In the field of metal cutting, end mill drills and end mills are often mentioned together, especially in slotting, drilling, and combined machining operations. These two types of tools are easily confused in practice. Many engineers often ask during tool selection: Are end mill drills and end mills essentially the same? Can they be used interchangeably? And how should one make a more rational choice based on different machining requirements?

From structural design to machining methods and actual cutting performance, there are significant differences between end mill drill tools and traditional end mills. In slotting, blind hole entry, and multi-process combined applications, end mill drill cutters often perform differently from ordinary end mills. Meanwhile, end mill slot drills, specifically designed for straight slot machining, also play an important role in improving machining efficiency and stability.

For factories pursuing stable mass production and consistent machining quality, the manufacturing process and material selection of the tools themselves are equally important. Carbide end mill drills from wholesale carbide end mill drill manufacturers are increasingly chosen in many machining scenarios due to their rigidity, wear resistance, and extended service life. Therefore, understanding the differences between end mill drills and end mills is crucial for improving machining efficiency and controlling costs in tool procurement and application.

Core Differences in Machining Functionality Between End Mill Drill and End Mill

In actual machining, the functional role of a tool directly affects machining methods and process planning. Although end mill drills and end mills may look similar, they serve different purposes. End mill drills emphasize cutting-in capability and multi-process integration, while end mills are more suited for stable lateral cutting and contour shaping. Ignoring these differences during tool selection can reduce machining efficiency and even lead to abnormal tool wear.

Performance of End Mill Drills in Combined Drilling and Milling Operations

When a process requires initial workpiece penetration followed by milling, end mill drills show clear advantages. These tools typically feature a cutting-edge design that allows direct axial feed, enabling cutting-in without pre-drilling while simultaneously performing slotting or cavity machining. For tasks such as straight grooves, blind grooves, and complex paths, using the appropriate end mill drill tool can reduce tool changes, improve cycle time, and simplify programming.

In mass production, carbide end mill drill cutters used for integrated drilling and milling maintain consistent machining results, especially in groove operations with common materials like aluminum alloys and carbon steel.

Limitations of Ordinary End Mills in Side Milling and Contour Machining

Traditional end mills are better suited for side milling, contouring, and surface machining. In processes requiring direct axial plunging, they often depend on pre-drilled holes or ramped entry, which increases process steps and demands higher program accuracy and machine stability.

In deeper or blind groove machining, ordinary end mills are more susceptible to chip evacuation issues and uneven force distribution. Using them in unsuitable conditions may cause vibration, reduce surface quality, or even lead to tool breakage.

Why it’s Necessary to Differentiate Between End Mill Drill Tools and End Mills in CNC Machining

Clearly distinguishing between end mill drill tools and end mills helps select the most suitable tool for different machining stages. A proper combination improves efficiency, controls tool wear, and extends service life. In groove machining, combined hole-groove operations, or high-volume production, choosing the right tool type is particularly critical.

Moreover, partnering with a wholesale carbide end mill drill manufacturer with stable production capabilities allows for customized or bulk procurement based on specific needs, ensuring long-term consistency in machining quality. This function-oriented approach is essential for achieving efficient and reliable machining.

Differences Between End Mill Drills and End Mills from a Structural Design Perspective

The structural design of a cutting tool directly affects machining efficiency, tool life, and surface quality. Although end mill drills and traditional end mills share a similar overall shape, there are notable differences in cutting edge layout, tip design, and chip evacuation structures. These differences determine performance in drilling, grooving, and side milling operations. Understanding these structural characteristics helps make more informed tool selections and process planning decisions, particularly for deep groove machining, high-speed cutting, and multi-process operations, where structural advantages significantly improve machining stability and efficiency.

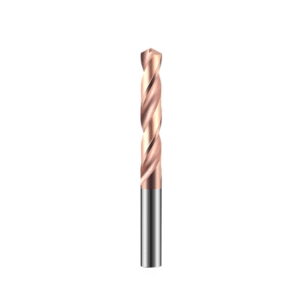

The Impact of End Mill Drill Cutter Tip Structure on Cutting Entry

The tip of an end mill drill cutter is designed for direct axial entry, enabling machining without pre-drilling. This allows the tool to perform drilling and milling simultaneously, reducing tool changes and shortening cycle time. In blind hole or multi-depth groove operations, the tip geometry ensures smooth entry, balanced force distribution, and minimal vibration, maintaining cutting stability.

For carbide end mill drill tools, optimizing tip geometry further enhances rigidity and wear resistance, especially during high-efficiency cutting of aluminum alloys, carbon steel, and medium-hardness alloys. This results in consistent surface quality and extended tool life.

The Impact of Chip Flute Design on Machining Stability

Chip flute design plays a key role in chip evacuation and surface finish. End mill drills use spiral or widened flutes to remove chips quickly, reducing heat accumulation and minimizing tool wear. In deep or blind groove machining, poor chip evacuation can cause tool clogging, vibration, or chipping. Optimizing the flute design improves machining stability and extends tool life.

Additionally, the helix angle, flute width, and flute depth determine cutting force distribution and balance, which helps maintain accuracy and surface quality in high-speed milling or multi-level groove operations.

Structural Advantages of End Mill Slot Drills in Groove Machining

End mill slot drills, designed specifically for groove machining, feature optimized tip geometry and chip flute layout. This design results in higher efficiency and stability during straight, narrow, and blind groove machining. Shorter tip protrusion and well-designed cutting edges reduce vibration while balancing cutting forces, allowing precise control of groove width and depth.

In mass production or high-speed operations, using end mill slot drills reduces processing time and significantly lowers tool wear. Combined with carbide materials from wholesale carbide end mill drill manufacturers, these tools offer excellent wear resistance and long service life, providing reliable performance for long-term, efficient production.

Practical Advantages of End Mill Drills in Slot Milling

Tool design and functionality directly influence slot milling efficiency, surface finish, and production stability. Compared to traditional end mills, specialized end mill slot drills significantly enhance performance in straight slots, blind slots, and multi-level grooves. With optimized tool geometry, cutting edges, and high-rigidity materials, these tools reduce tool changes while maintaining consistent machining performance under high-speed, high-feed conditions, supporting mass production and complex part machining.

Performance of End Mill Slot Drills in Straight and Blind Slot Machining

End mill slot drills ensure smooth entry and stable cutting. Proper helix angles and chip flute designs facilitate rapid chip removal, minimizing cutting resistance and preserving surface quality. Their axial cutting ability and balanced force distribution reduce vibration risk while maintaining accuracy and tool life, particularly in deep or blind grooves.

With carbide end mill drill cutters, tool rigidity is further enhanced, allowing higher cutting forces and multi-layer depths while achieving efficient and stable performance.

Reducing Tool Changes to Improve Machining Cycle Time

Using end mill drill tools capable of both drilling and milling in a single setup allows axial entry and slotting in one operation. This integrated approach reduces pre-drilling and multiple tool changes, shortening cycle time. In mass production, fewer tool changes reduce machine downtime, simplify tool management, and improve efficiency and cost control. Selecting an end mill slot drill that matches the workpiece material ensures consistent groove depth and surface quality, further enhancing production reliability.

Stability Analysis of Slotting with End Mill Drill Tools

Slotting stability depends on tool rigidity, cutting force distribution, and chip evacuation efficiency. End mill drill tools balance axial and radial forces, minimizing vibration and preventing chatter or chipping common with traditional end mills. Optimized chip flute designs enable smooth chip removal, reduce heat buildup, and minimize tool wear. Combined with high-performance carbide from wholesale carbide end mill drill manufacturers, these tools maintain stable cutting conditions during long-term, high-precision production, ensuring efficient and reliable slotting results.

Comparison of the Applicability of End Mill Drills and End Mills in Machining Different Materials

When machining various metal materials, cutting tool performance can differ significantly. End mill drills and traditional end mills have distinct structural designs and cutting geometries, resulting in different suitability for aluminum alloys, carbon steel, alloy steel, and stainless steel. Understanding the impact of material properties on tool rigidity, cutting force, chip evacuation efficiency, and wear rate is essential for improving machining efficiency, extending tool life, and ensuring surface quality. In production, selecting the appropriate end mill drill cutter or end mill based on the material improves cycle time and maintains stable performance under high-load conditions.

Cutting Feedback of End Mill Drill Cutters in Aluminum Alloy Machining

Aluminum alloys require high cutting speeds and are prone to chip adhesion. End mill drill cutters provide smooth axial entry and balanced cutting forces, resulting in stable cutting and a smooth surface finish. Their high-rigidity design and optimized cutting edges prevent chip entanglement, minimize vibration, and maintain dimensional accuracy in groove machining. When using carbide end mill drill tools for high-speed or composite machining of aluminum alloys, their superior wear resistance and efficient chip evacuation significantly improve productivity and ensure stable results in continuous mass production.

Differences in Stress and Tool Wear during Carbon Steel and Alloy Steel Machining

Machining carbon steel and alloy steel generates higher cutting forces than aluminum alloys, requiring increased tool rigidity and wear resistance. In deep groove or multi-level machining, end mill drill cutters disperse stress through optimized tip design, reducing vibration and chipping risks. Compared to ordinary end mills, integrated drilling and milling tools reduce the impact of multiple tool changes on processing stability. Using wear-resistant carbide end mill drill cutters extends tool life, lowers production costs, and ensures consistent machining performance.

Requirements for Tool Rigidity and Cutting Edge in Stainless Steel Machining

Stainless steel machining involves high-strength materials, where cutting tools face thermal expansion and chipping risks. End mill drill tools emphasize rigidity and cutting edge toughness, enabling them to withstand high cutting forces. Optimized chip flute designs ensure smooth chip evacuation, preventing excessive heat buildup. For straight grooves, blind grooves, and complex geometries, high-rigidity end mill drill cutters maintain machining accuracy, reduce machine vibration, and sustain consistent performance in long production runs. Partnering with wholesale carbide end mill drill manufacturers ensures high-performance tools suitable for continuous high-precision machining.

The Influence of CNC Machining Parameters on End Mill Drill Performance

In precision machining, the performance of end mill drills depends not only on structural design and material but also significantly on machining parameters. Proper spindle speed, feed rate, depth of cut, and cooling method directly affect efficiency, tool life, and surface quality. Especially when using end mill drill tools for grooving or complex machining, optimizing parameters maximizes tool rigidity, reduces vibration risk, and ensures stable cutting forces. This results in efficient and reliable machining across different materials and complex parts.

The Impact of Spindle Speed and Feed Rate on End Mill Drills

Spindle speed and feed rate directly influence cutting force, cutting temperature, and surface finish. Too low a spindle speed can cause chip buildup and increased tool wear, while too high a speed may lead to tool tip chipping or vibration. Optimizing feed rate during high-speed operations ensures even force distribution, minimizes vibration, and maintains tool rigidity. Matching the right spindle speed and feed rate for aluminum alloys, carbon steel, or stainless steel enables continuous, efficient machining and extends tool life.

Rational Control of Axial and Radial Depth of Cut

Proper distribution of axial and radial depth of cut is crucial for cutting stability and machining accuracy. In deep groove or blind hole machining, excessive axial depth overloads the tool, increasing vibration and chipping risk. Excessive radial depth can cause tool deflection and rough surfaces. By carefully setting parameters for end mill drill tools, you can balance cutting forces, improve chip evacuation, and maintain stable cutting under high loads, achieving high-precision machining and extended tool life.

The Impact of Cooling Methods on End Mill Drill Tool Life

Cutting temperature affects both tool wear and surface quality. Appropriate cooling reduces frictional heat, prevents tool tip chipping, and avoids material adhesion. For carbide end mill drill cutters, high-pressure or mist cooling improves chip evacuation, reduces wear, and extends service life. In high-speed grooving or multi-layer cutting, proper cooling is essential to maintain machining efficiency and part consistency.

How to Select the Right End Mill Drill Tool Based on Machining Requirements

Different machining tasks have unique tool requirements. Selecting the right end mill drill cutter affects efficiency, surface finish, dimensional accuracy, and tool life. For grooving, hole-groove composite operations, or multi-process tasks, choosing tools based on material, groove depth, groove width, and machine rigidity is key. Properly matching tool specifications and geometry enhances chip evacuation, reduces tool changes, and lowers wear and machining risks.

Selecting the Appropriate End Mill Slot Drill Based on Groove Depth and Width

Groove depth and width determine tool diameter, cutting edge length, and cutting approach. For deep grooves, selecting an end mill slot drill with high rigidity and suitable cutting edge length minimizes vibration and enhances stability. For narrow grooves, tool diameter and chip flute design must ensure effective chip evacuation, avoiding clogging or overheating. Choosing the right carbide end mill drill tool for the groove type improves efficiency and maintains machining accuracy.

The Impact of the Number of Flutes on Surface Quality and Chip Evacuation

The number of flutes affects cutting force distribution, surface finish, and chip removal. End mill drill cutters with fewer flutes suit high-feed operations but may leave rough surfaces. Tools with more flutes support high-precision machining but may limit chip evacuation in deep or blind grooves. Optimizing flute count with the helix angle enhances chip removal, preserves surface quality, reduces vibration, and supports efficient continuous machining.

Tool Selection Recommendations Under Different Machine Tool Rigidity Conditions

Machine tool rigidity directly affects a tool’s ability to withstand cutting forces. High-rigidity five-axis or vertical machining centers can use long-flute, high-flute-count end mill drill tools for deep or complex machining. Lower-rigidity machines benefit from short-flute, high-rigidity cutters to minimize vibration and chipping risks. Using high-performance tools from wholesale carbide end mill drill manufacturers ensures proper selection for machine characteristics and process requirements, achieving stable and efficient machining.

Common Failure Modes and Prevention Methods for End Mill Drill Cutters

In high-precision or high-volume production, tool failure reduces efficiency, increases scrap, and stresses equipment. Common failures include chipping, breakage, and instability caused by vibration or poor chip evacuation. These issues are closely linked to cutting force distribution, tool geometry, machining parameters, and material properties. By selecting the right tool, optimizing parameters, and improving chip evacuation, you can effectively reduce failure risk, extend tool life, and maintain stable machining quality.

Common Machining Scenarios for Chipping and Breakage

Chipping and breakage occur in high-load, deep groove, or blind hole machining. Excessive axial or radial forces, insufficient rigidity, or improper parameters increase these risks. Machining hard alloys or high-strength steel amplifies the risk. Choosing the correct end mill drill cutter and optimizing feed rate and spindle speed are key preventive measures.

Practical Reasons for Vibration Problems in Groove Machining

Vibration often appears in deep groove or long-flute machining due to insufficient tool or machine rigidity, concentrated forces, and poor chip evacuation. It reduces surface quality, accelerates tool wear, and raises breakage risk. Using end mill slot drills or end mill drill cutters with optimized helix angles, shorter tip protrusions, and well-designed chip flutes effectively suppresses vibration and stabilizes machining.

Reducing Machining Risks Through Tool Selection

Proper tool selection is the most effective way to mitigate machining risks. High-rigidity end mill drill cutters with moderate cutting edge lengths distribute forces evenly, reducing vibration and chipping. Optimized geometry and carbide materials improve chip evacuation and maintain tool life and surface quality in high-speed or high-feed operations. Partnering with a wholesale carbide end mill drill manufacturer ensures tools meet machining conditions, minimizing risk and improving production reliability.

The Value of Carbide End Mill Drills in Batch Machining

In large-scale production and high-speed machining, cutting tool stability and durability have a direct impact on productivity and overall manufacturing cost. Carbide end mill drills offer high rigidity, excellent wear resistance, and strong thermal stability, allowing them to maintain dimensional accuracy and consistent surface finish under continuous cutting conditions. These tools are well suited for deep grooves, blind holes, and complex machining operations. They also reduce tool changes in multi-process machining, improving machine utilization and shortening cycle time. In batch machining environments, selecting high-performance carbide end mill drill cutters helps streamline processes, reduce production risks, and achieve stable, controllable machining results.

Advantages of Carbide End Mill Drills in Stability

Carbide materials provide end mill drills with exceptional rigidity and wear resistance, enabling stable cutting force control during high-speed, high-feed, and multi-layer machining. This stability improves surface quality while significantly reducing vibration and edge chipping. In complex groove machining and continuous batch production, the thermal stability and cutting consistency of carbide end mill drills help maintain uniform machining accuracy throughout long production runs, minimizing rework and scrap caused by tool performance variation.

The Importance of Tool Consistency in Batch Production

In batch machining, tool consistency directly affects dimensional accuracy and overall production stability. By selecting high-quality end mill drill tools manufactured under strict process control, consistency in flute length, diameter, and cutting geometry can be maintained. This is especially critical when machining large quantities of parts, as it ensures uniform surface finish and dimensional repeatability while reducing downtime and machine adjustments caused by tool variation. Consistent tooling directly contributes to higher throughput and predictable machining results.

Practical Ways to Reduce Unit Machining Costs

Using high-performance carbide end mill drill cutters in batch machining is an effective way to lower unit machining costs. Their long tool life and wear resistance reduce tool replacement frequency and inventory requirements, while optimizing machining cycles and minimizing machine idle time. In addition, selecting appropriate end mill slot drills and optimizing cutting parameters helps reduce energy consumption and material waste without compromising accuracy. Long-term cooperation with wholesale carbide end mill drill manufacturers enables bulk purchasing of high-quality tools, improving consistency while effectively controlling per-part production costs.

End Mill Drill and End Mill Selection Strategies from a Procurement Perspective

In manufacturing operations, tooling procurement strategy has a direct impact on machining cost, production efficiency, and overall quality stability. Different machining tasks require different levels of rigidity, cutting efficiency, wear resistance, and material compatibility. For mass production and multi-process machining, a well-balanced combination of end mill drill cutters and conventional end mills can improve machine utilization while reducing operational risk. From a procurement standpoint, evaluating tool performance together with supplier capability enables a more systematic and cost-effective tooling strategy that aligns production needs with long-term cost control.

Why More Factories Are Choosing End Mill Drill Cutters to Replace Some End Mills

As production cycles shorten and part geometries become more complex, end mill drill cutters are increasingly used to replace traditional end mills in specific machining operations. Their ability to perform both drilling and milling in a single setup reduces tool changes and machine downtime while improving stability in deep groove and blind hole machining. In high-efficiency production environments, end mill drill tools simplify tool management, streamline process planning, and enhance overall machining consistency, making them a practical choice for many modern CNC operations.

Advantages of Partnering with Wholesale Carbide End Mill Drill Manufacturers

Partnering with reliable wholesale carbide end mill drill manufacturers allows factories to access tools with stable performance and consistent geometric specifications. This cooperation ensures predictable wear resistance, cutting efficiency, and dimensional consistency across batches. In addition, experienced manufacturers can provide customized tool solutions for specific materials or complex groove machining requirements. A stable supply chain and consistent tooling help reduce production interruptions and support continuous, high-volume machining with controlled quality.

The Impact of Bulk Purchasing on Quality Stability and Delivery Control

In large-scale production, bulk purchasing of high-performance end mill drill cutters helps ensure consistency in tool geometry and cutting performance. This consistency directly supports stable dimensional accuracy and surface finish across large production runs. Centralized procurement also improves inventory planning, reduces unit cost, and shortens lead times, minimizing the risk of production delays caused by tool shortages. When combined with standardized cutting parameters and effective tool management, bulk purchasing becomes a key factor in improving production stability and cost efficiency.

Can End Mill Drills Completely Replace End Mills?

In practical machining applications, end mill drills and conventional end mills each serve distinct roles. While end mill drill cutters offer advantages in rigidity, efficiency, and process integration for deep grooves, blind grooves, and high-speed batch production, traditional end mills remain essential for side milling, contouring, and large-area surface machining. Complete replacement is rarely the optimal solution. Instead, tool selection should be based on machining conditions, workpiece material, machine rigidity, and production volume to achieve the best balance between efficiency, accuracy, and cost. A rational combination of both tool types improves overall productivity while maintaining machining stability and surface quality.

Suitable Machining Scenarios for End Mill Drills

End mill drill tools are particularly well suited for applications that require combined drilling and milling, such as deep grooves, blind grooves, and multi-level slot machining. Their tip geometry enables direct axial entry, while optimized chip evacuation supports stable cutting conditions. High-rigidity carbide construction allows consistent performance under high-speed and high-feed conditions. In batch production environments, end mill drill cutters reduce tool changes, improve machine utilization, and lower the risk of tool-related machining issues.

Typical Scenarios Where Conventional End Mills Are Still Required

Conventional end mills remain the preferred option for side milling, contouring, and large-area surface machining due to their flexible cutting edge length and balanced radial cutting forces. In situations where machine rigidity is limited or workspace constraints exist, traditional end mills can perform ramp entry or pre-drilled operations more safely, reducing the risk of vibration or tool breakage. These applications highlight the continued importance of end mills in precision machining and low-rigidity CNC setups.

Rational Tool Matching in Actual CNC Production

By aligning tool selection with specific machining requirements, a rational combination of end mill drills and conventional end mills delivers optimal results. End mill drill cutters should be prioritized for deep and blind groove machining, while end mills are better suited for side milling, contouring, and surface finishing. Bulk purchasing of carbide end mill drill tools, combined with optimized cutting parameters, supports stable tool life and consistent machining performance. Using conventional end mills for auxiliary operations further enhances process flexibility. This balanced approach improves machine utilization, ensures consistent part quality, and provides a reliable solution for large-scale CNC production.