Achieving a mirror-quality surface finish is one of the most challenging aspects of precision mold manufacturing and high-end component machining. To attain ideal reflective properties and extremely low surface roughness when machining complex curved surfaces or 3D cavities, a ball nose end mill is the most critical tool. It not only performs finishing and surface transitions but also directly determines the final visual quality and functional performance of the workpiece.

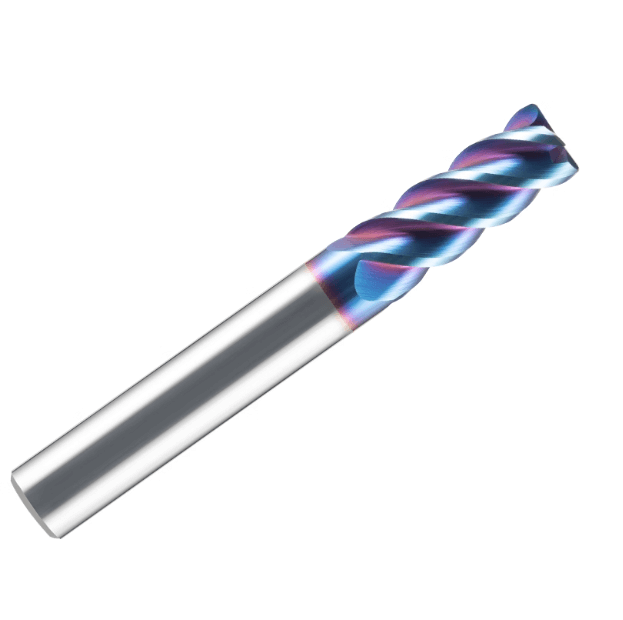

In high-precision machining, tool material, flute count, coating, and geometry significantly affect surface quality. Solid carbide ball nose end mills can maintain tool rigidity and wear resistance while achieving stable micro-cutting. Choosing between a 2 flute vs 4 flute ball nose end mill depends on workpiece material, chip evacuation, and target finish.

For hardened steel or heat-treated mold materials, machining demands are higher. Optimized toolpath strategies and advanced coating technologies are necessary to minimize tool wear, control heat, and prevent microcracks on the surface. Even slight feed inconsistencies or vibrations can result in visible tool marks, placing high demands on machine tool accuracy, fixture stability, and cutting parameter matching.

Many companies partner with OEM custom ball nose end mill manufacturers in China to meet these complex requirements. Custom tool design, optimized cutting edges, and specialized coatings enable efficient machining solutions tailored to specific materials and surface finish requirements.

The Importance of Mirror-Grade Surface Finishing in CNC Mold Manufacturing

In precision mold and high-end component manufacturing, mirror-grade surface finishing represents the ultimate in process accuracy and demonstrates a company’s manufacturing capabilities. Effective use of ball nose end mills enables extremely high finishes on complex 3D surfaces, reducing subsequent polishing steps and improving overall production efficiency. For mold makers, mirror finishes are not just cosmetic—they directly impact product lifespan, performance stability, and customer satisfaction.

Using solid carbide ball nose end mills significantly improves the consistency and accuracy of the cut surface. Their highly rigid structure ensures tool stability at high speeds, producing near-mirror-quality finishes. This high-precision machining technology is indispensable in automotive, optical, and precision electronic mold industries. In high-demand applications, such as machining hardened steel, the wear resistance and coating properties of ball nose end mills are critical for achieving top-quality surface finishes.

A high-quality surface not only improves part appearance and functionality but also enhances demolding, reduces friction and wear, and extends mold life. Mastering key technical aspects of mirror-grade finishing is essential to improve overall process quality and competitiveness in mold manufacturing.

Impact of Mirror Finishing on Mold Performance and Part Precision

Mirror-grade surfaces provide functional benefits in mold applications. A smooth cavity surface reduces friction between the part and mold, improving demolding efficiency and preventing scratches or scuffing. Mirror finishing also reduces microscopic defects, maintaining stable dimensional accuracy under high temperatures and pressures, which prolongs mold life.

For products with high aesthetic requirements—such as optical lenses, electronic housings, and automotive interior components—mirror finish directly determines visual quality and reflectivity. Using high-precision ball nose end mills for fine cutting can achieve extremely low surface roughness (Ra ≤ 0.1 μm), reducing reliance on polishing and improving consistency and repeatability.

Key Factors Affecting Surface Roughness

Achieving mirror-quality finishes requires control of multiple factors:

-

Tool Geometry: Nose radius, helix angle, and clearance angle directly affect cutting path smoothness.

-

Flute Count: 2-flute vs 4-flute ball nose end mills perform differently. Two-flute tools provide better chip evacuation for soft or sticky materials, while four-flute tools offer smoother cutting for hardened steel and finishing operations.

-

Workpiece Material and Coating: Hardened steels need high wear resistance and thermal stability. Coatings such as TiAlN, AlTiN, or CVD diamond significantly impact surface quality.

-

Cutting Parameters & Machine Rigidity: High spindle speed, microfeeds, precise step-over control, and low-vibration spindles are essential for smooth surfaces.

Partnering with an OEM custom ball nose end mill manufacturer in China allows users to customize tool geometry and coatings for specific materials and machine characteristics, achieving optimal mirror finishes.

Selecting the Right Ball Nose End Mill to Achieve High-Quality Surface Finish

Tool selection is critical for achieving mirror-quality surfaces. Ball nose end mills are essential for finishing 3D surfaces and mold cavities. Tool geometry, flute count, material, and coating technology directly influence cutting smoothness and surface finish. Matching solid carbide ball nose end mills, the correct 2 flute vs 4 flute design, and tools designed for hardened steel significantly improve surface quality, extend tool life, and reduce polishing needs.

Stability and precision are vital for mold manufacturing, aerospace parts, and high-hardness materials. Selecting high-performance tools prevents surface defects like tool marks and micro-ripples caused by vibration or poor chip evacuation. The following sections systematically analyze the advantages of different ball nose end mills for high-finish machining.

Advantages of Solid Carbide Ball Nose End Mills

Solid carbide ball nose end mills provide high rigidity, precision, and wear resistance. Compared to brazed or insert tools, they resist vibration and maintain dimensional stability, reducing tool marks during high-speed micro-cutting.

Their fine-grain carbide substrate, combined with advanced PVD or CVD coatings (such as TiAlN, AlTiN, or DLC), maintains sharp cutting edges and prevents chip sticking. For applications requiring extreme finish and precision, such as optical molds, electronic connector molds, or reflective parts, solid carbide ball nose end mills can achieve mirror finishes (Ra < 0.1 μm) at low feed rates.

They also offer excellent heat and chipping resistance, ensuring consistent surface quality during long cutting periods, making them ideal for ball nose end mills for high-precision surface finishes.

Comparison of 2 Flute vs 4 Flute Ball Nose End Mills

Flute design influences both surface finish and machining efficiency. Two-flute ball nose end mills provide better chip clearance and are suited for high-speed finishing of soft materials like aluminum or copper alloys. They prevent chip clogging and maintain tool cooling.

Four-flute tools have more cutting edges for smoother cutting, ideal for hardened steel and mold steels. They produce more continuous cuts and a finer surface finish at high speeds. In 3D contour machining, two-flute cutters are often used in roughing or semi-finishing, while four-flute cutters are preferred for final finishing to achieve mirror-quality surfaces.

Engineers should select flute count based on material, spindle speed, feed rate, and desired surface finish to optimize machining performance.

Key Application Points for Ball Nose End Mills for Hardened Steel

For steels above HRC 50, conventional ball nose cutters may struggle to balance tool life and surface quality. Hardened steel ball nose end mills feature fine-grain carbide substrates, high-temperature stable coatings, and reinforced cutting edges.

Coatings such as TiAlN, AlTiN, or nano-TiSiN maintain hardness and oxidation resistance at high temperatures, reducing friction and built-up edge formation. Recommended machining strategies include high-speed, low-feed, and small-step-over cutting to minimize tool tip load and achieve smoother surfaces.

Using a rigid toolholder system with precise runout control avoids tool marks and uneven reflections caused by micro-vibration. Partnering with OEM custom ball nose end mill manufacturers in China allows tailored solutions for complex or mass-production molds, ensuring superior stability and surface quality.

Key Machining Strategies for Achieving Mirror-Quality Surfaces

In CNC machining for mirror-quality surfaces, relying solely on high-performance ball nose end mills is not enough. Achieving a true mirror finish requires a systematic approach throughout the machining process, including toolpath optimization, cutting parameter control, spindle and fixture stability, and cooling and lubrication strategies.

By carefully planning machining paths, optimizing feed rates and step-over distances, and ensuring machine rigidity and spindle accuracy, tool marks can be minimized, uneven surface reflections suppressed, and a high-precision mirror finish achieved. These strategies are particularly critical during finishing operations for high-hardness materials or complex 3D surfaces.

Optimizing Toolpath and Step-Over Planning

Toolpath design is one of the most critical factors affecting surface roughness and machining efficiency. To achieve mirror-quality surfaces, contour machining or constant step-over finishing strategies are commonly used to maintain smooth cutting paths and uniform tool loading.

Step-over control is essential. Excessively large step-overs can cause visible tool marks and uneven reflections, while too small step-overs reduce efficiency. For solid carbide ball nose end mills under 3mm in diameter, a step-over of 3–5% of the tool diameter is recommended for consistent surface texture.

For high-precision machining, combining Z-level finishing with fine-step strategies ensures accurate form while reducing the need for post-polishing.

Optimizing Cutting Parameters to Reduce Tool Marks and Surface Reflection

Cutting parameters directly affect surface finish and tool life. Spindle speed, feed rate, and depth of cut must be optimized according to workpiece material and tool flute count.

-

2-flute ball nose end mills allow slightly higher spindle speeds and feed rates due to superior chip evacuation.

-

4-flute ball nose end mills are ideal for hard materials, providing smoother, more stable tool paths.

High spindle speeds (e.g., above 20,000 RPM) and low feed rates can minimize tool marks. Optimizing Z-stepdown maintains continuous tool contact with the surface, reducing uneven reflections.

The Impact of Spindle Accuracy and Fixture Rigidity

Even the most advanced solid carbide ball nose end mill cannot compensate for poor machine tool accuracy. Spindle runout exceeding 3μm directly causes uneven surface roughness. Fixture rigidity is equally critical, especially for hardened steel molds or thin-walled parts. High-precision HSK or BT shrink-fit systems are recommended to reduce vibration and micro-displacement.

Regular inspection of spindle bearings and toolholder concentricity ensures dynamic balance, stable cutting loads, and consistent mirror-quality finishes even at high speeds.

Cooling and Lubrication Strategies in Mirror Machining

Cooling and lubrication directly impact tool life, surface reflectivity, and microstructural integrity.

-

Dry machining works well for graphite or non-metal molds.

-

MQL or cold-air systems are recommended for metals, particularly hardened steels.

MQL reduces cutting heat, minimizes tool build-up, and achieves finer surface roughness (Ra < 0.1 μm). OEM custom ball nose end mill manufacturers in China can design tool geometries and coatings optimized for different materials and cooling methods to improve surface consistency and process stability.

Common Problems and Solutions in High-Precision Surface Machining

Even with high-performance ball nose end mills and solid carbide ball nose end mills, surface defects and tool issues may still occur during high-precision mirror finish machining. Common problems include noticeable tool marks, micro-vibration lines, chipping, premature tool wear, and inconsistent machining. Achieving extremely low Ra values and smooth, uniform surfaces requires engineers to integrate tool performance, cutting parameters, and equipment conditions into a scientific strategy to prevent and resolve these issues.

Rational toolpath planning, feed rate optimization, depth-of-cut control, and proper tool geometry and coatings can significantly improve surface quality and extend tool life. For high-hardness steel, complex 3D surfaces, or precision molds, meticulous management of each machining step is essential to avoid tool vibration and surface defect accumulation.

Causes and Improvement Methods of Surface Tool Marks and Micro-Chatter Marks

Tool marks and micro-chatter marks are typically caused by:

-

Tool wear: Worn tip radius or cutting edges result in uneven cutting and higher surface roughness.

-

Unstable feed rates or improper toolpath design: Excessive stepovers or discontinuous cutting paths leave visible marks, especially on complex curves.

-

Machine vibration or insufficient fixture rigidity: Small vibrations create periodic ripples, affecting reflected light consistency.

Improvement strategies include using high-precision ball nose end mills for micro-feed machining, optimizing toolpath planning (e.g., contour machining or Z-axis layered finishing), and ensuring spindle and fixture rigidity to reduce tool marks and micro-chatter at the source.

Tips for Preventing Tool Chipping and Premature Wear

Tool chipping and premature wear directly impact surface finish and machining consistency. Effective measures include:

-

Optimizing the entry angle: Reduces load on the tool tip and minimizes stress on the cutting edge.

-

Vibration reduction strategies: Control cutting depth and feed rate, combined with dynamic toolpath optimization.

-

Using high-performance coatings: HG, HH, or CVD diamond coatings reduce wear and prevent chipping, particularly for ball nose end mills for hardened steel.

These approaches extend tool life, reduce maintenance, and maintain high-quality mirror finishes.

Tool Life Management and Replacement Strategies

Stable, repeatable tool performance is critical. Recommended practices:

-

Monitor tool wear regularly: Use microscopy or surface roughness testing to detect wear early.

-

Maintain tool records: Track machining time, material, and surface performance for digital management.

-

Develop replacement cycles: Schedule tool changes based on material hardness and surface finish requirements to prevent defect accumulation.

OEM custom ball nose end mill manufacturers in China can optimize tool geometry and coatings for specific materials and machining conditions, achieving longer tool life and consistent mirror-quality finishes.

OEM Custom Solutions for High-End Machining

When machining high-precision molds, complex 3D curved parts, and hard materials, standard ball nose end mills often cannot meet all machining requirements. OEM custom ball nose end mills provide tailored solutions by optimizing tool geometry, flute count, coating, and helix angle based on the workpiece material, geometry, and desired surface finish. These custom tools deliver more consistent cutting performance and mirror-quality finishes. Custom tool design also extends tool life, improves machining efficiency, and enhances the stability of high-precision surface finishes.

The key advantage of OEM customization lies in the ability to configure specialized tools for different materials—such as high-hardness steel, titanium alloys, or aluminum—and complex surfaces while controlling costs. This offers integrated support from tool design to machining solutions for high-end B2B customers.

Advantages of OEM Custom Ball Nose End Mill Manufacturers in China

Chinese OEM tool manufacturers offer significant competitive advantages in high-precision custom ball nose end mills:

-

High-precision manufacturing: Advanced CNC grinding and quality management systems allow production of ball nose end mills with diameters below 1mm and tip radius accuracy at the micrometer level.

-

Cost and delivery efficiency: Large-scale production reduces costs and ensures fast delivery to meet tight deadlines for B2B customers.

-

Technical expertise: Extensive experience with hard steels, highly reflective molds, and complex 3D surfaces allows manufacturers to provide tool selection, cutting parameter optimization, and process guidance, helping clients achieve high-efficiency, high-quality finishes.

How Customized Parameter Design Supports Mirror Machining

Customization focuses on aligning tool design with the workpiece machining requirements:

-

Tool radius and cutting edge design: Selecting the right tip radius for the surface curvature and required accuracy minimizes tool marks and ensures consistent mirror-quality surfaces.

-

Coating optimization: HG, HH, or CVD coatings reduce cutting temperatures, minimize wear, and improve surface finish for hard or high-temperature applications.

-

Helix angle and flute count: Balances chip evacuation with cutting smoothness, enabling high-precision machining of complex 3D surfaces.

With these optimized parameters, ball nose end mills maintain high rigidity and low vibration, achieving Ra ≤ 0.1 μm even under low feed rates and high-speed cutting.

Collaborating with a Professional Tool Manufacturer to Improve Machining Capabilities

B2B customers gain multiple benefits from working with professional OEM manufacturers:

-

Enhanced machining efficiency: Customized tools and optimized cutting parameters reduce multiple grinding and polishing steps.

-

Consistent product quality: Tailored tools ensure uniform surface finish and dimensional accuracy across batches, reducing rework.

-

Technical support and process optimization: Manufacturers provide tool usage guidelines, cutting parameter recommendations, and problem diagnosis to maintain consistent mirror-quality machining on complex molds and hard materials.

By combining OEM customized tools with professional process support, companies can achieve ideal mirror finishes on high-hardness steel and complex curved surfaces while improving overall machining capabilities and competitiveness.

Achieving True Mirror-Quality Finishing

Achieving mirror-quality surface finishing requires more than high-performance tools—it requires a systematic machining strategy and precise process control. Solid carbide ball nose end mills are essential for high-precision 3D surface machining due to their rigidity, wear resistance, and sharp cutting edges. Proper selection of tool type, flute count, and ball nose end mills for hardened steel significantly reduces tool marks, chatter, and chipping, ensuring stable, high-quality results.

In addition to tool selection, factors like toolpath optimization, stepover control, spindle accuracy, fixture rigidity, and cutting parameter matching are critical. Techniques such as contouring, micro-stepover refinement, and controlled feed rates reduce surface roughness (Ra) and minimize uneven reflections. Cooling and lubrication strategies, including MQL or cold air systems, further enhance surface uniformity and tool life when machining hard steel and complex 3D surfaces.

Collaborating with an OEM custom ball nose end mill manufacturer in China allows customization of tool geometry, coatings, and helix angles based on workpiece material, surface complexity, and machining requirements. This approach ensures high-precision machining, extends tool life, and improves productivity.

In summary, combining high-performance ball nose end mills, systematic machining strategies, and customized tooling solutions enables companies to achieve true mirror-quality finishes on complex surfaces and hard materials while optimizing tool life, productivity, and consistency.