End Mill Types Explained: Choosing the Right Tool for Every Machining Job

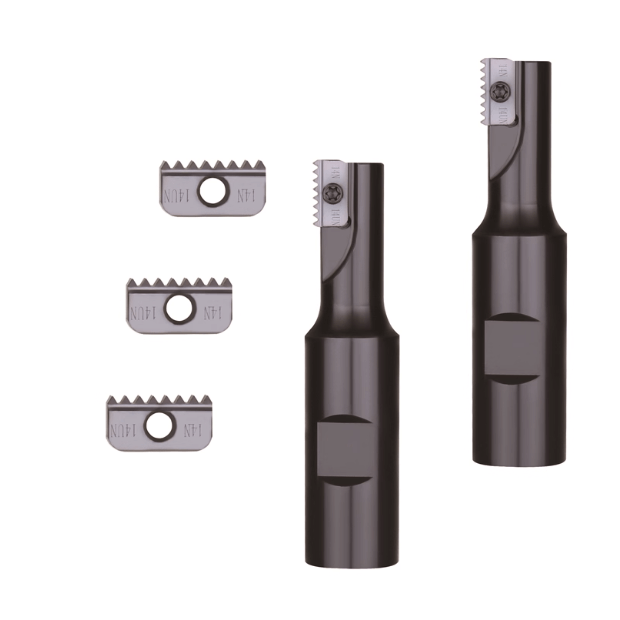

In modern CNC machining, end mills are among the most commonly used and versatile cutting tools. Different end mill types are suited for various machining tasks and materials, such as steel machining, aluminum machining, graphite machining, hard materials machining, high-speed machining, and deep cavity milling. Choosing the right type of end mill not only improves […]

End Mill Types Explained: Choosing the Right Tool for Every Machining Job Read More »