Selecting the right milling cutter is crucial for both machining efficiency and surface quality in 3D contour milling and complex part manufacturing. Custom end mill bits not only meet the geometric requirements of non-standard workpieces but also provide more stable cutting performance through optimized tool geometry, flute count, and helix angle.

For high-hardness materials or small precision parts, carbide end mill bits and micro end mill bits deliver outstanding wear resistance and cutting accuracy. Meanwhile, high-speed milling end mill bits significantly enhance productivity when machining softer metals such as aluminum and copper alloys.

During the custom milling cutter design process, carefully adjusting cutting parameters, cutting depth, and chip evacuation improves surface finish and extends tool life. Moreover, using custom or wholesale end mill bits provides a cost-effective solution for large-scale production. This article explores design principles, application strategies, and practical insights for custom milling cutters in 3D surface machining—helping engineers choose and optimize the right tools for complex part machining.

Selection Strategies for Milling Cutters of Different Materials in 3D Contour Machining

In 3D contour milling, the choice of cutter material directly affects machining performance and part quality. Selecting the right material not only boosts cutting efficiency but also extends tool life, reduces costs, and ensures dimensional accuracy. Engineers must match the cutter type to the workpiece material, machining depth, geometry, and required tolerance.

This section discusses the application advantages and practical experience of carbide, micro, and high-speed milling end mill bits in 3D contour machining, offering a reference for selecting the most suitable custom tools for complex workpieces.

Advantages of Carbide End Mill Bits

Carbide end mill bits offer exceptional wear resistance and rigidity, making them ideal for machining hard materials and complex 3D surfaces. They maintain cutting-edge stability at high speeds, reducing tool wear, burr formation, and improving surface accuracy.

Carbide tools are also well-suited for long-run production and deep groove machining. With optimized cutting parameters, they deliver longer tool life and fewer tool changes. For non-standard geometries, custom carbide end mill bits can be tailored for specific requirements such as tip radius, flute count, and helix angle—offering greater machining flexibility.

The Role of Micro End Mill Bits in Precision Surface Machining

Micro end mill bits play a vital role in precision mold making and micro-part machining. Their small diameter allows for intricate feature machining, delicate curve finishing, and fine groove cutting with minimal cutting force.

Proper tool material, coating, and geometry selection—combined with precise feed control—enables micro end mills to achieve high accuracy without surface deformation. These tools are particularly effective in electronics, medical components, and fine mold manufacturing where sub-micron precision is critical.

Practical Experience in Improving Efficiency with High-Speed Milling End Mill Bits

High-speed milling end mill bits are optimized for cutting aluminum, copper, and other soft metals at high spindle speeds. In practice, they dramatically increase cutting speed and overall productivity while maintaining dimensional stability and excellent surface quality.

By fine-tuning tool geometry, flute count, and cutting parameters, these tools minimize chip buildup, reduce heat generation, and prevent premature wear. In high-volume or multi-axis 3D contour operations, the proper use of high-speed end mills can shorten cycle times and deliver consistent, high-precision results.

Key Design Considerations for Custom Milling Cutters in Complex Part Machining

When machining complex parts and 3D contours, standard milling cutters often fail to meet the precision and geometric requirements of non-standard workpieces. In such cases, the design of custom end mill bits becomes essential for improving machining efficiency, ensuring surface quality, and extending tool life.

By carefully optimizing tool geometry, number of flutes, helix angle, nose radius, and coating material, engineers can develop the most effective cutting solutions for specific materials and machining applications. These custom end mill bits can be tailored for various tool categories—including carbide end mill bits, micro end mill bits, and high-speed milling end mill bits—to achieve stable and efficient performance in 3D contour machining and precision mold manufacturing.

Effective custom tool design ensures consistent chip removal, improved dimensional accuracy, and longer tool lifespan, making it a critical factor for modern CNC manufacturing lines.

The Impact of Tool Geometry Optimization on Cutting Performance

Tool geometry—including cutting edge shape, rake angle, relief angle, and tool body curvature—is one of the most influential factors determining overall cutting performance. Proper geometry optimization reduces cutting resistance, minimizes chip buildup, and decreases heat generation, resulting in smoother machining and finer surface finishes.

In micro-scale machining and complex surface milling, even slight variations in tool geometry can affect vibration control, dimensional accuracy, and tool wear. For instance, optimizing rake and clearance angles can significantly enhance the stability and cutting efficiency of carbide end mill bits and micro end mill bits under heavy or high-speed cutting conditions.

By adjusting geometric parameters such as cutting edge radius and relief profile according to workpiece material and cutting depth, engineers can achieve a balance between sharpness, durability, and surface integrity—key goals in advanced 3D machining.

Selection Methods for Number of Flutes, Helix Angle, and Nose Radius

The number of flutes, helix angle, and nose radius are three critical parameters that directly determine cutting performance and surface quality. A higher number of flutes generally improves cutting smoothness and surface finish, but may reduce chip evacuation efficiency, especially in deep-pocket or high-feed applications.

The helix angle influences both cutting force direction and vibration stability. A higher helix angle provides a smoother cutting action but may generate additional heat, while a lower helix angle enhances rigidity for harder materials. Similarly, optimizing the nose radius helps achieve cleaner corner transitions, reduces burr formation, and improves the overall accuracy of 3D contour machining.

In practical applications, these parameters should be tuned according to material type, feed rate, and depth of cut. Doing so ensures optimal performance of custom end mill bits and high-speed milling end mill bits, enabling both efficient material removal and superior surface consistency.

Coating and Material Combinations to Enhance Wear Resistance and Surface Quality

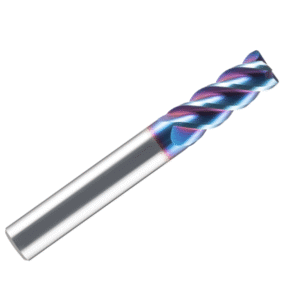

The choice of tool material and coating is vital to extending tool life, maintaining cutting stability, and improving machined surface quality. Common coatings such as TiN, TiAlN, and diamond coatings significantly increase wear resistance, reduce friction, and provide superior heat resistance for high-speed cutting environments.

By combining carbide substrates with advanced coatings, custom end mill bits can retain their cutting sharpness and dimensional accuracy even under heavy-duty or high-temperature operations. For micro end mill bits used in fine-detail machining, specialized coatings also prevent micro-chipping and improve tool lifespan.

In batch production and precision 3D contour milling, a well-matched combination of coating and substrate ensures consistent cutting quality and long-term tool stability. Whether using carbide, micro, or high-speed milling end mill bits, the right coating selection plays a pivotal role in achieving both productivity and precision.

Mass Customization and Procurement Strategies

In large-scale production and complex part manufacturing, the strategic selection of custom and wholesale end mill bits plays a decisive role in achieving higher machining efficiency, stable quality, and cost control. Through well-planned customization and bulk procurement strategies, manufacturers can reduce per-unit tool costs, extend tool life, and maintain precision across multiple production batches.

When combining different tool materials—such as carbide end mill bits, micro end mill bits, and high-speed milling end mill bits—engineers should consider part material, surface complexity, and production volume. This enables a data-driven procurement plan that balances productivity, tool performance, and cost-effectiveness, while ensuring process stability during long-term 3D contour machining operations.

Cost Comparison of Custom End Mill Bits and Standard Mill Bits

Mass customization of milling tools involves design flexibility in geometry, coating, and cutting-edge configuration, leading to higher upfront costs compared with standard tools. However, for complex part machining or non-standard 3D surface milling, custom end mill bits deliver measurable benefits: shorter machining cycles, fewer secondary operations, and reduced rework.

When evaluating economic feasibility, engineers should assess factors such as batch size, tool longevity, and cycle time. Over the full production lifecycle, custom-designed cutters can often outperform standard options by minimizing downtime and improving throughput consistency—especially in precision or high-value manufacturing.

Wholesale End Mill Bit Supplier Selection Guide

Choosing a reliable wholesale end mill bits supplier directly influences machining stability, batch quality, and long-term process control. A strong supplier should offer comprehensive tool categories—covering carbide, high-speed, and micro end mill bits—and maintain strict quality assurance across bulk orders.

When selecting a partner, engineers should review certifications, material traceability, manufacturing experience, and the supplier’s ability to support custom specifications. Evaluating feedback from existing customers and examining cutting performance data ensures both product consistency and optimized tool life for continuous production runs.

Managing Tool Life and Process Stability in Batch Machining

In high-volume machining environments, efficient tool life management and process stability are vital. Maintaining detailed tool usage records, tracking wear patterns, and optimizing cutting parameters (feed rate, spindle speed, and depth of cut) help extend the service life of carbide and custom end mill bits.

By adopting predictive maintenance and tool rotation strategies, production teams can minimize unplanned tool changes and ensure consistent machining accuracy in 3D contour milling. Proper process planning and toolpath optimization also prevent heat buildup and vibration, improving both surface quality and dimensional precision.

Practical Techniques for 3D Contour Machining

Achieving superior results in 3D contour machining requires more than advanced tool design—it demands precise control of machining parameters and in-depth understanding of material behavior. By fine-tuning cutting conditions, selecting optimal tool geometries, and managing chip evacuation, engineers can enhance surface quality, extend tool life, and achieve better repeatability in complex surface machining.

Feed Rate and Spindle Speed Optimization Strategies

Feed rate and spindle speed directly affect tool wear, chip load, and cutting temperature. The optimal parameters depend on workpiece hardness, tool diameter, and tool type—whether using a carbide end mill bit for hard metals or a micro end mill bit for small, detailed features.

High-speed milling end mill bits are particularly effective for aluminum, copper, and other non-ferrous materials, allowing for aggressive cutting without sacrificing surface integrity. Balancing feed and speed through data-based optimization minimizes heat generation and tool vibration, ensuring consistent performance and longer tool life.

Depth of Cut, Chip Evacuation, and Surface Quality Control

The depth of cut and chip removal strategy are critical to achieving both tool longevity and surface finish quality. For 3D surface milling, layered or step-down cutting should be adopted to avoid excessive cutting forces. Micro end mill bits require precise depth control to prevent deflection or breakage, while carbide end mill bits are suitable for segmented cutting in harder materials.

Optimizing chip evacuation—by using proper coolant flow, flute design, and cutting path strategy—prevents chip accumulation and thermal damage. This leads to a smoother surface finish, better dimensional accuracy, and reduced rework rates in complex contour machining.

Tool Parameter Adjustment for Multi-Material Machining

When machining multiple materials in one setup, engineers must tailor tool parameters to match each material’s hardness and machinability. For example, carbide end mill bits require lower cutting speeds for hardened steel, while high-speed milling end mill bits can use higher RPMs for aluminum.

Micro end mills used in high-precision applications demand tighter control of feed per tooth and spindle speed to avoid micro-chipping. Adjusting feed, depth, and toolpath according to material properties not only enhances surface consistency but also significantly reduces overall tool wear during multi-material 3D contour machining.

Case Study: Application of Customized Milling Cutters in 3D Surface Machining

In 3D contour machining, standard milling cutters often struggle to maintain both geometric accuracy and surface finish on complex curved surfaces. Customized end mill bits, however, are specifically designed to match part geometry, material properties, and machining methods, resulting in significant improvements in cutting efficiency, dimensional accuracy, and tool longevity.

In real-world manufacturing—such as mold making, aerospace component production, and CNC machining of precision medical parts—customized milling cutters effectively solve the adaptability problems that conventional tools face when machining confined spaces, free-form surfaces, or composite materials. By optimizing tool geometry, nose radius, and coating design, engineers can achieve stable cutting performance and excellent surface finishes, even at high speeds and feeds.

The following case studies illustrate how micro end mills, high-speed milling cutters, and custom carbide tools perform across various materials and machining conditions, providing engineers with valuable insights and proven practices.

Micro Milling Cutters in Precision Mold Machining

In precision mold manufacturing and micro-cavity machining, micro end mills deliver extremely fine surface finishes thanks to their small diameters and precise cutting edges. However, their low rigidity and sensitivity to cutting forces require optimized spindle speed, feed rate, and depth of cut to prevent tool breakage or surface damage.

Practical experience shows that custom micro end mills made from ultra-fine grain carbide or coated with CVD diamond coatings offer significantly enhanced wear resistance and heat dissipation. When paired with high-precision spindle systems and constant feed control, these tools ensure mirror-like finishes on intricate curves and narrow grooves, meeting the demanding standards of mold and die production.

Advantages of High Speed End Mill Bits in Complex Aluminum Alloy Machining

Aluminum alloys are widely used in aerospace and automotive part manufacturing due to their lightweight nature and high machinability. For such materials, high-speed milling end mill bits are ideal for achieving efficient material removal at spindle speeds of 20,000–40,000 rpm.

Custom-designed high-speed aluminum end mills typically feature large helix angles (45°–55°) and polished chip flutes to improve chip evacuation and minimize built-up edge formation. Additionally, advanced coatings such as TiB₂ or DLC reduce cutting temperatures and enhance both tool life and surface quality.

In 5-axis CNC machining, these custom high-speed tools allow for optimized toolpaths, reducing the number of passes required for complex 3D surfaces, thus boosting productivity and minimizing secondary finishing operations.

Practical Results of Custom Carbide Tools in High-Hardness Material Machining

When machining hardened steels (HRC55+), titanium alloys, or nickel-based alloys, traditional HSS cutters wear out quickly and fail to meet precision or surface requirements. Custom carbide end mill bits designed for hard materials offer superior hardness, thermal resistance, and cutting-edge stability under extreme conditions.

Specialized designs—such as optimized rake angles, AlTiN or TiAlSiN coatings, and reinforced tool tips—help maintain tool life during dry or semi-dry cutting. Asymmetric flute structures further reduce vibration and increase tool rigidity, ensuring consistent performance.

In applications such as mold repair, secondary machining of hardened parts, and hard-milling replacements for turning, these customized carbide tools deliver significant gains in efficiency and dimensional consistency, supporting precision and repeatability in large-scale production.

A Comprehensive Strategy for Improving Efficiency and Precision in 3D Contour Milling with Custom End Mill Bits

In today’s CNC manufacturing, customized end mill bits are no longer reserved for high-end industries—they have become a core strategy for enhancing both efficiency and accuracy in 3D contour machining. Through personalized tool designs tailored to specific materials, part geometries, and machining conditions, engineers can achieve an optimal balance between cutting performance, tool life, and surface quality.

Whether machining precision molds, aerospace-grade aluminum components, or hardened steel parts, custom milling cutters provide unmatched performance compared to standard tools. When combined with optimized tool geometry, advanced coating technologies, and scientifically tuned cutting parameters, they deliver exceptional stability and repeatability in complex surface machining.

Additionally, from single-piece customization to bulk end mill production, integrated process management has become an effective way for manufacturers to reduce overall costs while maintaining tool consistency and supply reliability. Ultimately, the value of custom end mills lies not only in the design of the tool itself but in the system-wide improvements they bring to manufacturing efficiency and product quality.

Optimal Application Scenarios for Different Materials and Tool Types

The machining characteristics of different materials dictate the key priorities in milling cutter design. For instance, in high-speed aluminum machining, custom end mills with high helix angles and polished flutes effectively reduce built-up edge and improve surface finish. When cutting hardened steels or titanium alloys, carbide end mills with heat-resistant coatings ensure edge stability and long service life under high temperatures.

For small, intricate parts—such as precision molds or medical components—micro end mills excel in achieving fine detail and smooth contour transitions. Adapting tool type and geometry to the workpiece material and structure is therefore the foundation for achieving high-efficiency 3D machining.

The Advantages of Customized Tools in Complex Part Machining

In complex surface machining, standard tools often fall short due to geometric limitations and restricted cutting angles. Custom end mills for 3D contour machining overcome these issues by matching the tool design precisely to the part geometry and machining path.

By optimizing parameters such as tool nose radius, helix angle, and edge design, these tools minimize vibration, balance cutting loads, and improve overall surface consistency. When combined with precision dynamic balancing and high-performance coatings, they enable high-speed, high-accuracy machining—ideal for applications in aerospace, automotive molds, and multi-axis CNC systems.

Comprehensive Recommendations for Bulk Procurement and Machining Optimization

For manufacturers engaged in mass production, performance optimization should go hand in hand with supply chain management. When sourcing bulk customized end mills, it is recommended to work with suppliers that offer in-house design expertise, material traceability, and quality consistency. Long-term partnerships help achieve better control over cost, delivery time, and tool uniformity.

Additionally, implementing a tool life management system—tracking wear data, adjusting cutting parameters, and optimizing feed and spindle speed—helps maintain machining consistency and reduce downtime.

By integrating digital tool management and process analytics, companies can move beyond single-tool optimization toward full-system efficiency, maximizing both the economic and technical benefits of customized milling cutters.