In mechanical processing and precision manufacturing, the quality of hole machining directly affects product performance and service life. Flat bottom drills are widely applied because they produce bottoms with consistent flatness, but in actual operation, common issues such as diameter deviation, uneven hole bottoms, and burr formation still occur frequently. These problems not only lower machining efficiency but may also lead to assembly challenges or even part rejection.

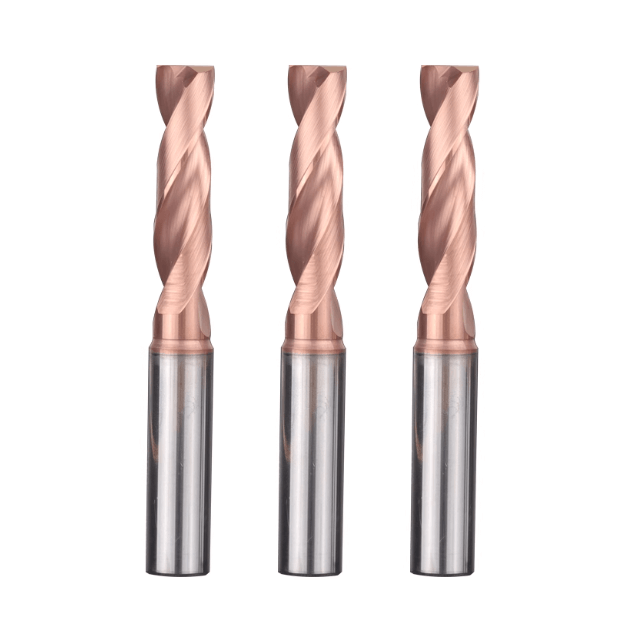

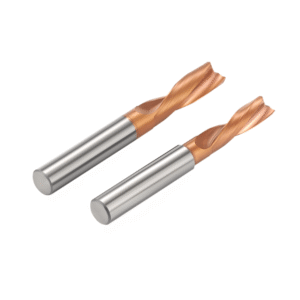

Although using appropriate flat bottom drilling tools and high-precision flat bottom milling drills helps reduce machining defects, cutting results are still significantly influenced by tool selection, parameter settings, machine tool condition, and the cooling and lubrication method used. Additionally, sourcing high-quality tools from a reliable flat bottom drill supplier is essential to ensuring machining stability and extending tool life.

Overview of Common Flat Bottom Drilling Problems

In real-world production, even with high-quality tools and precision machinery, various issues can arise during flat bottom hole machining. These problems affect dimensional accuracy, flatness, and the surface finish of the hole, and they also have a direct impact on assembly precision and long-term component performance.

Analyzing these issues helps manufacturers choose suitable flat bottom drills, optimize machining parameters, improve tool life management, and select efficient cooling and lubrication strategies, ultimately enhancing machining stability and overall productivity.

Excessive Tool Wear

Tool wear is one of the primary factors affecting machining efficiency and hole quality. If the tool material, coating, or geometry is not well matched to the workpiece, or cutting parameters are inappropriate, wear accelerates quickly. Excessive wear often leads to burrs, oversized hole diameters, and rough surfaces while increasing tool change frequency and production costs. Selecting wear-resistant flat bottom drills and using appropriate spindle speeds and feed rates are key measures to extend tool life.

Insufficient Hole Diameter Accuracy

Hole diameter accuracy issues typically include oversized diameters, roundness deviation, or positional errors. These can result from tool wear, insufficient machine rigidity, unstable clamping, or incorrect cutting parameters. Using precision flat bottom milling drills, proper feed and speed settings, and rigid fixtures effectively improves dimensional accuracy and ensures consistency across multiple machined holes.

Surface Burrs and Flashing

Burr formation is common, especially when machining thin-walled or high-hardness materials. Causes include worn cutting edges, insufficient coolant, overly aggressive cutting parameters, or tool vibration. Using sharp tools, maintaining stable clamping, and applying proper cooling and lubrication can significantly reduce burrs and improve surface quality, thereby reducing secondary deburring costs.

Uneven or Stepped Hole Bottoms

Uneven or stepped hole bottoms typically result from improper tool geometry, poor toolpath control, or micro-vibration in the machine tool. Tool tilting, inconsistent cutting depth, or slight positioning errors during multiple passes may also contribute. Selecting tools with proper geometry, optimizing the cutting sequence, and ensuring machine rigidity and accurate positioning help eliminate these defects.

Thermal Deformation Leading to Machining Errors

During prolonged or high-load machining, heat accumulation can cause thermal deformation in both the tool and the workpiece, reducing dimensional accuracy and surface quality. This effect is more pronounced in deep hole machining or when cutting high-hardness materials. Controlling cutting speed, using efficient coolants, selecting heat-resistant coated tools, and adopting intermittent cutting strategies help minimize thermal deformation and maintain consistent machining accuracy.

Tool Selection and Usage Issues

Tool selection has a decisive impact on the final machining quality of flat bottom holes. Variations in tool structure, material, and coating directly affect cutting stability, bottom flatness, and tool life. Even with proper machining parameters, inappropriate tool selection can cause diameter errors, uneven bottoms, vibration, and accelerated wear.

Therefore, when planning machining operations, tool selection should be evaluated from multiple angles, including structure, workpiece compatibility, cutting edge profile, and supplier reliability, to ensure consistent performance throughout the machining process.

How to Choose the Right Flat Bottom Drill

Choosing the right flat bottom drill requires consideration of workpiece hardness, hole depth and diameter, tolerance requirements, and machine rigidity. For applications requiring a clean, flat bottom, tools with stable head geometry, sharp cutting edges, and a balanced core thickness help reduce cutting resistance and vibration. For long continuous machining, wear-resistant coated tools are preferred. Additionally, selecting the correct helix angle and flute profile enhances chip evacuation and reduces the risk of chip packing or hole wall damage.

Material Matching for Flat Bottom Hole Drilling Tools

Tool material must match the workpiece to achieve stable, efficient machining. For aluminum, tools with high sharpness help prevent built-up edge; for stainless steel or heat-resistant alloys, materials with strong toughness and wear resistance prevent chipping. When machining steel or high-hardness materials, coated tools improve wear and oxidation resistance. The core strength of the tool must also be considered to prevent breakage during deep or heavy-duty cutting.

The Impact of Cutting Edge Geometry on Flat Bottom Milling Drill Performance

Cutting edge geometry directly affects cutting resistance, bottom flatness, chip evacuation, and overall stability. Sharp cutting edges improve surface quality, but for hard materials, the edge radius should be increased slightly to enhance durability. Rake and relief angles must be optimized for smooth cutting and consistent finish. Poor edge symmetry or unsuitable geometry leads to vibration, stepped bottoms, or uneven surfaces. Tools with balanced edges and efficient flutes maintain stable cutting and improve bottom flatness.

Tips for Selecting High-Quality Tools from a Flat Bottom Drill Supplier

A reliable supplier ensures consistent tool geometry, stable coating quality, and traceable material specifications. Quality suppliers also offer machining parameter guidance, tool life analysis, and sample testing data to help users choose the most suitable tool configuration. When evaluating suppliers, consider tool performance feedback, batch-to-batch consistency, dimensional accuracy, and available technical support to ensure machining reliability during high-load production.

Problems Caused by Processing Parameters

Machining parameters directly influence the results of flat bottom hole processing. Regardless of tool quality, improper settings for feed rate, spindle speed, cutting depth, coolant method, or tool overhang can lead to uneven bottoms, hole wall damage, accelerated wear, or tool breakage.

Achieving stable results requires adjusting parameters based on material characteristics, tool design, and machine tool capability so the cutting process stays within a controlled and repeatable range.

Improper Feed Rate and Spindle Speed Settings

Feed rate and spindle speed are critical to flat bottom hole quality. A low speed combined with excessive feed increases cutting load, causing vibration and rough surfaces. Conversely, high speed with insufficient feed may lead to tool rubbing, heat buildup, and uneven bottoms. Different materials require distinct cutting speeds—for example, aluminum benefits from high-speed cutting, while stainless steel requires controlled speed to manage heat. Proper tuning of parameters enhances cutting stability and extends tool life, especially in deep holes or mass production.

Improper Coolant Use Leading to Tool Overheating

Insufficient coolant flow, incorrect nozzle positioning, or inadequate cooling strength easily cause temperature spikes at the cutting edge. Excessive heat may degrade the tool coating, soften the cutting edge, or cause chipping. Workpiece defects such as hole wall burning, bottom discoloration, or rough surfaces may occur. To avoid this, select the correct coolant type for the material and ensure accurate delivery to the cutting zone. High-pressure cooling improves heat dissipation during long, continuous machining.

Excessive Tool Overhang Causing Vibration

Tool overhang is closely related to machining stability. Excessive overhang reduces rigidity, making the tool prone to vibration. This vibration negatively affects hole bottom flatness, diameter accuracy, and tool edge integrity. The effect is amplified when machining high-hardness materials or deeper holes. To reduce vibration, minimize tool overhang, use high-rigidity holders, and adjust parameters to maintain cutting load within a stable range.

Repeat Positioning Errors in Multi-Hole Machining

In multi-hole machining, inaccurate positioning, unstable clamping, or compensation errors may cause cumulative deviations between holes. These deviations affect relative positioning accuracy and may also create uneven bottoms or varying diameters across holes. To ensure repeatability, maintain fixture stability, regularly calibrate machine coordinates, and use reliable positioning methods. For mass production, maintaining machining logs helps detect gradual shifts so adjustments can be made promptly.

Machine Tool and Fixture Factors

During flat bottom hole machining, the performance of the machine tool and the stability of the fixture directly determine machining accuracy and the quality of the hole bottom. Even with high-quality tools and proper cutting parameters, inadequate spindle accuracy, unstable clamping, or wear in mechanical components can still lead to diameter deviations, uneven hole bottoms, or reduced surface finish. Therefore, when developing a machining plan, the condition of the machine tool, overall fixture rigidity, and clamping strategy must be evaluated together to maintain stable and controllable cutting performance and ensure consistent and reliable machining results.

Impact of CNC Machine Tool Spindle Accuracy on Flat Bottom Drilling Tools

Spindle accuracy is a key factor influencing cutting stability. If spindle runout exceeds allowable limits, the tool will deviate during rotation, resulting in uneven hole bottoms, inconsistent diameters, or visible marks on the hole wall. These effects become more pronounced when using longer or slender tools. During flat bottom drilling, the spindle’s rotational precision and the concentricity of the tool holder must be strictly controlled; otherwise, even high-performance flat bottom drills will not achieve ideal results. Regular spindle condition checks, proper cleaning of the tool holder, and correct tool clamping are essential for maintaining stable machining quality.

Unstable Workpiece Clamping Leading to Uneven Hole Bottoms

Workpiece stability directly affects hole bottom flatness and positional accuracy. If the fixture does not clamp securely, even minor movement under cutting forces can shift the toolpath, resulting in steps, depressions, or uneven surfaces at the bottom of the hole. This problem becomes more severe when machining hard materials or using higher feed rates. To improve stability, appropriate fixture structures should be used, ensuring adequate support and contact area. For irregular-shaped parts, dedicated fixtures can further prevent micro-movement and help maintain consistent machining quality.

Machining Deviations Caused by Machine Tool Guide Rail or Ball Screw Wear

Guide rails and ball screws gradually wear after prolonged machine tool operation. This reduces positioning accuracy and may lead to path deviations during machining. In flat bottom hole machining, these symptoms may appear as diameter errors, positional deviations, and slight unevenness at the bottom of the hole. Severe wear also increases friction and resistance, causing inconsistent feed rates and further affecting surface quality. In deep hole or multi-hole machining tasks, such deviations may accumulate, making dimensional control more difficult. Regular machine tool maintenance, coordinate system calibration, and verification of ball screw preload are necessary to ensure stable and predictable machining accuracy.

Troubleshooting and Solutions

Timely identification of issues during flat bottom hole machining is critical to maintaining stable and consistent quality. Problems such as tool wear, improper cutting parameters, insufficient clamping force, or inadequate coolant delivery can affect the finished hole at various stages. Through systematic troubleshooting and analysis, the root cause can be accurately identified, and suitable corrective measures can be implemented based on material characteristics, tool structure, and machine tool condition to stabilize the cutting process.

Strategies for Monitoring and Replacing Worn Tools

Tool wear is frequently the main source of machining defects, so it is crucial to implement a well-defined monitoring and replacement system. Tool life can be assessed according to factors such as the machining distance, workpiece material, and hole diameter specifications. Indicators such as increased edge rounding, higher cutting resistance, or deteriorating surface finish can help identify wear early. For continuous production, scheduled inspections or machining-batch tracking can be used to predict tool life and prevent issues such as uneven bottoms, diameter deviations, or tool breakage caused by excessive wear. Using coated, wear-resistant models can further extend tool life and improve consistency.

Optimizing Processing Parameters to Improve Hole Diameter Accuracy

Cutting parameters strongly influence hole diameter accuracy. Adjusting spindle speed, feed rate, depth of cut, and step-down increments can significantly improve diameter consistency and hole bottom flatness. If the hole diameter is oversized, reducing cutting speed and feed rate will help stabilize the cut. If the diameter is undersized, the cutting force may need to be increased to prevent elastic deformation of the tool. In addition, selecting the appropriate chip evacuation strategy helps prevent chip packing, which can lead to dimensional instability or surface defects.

Using Appropriate Coolant and Cutting Lubrication Methods

Proper cooling and lubrication improve machining stability, reduce tool wear, and minimize thermal deformation of the hole wall. When machining hard materials or those with poor thermal conductivity, enhanced cooling is necessary to reduce temperature build-up. For softer materials such as aluminum, preventing built-up edge is the priority. Cooling methods such as external spraying, internal coolant supply, or high-pressure cooling should be chosen based on tool structure and hole depth. Insufficient lubrication or improper spray direction will reduce cutting quality, making accurate coolant delivery essential.

Adjusting Fixtures and Positioning Methods

Clamping directly affects workpiece stability and therefore the flatness of the hole bottom and positional accuracy. If tilting, steps, or positional deviations occur, it is necessary to check whether the fixture is loose, whether clamping force is uniform, and whether contaminants are present on the clamping surfaces. For workpieces with complex shapes or uneven thickness, special fixtures can increase the support area and reduce micro-movement under cutting forces. In multi-hole machining tasks, the positioning datum should be checked regularly to avoid repeated errors caused by fixture wear or loose positioning components.

Obtaining Professional Technical Support from a Flat Bottom Drill Supplier

If troubleshooting does not resolve the issue, consulting a reliable flat bottom drill supplier provides an effective solution. Quality suppliers offer machining case studies, tool application data, and recommendations tailored to specific materials, hole sizes, and machine tool capabilities. They may also provide tool performance reports, parameter suggestions, and trial-cut analysis to help identify and correct issues quickly. In mass production or high-precision environments, technical support significantly improves process stability and reduces trial-and-error costs.

Daily Maintenance and Quality Control

Maintaining stable accuracy and surface quality during continuous flat bottom hole machining requires standardized maintenance procedures and effective quality control. By optimizing the machining environment, performing regular tool and machine checks, managing tool usage data, and analyzing machining feedback, manufacturers can reduce scrap rates and ensure consistent output, especially in multi-material or multi-batch production scenarios.

Tool Cleaning and Regular Maintenance

Flat bottom drills often accumulate chips and residue during machining. If not cleaned promptly, the cutting geometry may be altered, causing subtle steps or scratches at the hole bottom. After each machining task, tools should be cleaned thoroughly, residue removed from the cutting edges, and the tool holder taper inspected for contamination. Tools used long-term should undergo wear inspection to determine whether regrinding or edge correction is necessary to maintain consistent performance.

Machining Environment and Machine Tool Maintenance

The internal condition of the machine tool and the stability of the workshop environment have a direct impact on machining accuracy. Issues such as spindle thermal deformation, backlash in the lead screw, or inadequate guide rail lubrication may cause cumulative errors, affecting hole bottom flatness and diameter consistency. Regular guide rail cleaning, lubrication replenishment, spindle temperature monitoring, and geometric accuracy calibration help reduce positional deviations and micro-vibrations.

Environmental stability—particularly temperature and humidity—also plays an important role. Variations in ambient conditions can cause dimensional drift, especially when machining aluminum alloys, tool steels, or high-hardness materials. Maintaining a stable environment improves repeatability and overall dimensional accuracy.

Establishing Flat Bottom Drill Usage Records

A tool usage log allows tracking tool performance, machining time, wear progression, and the cutting material used. These records help accurately determine replacement intervals and compare performance between different tool batches, particularly those with specialized coatings or edge geometries. When linked with hole diameter inspection data, the records allow quick identification of whether defects are caused by tool wear, reducing repeated issues in mass production.

Finished Product Inspection and Machining Data Feedback

After machining, key dimensions such as hole diameter, perpendicularity, and bottom flatness should be inspected to confirm process stability. If depressions, increased burrs, or dimensional deviations are detected, the data should be fed back into parameter optimization, tool replacement strategies, and fixture adjustments. In environments requiring frequent changeovers or diverse machining tasks, establishing a complete data feedback system improves parameter retrieval efficiency, reduces trial cutting, and enhances productivity.