HRC70 Super Hard Thread Cutter (Metric)

Upgrade Your Milling Experience with SAMHO HRC70 2-tooth Thread Mill (Metric)!

For precise threads in textiles, consider SAMHO’s HRC70 super hard thread milling cutter (metric). Crafted with quality materials and modern tech. Elevate your sewing projects now. Contact us for orders and performance details.

Home » Thread End Mill » HRC70 Super Hard Thread Mill (Metric)

HRC70 Super Hard Thread Milling Cutter (Metric)

Truly covering ultra-hard materials up to HRC70, with an application range far exceeding conventional thread mills.

This HRC70 ultra-hard 2-tooth thread mill can reliably machine ultra-hard materials up to HRC70, including HRC68 high-speed steel, ultra-high hardness quenched steel, and mold steel – materials traditionally considered “forbidden zones” for thread machining. It effectively solves the problems of difficult one-pass thread formation and easy tool chipping in high-hardness materials, significantly expanding the application boundaries of thread milling cutters in the field of ultra-hard materials.

Extra-long service life, significantly reducing per-hole machining costs.

Using a highly wear-resistant base material, combined with a high-performance wear-resistant coating and an optimized 2-tooth design, this thread milling cutter maintains a stable cutting state even when machining ultra-hard materials. It effectively reduces tool wear and the risk of micro-chipping, significantly increasing the lifespan compared to ordinary thread mills, making it particularly suitable for mass production and high-value workpiece processing, significantly reducing the overall cost per hole.

Stable thread accuracy, 100% meeting go/no-go gauge inspection requirements.

The thread mill’s cutting edge profile is highly consistent with the standard thread contour. Through precise thread milling, it ensures complete internal thread profiles and high dimensional consistency. The machined threaded holes can successfully pass go/no-go gauge inspection, effectively avoiding rework and scrap, and are widely applicable to molds, precision parts, and high-precision assembly industries.

2-tooth thread mill design, balancing cutting stability and chip evacuation capabilities.

Compared to multi-flute thread mill structures, this 2-tooth thread mill distributes the cutting load more reasonably in ultra-hard materials, resulting in a “gentler” cutting process and significantly reduced vibration. At the same time, ample chip evacuation space helps reduce problems such as chip adhesion and scratching, significantly improving thread surface quality and machining stability.

Thread milling process offers significant advantages, with higher safety and flexibility.

Using the thread milling process, compared to traditional tapping, different internal thread specifications can be flexibly adjusted through programming. One thread mill can cover multiple thread sizes, avoiding the risk of tap breakage; even if the tool malfunctions, it is less likely to damage the workpiece, making it particularly suitable for thread machining of high-hardness, high-value parts.

Designed specifically for high-end molds and difficult-to-machine materials, this thread milling cutter is positioned for high-value applications.

This ultra-hard thread milling cutter is developed for threading applications in hardened molds, precision parts, and difficult-to-machine materials, making it an ideal alternative to imported high-end thread milling cutters. While ensuring excellent threading performance and stability, it also focuses on cost control, making it suitable for professional users who demand high quality and efficiency.

-

Specialty

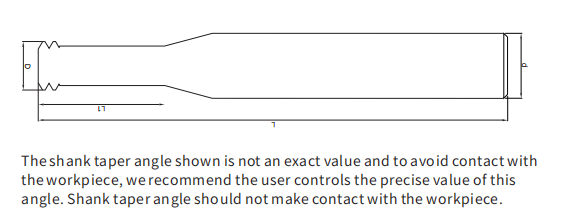

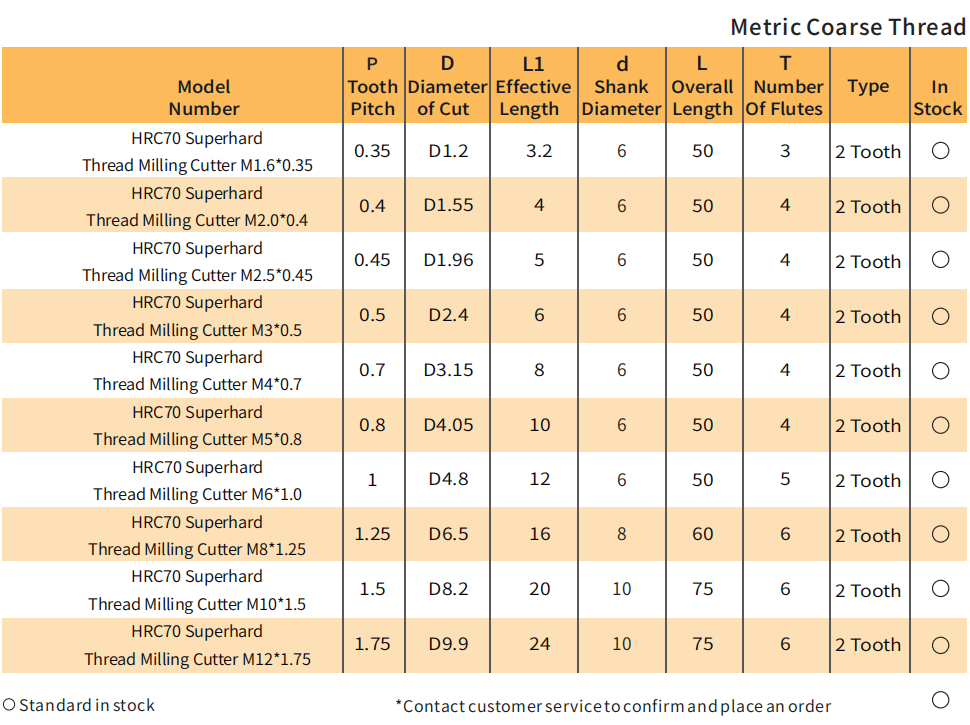

HRC70 Super Hard Thread Mill (Metric) Catalog

HRC70 Super Hard Thread Milling Cutter (Metric)

Related Product Recommendation

HRC65 Full Tooth Thread Cutter(Metric)

HRC65 Full Tooth Thread Cutter(Metric) Upgrade Your...

Read MoreHRC65 Full Tooth Thread Cutter(NPT)

HRC65 Full Tooth Thread Cutter(NPT) Upgrade Your...

Read MoreHRC65 Full Tooth Thread Cutter(UNC, UNF, UNEF)

HRC65 Full Tooth Thread Cutter(UNC, UNF, UNEF)...

Read MoreHRC65 Super Hard Drill Bits(Internal Cooling)

HRC65 Super Hard Drill Bits(Internal Cooling) Upgrade...

Read MoreHRC65 Super Hard Drill Bits(Solid)

HRC65 Super Hard Drill Bits(Solid) Upgrade Your...

Read MoreHRC65 Three-teeth Thread Cutter(Metric)

HRC65 Three-teeth Thread Cutter(Metric) Upgrade Your Milling...

Read More

-白底主图3.jpg)

白底-主图2.jpg)