Top Mistakes When Choosing CNC Milling Cutting Tools

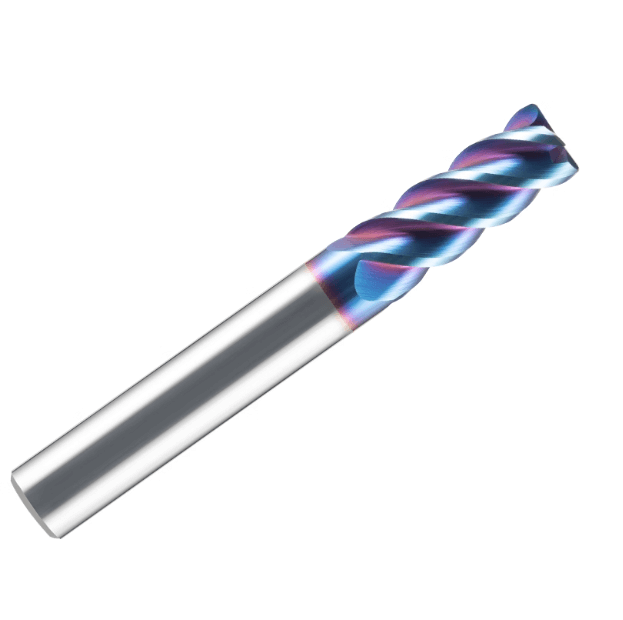

Choosing the right CNC milling cutter directly impacts metalworking efficiency, part accuracy, and production costs. Yet many engineers and purchasing personnel make common mistakes during the selection process, leading to reduced machining efficiency, shortened tool life, and increased production costs. Whether selecting between HSS and carbide CNC milling cutting tools for high-speed cutting or finding […]

Top Mistakes When Choosing CNC Milling Cutting Tools Read More »