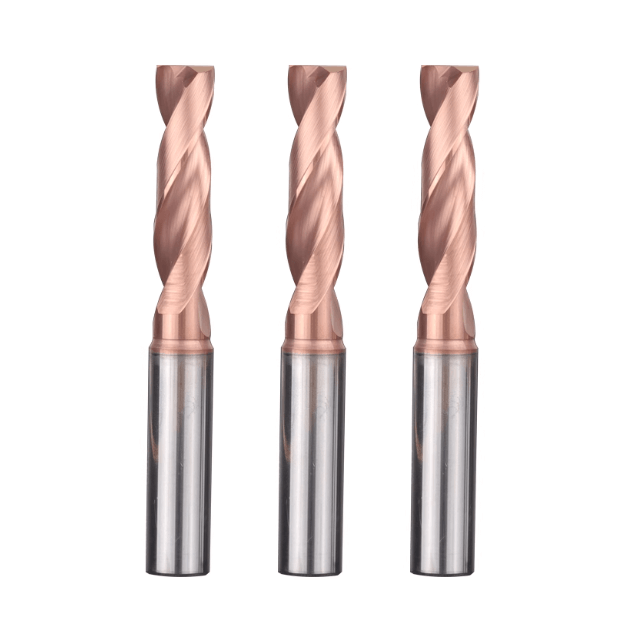

Metal drilling requires high-performance tools. Choosing the right drill bit affects hole accuracy, surface quality, machining efficiency, and tool life. Engineers working with metals such as stainless steel, carbon steel, aluminum, and copper must select the best bit for drilling metal based on hardness, thermal conductivity, and workpiece characteristics. Whether performing high-efficiency CNC drilling or custom drilling for specialized parts, proper tool selection is critical for stable production.

The right combination of tool material, drill point angle, coating technology, and cutting parameters determines drilling performance. Carbide drills offer excellent heat and wear resistance for hard materials, while cobalt alloy drills provide stability in medium-hard metals. Proper cutting speed and feed rate are equally essential: too high a speed can overheat the tool, while too low a feed can lead to chip buildup and uneven hole walls.

For manufacturers pursuing high precision and productivity, selecting the optimal drill bit involves considering not just the tool material and brand but also overall process optimization. From standard batch drilling to CNC precision machining, the best bit for drilling metal balances tool performance, material properties, and machining parameters.

Understanding the Challenges of Metal Drilling

Metal drilling is a high-load, high-precision process that places strict demands on tool performance, material selection, and cutting parameters. Metals vary widely in hardness, plasticity, and thermal conductivity, which affects cutting forces, heat generation, and chip evacuation. Unlike softer materials like wood or plastic, metals such as steel, aluminum, stainless steel, and titanium alloys require tools that combine wear resistance, toughness, and thermal stability.

In CNC machining, specialized drill bits for metal or carbide CNC drill bits are essential for high-speed cutting and continuous production. Proper selection of tool material, geometry, and coating improves hole quality, extends tool life, and reduces costs. Understanding these challenges is critical for selecting the best bit for drilling metal.

Why Metal Drilling Requires Specialized Drill Bits

Metals present unique challenges:

-

High hardness and strength: Drill bits face higher cutting forces and axial pressure.

-

Limited thermal conductivity: Heat dissipation is slow, increasing tool temperature and wear.

-

Long, stubborn chips: Poor evacuation can cause jamming or hole wall scratches.

Specialized metal drill bits, including high-cobalt HSS or carbide drills, with optimized point angles (e.g., 135°) and coatings (TiAlN or CVD diamond), address these challenges. Proper geometry and coatings reduce cutting temperatures, improve chip evacuation, and increase drilling accuracy and efficiency.

Common Problems When Using the Wrong Drill Bit

Using the wrong bit can cause:

-

Breakage and chipping: Cutting forces exceed tool capability.

-

Burning or annealing: Improper speed/feed causes overheating and coating failure.

-

Hole diameter inaccuracies: Runout or worn edges cause errors.

-

Burrs and rough surfaces: Poor chip evacuation leads to defects.

Adjusting speed and feed for each metal type and using the appropriate drill bit, including custom drill bits for metal when necessary, is key to maintaining hole quality and tool longevity.

Key Factors to Consider When Choosing Drill Bits for Metal

Selecting a drill bit for metal drilling requires careful consideration. Material properties, machining conditions, and machining objectives all play a critical role. Hardness, toughness, and thermal conductivity of metals directly impact tool performance and life, while cutting speed, feed rate, and cooling affect hole quality and surface finish. Choosing the best bit for drilling metal also depends on the application scenario, whether it’s high-volume production, CNC high-speed drilling, hard metal machining, or specialized custom drill bits for metal. Evaluating these factors helps ensure machining efficiency, extend tool life, and reduce production costs.

Material of the Drill Bit

Drill bit material strongly affects performance:

-

High-Speed Steel (HSS): Suitable for medium-hard metals. Offers toughness, fracture resistance, and a lower price point, but wears faster at high speeds or with hard metals.

-

Cobalt Alloy Steel (Cobalt HSS): Superior heat resistance and hardness. Ideal for stainless steel and harder steels, providing longer tool life than standard HSS.

-

Carbide: Best for high-speed cutting and hard metals. Extremely wear-resistant and capable of handling high cutting forces, though more expensive and requiring rigid machines.

-

Coated Drills (TiN, TiAlN, CVD Diamond, etc.): Coatings reduce friction, increase heat resistance, and prevent material adhesion. Perfect for high-temperature cutting or metals prone to sticking.

For high-volume CNC machining or challenging hole creation, coated carbide drills are often the top choice.

Drill Bit Geometry and Point Angle Design

Drill geometry affects performance in several ways:

-

Point Angle: 135° split-point for hard metals and stainless steel reduces runout and uneven force; 118° is suitable for soft metals and aluminum for faster drilling.

-

Helix Angle: Influences chip evacuation and cutting force. Higher angles improve chip removal in soft metals; lower angles increase stability in hard metals.

-

Flute Design: Proper depth and number of spiral flutes improve chip evacuation and reduce burrs or tool breakage.

-

Tip Design (Split Point, Parabolic Flute): Minimizes center runout, improves hole diameter accuracy, and is ideal for CNC precision drilling.

Selecting the right combination of geometry parameters enhances drilling accuracy, surface finish, and tool life across different metals.

CNC Drill Bits for Metal: What Makes Them Different

CNC drilling imposes higher demands on drill bits:

-

High-Precision Manufacturing: Tight tolerances ensure consistent, repeatable holes.

-

Specialized Cooling and Chip Evacuation: Internal or external coolant channels improve fluid efficiency, chip removal, and reduce wear.

-

High-Temperature, Wear-Resistant Coatings: Carbide drills with CVD/PVD coatings extend life and boost efficiency.

-

Optimized Nose and Helix Angles: Designed for CNC feed rates and machining stability.

-

Mass Production and Precision Drilling: Ensures consistent performance in high-volume, multi-hole applications.

For CNC professionals, using CNC drill bits for metal alongside the proper cutting speed and feed for drilling metal is crucial for productivity and hole quality.

Performance Comparison of the Best Bits for Drilling Metal

Selecting the best bit depends on material, machining conditions, and production goals. Drill materials and coatings vary widely in cutting speed, heat resistance, tool life, and efficiency. Comparing these options helps engineers identify the most suitable drill for CNC metal drilling or high-hardness materials. Performance comparison improves efficiency, reduces costs, and lowers rework rates.

HSS vs. Cobalt vs. Carbide Performance Comparison

-

HSS: Tough, affordable, ideal for medium-hard metals like carbon steel; wears faster on hard metals.

-

Cobalt HSS: Heat-resistant, excellent for stainless steel and hardened steel; longer life.

-

Carbide: Perfect for hard metals and high-speed drilling; highly wear-resistant, more expensive, requires rigid machines.

For high-hardness metals or high-volume CNC drilling, coated carbide drills are usually the best-performing option.

Coatings for Improved Drilling Efficiency

Coatings significantly enhance drill performance:

-

TiN: Reduces friction, increases wear resistance; suitable for medium-hard metals.

-

TiAlN: High-temperature resistance for hardened steel and high-speed applications.

-

CVD/PVD Diamond: Excellent for non-ferrous metals and composites; improves cutting speed and tool life.

Combining coatings with carbide or cobalt alloy drills ensures efficient chip evacuation, fewer burrs, and smoother hole walls.

Selecting Drill Bits for Various Metals

Different metals require different drills:

-

Stainless Steel: Cobalt HSS or carbide; 135° point angle.

-

Carbon Steel/Low-Alloy Steel: HSS or cobalt; high-speed cutting improves efficiency.

-

Aluminum/Copper: Carbide or coated HSS; large helix angle for smooth chip flow.

-

Titanium/Hard Steels: Carbide with TiAlN or CVD coatings for tool life and hole accuracy.

Combining material, coating, and geometry ensures high drilling efficiency and quality, answering the question: What is the best bit for drilling metal?

Optimizing Cutting Speed and Feed for Drilling Metal

Cutting speed and feed are critical parameters that directly affect machining efficiency, hole accuracy, and tool life. Different metals vary in hardness, thermal conductivity, and plasticity, which leads to significant differences in optimal cutting conditions for the same drill bit. Properly optimizing these parameters reduces tool wear, prevents overheating, and ensures accurate, smooth holes. Engineers should not only refer to standard tables but also adjust parameters based on CNC machining conditions, drill material (HSS, cobalt alloy, carbide), and coating type (TiN, TiAlN, CVD/PVD) to achieve stable and efficient drilling.

Cutting Parameters for Common Metals

Typical cutting speed and feed ranges for common metals are as follows:

-

Carbon Steel and Low-Alloy Steel: HSS or cobalt drill, 20–35 m/min cutting speed, 0.05–0.15 mm/rev feed.

-

Stainless Steel: Cobalt or carbide drill, 15–25 m/min cutting speed, 0.03–0.10 mm/rev feed.

-

Aluminum and Copper: Carbide or coated HSS drill, 60–120 m/min cutting speed, 0.1–0.3 mm/rev feed.

-

Titanium and High-Hardness Steel: Carbide with TiAlN or CVD coating, 10–20 m/min cutting speed, 0.02–0.08 mm/rev feed.

Matching drill material and coating to metal type ensures efficiency, tool longevity, and consistent hole quality.

Impact of Speed and Feed on Hole Quality and Tool Life

The cutting speed and feed rate have a major influence on drilling outcomes:

-

Excessive Speed: Increases tool temperature, potentially causing tool burning, coating failure, and accelerated wear.

-

Insufficient Speed: Can reduce cutting efficiency and cause chip jamming.

-

Excessive Feed: Leads to high cutting forces, drill breakage, hole deviation, and rough walls.

-

Insufficient Feed: Results in poor chip evacuation, scratches, or burrs on hole walls.

Properly balancing speed and feed ensures accurate holes, smooth surfaces, and long tool life.

Adjusting Parameters for CNC Drilling

CNC operations require dynamic adjustments based on machine rigidity, fixture stability, and actual conditions:

-

Step Drilling: Ideal for deep holes, reduces tool load and prevents chip jamming.

-

Dynamic Speed Adjustment: CNC programs can lower RPM in hard material zones to reduce tool wear.

-

Feed Optimization: Adjust feed per revolution according to material hardness and hole depth.

-

Coolant and Lubrication: Internal or external coolant improves chip evacuation and lowers tool temperature.

These measures enhance precision, efficiency, and the life of the best bit for drilling metal, while reducing rework and production costs.

白底-主图2-300x300.jpg)

When to Consider Custom Drill Bits for Metal

In the metalworking industry, standard drill bits cannot meet all production needs. When machining unusual workpiece shapes, non-standard holes, or challenging materials, custom drill bits are essential for improving machining efficiency and precision. Custom bits optimize tool geometry based on material hardness, hole diameter, depth, and production volume. They also enhance wear resistance, high-temperature performance, and chip evacuation through appropriate coatings and tool materials. For both B2B procurement and manufacturing companies, knowing when to use custom drill bits can reduce production risks, improve machining consistency, and provide significant economic benefits in high-volume or high-precision operations.

Applications Requiring Custom Metal Drill Bits

Custom drill bits are particularly valuable in the following scenarios:

-

Non-standard holes: Irregularly shaped, angled, or deep holes where standard drill bits are ineffective.

-

High-volume production: Optimizes tool life and ensures consistent hole quality for long-run machining.

-

Special materials: Titanium alloys, high-hardness steels, or composites require specific tool materials and coatings.

-

Composite parts: Multi-layer metals or mixed-metal components need tailored geometries for cutting stability.

By using custom drill bits, manufacturers can maintain accuracy, reduce scrap, and improve overall production efficiency.

Advantages of Custom CNC Drill Bits

Customized CNC drill bits provide several benefits over standard tools:

-

Extended tool life: Optimized material, coating, and geometry minimize wear and chipping.

-

Enhanced hole accuracy and surface finish: Reduces deflection, burrs, and wall roughness, even for special diameters and deep holes.

-

Higher productivity: Allows faster feeds and speeds while minimizing maintenance downtime.

-

Lower production costs: Fewer tool changes and rework result in cost-effective high-volume production.

Working with OEMs and Tool Manufacturers

Selecting the right OEM supplier or specialized tool manufacturer is critical for custom drill success:

-

Evaluate capabilities: Check machining processes, material expertise, coating technology, and mass production capacity.

-

Communicate requirements: Share material type, hole size, depth, batch quantity, and precision specifications for tool design.

-

Verify performance: Conduct trial machining to ensure stability and consistency.

-

Establish long-term support: Reliable suppliers offer parameter optimization, tool repair, and upgrade services for continuous efficiency improvements.

Partnering with experienced OEMs ensures long-term stability, efficiency, and economic benefits in CNC metal drilling.

Practical Tips for Extending Drill Bit Life

Even the best bit for drilling metal can wear out quickly if improperly used or poorly maintained. To improve process stability, reduce production costs, and maintain hole accuracy and surface finish, engineers must follow practical techniques for extending drill bit life. This includes proper cooling and lubrication, correct drilling methods, feed control, and routine tool maintenance. In CNC mass production or when machining high-hardness materials, adhering to these practices helps prevent tool breakage, overheating, and hole deviations, while optimizing cutting speed and feed rates.

Proper Coolant Use and Lubrication Techniques

Coolant and lubrication are critical to drill performance:

-

Coolant selection: Use water-soluble cutting fluids for steel and oil-based fluids for high-hardness steel or aluminum alloys.

-

Coolant delivery: Internal coolant (through-tool) directly cools the tip, improves chip evacuation, and reduces tool temperature. External spray works for shallow to medium-depth holes.

-

Lubrication: Reduces friction, extends tool life, and improves hole wall finish—especially important in high-speed CNC drilling.

Proper cooling and lubrication protect the tool, enhance efficiency, and ensure consistent hole quality, making them essential for high-precision and mass-production environments.

Correct Drilling Techniques and Feed Control

Applying the right drilling techniques helps extend tool life:

-

Step drilling: Segmented cutting reduces forces and minimizes chipping, ideal for deep holes.

-

Peck drilling: Intermittent chip removal prevents blockage and ensures smooth hole surfaces.

-

Incremental feed: Adjust feed rates for each segment based on material hardness and hole depth to reduce tool load.

-

Feed speed control: Match cutting speed and feed to tool material and workpiece for a stable cutting process.

These techniques improve hole accuracy, surface finish, and significantly extend the life of CNC metal drill bits.

Tool Maintenance and Inspection Practices

Regular maintenance and inspections are key to prolonging drill life:

-

Wear inspection: Check cutting edges for wear, cracks, or coating damage.

-

Resharpening: Timely resharpening restores cutting performance for HSS or cobalt drills.

-

Replacement planning: Schedule tool replacement to avoid excessive wear or loss of accuracy.

-

Data tracking: Record cutting parameters and tool performance trends to guide future operations.

Systematic maintenance ensures high performance, reduces downtime, and lowers tool costs, while supporting consistent, accurate hole production.

How to Select the Best Bit for Your Metal Drilling Needs

Selecting the best drill bit for metal drilling requires careful consideration of:

-

Material properties: Hardness, thermal conductivity, adhesion, and other characteristics.

-

Machining method: CNC high-speed, deep hole, or mass production.

-

Tool grade and coating: HSS, cobalt alloy, carbide, and TiN/TiAlN/CVD coatings.

-

Cutting parameters: Optimize speed and feed for accuracy and tool longevity.

-

Maintenance and monitoring: Coolant, lubrication, inspections, and resharpening strategies.

-

Custom requirements: Non-standard holes or special materials may require custom CNC drill bits.

Matching the tool material, coating, cutting speed, and feed to the workpiece ensures consistent hole accuracy, prevents tool damage, and maximizes productivity. For non-standard or high-volume applications, custom CNC drill bits provide extended life, superior hole quality, and optimized machining efficiency.

By applying these practices, engineers and procurement teams can select the optimal drill bit solution, ensuring cost-effective, high-quality, and efficient metal drilling operations.