How Solid Carbide End Mills Improve Productivity in CNC Milling

Carbide end mills, with their high hardness, wear resistance, and excellent cutting stability, are essential tools for improving productivity in CNC milling. Compared to traditional high speed steel (HSS) end mills, solid carbide end mills maintain a sharp cutting edge at higher speeds and feed rates, reducing tool changes and downtime, which significantly improves overall […]

How Solid Carbide End Mills Improve Productivity in CNC Milling Read More »

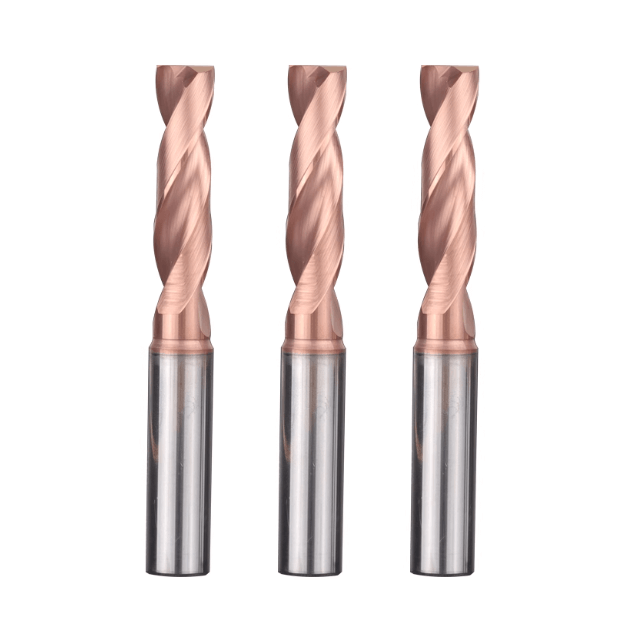

-白底主图2.jpg)