilling tips, and choosing a reliable OEM drill bit supplier are essential steps to achieve high efficiency and cost savings. Adjusting cutting speeds, feed rates, and cooling solutions for different stainless steel grades (304, 316, or 410) can significantly extend drill life and ensure precise holes.

Comparison of the Most Recommended Stainless Steel Drill Bit Models in 2025

Drill bit selection directly affects machining efficiency, hole accuracy, and tool life. By 2025, advanced HSS, cobalt alloy, and carbide drill bits will offer unique benefits in wear resistance, cutting performance, and precision drilling. Engineers and procurement teams can select the best drill bit for stainless steel by comparing materials, geometries, and coating technologies, balancing cost, durability, and application requirements.

1. Advantages and Limitations of HSS Drill Bits

HSS drill bits are renowned for toughness and machining stability, making them suitable for medium-thick stainless steel and small-batch production. Their advantages include low chipping, cost-effectiveness, and easy resharpening. However, HSS exhibits lower wear resistance during high-hardness or prolonged continuous drilling, making it more prone to thermal deformation and reduced tool life. HSS is ideal when extreme precision is not the primary concern.

2. Performance of Cobalt Alloy Drills in Stainless Steel Machining

Cobalt drills offer high hardness and heat resistance, making them ideal for austenitic stainless steels (304, 316) and harder workpieces. Compared to HSS, cobalt drills maintain sharpness under high-speed cutting, improving drilling efficiency and reducing burr formation. For medium- to high-volume production, cobalt drills reduce tool change frequency while maintaining consistent hole quality.

3. Wear Resistance Analysis of Carbide Drills

Carbide drills deliver exceptional hardness and wear resistance, making them ideal for high-hardness stainless steel and thick plates. They excel in high-speed and continuous production environments, ensuring stable hole dimensions and fewer tool changes. While costlier and requiring precise cooling, carbide drills offer superior performance for high-volume or precision-critical applications.

4. Cobalt Alloy vs Carbide Drill Bits: Efficiency and Life Comparison

Cobalt alloy drill bits provide balanced performance for medium-hard stainless steel and moderate production volumes. Carbide drill bits deliver longer life and higher efficiency for high-hardness materials and high-speed operations. Understanding these differences helps factories optimize tool selection, production costs, and machining efficiency for stainless steel drilling.

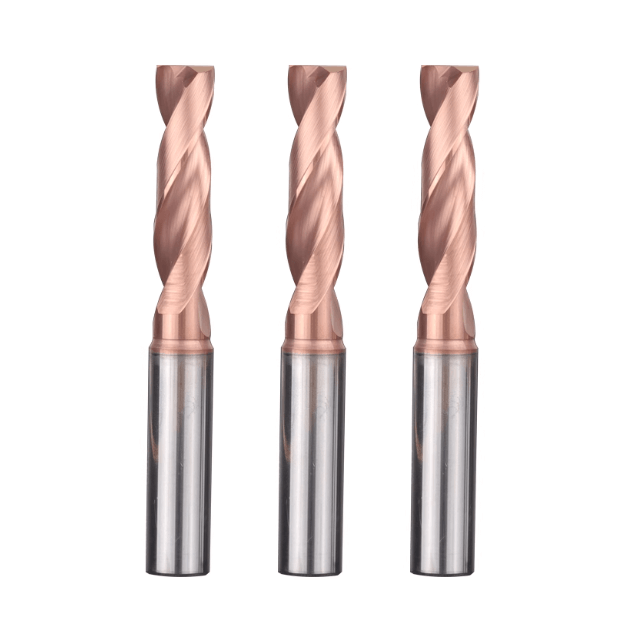

5. Coated Drill Bits Enhance Cutting Performance

Coatings such as TiN, TiAlN, and TiCN reduce cutting friction, increase wear resistance, and extend drill life. Selecting the right coating type helps control drilling temperature, prevent chip adhesion, and improve hole quality, especially in high-precision or hard-material applications. Combining coated drill bits with optimized cutting parameters ensures stable and efficient production.

Practical Tips and Efficient Drilling Techniques for Stainless Steel

Drilling stainless steel requires careful attention due to its low thermal conductivity, high strength, and tendency to work-harden. Following structured preparation, optimal cutting parameters, effective cooling, and correct drilling strategies can reduce tool wear, improve hole quality, and boost overall production efficiency. These tips are essential for precision machining companies and B2B factories seeking consistent and reliable results.

Workpiece Preparation and Positioning Methods Before Drilling

Ensuring a flat, stable workpiece is the first step to accurate hole drilling. Using locating fixtures, guide sleeves, or pre-drilled pilot holes prevents drill wandering. For thick plates or large workpieces, zoned clamping and adequate support reduce vibration, burr formation, and the risk of overloading the drill. High-precision alignment tools further enhance hole accuracy and repeatability.

Optimal Cutting Speed and Feed Rate Settings

Cutting speed and feed rate should be tailored to the stainless steel type and thickness. For austenitic grades like 304 and 316, lower speeds and moderate feed rates reduce cutting temperature and wear. Matching cutting parameters with drill material (HSS, Cobalt, or Carbide) and coating type helps extend drill life and maintain machining efficiency.

Coolant Use and Chip Removal Techniques

Low thermal conductivity makes stainless steel prone to overheating, which can cause chipping and reduce hole quality. Using high-efficiency coolant or cutting oil at the correct angle and flow rate helps manage temperature. Optimizing drill flute design and chip evacuation prevents blockages, ensures smooth chip flow, and maintains stable production.

Methods for Preventing Drill Overheating and Chip Chipping

Overheating is a leading cause of shortened drill life. Techniques like segmented drilling, slow feed with fast retraction, and step drilling reduce cutting loads. Regular inspection and resharpening of drills further prevent chipping and maintain consistent hole quality.

Different Strategies for Thin and Thick Plate Machining

Thin plate drilling requires lower cutting speeds, secure clamping, and support plates to minimize deformation, burrs, and hole deviation. Thick plates need attention to heat accumulation, smooth chip evacuation, and multi-stage drilling to avoid overload. Selecting appropriate drill diameter and material based on plate thickness ensures high-quality holes and efficient machining.

How to Choose the Best Drill Bit for Stainless Steel

Choosing the right drill bit ensures optimal machining efficiency, accurate holes, and extended tool life. Differences in hardness, thermal expansion, and wear resistance among stainless steel grades must be considered. Drill selection should account for material, geometry, cutting parameters, and batch size to reduce costs and machine wear.

Select Drill Bit Material Based on Stainless Steel Grade (304, 316, 410, etc.)

-

Austenitic stainless steels (304, 316): Cobalt alloy drills maintain sharpness at high temperature, suitable for medium- and high-speed cutting.

-

Martensitic or high-hardness steels (410): Carbide drills handle continuous machining and thick plate drilling, extending tool life.

-

Thin plates or small-batch runs: HSS drills provide cost-effective toughness and easy resharpening.

Matching drill material to stainless steel grade balances cutting efficiency, tool wear resistance, and precision hole quality.

The Impact of Drill Bit Geometry and Angles on Cutting Performance

Point angle, helix angle, and blade profile design significantly affect cutting performance.

-

Point angle influences cutting force and hole entry quality. Smaller angles suit thin plates; larger angles suit thick plates.

-

Helix angle affects chip evacuation and drilling stability. High angles improve chip flow but must be controlled for hard steels.

-

Blade profile (split point, parabolic flute) reduces torque and prevents deviation.

Optimizing drill geometry ensures precision and consistent production.

Machining Accuracy Requirements and Drill Bit Selection Strategies

High-precision parts require drills that maintain wear resistance and dimensional accuracy. Coated carbide or high-precision cobalt drills are recommended for strict tolerances. For moderate precision, HSS or cobalt drills combined with optimized cutting parameters suffice. CNC production benefits from stable, repeatable drills to minimize secondary operations.

Cost-Effectiveness Analysis: Balancing Lifespan, Efficiency, and Cost

-

Carbide drills: Higher initial cost, longer life, suitable for high-volume or thick plate machining.

-

Cobalt drills: Moderate cost, excellent wear resistance, suitable for medium-hard stainless steel and medium production runs.

-

HSS drills: Low cost, easy to sharpen, ideal for short-run or small-batch production.

Balancing drill life, machining efficiency, and procurement cost is key to an optimized stainless steel drilling strategy.

OEM Drill Bit Supplier Selection and Purchasing Guide

In stainless steel machining and CNC production, selecting a reliable OEM drill bit supplier not only affects tool quality but also directly impacts production efficiency and process stability. Whether purchasing high-wear-resistant drill bits in bulk or customizing precision drilling solutions, engineers and procurement personnel must consider the supplier’s technical expertise, production capacity, quality control systems, and after-sales service. Evaluating suppliers scientifically reduces procurement risks while ensuring access to high-performance stainless steel drill bits and long-life CNC drilling tools.

Key Indicators for Selecting a Reliable Supplier

When choosing an OEM drill bit supplier, consider the following critical indicators:

-

Product Quality and Durability: Verify that the supplier offers standard cobalt alloy, carbide, or coated drill bits to ensure wear resistance and cutting efficiency.

-

Technical Capabilities and R&D Strength: Suppliers with precision tool design experience and material optimization expertise can provide customized drill solutions tailored to CNC machining requirements.

-

Production Capacity and Delivery Reliability: Stable production and on-time delivery prevent tool shortages from disrupting production schedules.

Assessing these indicators ensures long-term, stable cooperation with high-quality OEM drill bit suppliers.

Considerations for Bulk Procurement and Customized Services

For high-volume production or special workpieces, supplier customization capabilities are crucial:

-

Custom drill geometries, coating types, and tool lengths can be specified based on stainless steel grade, thickness, and hole diameter.

-

Define quality standards and tolerance requirements clearly for bulk orders to prevent batch-to-batch performance variation.

-

Establish clear purchase contracts detailing delivery schedules, acceptance criteria, and technical support to ensure customized drill bits meet production demands.

Recommendations for Quality Inspection and After-Sales Support

High-performance drill bits rely on rigorous quality control and after-sales support:

-

Confirm that the supplier provides factory inspection reports, hardness testing, and geometric dimensional verification for consistent drill performance.

-

Set up after-sales communication channels to address tool issues, such as premature wear, chipping, or deviation in hole accuracy.

-

Prefer suppliers with technical support teams capable of recommending CNC cutting parameter optimization to improve production efficiency.

International Sourcing Experience and Logistics Considerations

For global procurement, logistics and supply chain management are critical:

-

Choose suppliers familiar with international shipping, tariffs, and customs regulations to ensure timely tool delivery.

-

Assess packaging and transportation safety to prevent damage or corrosion.

-

Establish long-term partnerships for priority supply and technical support, especially for urgent or high-volume orders.

Rational planning of international sourcing ensures efficient, stable stainless steel drilling operations while minimizing supply risks.

Best Drill Bit Selection and OEM Procurement Strategies for Stainless Steel in 2025

Selecting the right drill bit and optimizing procurement strategies are key to efficient stainless steel processing, reduced tool wear, and accurate holes. This analysis of high-speed steel (HSS), cobalt alloy, carbide, and coated drill bits provides a systematic guide for engineers and purchasing personnel. By integrating practical drilling techniques, optimized cutting parameters, and reliable OEM supplier selection, companies can develop an efficient production solution balancing performance, quality, and cost.

Summary of Drill Bit Advantages, Disadvantages, and Application Scenarios

-

HSS Drill Bits: Cost-effective, tough, suitable for thin plates and small-batch production, but limited wear resistance in high-hardness or continuous machining.

-

Cobalt Alloy Drill Bits: High hardness and temperature resistance, ideal for medium-thick plates and austenitic stainless steel, improving efficiency and hole accuracy.

-

Carbide Drill Bits: Excellent wear resistance, suitable for high-hardness and thick plates, offering long life at higher cost.

-

Cobalt vs. Carbide: Cobalt is best for medium-hardness and small-to-medium batches; carbide excels in high-hardness or high-speed applications.

-

Coated Drill Bits: Reduce friction, increase wear resistance, manage heat, and improve hole surface quality, especially in precision machining.

Matching drill material to stainless steel grade, hole diameter, and batch size achieves a balance between efficiency and quality.

Summary of Machining Techniques and Cutting Parameter Optimization

-

Proper cutting speed, feed rate, and cooling strategies extend drill life and ensure hole accuracy.

-

Workpiece preparation and positioning minimize hole deflection and vibration.

-

Optimized coolant and chip removal improve production stability and prevent overheating or chipping.

-

Different drilling strategies for thin and thick plates enable efficient machining across various workpieces.

Combining these techniques significantly enhances CNC stainless steel drilling efficiency and production stability.

Summary of OEM Drill Purchasing Strategies

-

Evaluate supplier quality, technical capabilities, and production capacity.

-

Bulk and custom purchases require defined tolerances, geometry, and coatings.

-

Establish quality inspection and after-sales systems for consistent performance.

-

For international procurement, prioritize logistics, packaging, and long-term partnerships to reduce supply risks.

Scientific procurement and strong OEM collaboration ensure an efficient, stable tool supply chain for stainless steel drilling.

Quick Selection Decision Reference for Engineers and Purchasers

-

Material Matching: Select HSS, Cobalt, or Carbide based on stainless steel grade.

-

Machining Efficiency: Carbide for high-hardness or thick plates; HSS or Cobalt for thin plates or small-to-medium batches.

-

Hole Accuracy: Use coated or precision Cobalt drills for high-precision applications.

-

Cost-Effectiveness: Balance drill lifespan, efficiency, and procurement costs.

-

Supply Chain Assurance: Choose reliable OEM suppliers for consistent quality and on-time delivery.

Following these strategies enables companies to achieve efficient, stable, and cost-effective stainless steel drilling by 2025, supporting CNC production and large-scale manufacturing.