In metalworking, selecting the right cutting tool directly affects machining efficiency, part accuracy, and tool life. Carbide end mill cutters perform differently depending on the machining process. Roughing prioritizes high material removal rates and tool strength, while finishing emphasizes surface quality and dimensional consistency. Properly matching roughing and finishing tools can improve overall efficiency, extend tool life, and reduce production costs.

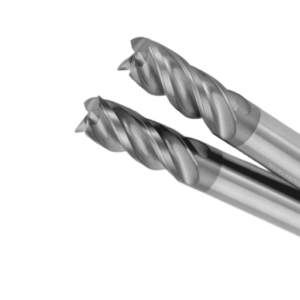

Solid carbide end mill cutters excel in machining a variety of metals, including high-strength steel, stainless steel, aluminum alloys, and mold steel, due to their high rigidity and wear resistance. They maintain stable cutting performance under both heavy-duty and light-load conditions. Meanwhile, China CNC carbide end mill cutters are continually optimized in tool geometry, coating processes, and production capabilities to meet the specific requirements of both roughing and finishing operations.

Beyond tool material, geometry and chip evacuation play critical roles. Roughing tools typically feature thicker bodies, wider flutes, and reinforced edges to withstand high cutting forces and ensure effective chip removal. Finishing tools focus on sharp cutting edges, optimized helix angles, and precise tip geometry to reduce vibrations and achieve superior surface finish. Combining proper tool selection with optimized machining parameters and cutting strategies is key to achieving efficient, low-cost production.

Key Differences Between Roughing and Finishing in CNC Machining

During metal part machining, cutting tool requirements vary significantly across different stages of the process. Roughing focuses on achieving a high material removal rate and maintaining tool strength to enable rapid stock removal and efficient part shaping. At this stage, solid carbide end milling cutters are commonly used to handle high cutting loads while maintaining tool stability and reducing the risk of breakage or edge chipping. In addition, tool designs with effective chip evacuation help prevent chip accumulation, surface scratching, and cutting instability, ensuring smooth and reliable roughing operations.

Finishing, by contrast, places greater emphasis on surface finish, dimensional accuracy, and machining consistency. Finishing tools typically feature smaller diameters, sharper cutting edges, and optimized helix angles to minimize cutting vibration and improve process stability. High-performance CNC carbide end mill cutters produced by manufacturers in China perform particularly well in this stage. With precise geometry control and advanced coating technologies, these tools maintain stable cutting performance and extended tool life under lower cutting loads, delivering consistent surface quality and tight dimensional tolerances.

Differences in Machining Objectives and Cutting Loads

The primary objective of roughing is to remove large volumes of material in a short time to establish the basic shape of the part. This requires cutting tools with high wear resistance and strong resistance to edge chipping, capable of withstanding substantial cutting forces. Solid carbide end milling cutters maintain geometric stability under heavy loads, helping to suppress chatter and prevent premature tool failure. Roughing parameters typically involve higher feed rates and deeper cuts to maximize efficiency, while proper tool selection and setup help control wear.

Finishing aims to achieve the final surface quality and dimensional accuracy of the part. Cutting loads are lower, making cutting edge sharpness and tool rigidity critical factors. High-precision tool designs reduce vibration and help achieve the required surface roughness. At the same time, tool life becomes closely tied to machining consistency. Proper parameter selection and tool material optimization help minimize wear and ensure stable performance, especially in high-volume production.

Impact on Carbide End Mill Cutter Structural Design

Roughing tools generally feature thicker tool bodies and wider chip flutes to handle heavy cutting forces and evacuate large chip volumes. This structural design improves resistance to breakage while enhancing heat dissipation, allowing the tool to remain stable during extended cutting cycles. China carbide end mill cutter manufacturers typically integrate material properties and machining conditions into tool design, using precision grinding and reinforced coating technologies to improve wear resistance and extend tool life.

Finishing tools place greater emphasis on cutting edge sharpness, optimized helix angles, and precise tip geometry to ensure smooth cutting with minimal vibration. Proper edge geometry and accurate tip grinding help control surface roughness and improve dimensional consistency. Through optimized substrate selection and coating systems, finishing tools maintain high precision and stability under light cutting loads, making them well suited for precision machining of complex parts.

Trade-off Between Material Removal Rate and Surface Quality

In roughing operations, material removal rate is a key indicator of machining efficiency. Increasing cutting depth and feed rate accelerates stock removal but also raises cutting forces and tool wear. By selecting wear-resistant, chip-resistant solid carbide end milling cutters with optimized flute design, it is possible to maintain tool life and machining safety while operating at high efficiency.

Finishing requires a careful balance between productivity and surface quality. Sharp cutting edges and refined tool geometry reduce cutting loads, vibration, and thermal deformation, ensuring consistent surface finish and dimensional accuracy. Excessive emphasis on removal rate at this stage can compromise surface quality, so cutting parameters, tool selection, and chip evacuation strategies must be optimized together to achieve the best balance between efficiency and quality.

Key Features of Carbide End Mill Cutters for Roughing

Tools used in roughing operations must deliver high stability and durability under heavy cutting loads. Solid carbide end milling cutters are well suited for this purpose, as they can withstand large cutting forces while minimizing the risk of chipping or breakage. These tools are typically optimized in terms of substrate strength, edge thickness, and coating systems to maintain stable performance during high-efficiency, heavy-duty cutting. Many China carbide end mill cutter manufacturers focus on rigidity, wear resistance, and thermal stability when developing roughing tools for mass production environments.

Tool geometry also plays a critical role in roughing performance. A well-designed chip flute and appropriate edge treatment reduce cutting resistance and prevent chip congestion, minimizing surface damage and premature wear. Through optimization of geometric parameters and cutting conditions, roughing tools can sustain high material removal rates in high-speed, heavy-load machining while achieving maximum tool life.

Tool Strength and Chipping Resistance Requirements

During roughing, tools must withstand high cutting forces and sudden impact loads, making strength and chipping resistance top priorities. Solid carbide tools with optimized edge thickness, tip geometry, and coating materials maintain geometric stability under high-speed, heavy-load conditions and significantly reduce the likelihood of edge failure. High-quality China CNC carbide end mill cutters demonstrate strong chipping resistance in real-world machining, particularly when cutting high-hardness steels or mold steels.

Chipping resistance directly affects both tool life and machining efficiency. High-strength tools allow for deeper cuts and higher feed rates, increasing material removal while reducing tool change frequency and machine downtime. This is especially important in mass production and high-efficiency machining environments.

Comparison of Chip Flute Number and Flute Design

Efficient chip evacuation is essential during roughing. Wider chip flutes enable rapid chip removal, reducing friction between the tool and workpiece and lowering the risk of overheating or surface damage. However, flute design must balance chip evacuation capacity with tool rigidity. Excessively wide flutes may weaken the tool body, while optimized solid carbide end milling cutters maintain sufficient strength under heavy cutting loads.

The number and angle of flutes also influence cutting vibration and stability. Multi-flute designs increase chip channels, but overall tool strength must be preserved. China carbide end mill cutter manufacturers typically tailor flute geometry to the workpiece material and part geometry, providing targeted chip evacuation solutions that improve machining efficiency and tool life.

Role of Edge Honing in Heavy Cutting

Edge honing plays an important role in improving chipping resistance during roughing. A moderately honed cutting edge can withstand higher cutting loads while reducing the risk of edge failure caused by impact or interrupted cutting. After precision honing and coating, solid carbide tools exhibit improved thermal stability and consistent cutting performance in high-speed, heavy-duty applications.

Edge honing also helps extend tool life and reduce production interruptions caused by frequent tool changes. For rough machining of high-hardness steels, mold steels, and parts with complex geometries, honed edges combined with optimized cutting parameters significantly improve machining reliability and reduce overall production costs.

Applicable Scenarios for Solid Carbide End Milling Cutters in Rough Machining

Solid carbide end milling cutters perform exceptionally well in most heavy-duty machining applications, particularly when cutting high-hardness steel, stainless steel, aluminum alloys, and mold steel. Their high rigidity and wear resistance support large depths of cut and high feed rates, enabling rapid material removal while maintaining stable cutting performance and tool life. China CNC carbide end mill cutters are widely used in mass production and complex part machining, providing reliable roughing solutions.

These tools also offer strong versatility in multi-stage machining processes. By selecting appropriate flute numbers, flute lengths, and chip evacuation designs, roughing tools can accommodate a wide range of part sizes and geometries. At the same time, they provide a stable machined surface and accurate reference geometry for subsequent finishing operations, ensuring overall machining efficiency and final part quality.

Key Features of Carbide End Mill Cutters for Finishing

The primary objective of the finishing stage is to achieve precise dimensional accuracy and high-quality surface finish, which places stricter demands on tool performance compared to roughing. Finishing operations typically involve smaller tool diameters and shallower depths of cut to minimize cutting forces and vibration. Solid carbide end milling cutters, known for their high rigidity and wear resistance, maintain geometric stability under light cutting loads, ensuring consistent surface roughness and dimensional accuracy throughout the process. In finishing applications, China CNC carbide end mill cutters are widely recognized for their stable performance and repeatable machining accuracy, particularly in demanding precision parts.

In addition, the geometric design, coating system, and edge preparation of finishing tools have a direct impact on surface quality and cutting efficiency. Proper selection of flute count, helix angle, and cutting edge radius helps reduce vibration and control tool wear, extending tool life. For mass production and complex part machining, finishing tool stability and cutting consistency are critical factors in maintaining high part quality and low scrap rates.

Rigidity and Vibration Control of Solid Carbide End Milling Cutters

Tool rigidity is a fundamental requirement for maintaining accuracy during finishing operations. Insufficient rigidity often leads to cutting vibration, resulting in surface marks, burr formation, and dimensional deviation. High-rigidity solid carbide end milling cutters effectively resist cutting forces and spindle-induced vibration, ensuring smooth and stable cutting. Tools produced by experienced China carbide end mill cutter manufacturers perform particularly well when machining complex geometries, deep cavities, or features with extended tool overhang.

Effective vibration control not only improves surface quality but also has a direct impact on tool life. By optimizing tool material, core structure, and helix angle design, vibration can be minimized while maintaining cutting efficiency. In high-precision and high-volume machining environments, this stability significantly improves overall productivity and machining consistency.

Relationship Between Edge Sharpness and Surface Finish

Cutting edge sharpness directly influences surface finish quality. Sharp edges reduce cutting resistance and heat generation, minimizing vibration and producing smoother, more uniform surfaces. Solid carbide end milling cutters, after precision grinding and advanced coating treatment, consistently deliver high-quality finishing results under low cutting loads.

However, edge sharpness must be properly balanced with tool strength. Excessively dull edges increase cutting forces and may cause surface defects, while overly thin edges are prone to chipping when machining harder materials. Through optimized edge geometry and substrate selection, modern China CNC carbide end mill cutters achieve an effective balance between sharpness, durability, and surface quality.

Helix Angle and Cutting Stability

Helix angle design plays a critical role in cutting force distribution and chip evacuation during finishing. Tools used for finishing typically feature medium-to-high helix angles, which promote smooth chip flow and uniform cutting engagement. This design reduces vibration and enhances surface accuracy while maintaining machining stability. High-quality solid carbide end milling cutters utilize optimized helix angles to improve cutting smoothness without sacrificing rigidity.

An appropriate helix angle also helps reduce thermal load on both the tool and the workpiece, minimizing tool wear and thermal distortion. In deep cavity machining or complex part finishing, optimized helix geometry significantly improves consistency and reliability, meeting the requirements of high-precision components.

Advantages of Solid Carbide End Milling Cutters in Finishing

Solid carbide end milling cutters offer clear advantages in finishing operations. Their high rigidity and sharp cutting edges enable excellent surface finish and dimensional stability under light cutting conditions, while reducing vibration and heat accumulation. Many China carbide end mill cutter manufacturers combine fine grinding processes with high-performance coating technologies to ensure long tool life and consistent performance across a wide range of materials.

These tools also demonstrate strong versatility in both complex part machining and mass production. Whether machining aluminum alloys, high-hardness steels, or mold steels, optimized solid carbide tools provide a reliable balance between surface quality, machining stability, and tool life, ensuring consistent results and high overall machining efficiency.

How to Rationally Match Roughing and Finishing Tools in the Same Part

In part machining, proper coordination between roughing and finishing tools is essential for achieving high efficiency and consistent quality. Roughing tools are designed to remove material rapidly and establish a stable blank geometry, while finishing tools focus on achieving precise surface finish and dimensional accuracy. By selecting and combining solid carbide end milling cutters appropriately, manufacturers can reduce machining costs, extend tool life, and improve process consistency.

Effective tool matching also depends on machining sequence and cutting strategy. High-performance CNC carbide end mill cutters manufactured in China offer a wide range of geometries and specifications, allowing machinists to select suitable tool combinations based on material type, part geometry, and production volume. This approach ensures smooth transitions between roughing and finishing operations.

Logic Behind Selecting Tool Diameter, Flute Length, and Projection Length

Tool diameter, flute length, and projection length directly influence rigidity and machining stability. Roughing operations generally favor larger diameters and shorter flute lengths to withstand high cutting forces and feed rates while minimizing vibration. Finishing operations often require smaller diameters and longer flutes to access complex features while maintaining surface quality and accuracy. Solid carbide end milling cutters are engineered to maintain rigidity across different size and length combinations.

Projection length is another critical factor. Excessive overhang increases the risk of vibration and tool deflection, negatively affecting accuracy and tool life. By carefully matching tool diameter, flute length, and projection length—and using high-performance CNC carbide end mill cutters from China—machinists can effectively control vibration and ensure stable transitions between roughing and finishing.

Differences in Cutting Parameters Between Roughing and Finishing

Cutting parameters differ significantly between roughing and finishing. Roughing typically uses greater depths of cut, higher feed rates, and aggressive cutting speeds to maximize material removal. Finishing emphasizes shallow cuts, lower feed rates, and controlled cutting speeds to achieve superior surface finish and dimensional consistency. Solid carbide end milling cutters maintain stable performance across these varying conditions while supporting extended tool life.

Tool substrate, coating, and edge geometry also influence parameter selection. Optimized cutting conditions reduce tool wear and thermal deformation, improving machining consistency. The wide range of tool specifications offered by China carbide end mill cutter manufacturers supports efficient transitions from roughing to finishing, enabling high productivity and low scrap rates in mass production.

Avoiding Risks Caused by Using One Tool for Multiple Operations

Using a single tool for both roughing and finishing often leads to machining risks. Roughing tools prioritize strength and wear resistance but lack the sharpness required for precision finishing. Finishing tools, while sharp, have limited resistance to heavy cutting loads and are more susceptible to chipping or breakage during roughing. Improper use can result in surface defects, dimensional inaccuracies, and premature tool failure.

To avoid these issues, dedicated tools should be used for each machining stage, and cutting sequences should be properly planned. By combining roughing and finishing solid carbide end milling cutters with optimized cutting parameters and effective chip evacuation, manufacturers can achieve both high material removal efficiency and precision surface quality while maintaining stable production.

Key Considerations for Roughing and Finishing Tool Selection for Different Materials

Different materials exhibit distinct cutting behaviors, requiring tailored tool selection strategies. Aluminum alloys, carbon steels, stainless steels, and mold steels vary significantly in cutting forces, heat generation, and wear mechanisms. As a result, roughing and finishing tools must be configured with appropriate substrates, geometries, and coatings. Proper selection of solid carbide end milling cutters, combined with optimized cutting parameters, extends tool life while maintaining high machining efficiency.

High-performance carbide end mill cutters manufactured in China are available in a wide range of geometries and edge configurations to meet material-specific requirements. By aligning tool design with material characteristics, chip evacuation efficiency improves, vibration is reduced, and rough-machined surfaces provide a stable foundation for finishing operations, ensuring both efficiency and precision.

Tool Configuration Strategy for Aluminum Alloy Machining

Aluminum alloys are relatively soft, generate low cutting forces, and tend to produce adhesive chips. Roughing tools for aluminum typically feature larger diameters, lower helix angles, and wide flutes to enable rapid material removal and smooth chip evacuation. Finishing tools emphasize sharp cutting edges and higher helix angles to minimize vibration and achieve excellent surface finish. Solid carbide end milling cutters effectively balance removal rate and surface quality in aluminum machining.

Coating selection and edge geometry are particularly important. Suitable coatings reduce chip adhesion, while optimized edge preparation further minimizes vibration and wear. Many China CNC carbide end mill cutter manufacturers offer dedicated aluminum-specific tools optimized for both roughing and finishing applications.

Wear Resistance Requirements in Stainless Steel Machining

Stainless steel generates high cutting forces and heat, placing significant demands on tool wear resistance. Roughing tools require strong chipping resistance and wear-resistant coatings to handle deep cuts and high feed rates. Finishing tools require sharp edges and refined geometry to achieve high surface quality while minimizing vibration. Solid carbide end milling cutters provide the hardness and thermal stability needed for consistent stainless steel machining.

Advanced coatings such as TiAlN or AlTiN further enhance wear resistance and extend tool life. Optimized helix and edge angles help distribute cutting forces and control heat generation. These features are commonly incorporated into high-performance carbide end mill cutters manufactured in China for both roughing and finishing stainless steel applications.

Tool Differentiation for Mold Steel and High-Hardness Materials

Machining mold steel and high-hardness materials places the highest demands on tool rigidity, chipping resistance, and wear resistance. Roughing tools require reinforced bodies, wide flutes, and durable coatings to withstand heavy cutting loads. Finishing tools emphasize sharp edges, high rigidity, and optimized helix angles to ensure precise dimensions and superior surface finish. Solid carbide end milling cutters with optimized geometry and advanced coatings perform reliably in these demanding applications.

Tool selection must also align with cutting strategy and parameters. Roughing typically uses aggressive feeds and depths of cut, while finishing relies on controlled cutting loads to reduce vibration and wear. Experienced carbide end mill cutter manufacturers in China provide comprehensive tool solutions for different hardness levels, enabling seamless transitions between roughing and finishing while ensuring stable and efficient machining.

Actual Performance of Solid Carbide Cutting Tools in Rough and Finish Machining

Solid carbide cutting tools deliver stable and reliable performance in both roughing and finishing operations across a wide range of materials, including high-hardness steel, stainless steel, aluminum alloys, and mold steel. With optimized tool geometry and high intrinsic rigidity, solid carbide end milling cutters maintain geometric accuracy under heavy cutting loads and during complex machining paths, effectively minimizing vibration and cutting force fluctuation. High-performance carbide end mill cutters produced in China, supported by precision grinding and advanced coating technologies, achieve a practical balance between aggressive material removal in roughing and surface integrity control in finishing.

In addition to cutting capability, solid carbide tools offer clear advantages in production efficiency and consistency. Optimized flute design, coating selection, and chip evacuation geometry allow the tools to perform reliably during long machining cycles. In mass production environments, this stability directly contributes to lower scrap rates, reduced rework, and predictable machining results, providing strong support for cost control and process management.

Stability of Solid Carbide End Milling Cutters in Continuous Machining

In continuous machining operations, maintaining stable cutting performance over extended periods is critical. Solid carbide end milling cutters feature high structural rigidity and wear-resistant coatings, enabling them to withstand prolonged cutting under elevated loads without edge chipping or abnormal vibration. For components requiring long cycle times or multi-stage machining, this stability ensures consistent dimensional accuracy and surface quality throughout the production run.

Stability in continuous machining is influenced not only by material hardness but also by tool geometry. Proper selection of helix angle, flute count, and flute length helps distribute cutting forces evenly and promotes smooth chip evacuation. Chinese CNC carbide end mill cutter manufacturers emphasize rigidity optimization and chip control in tool design, delivering dependable solutions for complex geometries and high-volume production.

Tool Life and Processing Consistency Control

Tool life plays a decisive role in maintaining processing consistency, especially in batch and mass production. Solid carbide cutting tools with optimized edge geometry and high-performance coatings exhibit controlled wear patterns, allowing them to maintain stable cutting behavior over extended machining periods. This is particularly important in finishing operations, where even minor tool wear can affect surface finish and dimensional tolerance.

Extended tool life also directly improves production efficiency. Reduced tool change frequency minimizes machine downtime and helps maintain consistent cutting conditions. Chinese carbide end mill cutter manufacturers offer comprehensive tool specifications and customization options, enabling manufacturers to balance tool life and machining consistency across different materials and machining stages.

Cost Advantages of Solid Carbide Tools in Mass Production

From a cost perspective, solid carbide tools offer long-term advantages in mass production settings. While the initial tool cost may be higher, extended service life and stable cutting performance significantly reduce replacement frequency and unplanned downtime. When roughing and finishing tools are properly matched, overall production costs can be optimized without sacrificing efficiency or precision.

Additionally, consistent tool performance helps reduce scrap and rework rates. Chinese carbide end mill cutter manufacturers have demonstrated strong reliability in high-volume production environments, offering stable supply capacity and cost-effective machining solutions that support both productivity and quality control throughout roughing and finishing operations.

Current Application Status of Chinese CNC Carbide End Mills in Roughing and Finishing

With ongoing advancements in manufacturing technology, Chinese CNC carbide end mills are increasingly adopted in both roughing and finishing applications. Continuous improvements in tool geometry, coating technology, and chip evacuation design have enabled domestically produced solid carbide end milling cutters to meet the demands of various materials and machining conditions. These tools demonstrate stable performance in maintaining machining efficiency and dimensional accuracy, offering practical and cost-effective solutions for both small-batch and large-scale production.

The progress of domestic tools is also reflected in product line diversity. Chinese-made CNC carbide end mill cutters cover a broad range of diameters, flute lengths, helix angles, and coating options, supporting distinct requirements from roughing to finishing. This targeted differentiation allows manufacturers to efficiently select suitable tools for multi-process machining, improving overall productivity and process stability.

Maturity of China CNC Carbide End Mill Cutter Manufacturing Process

The manufacturing process for domestically produced solid carbide cutting tools has reached a high level of maturity. Modern production integrates precision grinding, advanced coating systems, and strict quality control, ensuring stable cutting edge geometry during both heavy roughing and precision finishing. Solid carbide end milling cutters maintain dimensional consistency during extended machining cycles, effectively reducing edge chipping and premature wear.

This level of process maturity enhances both tool durability and machining reliability. Optimized flute design, controlled edge preparation, and balanced geometry allow tools to perform consistently under high-speed and high-load cutting conditions. Through standardized production and inspection systems, Chinese carbide end mill cutter manufacturers deliver reliable performance for demanding machining applications.

Product Line Differentiation for Roughing and Finishing Tools

Roughing and finishing operations impose different functional requirements on cutting tools. Roughing tools prioritize chipping resistance, wear resistance, and chip evacuation capacity to handle large cutting depths and high feed rates. Finishing tools emphasize cutting edge sharpness, rigidity, and surface quality control to achieve dimensional accuracy and consistent surface finish. Domestically produced solid carbide end milling cutters address these requirements through clearly differentiated product lines.

This differentiation extends to coating selection and flute configuration. Roughing tools typically feature robust coatings and fewer flutes to manage high cutting loads, while finishing tools adopt sharper coatings and optimized flute designs for improved surface integrity. Chinese CNC carbide end mill cutters offer flexible tool combinations that support smooth transitions between roughing and finishing.

Practical Feedback on Domestic Cutting Tools in Multi-Process Machining

In real-world machining applications, domestically produced solid carbide cutting tools have demonstrated strong adaptability in multi-process environments. Whether in high-volume production or small-batch machining of complex components, these tools maintain stable performance across both roughing and finishing stages, reducing tool change frequency and machine downtime.

Feedback from production environments indicates that domestic tools continue to narrow the gap with international brands in terms of chip control, chipping resistance, and surface finish stability. With appropriate tool selection and parameter optimization, manufacturers can achieve efficient, low-cost machining across multiple materials. The technical support and product reliability provided by Chinese carbide end mill cutter manufacturers have earned broad recognition in continuous machining and mass production applications.

How to Evaluate the Machining Matching Capabilities of Chinese Carbide End Mill Manufacturers

When selecting a end mill supplier, machining matching capability is a critical evaluation factor. A qualified China carbide end mill cutter manufacturer should provide not only reliable tools but also comprehensive production processes, inspection systems, and technical support to accommodate different roughing and finishing requirements. Strong matching capability ensures stable performance across multiple materials and machining strategies.

Key evaluation factors include consistency in tool geometry, coating uniformity, and cutting performance. Precision grinding accuracy, edge quality, and dimensional repeatability directly influence machining stability, vibration control, and tool life. High-quality tools maintain balanced cutting forces during continuous machining, helping reduce scrap rates and rework while improving overall production efficiency.

Grinding and Testing Capabilities of China Carbide End Mill Manufacturers

Grinding precision and inspection capability are fundamental indicators of tool quality. High-precision grinding equipment ensures sharp cutting edges and consistent geometric parameters such as diameter, helix angle, and flute length. Comprehensive inspection systems—including coordinate measurement, optical inspection, and edge profile analysis—enable manufacturers to monitor tool quality throughout production.

Strict control of geometry accuracy, coating thickness, and flute consistency allows Chinese-made CNC carbide end mill cutters to deliver repeatable machining results across different processes and materials. This level of quality assurance provides reliable support for both roughing and finishing applications.

Customized Support Capabilities for Roughing and Finishing

Customization capability is an important factor in evaluating manufacturer competence. For roughing tools, customization typically focuses on improving chipping resistance, wear resistance, and chip evacuation. For finishing tools, design emphasis shifts toward edge sharpness, rigidity, and surface finish control. Targeted customization allows solid carbide end milling cutters to achieve optimal performance under specific machining conditions.

In addition to tool design, manufacturers may provide cutting parameter recommendations based on material properties, part geometry, and machine conditions. This integrated support shortens the trial phase, improves machining consistency, and helps achieve efficient coordination between roughing and finishing operations.

The Importance of Sample Testing in Tool Selection

Sample testing is an essential step in verifying tool suitability. Through actual machining trials, users can evaluate cutting stability, surface finish, chip evacuation, and tool wear behavior under real production conditions. Performance consistency observed during testing is a key indicator for determining whether a tool is suitable for long-term or mass production use.

Sample testing also enables optimization of tool selection and cutting parameters, reducing production risk. By analyzing trial results from both roughing and finishing operations, manufacturers can refine tool geometry and machining strategies to achieve stable, high-precision, and cost-effective production. This practical validation process is a major reason why Chinese-made CNC carbide end mill cutters continue to gain acceptance in global machining markets.

Common Misconceptions and Improvement Suggestions for Rough and Finish Machining Tools

In practical machining operations, the correct use of roughing and finishing tools is essential for achieving stable machining efficiency, dimensional accuracy, and predictable tool life. However, misuse of tools—such as applying the wrong tool to the wrong process—is still common in production environments. These mistakes often lead to poor surface quality, accelerated tool wear, increased vibration, and higher rework or scrap rates. A clear understanding of the functional differences between roughing and finishing tools, along with proper parameter selection, is critical to avoiding these issues.

By properly matching tools to their intended machining stages and material characteristics, manufacturers can fully utilize the rigidity, wear resistance, and chip evacuation performance of solid carbide tools. When combined with reasonable cutting strategies and sample testing, this approach significantly improves machining consistency in both mass production and multi-process applications, especially when working with aluminum alloys, stainless steel, mold steel, and high-hardness materials.

Typical Problems Caused by Using Roughing Tools for Finishing Operations

Using roughing tools for finishing operations often results in unsatisfactory machining outcomes. Roughing tools are designed with stronger cutting edges and higher chipping resistance but relatively lower sharpness, making them unsuitable for achieving fine surface finishes or tight dimensional tolerances. As a result, parts may exhibit rough surfaces, burr formation, and dimensional deviations. In addition, the chip flute design and cutting geometry optimized for heavy cutting loads can introduce unnecessary vibration during finishing.

Although solid carbide end milling cutters perform effectively in roughing operations, applying them directly to finishing without proper tool differentiation prevents the machining process from benefiting from features such as optimized helix angles, sharper edges, and refined edge preparation. To address this issue, roughing and finishing tools should be clearly separated in tool selection, with tool diameter, cutting length, and overhang length chosen according to material properties and machining requirements.

Risks of Using Finishing Tools for Heavy Cutting

Using finishing tools for heavy cutting presents equally serious risks. Finishing tools are typically designed for low cutting loads and high surface quality, featuring sharp cutting edges and relatively slender tool bodies. When subjected to deep cuts or high feed rates, these tools are more susceptible to edge chipping, breakage, or rapid wear, which can lead to production interruptions and part rejection.

Roughing tools, by contrast, are engineered to handle high cutting forces and aggressive material removal. Their reinforced cutting edges and wear-resistant coatings provide durability that finishing tools cannot replace. To reduce machining risks, dedicated tools should be assigned to each process stage, with cutting parameters optimized accordingly. This separation not only protects tool integrity but also improves overall machining stability and efficiency.

Improving Overall Machining Efficiency Through Correct Tool Selection

Overall machining efficiency is directly influenced by scientific tool selection and proper process coordination. By considering part material, machining sequence, cutting parameters, and tool geometry, manufacturers can achieve a smooth transition from high-efficiency roughing to high-precision finishing. The broad range of tool geometries, coatings, and specifications available in Chinese-made CNC carbide end mill cutters enables flexible matching for different machining stages.

In addition, sample testing and parameter optimization play an important role in validating tool performance before full-scale production. With proper tool selection, controlled cutting loads, and effective vibration management, manufacturers can significantly improve machining efficiency while maintaining surface quality, dimensional accuracy, and tool life. This structured approach supports stable, low-cost production and long-term process reliability across a wide range of machining applications.