How to Select the Right End Mill Diameter for Steel Machining

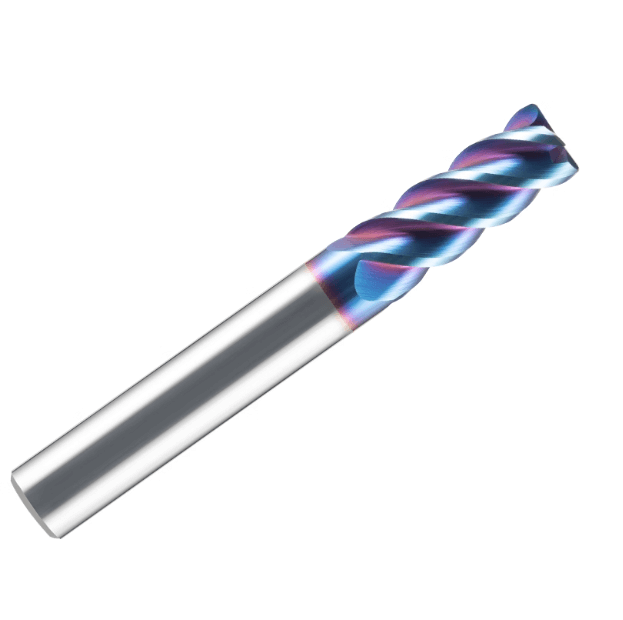

Steel milling is highly sensitive to tool selection, and the choice of cutter diameter directly affects cutting efficiency, surface finish, and tool life. Selecting the right end mill for steel requires considering material type and evaluating factors such as machine rigidity, depth of cut, spindle speed, and feed rate. For engineers working on mold manufacturing, […]

How to Select the Right End Mill Diameter for Steel Machining Read More »