Choosing the right CNC milling cutter directly impacts metalworking efficiency, part accuracy, and production costs. Yet many engineers and purchasing personnel make common mistakes during the selection process, leading to reduced machining efficiency, shortened tool life, and increased production costs. Whether selecting between HSS and carbide CNC milling cutting tools for high-speed cutting or finding the best cutting tool for metal, a strategic approach to tool selection is essential.

In practice, understanding how to choose CNC milling cutting tools for metal machining based on workpiece material, machining depth, and surface requirements is often overlooked. For high-precision manufacturers, bulk custom CNC milling cutting tools can improve production efficiency and ensure consistent part quality. However, improper selection can result in unnecessary cost waste and reduced performance.

Efficiency Loss Due to Incorrect Tool Material Selection

The choice of tool material significantly affects cutting efficiency, tool life, and machining costs. Selecting inappropriate materials for the hardness, toughness, and cutting characteristics of different metals often results in reduced efficiency, substandard surface quality, and increased tool replacement frequency. For example, HSS and carbide tools differ greatly in wear resistance, cutting speed, and machining stability when working with metals such as aluminum, copper, and steel. Understanding the characteristics of HSS vs carbide CNC milling cutting tools is crucial.

In high-volume or precision part production, improper material selection can affect workpiece consistency and increase costs. This is especially true for high-hardness metals like titanium, stainless steel, or Inconel, where tool chipping and rough surfaces are common problems. Learning how to choose CNC milling cutting tools for metal machining not only improves efficiency but also extends tool life and reduces overall costs.

Misconceptions About HSS vs Carbide CNC Milling Cutting Tools

Many engineers choose tools based on intuition or price alone. Some assume HSS is suitable for all metals, while others blindly use carbide for high-hardness materials without adjusting cutting parameters. In reality, HSS is ideal for low- to medium-speed machining of low- and medium-hardness metals, offering cost-effectiveness, toughness, and breakage resistance. Carbide, in contrast, is suited for high-speed cutting of hard metals, maintaining stability under heavy loads and long cycles.

Understanding the differences in cutting speed, wear resistance, and cost is essential for selecting the best cutting tool for metal. Choosing the wrong tool material leads to efficiency loss, frequent tool changes, and higher machining costs.

Ignoring Material Hardness and Workpiece Type

Another common error is neglecting the hardness and type of the workpiece. Machining high-hardness metals like titanium alloys and stainless steel requires higher-quality tool materials, proper geometry, and optimized cutting parameters. Using low-hardness tools or improper cutting conditions can cause chipping, rough surfaces, and dimensional inaccuracies.

Tool selection should consider material hardness, workpiece shape, machining depth, and production volume. Combining careful analysis with bulk custom CNC milling cutting tools for precision manufacturers ensures optimal tool performance, efficient machining, and maximum tool life.

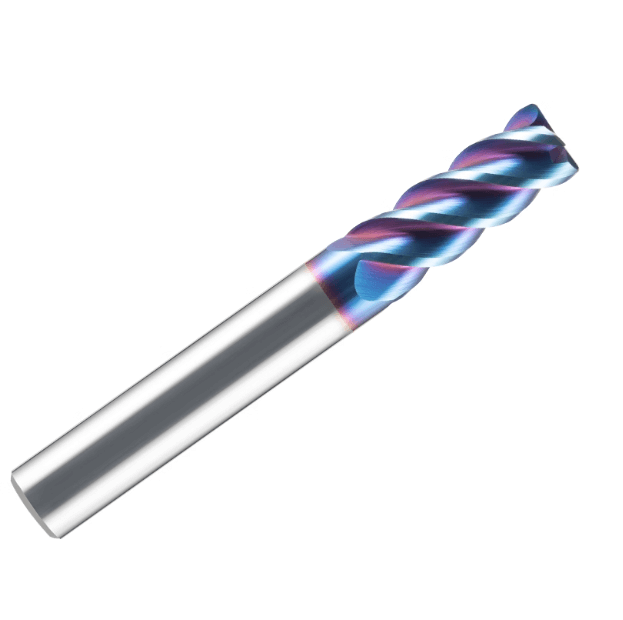

Improper Tool Geometry and Coating Selection

Tool geometry and coatings are critical for CNC metalworking. Even high-performance tools may fail if geometry or coating is mismatched to the material or process, resulting in excessive cutting forces, rough surfaces, and shortened tool life. Engineers must evaluate tool geometry and coating alongside material selection to ensure cutting stability and accuracy. Proper geometry design combined with suitable coatings improves machining performance and extends tool life—key factors when selecting the best cutting tool for metal.

Common Mistakes in Tool Geometry Selection

Ball-nose and flat-bottom end mills serve different purposes, yet engineers often select them incorrectly. Using a ball-nose mill for flat surfaces increases machining time and reduces surface finish; using a flat-bottom mill for curved surfaces leaves tool marks and rough finishes.

Cutting edge angles, helix angles, and flute designs significantly affect cutting forces, chip evacuation, and machining stability. Even premium materials and coatings cannot compensate for poor geometry. Bulk custom CNC milling cutting tools must consider these parameters to match the tool to the process.

Improper Coating Selection Leads to Reduced Tool Life

Coatings influence wear resistance, heat tolerance, and material compatibility. Misusing TiN, TiAlN, or CVD diamond coatings can shorten tool life or produce poor surfaces. CVD is suitable for hard metals but may increase resistance and cause stringing in aluminum. Incorrect TiN/TiAlN application on HSS or carbide also reduces wear resistance.

Coating selection should align with material, cutting speed, and machining type. Combined with optimized geometry, this approach enhances cutting efficiency, accuracy, and tool life, while minimizing downtime and costs.

Incorrect Machining Strategies and Parameter Settings

Proper machining strategies and cutting parameter settings are critical for achieving optimal performance from CNC milling cutters. Incorrect feed rates, cutting speeds, or cooling and lubrication methods not only reduce machining efficiency but also accelerate tool wear and can lead to chipping. Many engineers focus only on tool material and geometry when choosing CNC milling cutting tools for metal machining, neglecting parameter optimization. This prevents the tools from reaching their full potential. A sound machining strategy involves adjusting cutting parameters based on the workpiece material, balancing high-speed machining with tool life, and selecting appropriate cooling and lubrication methods—all essential for improving productivity and part quality.

Neglecting Feed and Cutting Speed Optimization

Different metals require different cutting speeds and feed rates. Soft metals such as aluminum and copper can tolerate higher cutting speeds, while hard metals like stainless steel or titanium alloys require lower speeds to prevent overheating and excessive wear. Ignoring feed and speed optimization can result in unstable cutting forces, poor surface finish, and reduced tool life.

In high-speed machining, balancing efficiency and tool wear is crucial. Even high-performance HSS or carbide CNC milling cutting tools cannot perform optimally if cutting parameters are not correctly set. This is especially important when purchasing bulk custom CNC milling cutting tools for precision manufacturers.

Not Considering Cooling and Lubrication Methods

Cooling and lubrication are equally important for CNC metalworking. Different materials and machining methods require different coolant types and application methods: dry cutting is suitable for low-power machining or specific metals; spray cooling reduces tool temperature and improves cutting efficiency; oil cooling effectively extends tool life when machining high-hardness materials.

Using improper cooling strategies, such as dry cutting high-hardness metals or insufficient coolant, can lead to overheating or tool chipping, compromising both accuracy and tool longevity. Combining correct cutting parameters with appropriate coatings can significantly enhance the performance of CNC milling cutters, achieving high efficiency, precision, and long tool life.

Misconceptions in Purchasing and Customizing Tools

Tool procurement and customization directly affect production efficiency, machining accuracy, and overall costs. Many companies fall into misconceptions during selection and procurement. When buying bulk custom CNC milling cutting tools for precision manufacturers, some fail to account for machining requirements or analyze workpiece materials and processes adequately. This can cause tool mismatches with actual machining conditions, increasing costs and tool replacement frequency.

Some companies focus solely on price, neglecting tool performance, lifespan, and efficiency. While this may save short-term costs, it can negatively impact part quality, increase downtime, and reduce long-term production efficiency. Understanding how to choose CNC milling cutting tools for metal machining is essential to ensure effective and cost-efficient production.

Mass-Customized CNC Milling Cutting Tools Ignoring Machining Requirements

Mass-customized CNC milling cutters can optimize designs for specific materials, geometries, and machining depths. Common errors include:

-

Failing to consider workpiece hardness or cutting conditions, resulting in inadequate tool durability;

-

Mismatching tool geometry or coatings with the material, reducing cutting stability;

-

Tool specifications that do not align with production schedules, lowering machining efficiency.

These errors lead to costly waste, production delays, and inconsistent part quality. When customizing tools, a comprehensive evaluation of process requirements, machining strategies, and tool performance is critical to ensure that tools meet precision manufacturing standards.

Purchasing Focused Solely on Price and Ignoring Performance

Many companies purchase cutting tools based only on cost, overlooking key performance indicators such as tool life, cutting efficiency, and machining stability. Inexpensive tools may initially reduce procurement costs but can lead to rapid wear, rough surfaces, or frequent replacements when machining hard metals or at high speeds, increasing overall production costs.

A sound procurement strategy considers cost-effectiveness, machining efficiency, and tool life. Combining bulk custom CNC milling cutting tools for precision manufacturers with standardized high-performance tools optimizes overall production costs while maintaining machining accuracy and efficiency, maximizing the long-term benefits of metalworking.

Lack of Maintenance and Tool Management Strategies

Tool maintenance and management are critical in CNC metalworking. Even high-performance tools, such as HSS or carbide CNC milling cutting tools, can suffer reduced tool life, lower machining accuracy, and increased production costs without effective maintenance. Tool wear, reduced cutting performance, and inconsistent surface quality often result from insufficient monitoring and improper maintenance. A comprehensive tool management strategy—including regular inspection, sharpening, coating protection, inventory management, and proper tool storage—can extend tool life, enhance machining efficiency, and stabilize production.

Inadequate Tool Wear Monitoring

Accurately assessing tool life is essential for maintaining machining accuracy and efficiency. Excessive tool wear increases cutting forces, produces rough surfaces, and may cause deviations in bore diameters or contours. Many companies lack proper tool wear monitoring systems, preventing timely detection and leading to reduced part quality and unnecessary production interruptions. By recording tool usage data, monitoring wear patterns, and analyzing machining conditions, engineers can scientifically predict tool life, optimize replacement cycles, and maintain stable performance.

Improper Maintenance Leads to Frequent Tool Replacements

Neglecting maintenance is a primary cause of frequent tool replacement. Cleaning, sharpening, and coating protection are fundamental for extending tool life. Ignoring these steps accelerates wear, reduces cutting efficiency, and increases downtime. Selecting appropriate coatings for different metals and machining processes helps prevent premature damage during high-speed or high-temperature cutting.

Factory management also plays a key role. Maintaining tool usage records, training operators, establishing maintenance protocols, and managing inventory can significantly reduce machining problems caused by poor tool management. For bulk custom CNC milling cutting tools for precision manufacturers, a sound maintenance strategy ensures long-term stable performance and production efficiency.

Avoid These Top Mistakes to Improve CNC Milling Cutting Tool Selection

In CNC metalworking, tool selection, machining strategies, customization, and maintenance collectively determine efficiency, part quality, and production costs. Common mistakes include improper tool material selection, incorrect geometry and coating choice, suboptimal machining parameters, errors in procurement and customization, and inadequate maintenance. Understanding and avoiding these mistakes is critical for engineers and manufacturers.

By considering workpiece material hardness, machining requirements, optimizing cutting parameters, and applying bulk custom CNC milling cutting tools for precision manufacturers, tools can be perfectly matched to machining conditions, achieving efficient, stable, and high-quality metalworking. Additionally, implementing a tool wear monitoring and maintenance strategy extends tool life, reduces downtime, and lowers production costs.

Comprehensive Strategy for Selecting the Best Cutting Tool for Metal

-

Material Selection: Choose HSS or carbide CNC milling cutting tools based on workpiece material and hardness to ensure cutting efficiency and wear resistance.

-

Geometry and Coating Matching: Combine tool type, cutting edge angle, helix angle, geometry, and coating properties to optimize cutting forces, chip evacuation, and surface finish.

-

Machining Strategy Optimization: Set feed rates and cutting speeds appropriately, and select suitable cooling and lubrication methods to balance high-speed machining with tool life.

-

Procurement and Customization Management: For bulk custom tools, evaluate cost-effectiveness, performance, and machining stability to avoid wasteful purchases.

-

Maintenance and Tool Management: Establish tool wear monitoring, regular maintenance, and coating protection to extend tool life and improve production stability.

By comprehensively applying these strategies, companies can select the best cutting tool for metal, significantly improve machining efficiency, extend tool life, reduce costs, and ensure consistent, high-precision part production—providing strong support for precision manufacturing.