In metalworking and precision part manufacturing, choosing the right tool directly impacts productivity, surface finish, and dimensional accuracy. End mills and drill bits differ significantly in machining methods, tool geometry, and cutting behavior. Understanding the core differences between end mills and drill bits helps engineers make informed decisions based on material type, machining depth, and hole or contour requirements.

For common metals such as steel, aluminum, and copper, the choice between an end mill and a drill bit affects spindle speed, feed rate, tool life, and surface finish. When machining complex parts or multiple holes, knowing when to use an end mill vs a drill bit is critical for maintaining precision and minimizing rework.

The process differences between CNC milling vs drilling also determine machining strategies: milling is ideal for contouring, slotting, or complex 3D surfaces, while drilling is more efficient for straight or deep holes. For high-precision or specialized materials, custom end mills and drill bits can be tailored to optimize tool geometry, enhance cutting efficiency, and extend tool life.

Tool Selection for Metal Machining: End Mill vs Drill Bit for Metal

Selecting the proper tool is essential to ensure machining accuracy, improve productivity, and extend tool life. Whether milling intricate contours or drilling deep holes, engineers must understand the performance differences of end mills vs drill bits for metal to make the best choice for steel, aluminum, or copper. End mills excel in contouring, grooving, and 3D surface machining, while drills are better suited for rapid hole formation and deep-hole operations. Proper tool selection, cutting parameters, and chip evacuation strategies can significantly reduce defects and rework while enhancing surface finish.

Machining Strategies for Steel, Aluminum, and Copper Materials

Material properties such as hardness, toughness, and thermal conductivity influence tool selection and machining strategy. High-hardness steels require wear-resistant, coated end mills to reduce tool wear and maintain dimensional accuracy. Aluminum machining benefits from sharp, high-speed end mills or drills to improve chip evacuation and prevent burrs. Copper, prone to sticking, requires optimized feed rates and coated tools for smooth surfaces. Matching spindle speed, feed rate, and depth of cut is crucial to achieve efficient machining and minimal tool wear.

Tool Life and Cutting Parameter Comparison

End mills withstand lateral cutting forces, resulting in even wear and relatively long life. Drills, however, experience concentrated axial forces in deep-hole drilling, making them more susceptible to wear or breakage. Optimizing cutting parameters—including spindle speed, feed rate, and depth of cut—combined with proper cooling, extends tool life and ensures stable machining and high-quality surfaces.

Common Machining Problems and Solutions

Common metalworking issues include burrs, hole eccentricity, excessive roughness, and rapid tool wear. Solutions include:

-

Selecting appropriate drill types and chip evacuation methods for deep holes;

-

Using custom end mills and drill bits to match part features for contouring;

-

Adjusting cutting parameters and applying suitable coolant or air blow to prevent heat buildup;

-

Regularly monitoring tool wear and replacing tools promptly to maintain accuracy.

Systematic understanding of differences between end mills and drill bits allows engineers to make better tool choices, achieving efficient, precise machining.

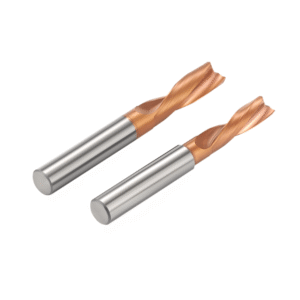

When to Use an End Mill vs a Drill Bit

Understanding when to use an end mill vs a drill bit in CNC machining is crucial for efficient production and high-precision results. End mills and drill bits differ in cutting methods, force distribution, and process suitability. Tool selection depends not only on material type but also on hole geometry, contour profile, and machining complexity. A well-planned strategy improves cutting efficiency, extends tool life, and ensures dimensional accuracy and surface finish.

Principles for Choosing Holemaking vs Contouring

Drills are primarily used for rapid hole creation and deep-hole operations. They are optimized for axial cutting and chip evacuation, enabling straight holes to be completed efficiently. End mills excel in contouring, slotting, and 3D surface machining. Engineers should consider part design, hole diameter tolerances, and surface finish requirements when selecting tools. For instance, high-precision small-diameter holes may first be drilled, then finished with an end mill. Complex contours or curved surfaces are better machined with an end mill for smoother finishes and precise dimensions.

Considerations for High-Precision and Complex Part Machining

In high-precision or complex part machining, cutting forces, tool paths, and chip removal strategies greatly impact part quality. End mills vs drill bits for metal exhibit different cutting behaviors: end mills perform well in lateral and multi-directional cutting, while drills are more efficient for axial cutting. Custom end mills and drill bits can be tailored for part contours, hole patterns, and multi-material properties, enhancing machining accuracy, surface quality, and process stability.

CNC Machining Case Studies

Real-world CNC machining demonstrates that using end mills and drill bits strategically improves efficiency and part accuracy. In aviation parts, drills create holes quickly, followed by end mills to finish contours and grooves. Mold manufacturing relies heavily on end mills for cavities and curved surfaces, using optimized cutting paths and chip management for high precision and long tool life. These cases clearly illustrate the practical differences and strategies for CNC milling vs drilling.

CNC Milling vs Drilling Process Comparison

Understanding CNC milling vs drilling process differences is key to selecting the right tool and machining strategy. End mills are ideal for contouring, grooving, and curved surfaces, while drills are more efficient for deep or rapid holes. Comparing end mills vs drill bits for metal across processes helps optimize cutting parameters, improve efficiency, extend tool life, and maintain part accuracy and surface finish.

Machining Efficiency and Cost Analysis

End mills are excellent for complex multi-directional cutting but wear faster due to intricate tool paths, requiring careful parameter selection. Drills offer fast hole creation, high efficiency, and ease of operation. Machining plans should account for material type, hole diameter, and depth to choose the right tool and calculate machining time for cost-effective CNC production. Custom end mills and drill bits further improve efficiency, reduce tool changes, and lower overall production costs.

Surface Quality and Tolerance Control

Surface finish and dimensional tolerances affect part functionality and assembly. End mills achieve smooth lateral cuts and precise contours, while drills may cause burrs or hole eccentricity if chip evacuation is insufficient. Optimizing feed rate, spindle speed, cutting depth, and using proper coolant ensures consistent surface quality and tight tolerance control in CNC milling vs drilling.

Tool Chip Evacuation and Heat Management

Chip evacuation and heat control are critical for tool life and process stability. Multi-directional cutting with end mills can cause chip accumulation, requiring effective cutting path design and air or coolant-assisted chip removal. Deep-hole drilling is prone to chip clogging, affecting hole accuracy and tool life. Proper coolant strategy and optimized tool geometry, combined with end mills vs drill bits for metal, reduce heat buildup, improve cutting efficiency, and extend tool longevity.

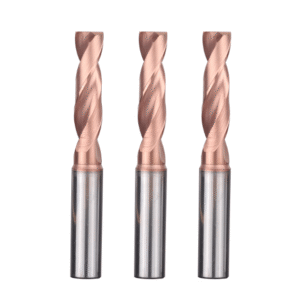

Advantages of Custom Tools: Custom End Mills and Drill Bits

For high-precision or complex parts, standard tools may fall short. Custom end mills and drill bits allow tool geometry and coatings to be designed according to material, part geometry, and hole shape, optimizing cutting efficiency, extending tool life, and ensuring machining accuracy. Custom tooling addresses complex challenges that standard tools cannot handle, providing flexible and efficient solutions for CNC machining.

Dealing with Special Materials and Complex Hole Patterns

Standard tools can wear quickly, struggle with chip evacuation, or compromise surface finish when machining mold steel, high-hardness alloys, or composites. Custom end mills and drill bits with specialized geometry and coatings improve wear resistance and process stability. For complex hole patterns—including deep holes, special shapes, or multiple holes—custom tools optimize cutting paths and chip evacuation to reduce defects and maintain dimensional accuracy and surface quality.

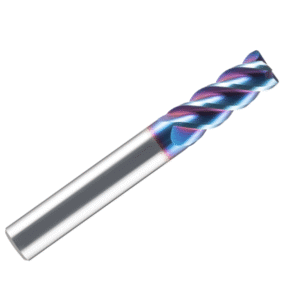

Improving Machining Precision and Efficiency

Customized tools extend tool life and significantly enhance machining efficiency. Optimizing tool diameter, flute count, helix angle, and coating allows more stable cutting forces and higher speeds in both CNC milling and drilling. For high-precision parts, custom end mills and drill bits reduce vibration and heat buildup, ensuring accuracy and shortening cycle times.

B2B Enterprise Procurement and Tool Optimization Case Studies

For B2B companies, custom tools improve both technology and cost efficiency. Tailored tools reduce replacement frequency, lower production costs, and increase process stability. Aviation manufacturers, for instance, combine deep-hole drilling with complex contour milling using custom end mills and drills, improving first-pass yield and overall production efficiency. This demonstrates the strategic value of custom tooling in industrial CNC machining.

Summary of the Difference Between End Mills and Drill Bits

The analysis above clearly demonstrates the core differences between end mills vs drill bits for metal machining, including their applications, tool geometry, and process suitability. End mills excel in contouring, grooving, and machining complex curved surfaces, while drills are more efficient for rapid hole drilling and deep-hole operations. Understanding these differences helps engineers select the right tool, optimize cutting parameters, and improve machining efficiency. Combining the practical applications of both end mills and drill bits allows for a balance between performance and cost, while ensuring part accuracy and surface quality.

Summary of Machining Application Scenarios

Different machining tasks require specific tools. End mills are ideal for CNC milling, contouring, and slotting, whereas drills are better suited for holemaking and deep-hole drilling. When machining high-hardness steel, aluminum, or copper, proper tool selection prevents burrs, hole eccentricity, and excessive surface roughness. By summarizing scenarios for when to use an end mill vs a drill bit, engineers can quickly determine which tool to prioritize for complex parts or multi-material components, improving productivity and process stability.

Tool Selection Considerations

Tool selection depends on material properties, part geometry, cutting force direction, and chip evacuation conditions. End mills typically experience uniform wear during lateral cutting, while drills face concentrated axial forces during deep-hole machining, making them prone to wear or breakage. Engineers must consider cutting speed, feed rate, tool wear, and cooling methods. Combining custom end mills and drill bits can optimize tool performance, enhance machining accuracy, and extend tool life.

Performance vs. Cost Tradeoff

End mills offer high precision and are suitable for complex contours, but they are more expensive and may require longer machining times. Drills are less costly and allow faster hole creation, but complex parts may need additional finishing or auxiliary operations. By carefully analyzing end mills vs drill bits in terms of performance, cost, and production goals, engineers can achieve efficient CNC machining while maintaining quality and controlling expenses.

How to Achieve Efficient and Precision Machining by Properly Choosing End Mills vs Drill Bits

Selecting the right end mill vs drill bit is crucial for efficient and precise CNC machining. By evaluating application scenarios, tool life, cutting parameters, machining processes, and the benefits of customized tooling, engineers can make informed decisions tailored to material types, part geometries, and machining complexity. Proper planning of tool selection, cutting strategies, and chip removal schemes enhances production efficiency while ensuring surface quality, dimensional accuracy, and tool longevity.

Comprehensive Material, Process, and Tool Customization Recommendations

When choosing a tool, consider the material type—steel, aluminum, copper, or high-hardness alloys—along with the machining process (milling or drilling) and part complexity. End mills are preferred for contouring, grooving, and complex surfaces, while drills are ideal for holemaking and deep-hole drilling. For high-precision or intricate parts, custom end mills and drill bits can be designed with optimized geometry and coatings to improve cutting force distribution, chip evacuation, and machining stability, ensuring higher accuracy and extended tool life.

Key Points for Improving Productivity and Machining Quality

Improving productivity and machining quality requires matching the tool to the task. By analyzing end mills vs drill bits alongside differences in CNC milling vs drilling processes, engineers can optimize feed rates, spindle speeds, cutting depths, and cooling strategies to prevent burrs, hole eccentricity, and poor surface finish. Proper use of custom tools reduces tool change frequency, increases first-pass yield, and establishes a stable, efficient CNC machining workflow, ultimately improving both productivity and cost-effectiveness.