In radius machining, chatter is often a critical factor affecting surface quality, machining accuracy, and tool life. Whether using a solid carbide corner rounding tool, a radius rounding end mill, or a corner rounding milling cutter on high-precision workpieces, even slight resonance can produce visible edge patterns, increase dimensional deviations, and even cause tool chipping. Effectively avoiding chatter is therefore a key concern for machining engineers and manufacturing professionals.

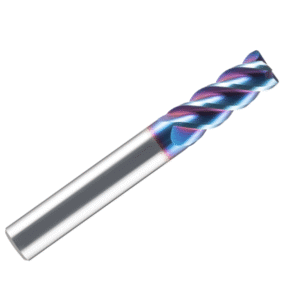

The force and vibration behavior of CNC corner rounding bits varies depending on material, radius size, and cutting method. Improper cutting parameters, excessive tool overhang, and insufficient machine tool rigidity can all amplify chatter. Compared to standard tools, solid carbide corner rounding tools offer superior stability, vibration resistance, and cutting continuity, yet they still require a proper tool path strategy and secure clamping. For companies focused on stable mass production, selecting high-consistency tools from an experienced OEM corner rounding end mill manufacturer can help reduce vibration at its source and improve overall machining reliability.

Typical Scenarios of Chatter in Corner Rounding End Mill Machining

Even with high-quality, rigid tools, slight changes in cutting forces or machine rigidity can amplify vibrations, ultimately affecting edge transitions and radius accuracy. The force patterns differ across materials, R sizes, and tool geometries, directly influencing machining stability. Many common issues arise not from operator error but from uneven tool load distribution, reaction forces, or insufficient dynamic rigidity of the machine system. Identifying these potential scenarios—during radius transitions, edge trimming, or large batch radius machining—can help prevent chatter and resonance.

Uneven Tool Loading During Small Radius Machining

Small R-value machining limits the contact area at the tool tip, concentrating stress. High-precision solid tools are especially affected, as concentrated loads can create stress peaks. Uneven loading may cause slight tool deflection when entering or exiting the workpiece edge, resulting in chatter marks or micro-tool marks. High feed rates or excessive overhang amplify local vibrations. For parts requiring small radii, such as precision components, mold corners, and rounded edges, it is crucial to reduce tool load and optimize the cutting path.

Resonance When Machining Hard Materials

Hard materials like stainless steel, mold steel, and titanium alloys present high cutting resistance. Improper combinations of tool geometry, cutting depth, and feed rate can lead to periodic reaction forces that dynamically couple with the machine structure, causing resonance. This often appears as deep corner textures, discontinuous transitions, or poor surface roughness. Even rigid, wear-resistant tools may vibrate if the material hardness approaches the tool’s cutting limit. When machining high-strength rounded areas, pay special attention to spindle load, tool entry angle, and cutting speed windows.

Chatter Caused by Insufficient Clamping and Machine Rigidity

Tool stability depends on the clamping method, tool holder structure, and overall machine rigidity. Large runout, insufficient clamping force, or excessive overhang can amplify minor disturbances, causing irregular chatter marks. Worn spindle bearings, degraded guide rails, or unstable worktables transmit vibrations to the tool, forming local ripples. For high-gloss corners or batch processing, dynamic stability of the clamping system and machine is critical. Using high-rigidity holders, reducing overhang, and ensuring machine maintenance significantly reduce vibration in corner areas.

Choosing the Right Corner Rounding End Mill to Reduce Chatter

Chatter affects surface finish, accelerates tool wear, and reduces efficiency. Selecting the right tool is crucial for machining stability. By matching the tool to material and cutting conditions, resonance can be minimized while ensuring accurate, smooth corner rounding. In high-hardness or small-radius scenarios, tool rigidity, geometry, and flute number play a key role. Combining this with solid carbide tools from a trusted OEM corner rounding end mill manufacturer reduces chatter and improves efficiency.

Stability Advantages of Solid Carbide Corner Rounding Tools

Solid carbide tools maintain stable cutting even at high speeds and feeds due to their rigidity and vibration damping. Compared to HSS or insert tools, they are ideal for CNC corner rounding bits on hard materials or precision corners, reducing vibration and surface ripples while extending tool life. OEM corner rounding end mill manufacturers provide tools with uniform tip strength, ensuring smooth cutting.

Impact of Radius Rounding End Mill Geometry on Cutting Smoothness

Tool geometry—including corner radius, tip angle, and flute design—affects cutting force distribution and smoothness. Optimized radius rounding end mills reduce instantaneous force variations and minimize vibration. In small radius or deep groove machining, proper flute design alleviates chatter caused by uneven forces, improving surface quality and ensuring CNC corner rounding bit stability.

Choosing Flute Count, R-Angle, and Shank Length

Flute count, R-angle, and shank length affect stability. Too many flutes increase cutting force, causing chatter; too few concentrate the load, increasing wear. Correct radius matching balances load and reduces force fluctuations. Long shanks amplify machine vibration; short or rigid CNC corner rounding bits improve stability. OEM guidance ensures optimized tool selection for efficient, stable corner rounding.

Reducing Chatter by Optimizing Machining Parameters

Chatter is often linked to improper cutting parameters. Optimizing spindle speed, feed rate, cutting speed, and feed per tooth finds a stable cutting zone, reducing vibration. Correct parameters improve surface finish, reduce tool wear, and extend solid carbide corner rounding tool life. Using OEM corner rounding end mill manufacturer data further enhances CNC corner rounding bit stability in precision machining.

Adjusting Spindle Speed to Find Stable Cutting Zones

Spindle speed influences tool vibration frequency and cutting force. Fine-tuning avoids resonance zones related to material or tool length. In small radius or hard material machining, appropriate spindle speed ensures smooth radius rounding end mill cutting and surface accuracy.

Configuring Cutting Speed, Feed Rate, and Feed per Tooth

Cutting speed and feed per tooth control instantaneous forces. Excessive values increase CNC corner rounding bit vibration; low values reduce efficiency. Considering material hardness, tool rigidity, and geometry ensures smooth cutting, reduces chatter marks, and improves surface consistency.

Shallow Depth and Light Cutting Strategies

Shallow depth and light cutting reduce instantaneous tool force fluctuations, minimizing vibration. This is particularly effective for small radii or deep grooves. Combined with solid carbide corner rounding tools, it ensures cutting stability. Proper strategy improves machining stability, extends tool life, and enhances CNC corner rounding bit performance in precision applications.

Improving the Clamping and Machine System Rigidity of CNC Corner Rounding Bits

In high-precision corner rounding milling, the clamping condition of the tool is crucial. The rigidity of the machine system also directly affects processing stability. Even a high-performance corner rounding milling cutter can produce chatter and surface ripples if the clamping is unstable or machine rigidity is insufficient.

Optimizing the tool holder design, shortening overhang length, using high-rigidity or anti-vibration tool holders, and ensuring the stability of the spindle, guide rails, and worktable can significantly reduce vibration. Moreover, these measures improve cutting efficiency and extend the service life of solid carbide corner rounding tools. Combined with high-quality tools from OEM corner rounding end mill manufacturers, operators can achieve smooth and efficient corner rounding even in complex machining environments.

Checking Tool Holder Runout and Using High-Rigidity Tool Holder Structures

Tool holder runout is a key factor causing chatter. Before machining, carefully check the fit between the tool holder and spindle to ensure proper coaxiality and clamping force. High-rigidity tool holders enhance the support of the CNC corner rounding bit, reducing the impact of sudden cutting force fluctuations. This ensures stable performance of the radius rounding end mill in deep groove or small radius machining.

Shortening Overhang and Using Anti-Vibration Tool Holders or Extended Shank Designs

Excessive overhang amplifies vibrations caused by cutting forces and increases the risk of chatter. Shortening the overhang according to processing depth or using anti-vibration holders or extended shank designs balances rigidity with flexibility. This setup maximizes the wear resistance and vibration damping advantages of solid carbide corner rounding tools, improving surface finish and tool life.

Ensuring Stability of the Spindle, Guide Rails, and Worktable

Insufficient machine rigidity is a major source of chatter. Regularly check spindle bearings, guide rail lubrication, and worktable fastening to maintain system stability. Proper maintenance reduces vibration from CNC corner rounding bits at high speeds and feeds. A stable machine environment allows radius rounding end mills and tools from OEM corner rounding end mill manufacturers to perform optimally, improving accuracy and efficiency.

Auxiliary Techniques and Machining Methods to Reduce Vibration

Beyond tool selection, clamping, and cutting parameters, auxiliary techniques and machining strategies are essential for vibration control. Proper use of cutting fluid, layered machining, and material-specific cutting strategies improves chip evacuation and cooling, reduces corner cutting load, and enhances CNC corner rounding bit stability. These methods also leverage the wear resistance and vibration damping of solid carbide corner rounding tools, ensuring reliable performance of corner rounding milling cutters.

Using Cutting Fluid to Improve Chip Evacuation and Cooling

Cutting fluid removes heat and evacuates chips, reducing friction and vibration. For deep grooves or small radii, applying cutting fluid keeps the CNC corner rounding bit cutting area clean, extends tool life, and improves surface finish. Using high-quality fluid with tools from OEM corner rounding end mill manufacturers ensures stable performance under complex conditions.

Reducing Corner Load Through Layered Machining

Single-pass cutting in deep grooves or large radii generates high instantaneous loads, increasing vibration risk. Layered machining divides the cut into several steps, reducing tool force fluctuations and ensuring smooth corner rounding. This approach minimizes vibration when machining small radii or hard materials with CNC corner rounding bits, enhancing accuracy and surface quality.

Optimizing Strategies for Different Materials

Material hardness and cutting characteristics significantly affect vibration. In aluminum, higher cutting speeds and feed rates maximize radius rounding end mill efficiency. For stainless steel, reduce cutting speed and increase cutting fluid cooling to control thermal deformation. For mold steel, use shallow cuts, light cutting strategies, and high-rigidity solid carbide corner rounding tools to reduce instantaneous force fluctuations. Adjusting cutting parameters for each material ensures stable and efficient machining.

The Importance of Choosing High-Quality Tools from an OEM Corner Rounding End Mill Manufacturer

High-precision corner rounding requires stable, wear-resistant tools. Choosing high-quality tools from a reliable OEM corner rounding end mill manufacturer ensures consistent edge accuracy and proper geometry, reducing chatter marks and surface defects. Quality tools enhance CNC corner rounding bit performance, complement the rigidity of solid carbide corner rounding tools, and improve machining efficiency. They maintain stable cutting across materials and complex conditions, providing a solid foundation for radius rounding end mills and corner rounding milling cutters.

Consistent Edge Machining Reduces Chatter

Edge accuracy affects cutting force distribution. Consistent edges minimize force fluctuations and chatter in deep groove or small radius machining. Using tools from a reputable OEM corner rounding end mill manufacturer ensures uniform edge quality, improving surface finish, repeatability, and reducing tool wear.

High-Quality Coatings Enhance Wear Resistance and Stability

Advanced coatings increase surface hardness and reduce friction, improving heat and wear resistance. High-quality coatings reduce tool wear and force fluctuations when machining hard materials, decreasing chatter risk. They also enhance CNC corner rounding bit stability for smoother continuous machining and longer tool life.

Customized Tool Geometry for Improved Vibration Resistance

Customized tool geometry optimizes cutting edge angle, tip radius, and helix angle for even cutting force distribution. OEM-customized radius rounding end mills and corner rounding milling cutters maintain stable cutting in small radii, hard materials, and deep grooves. Combined with high-rigidity solid carbide tools, this improves machining efficiency and surface accuracy.

Quickly Identifying and Addressing Chatter Signs During Machining

Even with high-rigidity solid carbide corner rounding tools and optimized CNC corner rounding bit parameters, chatter can occur. Timely identification and corrective measures are essential for quality and tool life. Observing edge ripples, deepened tool marks, or abnormal surface finish helps pinpoint chatter location and severity. Combined with optimized spindle speed, feed rate, layered machining, and OEM tool guidance, operators can quickly correct issues and ensure stable, precise corner rounding milling.

Recognizing Edge Ripples and Deepened Tool Marks

Regular ripples or deep tool marks indicate CNC corner rounding bit vibration. Observing cutting marks of radius rounding end mills during small radius or deep groove machining reveals uneven cutting forces. With solid carbide corner rounding tools, these anomalies help identify causes like insufficient rigidity, overhang, or parameter errors.

Adjusting Parameters Based on Vibration Source

Different vibration sources require different actions. Resonance between spindle speed and tool natural frequency can be addressed by fine-tuning speed or feed. Excessive cutting depth or wrong flute count can be corrected with shallow cuts, light cutting, or optimized geometry. Low machine or clamping rigidity may require shorter overhangs or anti-vibration holders. OEM guidance ensures minimal machining defects.

Timely Replacement of Worn Tools

Worn tools increase cutting force fluctuations and chatter. Regularly inspect solid carbide corner rounding tool edges and replace or regrind radius rounding end mills to maintain surface quality and CNC corner rounding bit stability. High-quality OEM tools ensure longer life and consistent performance, reducing chatter and maintaining efficiency during continuous machining.