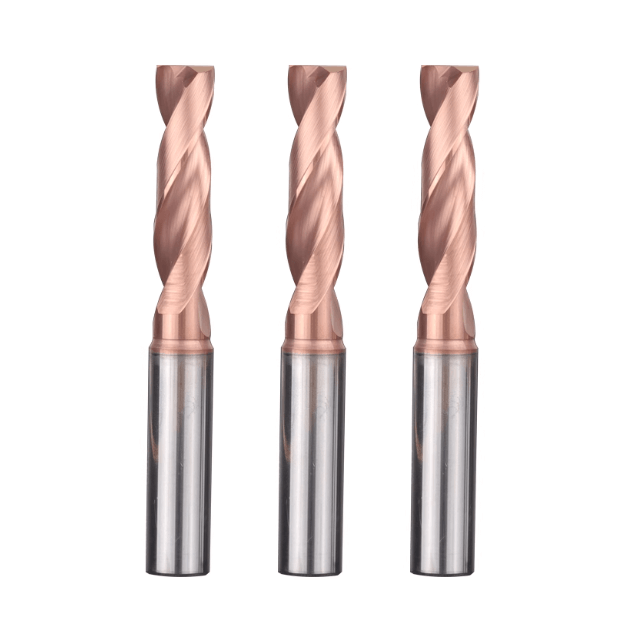

End Mill Cutters for Graphite and Composite Materials

Cutting graphite and composite materials places exceptionally high demands on tool wear resistance, cutting edge sharpness, and chip evacuation. Due to the high hardness, strong abrasiveness, and brittleness of these materials, conventional milling cutters often struggle to achieve both efficient machining and superior surface quality. Therefore, specialized end mill cutters for graphite and composite materials […]

End Mill Cutters for Graphite and Composite Materials Read More »