Global manufacturing demands for high-performance CNC tools continue to grow, and end mill manufacturers play a critical role in improving machining efficiency, tool life, and product quality. With the increasing variety of machining materials, different types of manufacturers have emerged in the market. For example, carbide end mill manufacturers focus on wear resistance and durability; HSS end mill manufacturers emphasize cost-effectiveness and versatility; finishing and roughing end mill manufacturers specialize in specific process stages; and some custom end mill manufacturers offer tailored solutions for complex geometries and specialized applications.

Globally, manufacturers in the United States, Europe, and China have each established distinct market positions. USA end mill manufacturers are generally known for innovation and strict quality standards. European end mill manufacturers emphasize precision machining and advanced coating technologies. China end mill manufacturers, with flexible production capabilities and cost advantages, have become key players in the global supply chain. For businesses, choosing the right manufacturer impacts not only tool life and cutting performance but also production costs, lead times, and overall competitiveness.

A comparative analysis of end mill manufacturers across the United States, Europe, and China—including differences in material selection, manufacturing processes, product positioning, and customized services—is highly valuable for engineers and purchasing decision-makers.

Why Choosing the Right End Mill Manufacturer Is Crucial

In precision manufacturing and mass production, end mills are core tools that directly influence cutting efficiency, machining accuracy, and tool life. Selecting the right end mill manufacturer affects not only machining quality but also production costs and delivery schedules. Evaluating manufacturers’ technical capabilities, supply chain stability, customization options, and after-sales support has become a critical factor for maintaining competitive operations.

With the growing number of carbide end mill manufacturers, HSS end mill manufacturers, and specialized roughing and finishing tool manufacturers, making an informed choice has become increasingly essential.

The Core Role of End Mills in CNC Machining

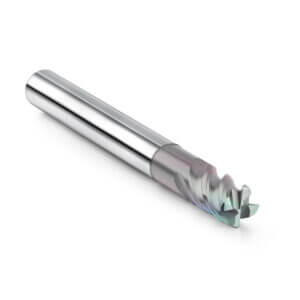

End mills are essential tools in CNC machining, handling processes such as roughing, forming, and finishing. Using the right tool can increase cutting speed, reduce machine load, and improve surface finish, reducing the need for secondary operations. Manufacturers specializing in optimized tool geometry, advanced coatings, and high-quality materials help companies achieve consistent tool life and higher productivity when machining high-hardness steels, stainless steel, or non-ferrous metals.

Common Challenges in Selecting a Tool Manufacturer

Factories often encounter the following issues during procurement:

-

Inconsistent quality: Variability between batches can lead to fluctuating tool life.

-

Uncertain delivery: Supply chain delays may disrupt production schedules.

-

Cost pressure: High-performance tools are expensive; balancing cost and performance between carbide and HSS end mills is critical.

-

Limited technical support: Insufficient guidance on tool selection or cutting parameters can reduce tool performance and machining efficiency.

These challenges highlight the importance of selecting reliable manufacturers who provide both high-performance tools and comprehensive technical support.

Differences Between Carbide, HSS, Roughing, and Finishing Tools

Different end mill types are optimized for specific applications:

-

Tungsten carbide end mills: High hardness and wear resistance make them ideal for machining hard-to-cut materials such as hardened steel, titanium alloys, and stainless steel. They are the core products of carbide end mill manufacturers.

-

HSS end mills: Excellent toughness and affordability suit medium- and low-speed cutting or cost-sensitive production. This is the strength of HSS end mill manufacturers.

-

Roughing end mills: Designed for high material removal rates, these tools are used for bulk stock removal, with tooth profiles that reduce cutting resistance and extend tool life.

-

Finishing end mills: Focused on surface quality and dimensional accuracy, these are the key products of finishing end mill manufacturers, commonly used in moldmaking and high-precision component machining.

Selecting the right tool type and manufacturer based on material properties and machining objectives helps factories balance cost, efficiency, and product quality.

Characteristics of USA End Mill Manufacturers

USA end mill manufacturers have long held a strong position in the high-end segment. They emphasize innovation, R&D, and strict quality management to ensure tool consistency and stability. Both carbide and custom end mill manufacturers in the U.S. excel in precision manufacturing, advanced coatings, and after-sales support. For CNC engineers seeking high performance, long tool life, and technical guidance, U.S. manufacturers are often the preferred choice.

Advantages of American Manufacturers

Key strengths of U.S. manufacturers include continuous technological innovation and process improvement. Breakthroughs in tool geometry, super-hard coatings, and heat treatment yield tools with reliable performance for high-hardness steels, titanium alloys, and aerospace components.

Additionally, American manufacturers provide strong after-sales support, including cutting parameter optimization, tool application training, and on-site engineering services. This enhances productivity, extends tool life, and improves cost control.

Carbide End Mill Manufacturers in the US Market

Carbide end mill manufacturers dominate the U.S. market. Tungsten carbide end mills are widely used in moldmaking, aerospace, and automotive applications. U.S. companies lead in nano-coating technology, multi-edge designs, and high-speed cutting processes. They supply both standard and custom solutions, helping engineers maintain precision and efficiency in complex or high-speed milling operations.

Custom End Mill Case Studies

U.S. custom end mill manufacturers offer tailored solutions for non-standard geometries, micro tools, and specialty applications. Examples include complex mold cavities, high-precision medical parts, and high-speed five-axis machining. Custom solutions improve process efficiency, reduce tool changes, and increase production capacity.

Characteristics of European End Mill Manufacturers

European end mill manufacturers are recognized for precision, process stability, and technological heritage. Germany, Switzerland, and Italy are key representatives:

-

Germany: Standardized processes, long tool life, wide applicability.

-

Switzerland: Ultra-precision applications like micro end mills, medical devices, and watch components.

-

Italy: Flexible manufacturing and expertise in mold and complex surface machining.

These manufacturers employ advanced powder metallurgy, PVD/CVD coatings, and automated production to ensure consistent tool performance across aerospace, automotive, medical, and mold industries.

Comparison of HSS and Carbide Tooling

European manufacturers maintain dual strengths:

-

HSS end mill manufacturers: Superior toughness and cost-performance for medium- and low-speed cutting.

-

Carbide end mill manufacturers: Leading in multi-layer coatings, edge optimization, and high-speed cutting for enhanced tool life and efficiency.

This allows Europe-based manufacturers to meet both cost-sensitive and high-performance machining needs.

Advantages in Finishing End Mills

European finishing end mill manufacturers excel in high-precision applications. Mirror-quality coatings, optimized cutting edges, and tight tolerances produce excellent surface finish and dimensional accuracy. They reduce secondary polishing steps and improve productivity, particularly for molds, aerospace components, and medical implants.

Characteristics of Chinese End Mill Manufacturers

China end mill manufacturers have become a significant force in the global CNC tool supply chain, leveraging competitive pricing, large-scale production, and fast delivery. With the rapid growth of the CNC machining industry, Chinese manufacturers excel not only in mass production of standard tools but are also increasingly competitive in carbide end mill and custom end mill markets.

Compared to American and European manufacturers, their key advantages are flexibility and cost-effectiveness. Whether for the high material removal efficiency of roughing end mills or the precise surface quality of finishing end mills, Chinese manufacturers provide comprehensive tooling solutions. This has made them widely adopted domestically and valuable supply partners for international customers in Europe, the USA, and Southeast Asia.

Competitiveness of Chinese Manufacturers: Price and Lead Time

Pricing advantage is the core strength of Chinese manufacturers. Leveraging a comprehensive supply chain and large-scale production, they can lower manufacturing costs while maintaining tool performance, offering globally competitive prices.

Lead time is another strength. Chinese manufacturers generally have flexible production scheduling and rapid response capabilities, meeting both bulk orders and small-batch custom requirements. This helps factories reduce inventory pressure while staying competitive in a rapidly evolving manufacturing environment.

Market Size and Price-Performance Ratio of Carbide End Mill Manufacturers in China

The scale of carbide end mill manufacturers in China has expanded in recent years. With improvements in domestic carbide materials and PVD/CVD coating technology, tool performance now approaches international standards.

Compared to US and European brands, Chinese tungsten carbide end mills offer a highly competitive price/performance ratio, making them ideal for cost-sensitive machining applications. For example, they are widely used in automotive parts, machinery manufacturing, and 3C electronics processing.

Supply Capabilities for Roughing and Finishing Tools

Chinese manufacturers provide a full range of roughing and finishing end mills:

-

Roughing end mills: Designed for efficient stock removal, suitable for high-efficiency machining in mass production.

-

Finishing end mills: Offer high surface quality and dimensional accuracy for mold processing, aerospace components, and high-precision parts.

This complete tool supply allows Chinese manufacturers to offer one-stop solutions, reducing procurement complexity and streamlining the production process.

Custom End Mill Manufacturers: Flexible Customization Advantage

Custom end mill manufacturers in China are highly flexible. They can quickly design and produce non-standard geometries, special-shaped blades, and micro tools based on customer needs. These solutions are especially suitable for complex molds, high-precision parts, and process optimization.

Custom services reduce tool changes, simplify production processes, and enhance efficiency. With fast response times and flexible production models, Chinese custom tool manufacturers are increasingly favored by international clients.

Global End Mill Manufacturer Comparison: USA vs. Europe vs. China

Comparing manufacturers across regions is crucial for selecting the optimal end mill supplier. Each region has distinct strengths in product quality, tool life, process stability, technological innovation, pricing, and customization. Understanding these differences helps factories and CNC engineers choose the best supplier for machining efficiency, tool longevity, cost control, and technical support.

-

USA manufacturers: Known for innovation and strict quality management.

-

European manufacturers: Renowned for precision manufacturing and advanced coating processes.

-

China manufacturers: Offer competitive pricing, fast delivery, and flexible customization.

This comparison clarifies the core competencies of each region and provides a basis for tool procurement strategy.

Product Quality and Tool Life Comparison

American and European manufacturers generally lead in tool life and quality:

-

US end mill manufacturers: Emphasize material selection, heat treatment, and cutting-edge precision for tungsten carbide and HSS tools, ensuring stability when machining high-hardness materials.

-

European end mill manufacturers: Excel in micro-precision, coating technologies, and tool geometry optimization, ideal for mold, aerospace, and high-precision parts.

-

China manufacturers: Slightly behind in raw materials and extreme machining performance but highly competitive in cost-effectiveness and rapid tool changeover, suitable for high-volume and standard production.

Technological Innovation and Process Capability Comparison

-

US manufacturers: Focus on new coatings, superhard materials, and high-efficiency tool designs for complex applications.

-

European manufacturers: Emphasize process stability, precision, and long-term durability.

-

Chinese manufacturers: Prioritize flexible production, rapid response, and continuous process improvements, including advanced coating and heat treatment technologies.

Price and Delivery Time Comparison

-

China: Competitive pricing and fast delivery due to large-scale production and efficient supply chains.

-

USA: Higher prices but consistent quality and robust technical support, suitable for high-end applications.

-

Europe: Moderate-to-high prices, stable delivery, and high-precision tools, particularly valuable for finishing and complex tooling.

Service and Customization Comparison

-

USA: Tool selection guidance, cutting parameter optimization, on-site support.

-

Europe: Precision customization, high-end process solutions for micro-parts and mold finishing.

-

China: Rapid, flexible customization for non-standard, special-shaped, or small-batch tools.

Selecting the right manufacturer based on service and customization ensures efficiency, optimized machining processes, and supply chain stability.

How to Choose the Right End Mill Manufacturer

Choosing the right end mill manufacturer is essential for maximizing machining efficiency, controlling costs, and ensuring tool life. Manufacturers differ in material selection, tool types, machining capabilities, customization, and supply chain management. A comprehensive evaluation based on actual machining needs is recommended.

Selecting Based on Material

-

Carbide end mill manufacturers: Ideal for high-hardness steels, stainless steels, titanium alloys, and aerospace components. Advanced coatings and optimized cutting edges enhance performance and surface quality.

-

HSS end mill manufacturers: Suitable for low- to medium-hardness materials or cost-sensitive applications. Reliable suppliers reduce machining risks and ensure consistent performance.

Selecting Based on Process Type (Roughing vs. Finishing)

-

Roughing end mills: Designed for high material removal; look for manufacturers skilled in tooth profile design and wear resistance.

-

Finishing end mills: Focus on surface quality and dimensional accuracy; top suppliers offer precise cutting edges, advanced coatings, and tight tolerance control.

Selecting Custom End Mill Manufacturers

Custom solutions are crucial for:

-

Non-standard geometries or micro-tools

-

High-hardness or composite materials

-

Process optimization to reduce tool changes and improve efficiency

Choose manufacturers with fast response, flexible design, and strong technical support to optimize tool geometry, coating, and cutting parameters, enhancing machining efficiency and cost-effectiveness.

Summary

In the global end mill market, manufacturers across different regions exhibit distinct core strengths and competitive characteristics. A comparative analysis of USA, Europe, and China end mill manufacturers reveals differences in product quality, tool life, technological innovation, pricing, delivery cycles, and customized services. Understanding these differences allows companies to make informed purchasing decisions, improve machining efficiency, reduce costs, and optimize production processes.

Core Differences Among Manufacturers in the United States, Europe, and China

USA end mill manufacturers are known for innovation, advanced coating technologies, tool stability, and after-sales technical support. They lead particularly in the carbide end mill sector and are ideal for machining high-hardness materials and complex applications in aerospace, automotive, and precision components.

European end mill manufacturers are renowned for precision manufacturing, process consistency, and high-precision tools. They excel in both HSS and carbide tooling, providing significant advantages for finishing end mill applications, especially in moldmaking, aerospace components, and micro-machining.

China end mill manufacturers are recognized for competitive pricing, rapid delivery, and flexible customization capabilities. They excel in roughing and standard production while also offering custom end mill solutions to meet diverse and non-standard machining requirements.

This comparison highlights the complementary performance, cost, and supply chain capabilities of manufacturers across regions, helping CNC engineers and procurement teams select the best-fit supplier.

Practical Tips for Selecting Global End Mill Manufacturers

When choosing an end mill manufacturer, consider the following factors:

-

Material: For high-hardness materials or special alloys, American or European carbide tools are preferred. USA manufacturers provide stability under high cutting loads, while European manufacturers excel in precision machining.

-

Processing Type: For roughing applications, Chinese manufacturers offer cost-effective, high-volume solutions. For finishing operations, European precision tools or high-performance American tools are more suitable.

-

Customization Requirements: Non-standard geometries, special materials, or complex processes require custom end mill manufacturers with fast response and strong design capabilities.

-

Cost and Delivery: Balance tool performance, price, and delivery time according to production volume and budget to optimize overall efficiency.

A systematic evaluation of machining needs and supplier capabilities ensures the best balance between tool life, production efficiency, and cost control.

Forecast of Future Tool Manufacturing Development Trends

Future trends in global end mill manufacturing include:

-

Material and Coating Technology Upgrades: More advanced coatings and superhard materials will enhance wear resistance and tool life of carbide end mills.

-

Intelligent and Digital Manufacturing: Automated production, CNC optimization, and tool inspection technologies will improve process consistency and quality control.

-

Customization and Flexible Production: Rising demand for non-standard, special-shaped, and complex tools will drive growth in custom end mill manufacturing.

-

Global Supply Chain Optimization: Manufacturers will enhance competitiveness through supply chain integration and rapid delivery, offering high-performance, cost-effective solutions to international customers.

These trends indicate that companies should not only consider current tool performance and price, but also evaluate technological innovation, customization capabilities, and supply chain stability when selecting end mill manufacturers.