End mill sizes and tolerances play a crucial role in high-precision CNC machining. Choosing the appropriate end mill sizes not only impacts cutting efficiency and machining stability but also directly affects part dimensional accuracy and surface quality. Different materials and machining types require carefully selected end mill sizes to optimize cutting performance and tool life. For example, carbide end mill sizes are typically used for high-hardness materials, enhancing cutting performance while maintaining tool life. Hardened steel end mill sizes, on the other hand, must balance rigidity and vibration resistance to avoid contour errors during machining.

In mold and die manufacturing, selecting the right end mill sizes is critical. Tool diameter, flute length, and tolerance control directly affect cavity accuracy and surface finish. When using standard carbide end mill sizes for CNC machining, engineers must also consider machining depth, slot width, and machine tool performance. For non-standard parts or complex surfaces, custom end mill sizes for CNC machining provide optimal machining compatibility and efficiency.

A comprehensive understanding of milling cutter dimensions and tolerances enables engineers to quickly determine tool specifications for various materials and machining conditions. This ensures efficient, high-precision, and cost-effective CNC machining, improving production stability and providing reliable support for high-end applications such as mold manufacturing, aerospace, and automotive parts processing.

Why End Mill Sizes and Tolerances Are Crucial for CNC Machining

End mill sizes and tolerance control are key factors in ensuring CNC machining accuracy, efficiency, and part consistency. Whether using standard carbide end mill sizes for CNC machining or custom end mill sizes, tool diameter, flute length, and tolerances directly affect vibration, tool wear, and surface quality during cutting. Even minor dimensional deviations can result in out-of-tolerance part contours, poor fit, or rework. In mold manufacturing, aerospace part processing, and medical device machining, strict control of tool dimensions and tolerances is critical.

Properly selecting tool dimensions and maintaining tight tolerance standards allows engineers to optimize cutting conditions, extend tool life, and reduce scrap. This makes dimensional matching and tolerance control for hardened steel end mill sizes and carbide end mill sizes essential aspects of CNC process planning.

How Dimensional Deviations Affect Cutting Accuracy and Surface Quality

Small deviations in tool diameter and flute length directly impact workpiece geometric accuracy and surface finish. For example, if carbide end mill sizes are too large or too small, groove width and cavity dimensions can easily deviate, causing out-of-tolerance or mismatched parts. Dimensional instability also increases cutting loads and vibration, reducing surface quality and tool life. This effect is particularly significant in precision mold machining or hardened steel machining. Selecting the proper tool diameter and controlling tolerances ensures machining stability, improves surface finish, and enhances part accuracy.

The Importance of Tolerance Control in Mass Production

In mass production, tool tolerance control directly affects part consistency and production efficiency. Mold and die end mill sizes, for instance, must maintain strict diameter and flute length tolerances to ensure consistent machining across multiple parts and avoid cavity mismatch or assembly issues. Tool manufacturing standards (such as H6 and H7 grades) are widely adopted in CNC machining, ensuring tool compatibility with machine tools and fixtures, as well as reliable dimensional repeatability. Proper tolerance selection and control in high-end precision machining significantly reduce rework and production costs.

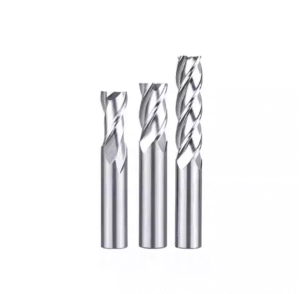

Standard Carbide End Mill Sizes for CNC Machining

Selecting the appropriate end mill sizes is crucial for machining efficiency and part accuracy. Different tasks and material types require tools with varying diameters and flute lengths. Standard carbide end mill sizes for CNC machining provide engineers with a comprehensive reference, helping them plan machining strategies, improve production efficiency, and achieve high precision across various materials.

Common Metric and Imperial Size Table

Standard milling cutter sizes cover both metric and imperial systems. Metric sizes typically range from φ1mm to φ20mm, suitable for small precision machining and general mechanical parts. Imperial sizes range from 1/16″ to 3/4″, commonly used on US-made machines or in export production. Tool size selection should also consider machine spindle diameter, fixture capacity, and workspace limitations. Small-diameter tools suit deep grooves or fine contours, while large-diameter tools excel in roughing and high material removal. Proper matching ensures cutting stability and machining accuracy.

Recommended Selection of Standard Tungsten Carbide End Milling Cutter Sizes

Different tool diameters correspond to varying cutting depths, feed rates, and spindle speeds. Small-diameter tools are ideal for finishing and surface machining, maintaining high precision while minimizing cutting vibration. Large-diameter tools suit roughing and rapid material removal, improving efficiency and extending tool life. Properly dividing small- and large-diameter tool functions allows seamless integration of roughing, semi-finishing, and finishing within a machining process. By combining standard size tables with specific machining requirements, engineers can select the optimal tool combination, optimize cutting conditions, and improve production stability.

Dimensional Matching Strategies for Different Materials

In CNC machining, different materials have specific requirements for end mill sizes and rigidity. Properly matching tool dimensions to material properties not only improves machining accuracy and surface quality but also extends tool life and minimizes machining risks. Whether machining general metals, hardened steels, or complex mold cavities, the combination of tool diameter, flute length, and material directly affects cutting load, vibration, and wear.

Therefore, when selecting tools, engineers should consider carbide end mill sizes, hardened steel end mill sizes, and mold and die end mill sizes to develop targeted dimensional matching strategies that ensure machining stability and efficiency.

Performance of Carbide End Mill Sizes in General Metal Machining

Tungsten carbide end mills excel in general metal machining, offering far greater dimensional stability and wear resistance compared to high-speed steel (HSS) tools. Tungsten carbide’s high hardness ensures tool diameter accuracy and flute length consistency even under high-speed, high-feed conditions.

Small-diameter carbide tools are ideal for finishing and fine grooves, while large-diameter tools are best for roughing and high material removal rate operations. Selecting the proper carbide end mill size improves machining efficiency, minimizes vibration, and helps maintain precise workpiece profiles.

Dimensional and Rigidity Requirements for Hardened Steel End Mill Sizes

Tool rigidity plays a critical role in hardened steel machining. Commonly used hardened steel end mill sizes include φ6, φ8, and φ10 mm, as these diameters offer a good balance between cutting strength and stability.

Using too small a diameter may cause tool deflection or breakage, while too large a diameter can restrict cutting depth and limit machine adaptability. Engineers must carefully balance diameter, flute length, and vibration resistance to maintain accuracy and prolong tool life when working with high-hardness materials. Optimizing these parameters also helps distribute cutting forces evenly for more efficient machining.

Typical Applications of Mold and Die Making End Mill Sizes

Mold and die machining demands extremely precise tool size selection, especially for cavity milling, 3D surface contouring, and radius machining. Different end mill sizes serve distinct roles across machining stages:

-

Small-diameter cutters handle fine contours and 3D surface finishing.

-

Medium-diameter cutters are ideal for semi-finishing.

-

Large-diameter cutters are used for roughing cavities and removing large volumes of material.

By strategically combining milling cutters of different diameters, engineers can achieve high accuracy, excellent surface finish, and superior productivity in mold manufacturing.

Advantages of Custom End Mill Sizes for CNC and Tolerance Applications

In complex part machining or high-precision mold manufacturing, standard end mill sizes may not fully meet CNC machining requirements. Using custom end mill sizes for CNC allows engineers to achieve better compatibility and stability for deep grooves, high aspect ratios, or non-standard contours.

Customized cutting tools not only improve dimensional accuracy and tolerance control, but also optimize cutting conditions—reducing vibration, tool wear, and machining time. In today’s advanced manufacturing, custom tooling has become essential for mold making, aerospace components, and high-end mechanical part production.

Why Standard Dimensions Can’t Meet All CNC Machining Needs

Although standard tools cover most machining applications, certain specialized conditions require non-standard sizes. For example, deep groove or complex contour machining often demands longer flute lengths or smaller diameters.

However, some CNC machines or tool holders impose limits on available tool diameters. In these cases, custom end mill sizes provide a practical solution, ensuring both cutting stability and machining precision. Custom dimensions allow engineers to select the best tool geometry for specific machines, fixtures, and machining strategies.

Key Points in Designing Custom Dimensions and Tolerances

The success of custom cutting tools lies in proper dimensional and tolerance design. Common strategies include extended flute lengths, reduced shanks, and non-standard flute diameters to handle deep grooves, deep holes, or intricate surfaces.

At the same time, custom tools must maintain strict control of dimensional accuracy, concentricity, and balance to ensure stable, repeatable high-speed cutting. With scientifically designed dimensions and tolerances, custom tools can maximize CNC machine performance, extend tool life, and minimize machining defects.

The Role of OEM Tool Suppliers in Non-Standard Size Manufacturing

Reliable OEM end mill manufacturers are vital partners for B2B customers pursuing high-precision machining. Engineers can collaborate closely with tool suppliers, sharing part specifications, material data, and machine parameters to develop optimized custom tool sizes and tolerances.

Although custom tooling may increase upfront costs or lead times, optimized design and bulk production can significantly reduce total manufacturing costs while improving machining quality and process stability.

Inspection and Verification Methods for Dimension and Tolerance Control

In CNC machining, tool dimensions and tolerance control directly determine machining accuracy, part quality, and production efficiency. Even with high-precision carbide end mill sizes or hardened steel end mill sizes, poor dimensional verification or tolerance monitoring can still lead to machining errors or poor surface finish.

That’s why establishing a reliable CNC tool inspection system—which regularly measures and verifies tool diameter, flute length, and tolerance accuracy—is essential for maintaining machining stability and extending tool life.

Through proper inspection and verification processes, engineers can detect tool wear or dimensional deviations early and make necessary machining compensations. This ensures consistent part accuracy and repeatable quality during mass production. Effective dimensional control not only helps engineers get the most out of each end mill size, but also provides reliable support for demanding applications such as mold manufacturing, aerospace components, and precision mechanical parts production.

Commonly Used Tool Measuring Equipment and Inspection Accuracy

Accurate measurement tools are fundamental for maintaining dimensional and tolerance control. Commonly used measuring devices include optical microscopes, laser diameter gauges, and tool presetters. These instruments allow precise measurement of diameter, flute length, tip radius, and concentricity.

Different methods serve different production needs: optical microscopes are ideal for small-diameter tool inspection, laser diameter gauges provide fast batch measurement, and tool presetters enable pre-machining verification and online compensation. Selecting the right measurement system ensures that end mill dimensions meet design requirements while minimizing measurement-induced machining errors.

How to Verify Tool Dimensional Stability on the Production Floor

Tool wear is inevitable in daily CNC production, making real-time wear monitoring and compensation systems crucial. Regularly checking tool dimensional changes and tolerance deviations—and integrating this data with CNC control systems—helps maintain stable machining accuracy and consistent surface quality.

In high-precision applications such as mold cavity or aerospace component machining, periodic dimensional verification prevents error accumulation, extends tool life, reduces scrap rates, and supports long-term process consistency. Consistent dimensional verification ensures that each carbide or hardened steel end mill size performs optimally throughout its service life.

Practical Application Case: From Size Selection to Improving Machining Stability

In real-world CNC machining, proper end mill size selection and optimization play a decisive role in improving machining stability, accuracy, and surface finish. Whether machining molds, die components, or carbide parts, tool diameter, flute length, and tolerance control directly affect machining outcomes.

By integrating custom end mill sizes for CNC with standard tool options, engineers can tailor tooling setups to specific machining conditions—achieving higher cutting efficiency, smoother operations, and reduced vibration. These case studies provide valuable reference points for B2B users, helping them select optimal tool specifications and minimize rework or production costs.

Tool Size Optimization Case Study for Stainless Steel Mold Cavities

In the machining of a stainless steel mold cavity, the original φ8 standard end mill was replaced with a φ6 custom carbide tool to better match cavity depth and 3D contour geometry. This adjustment significantly improved dimensional accuracy and surface finish while reducing vibration.

By precisely selecting tool diameter and flute length, engineers achieved higher material removal rates and extended tool life without compromising machining quality. This example illustrates how thoughtful end mill size optimization can enhance both efficiency and precision.

Tolerance Control Practices in Carbide Mold Machining

Tolerance selection is a key factor in carbide mold machining. Maintaining strict carbide end mill size tolerances and hardened steel end mill tolerances ensures better part fit and machining consistency.

For instance, OEM clients using custom carbide tools have reported that precise tolerance control minimizes assembly errors and eliminates the need for secondary machining during mold cavity production. In mass production environments, engineers can fine-tune tolerance ranges to achieve high precision and stable CNC machining while maintaining cost efficiency and predictable delivery times.

Proper Selection and Control of End Mill Sizes and Tolerances Are Key to High-Precision CNC Machining

In CNC machining, end mill size selection and tolerance control are fundamental to achieving high-precision, high-efficiency production. Choosing standard carbide end mill sizes for CNC machining ensures tool compatibility with machine spindles, fixtures, and workpiece materials—enhancing both stability and productivity.

Optimizing tool diameter, flute length, and cutting parameters based on material properties and machining requirements further improves accuracy and surface finish. For example, in hardened steel or mold cavity machining, selecting the right hardened steel end mill sizes and maintaining tight tolerances can effectively reduce vibration, improve dimensional accuracy, and extend tool life.

For specialized machining or complex geometries, custom CNC end mill sizes provide tailored solutions that ensure machining consistency through precise tolerance control. Practical results show that dimensional optimization and tolerance management can dramatically improve surface finish, boost CNC efficiency, and cut rework costs.

In the long term, manufacturers should combine standardized dimensional systems with customized tooling strategies to achieve scientific tool selection and refined process management. This integrated approach enhances mass production consistency and maintains a competitive edge in high-precision, high-complexity machining—delivering reliable tooling solutions for mold manufacturing, aerospace, and automotive component industries.