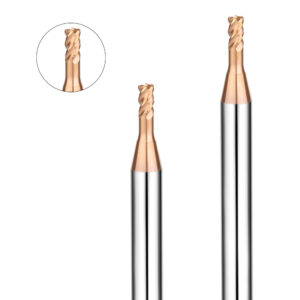

HRC65 corner radius end mills are widely used in high-hardness tool steel machining due to their rounded edge design, which effectively distributes cutting forces and improves tool life and machining stability. Compared to traditional flat-bottom end mills, corner radius end mills reduce the risk of chipping while providing higher precision and better surface quality when machining complex contours and rounded edges.

Selecting the appropriate end mill corner radius for hardened steel not only affects cutting efficiency but also directly impacts tool wear and workpiece surface integrity. For HRC65 tool steel, a properly designed corner radius can withstand high cutting forces, minimize micro-cracks and premature wear, and ensure reliable machining of high-strength materials.

Choosing high-quality corner radius end mill suppliers is also critical. Supplier capabilities in material hardness, heat treatment, and coating technology directly influence tool performance. High-quality HRC65 corner radius end mills maintain stable cutting performance, low wear rates, and excellent surface finish even under long-term, high-load machining conditions, improving production efficiency and consistency.

HRC65 corner radius end mills are suitable for precision mold cavities, tool part machining, as well as roughing and semi-finishing of high-hardness tool steel.

Why Corner Radius End Mills Are Preferred for Tool Steel Machining

Selecting the right tool structure is critical for machining efficiency and quality. Corner radius end mills feature a rounded edge design that evenly distributes cutting forces during the process, reducing stress concentration on both the tool and the material. This improves machining stability and significantly reduces chipping and micro-cracks, making cutting smoother on high-hardness steel.

Compared to flat-bottom end mills, corner radius tools maintain lower vibration amplitudes under high-speed or heavy-load cutting, optimizing tool wear patterns and enhancing workpiece surface finish and machining consistency. By carefully selecting the corner radius and tool geometry, higher cutting efficiency and longer tool life can be achieved during roughing, semi-finishing, and finishing stages. For HRC65 materials, matching the corner radius with tool diameter reduces peak cutting forces and ensures stability in intermittent or deep groove cutting, making the process more controllable.

Stress Advantages of Corner Radius End Mills in High-Hardness Tool Steel

Corner radius end mills distribute cutting forces from the tip along the tool body, avoiding high stress concentrations found in flat-bottom tools. This reduces chipping, micro-cracks, and the impact of vibration on workpiece accuracy.

In deep grooves, cavities, or inverted radius structures, uniform stress distribution ensures a stable cutting load, improving efficiency and extending tool life. For HRC65 tool steel, the rounded corner also disperses heat and local forces, maintaining geometric stability under high loads. This advantage is especially notable in long-term, continuous machining or complex contour operations, improving surface quality and minimizing tool marks.

Impact of Corner Radius Structure on Tool Life Compared to Flat-Bottom End Mills

Flat-bottom end mills concentrate stress at the tip during cutting, which can lead to chipping and microcracks, reducing tool life. Corner radius end mills distribute cutting forces smoothly along the edge, lowering peak stress and extending tool life.

The rounded design allows for higher cutting depths and lateral loads, making tools more reliable for high-hardness machining. Even under high-speed or intermittent conditions, vibration remains low and cutting forces stable, improving machining stability and production efficiency.

Stability Performance of Corner Radius End Mill Cutters in Intermittent Cutting

In intermittent cutting or complex contour operations, tools experience impact forces that can cause chipping or vibration with flat-bottom cutters. The geometry of corner radius end mills cushions these impacts, distributing forces evenly and enhancing stability.

HRC65 corner radius end mills demonstrate excellent vibration resistance in deep grooves and intermittent cutting. Tool wear is uniform, tip chipping is minimized, and cutting temperature rise is controlled, maintaining consistent workpiece surface quality and improving processing efficiency.

Tool Steel Grades Suitable for HRC65 Corner Radius End Mills

High-hardness tool steels are widely used in mold manufacturing, precision parts, and high-strength industrial components. Their machinability directly affects tool life and overall processing efficiency. HRC65 corner radius end mills can handle the high cutting forces and thermal loads associated with these steels and are suitable for a variety of wear-resistant, high-temperature resistant, and high-hardness grades. By selecting the proper corner radius and number of flutes, machining stability and surface quality can be significantly improved, reducing the risk of chipping and extending tool life.

The hardness, toughness, and heat treatment of different steel grades determine tool selection and processing parameters. Properly matching the tool structure, R-angle size, and cutting conditions maximizes tool performance and makes the machining process smoother and more efficient. In HRC65 hardened tool steel, using the end mill corner radius for hardened steel keeps the tool stable during high-load intermittent cutting and deep groove machining, improving overall production efficiency.

Common High-Hardness Tool Steel Materials and Processing Characteristics

Common high-hardness tool steels include D2, H13, S7, and SKD61, typically ranging from HRC58–65 after quenching or carburizing.

-

D2: Highly wear-resistant but low toughness, making it prone to localized chipping.

-

H13: Good thermal stability and impact resistance; requires high cutting forces, so careful control of feed rate and depth is necessary.

-

S7: High toughness with moderate hardness; suitable for machining conditions involving intermittent impacts.

When machining these steels, HRC65 corner radius end mills distribute cutting forces along the R-angle, reducing stress concentration at the tool edge and extending tool life. Optimizing tool geometry further improves surface finish and dimensional accuracy in complex cavities and inverse R-angle features.

Adaptability of End Mill Corner Radius for Hardened Steel in Different Steel Grades

The adaptability of corner radius end mills depends on stress distribution and wear resistance. For high-hardness steels like D2 or H13, a larger radius withstands higher cutting forces, reduces chipping, and maintains tool stability. For tougher or slightly softer steels like S7, a medium radius balances cutting efficiency and surface quality.

Heat treatment methods also affect tool wear. High-hardness steels generate more heat during cutting. Selecting the appropriate corner radius and coating helps control wear and maintain stable cutting performance, ensuring consistent machining results.

Influence of Material Hardness on Tool Corner Radius Selection

Material hardness directly affects stress at the tool edge. A small radius increases the risk of micro-cracks and chipping, while an excessively large radius increases cutting resistance, limiting feed rates and reducing machining efficiency.

For HRC60–65 tool steels, a medium to large radius HRC65 corner radius end mill improves chipping resistance and surface quality while maintaining tool stability. In deep grooves, complex cavities, or intermittent cutting, matching the radius to the tool diameter optimizes force distribution, reduces vibration impact, and extends tool life.

Key Design Factors of HRC65 Corner Radius End Mill

Machining high-hardness steels demands attention to tool material, geometry, edge strength, and chip evacuation. The design of an HRC65 corner radius end mill must balance cutting stability, wear resistance, and processing efficiency. A well-designed geometry maintains structural stability under high loads, reduces chipping and micro-cracks, and improves surface finish and machining consistency.

Factors such as corner radius, helix angle, flute number, and tool diameter directly influence cutting force distribution, chip evacuation, and vibration amplitude. Optimizing these parameters ensures long-term tool stability in deep groove, complex cavity, or intermittent cutting, improving production efficiency in high-hardness steel machining.

Relationship between Edge Strength and Corner Radius

Edge strength is critical for wear and chipping resistance. A larger corner radius increases the stress area at the tool edge, distributing cutting forces and reducing micro-cracks and chipping. For HRC65 steel, this is especially important due to high instantaneous cutting forces and thermal loads.

However, an excessively large radius increases cutting resistance and can reduce machining efficiency. Selecting the correct radius based on cutting depth, tool diameter, and material hardness balances edge strength and cutting performance, optimizing tool life and machining efficiency.

Helix Angle and Chip Evacuation of Corner Radius End Mill Cutters

The helix angle affects chip evacuation and cutting force direction. A higher helix angle ensures smooth chip flow, reduces friction and heat, and minimizes tool wear. A lower angle increases cutting load capacity and improves stability in hard material machining.

For HRC65 steel, selecting the right helix angle ensures efficient chip evacuation during high-speed or deep groove machining, prevents chip clogging or tool chipping, and optimizes vibration and heat distribution, improving tool life and surface quality.

Impact of Flute Configuration on Machining Efficiency and Stability in Hard Steel Machining

Flute number influences cutting force distribution, feed rate, and machining stability. Fewer flutes concentrate forces but remove more material per flute, ideal for roughing. More flutes distribute load evenly, reduce vibration, and suit semi-finishing or finishing.

For HRC65 corner radius end mills, a higher flute count improves stability during intermittent or complex contour machining while maintaining surface finish. Fewer flutes enhance cutting efficiency and reduce peak temperatures. Matching flute count with tool diameter, depth, and feed rate is crucial for achieving both efficiency and stability.

Cutting Performance of HRC65 Corner Radius End Mill Cutters

The performance of high-hardness tool steel machining depends not only on tool material but also on tool geometry and cutting parameters. HRC65 corner radius end mill cutters demonstrate excellent stability and efficiency across roughing, semi-finishing, and finishing operations. Their rounded corner design distributes cutting forces evenly, reducing stress concentration at the cutting edge, minimizing the risk of chipping, and extending tool life. Optimized geometry and helix angle ensure smooth chip evacuation, reduce vibration, and maintain consistent surface quality and dimensional accuracy.

By selecting appropriate feed rates, cutting depths, and corner radii for each machining stage, these tools maximize cutting performance and achieve stable, efficient machining of hardened steels. The typical characteristics of roughing and semi-finishing operations are discussed below.

Cutting Stability in the Roughing Stage

Roughing typically involves higher feed rates and deeper cuts, resulting in concentrated cutting forces. The HRC65 corner radius end mill evenly distributes these forces along the cutting edge, reducing stress concentration and minimizing chipping or micro-cracks.

A high helix angle and a suitable number of flutes contribute to smooth chip evacuation, prevent clogging, and reduce excessive heat buildup. In deep groove or complex cavity machining, its geometry effectively minimizes vibration, maintaining dimensional accuracy and surface consistency while reducing tool change frequency.

Surface Quality Improvement in Semi-Finishing

Semi-finishing requires high surface finish and geometric accuracy. The rounded cutting edges of HRC65 corner radius end mills reduce tool marks and workpiece damage caused by vibration.

Matching cutting depth and feed rate allows the tool to maintain stable cutting and improve surface finish. For complex contours and rounded corners, the tool distributes cutting forces evenly, ensuring shape consistency and higher machining efficiency.

Typical Cutting Performance in HRC65 Tool Steel

Machining HRC65 tool steel generates high cutting forces and heat, increasing the risk of wear and chipping. HRC65 corner radius end mills maintain stable cutting force distribution and high wear resistance under these conditions.

They retain geometric stability during intermittent cutting, deep groove operations, and complex cavity machining, ensuring smooth chip evacuation, low vibration, and consistent surface finish. Typical performance includes even force distribution, minimal tip wear, low vibration, and high surface quality, supporting efficient, cost-effective, and repeatable production.

End Mill Corner Radius for Hardened Steel: Practical Selection Guide

In machining high-hardness tool steel, the corner radius (R-angle) of the end mill directly affects cutting force distribution, tool life, and machining efficiency. By properly matching the R-angle, tool diameter, and cutting parameters, HRC65 corner radius end mills can reduce edge damage, minimize tool wear, and maintain consistent cutting performance.

Selecting the appropriate corner radius requires considering material hardness, cutting depth, feed rate, and part geometry. Deep cavities, narrow grooves, or complex contours require higher tool load capacity and stability. Larger R-angles enhance edge strength and disperse cutting impact, while smaller R-angles are suitable for fine contour work and applications requiring high surface quality. Careful evaluation of machining conditions and tool design maximizes tool life and lowers machining costs.

Application Scenarios of Different R-angle Sizes in Hardened Tool Steel

The size of the R-angle affects tool load capacity and cutting resistance.

-

Large R-angle: Ideal for deep grooves, roughing, or high-load intermittent cutting. Distributes forces, reduces edge damage, and extends tool life.

-

Medium R-angle: Balances cutting stability and efficiency in semi-finishing, suitable for complex contours and inverted R-structures.

-

Small R-angle: Provides high surface finish and precise dimensions in finishing operations.

High-hardness steels like D2 or H13 benefit from larger R-angles to withstand force peaks, while tougher steels such as S7 perform best with medium R-angles to balance efficiency and surface quality.

Selection Logic of Corner Radius End Mills in Deep Cavity and Narrow Groove Machining

Deep cavities and narrow grooves expose the tool to higher lateral forces and cutting impacts. Increasing the R-angle and optimizing flute number can distribute lateral forces, reduce cutting edge wear, and maintain tool stability during interrupted or complex cuts.

Selecting an appropriate ratio of tool diameter to R-angle reduces vibration effects on surface quality. Optimizing the helix angle and chip evacuation ensures smooth cutting and prevents chip clogging, which could otherwise lead to tool damage or reduced machining efficiency. Proper R-angle selection combined with tool path planning ensures optimal tool performance and workpiece quality.

Principles for Matching Corner Radius and Cutting Strategy to Prevent Tool Chipping

Preventing edge damage relies on both R-angle design and cutting strategy. During roughing, a larger R-angle with moderate feed can withstand high cutting forces. During semi-finishing or finishing, a slightly smaller R-angle improves surface quality and contour accuracy.

Coordination of cutting paths and interrupted cuts distributes the load evenly, minimizes localized wear, and extends tool life. Matching the corner radius with cutting strategy balances efficiency, stability, and cost-effectiveness in high-hardness tool steel machining.

Optimizing CNC Machining with Corner Radius End Mills

Machining high-hardness tool steel places strict requirements on tool geometry, cutting parameters, and machining strategy. By properly optimizing the machining approach for HRC65 corner radius end mills, tool life and production efficiency can be significantly improved while maintaining cutting stability and surface quality. Effective optimization involves coordinated control of cutting parameters, well-planned tool paths, and appropriate cooling and lubrication methods. When these factors are correctly matched, the risk of edge chipping is reduced, tool wear is minimized, and stable machining can be maintained even in deep grooves, complex cavities, and interrupted cutting conditions.

Optimized machining not only increases productivity but also improves surface finish and dimensional consistency, reducing the need for secondary finishing operations and lowering overall production costs. The geometric design and corner radius structure of the HRC65 corner radius end mill play a critical role in cutting force distribution and vibration suppression throughout the machining process, making them key contributors to efficient and reliable hardened steel machining.

Recommended Cutting Parameter Considerations for HRC65 Corner Radius End Mills

Proper cutting parameters are the foundation of successful high-hardness tool steel machining. For HRC65 corner radius end mills, cutting depth, feed rate, and spindle speed should be selected based on tool diameter, corner radius size, and flute count. During roughing operations, using a relatively shallow axial depth of cut combined with a moderate feed rate helps reduce peak cutting forces and lowers the risk of edge damage. In semi-finishing and finishing stages, the feed rate can be increased appropriately while maintaining controlled cutting depths to achieve the required surface finish and contour accuracy.

Cutting parameter adjustment must also balance cutting force, heat generation, and tool wear. A well-matched combination of cutting depth and feed rate, together with the geometric advantages of the corner radius design, allows the tool to carry a more uniform load. This improves machining stability, reduces vibration, and extends tool life during hardened steel machining.

The Impact of Tool Path Strategy on Tool Life and Machining Stability

Tool path strategy is a critical factor in machining high-hardness tool steel. Selecting suitable cutting paths and machining sequences can significantly reduce cutting impact and improve overall tool stability. In deep cavity and complex contour machining, strategies such as layered cutting, contour milling, and controlled interrupted cuts help distribute cutting forces more evenly. This reduces localized stress concentrations, limits vibration, and lowers the likelihood of edge chipping and premature wear.

With optimized tool paths, HRC65 corner radius end mills can maintain consistent cutting performance, ensuring stable surface quality and dimensional accuracy. In addition, well-designed tool paths support effective chip evacuation, preventing chip buildup that can negatively affect both the tool and the workpiece, while improving overall machining efficiency.

The Practical Impact of Cooling Methods on High-Hardness Tool Steel Machining

Cooling and lubrication play a vital role in machining hardened tool steel. Proper cooling methods help control cutting temperature, reduce tool wear, and minimize the risk of edge chipping, while maintaining stable cutting forces. Under dry machining or insufficient lubrication conditions, HRC65 corner radius end mills are more prone to localized overheating, which accelerates wear and increases the likelihood of edge failure. In contrast, high-pressure coolant systems, minimum quantity lubrication (MQL), or conventional flood cooling can effectively manage heat, improve chip evacuation, extend tool life, and preserve surface quality.

In interrupted cutting and deep groove applications, cooling methods also assist in directing chip flow and preventing chip packing or uneven force distribution on the cutting edge. When combined with optimized cutting parameters and well-planned tool paths, proper cooling selection becomes a key factor in achieving stable, efficient machining and maximizing the service life of HRC65 corner radius end mills.

Tool Wear and Failure Analysis in HRC65 Tool Steel Machining

In high-hardness tool steel machining, tool wear and edge failure are major factors influencing machining efficiency and part quality. HRC65 corner radius end mills are exposed to high cutting forces and thermal loads, and their geometric design, cutting parameters, and tool path strategy directly affect tool life and cutting stability. By understanding common wear patterns and failure mechanisms and applying appropriate process optimization, tool life can be extended while maintaining surface finish and dimensional consistency.

Cutting tools used for hardened steel machining commonly experience issues such as edge wear, tip chipping, and microcrack formation. These problems not only reduce machining efficiency but can also lead to part rework or scrap. A clear understanding of wear mechanisms, combined with proper process control and tool selection, is essential for ensuring long-term, stable performance of HRC65 corner radius end mills.

Common Wear Patterns of Corner Radius End Mills

During hardened tool steel machining, common wear patterns include cutting edge wear, flank wear, rake face wear, and tip chipping. Cutting edge wear increases cutting forces and degrades surface quality, while flank wear affects dimensional accuracy and machining stability. Rake face wear raises friction and cutting temperature, accelerating overall tool degradation.

The corner radius design of HRC65 end mills helps distribute localized cutting forces, slowing edge wear and reducing the likelihood of tip chipping. However, under conditions of high axial depth or frequent interrupted cuts, wear tends to concentrate at the tool tip and the transition zone between the cutting edge and flank. Regular tool condition monitoring and appropriate parameter adjustments are therefore essential.

Analysis of the Causes of Chipping and Microcracks in Corner Radius End Mills

Edge chipping and microcrack formation are typically caused by excessive instantaneous cutting forces, concentrated thermal loads, or inadequate chip evacuation. During hardened steel machining, impact forces and high temperatures tend to accumulate at the tool tip and edge transition area, promoting microcrack initiation and propagation, which can eventually lead to edge failure. Poor chip evacuation further increases tool loading, resulting in uneven stress distribution and accelerated wear.

HRC65 corner radius end mills are designed with optimized radius geometry and flute configurations to disperse cutting impact and enhance resistance to edge damage. However, in deep grooves, complex contours, or interrupted cutting conditions, improper cutting parameters or tool path strategies can still lead to localized chipping or microcrack formation. Comprehensive control of cutting forces, heat, and chip evacuation is therefore critical.

Extending the Service Life of HRC65 Corner Radius End Mills through Process Adjustments

Extending tool life requires a systematic approach that includes optimizing cutting parameters, tool path strategies, and cooling conditions. For HRC65 corner radius end mills, cutting depth, feed rate, and spindle speed should be adjusted according to the machining stage to avoid excessive peak cutting forces. During roughing, shallow cuts and layered machining strategies help reduce the load on the cutting edge. In semi-finishing and finishing operations, feed rates can be increased while controlling cutting depth to achieve the desired surface quality and contour accuracy.

At the same time, optimized tool paths that maintain uniform cutting loads and properly manage interrupted cuts can reduce vibration and impact, minimizing edge wear and chipping. The use of appropriate cooling methods, such as high-pressure coolant or MQL, further controls cutting temperature and improves chip evacuation. Through comprehensive process optimization, HRC65 corner radius end mills can deliver stable, efficient, and cost-effective performance in high-hardness tool steel machining.

Applications of Corner Radius End Mills in Tool Steel Components

In the machining of high-hardness tool steel components, cutting tools not only carry cutting loads but also directly determine dimensional accuracy and surface integrity. HRC65 corner radius end mills, with their rounded cutting edge geometry, offer excellent stability and durability in applications such as mold cavities, filleted structures, stepped surfaces, and precision part contours. The corner radius design distributes cutting forces more evenly and reduces stress concentration at the tool tip, helping maintain dimensional consistency and surface finish when machining complex features.

Corner radius end mills are widely used in both roughing and finishing operations for hardened tool steel components. Whether machining deep cavities, radius transitions, or high-precision contours, these tools provide stable cutting performance and extended tool life. When combined with optimized cutting parameters and machining strategies, HRC65 corner radius end mills deliver high efficiency, high accuracy, and a low risk of edge chipping in complex tool steel applications.

Machining of Mold Cavities and Rounded Corner Structures

In mold manufacturing, cavity machining and filleted corner structures require exceptional tool stability and uniform cutting performance. HRC65 corner radius end mills effectively disperse cutting forces through their rounded edge design, reducing stress concentration at the cutting edge and lowering the risk of chipping and microcrack formation.

For deep or complex cavities, proper selection of tool diameter, corner radius, and helix angle—combined with layered machining and contour toolpaths—ensures efficient chip evacuation and effective control of cutting heat and vibration. This improves machining efficiency, surface quality, and dimensional accuracy. During fillet machining, the corner radius end mill provides smooth contour transitions, minimizes tip wear, and ensures consistent chamfer and radius accuracy.

Machining of Tool Steel Part Contours and Stepped Surfaces

Contour and stepped surface machining of tool steel components requires tools that maintain cutting stability while achieving high material removal efficiency. HRC65 corner radius end mills distribute lateral cutting forces more evenly during contour machining, reducing vibration and improving process consistency. In stepped surface machining, the rounded edge design helps manage peak cutting forces, reduces localized chipping, and enhances tool life and surface finish.

By applying optimized cutting strategies and selecting an appropriate flute count, corner radius end mills maintain uniform wear when machining hardened materials. This enables efficient machining while ensuring that contour dimensions and step flatness meet design specifications.

Corner Radius Transition Machining of High-Precision Tool Steel Parts

High-precision tool steel components often include complex chamfers and radius transition features that demand tight tolerances and superior surface quality. HRC65 corner radius end mills enable smooth cutting through transition areas, reducing localized force concentration, minimizing vibration, and limiting microcrack formation at the cutting edge.

When machining deep cavities or intricate contours, proper cutting parameters and well-designed toolpaths allow corner radius tools to achieve stable cutting, excellent surface finish, and high repeatability. Their strong wear resistance and chipping resistance also support long-term continuous machining, reducing production costs while improving part consistency and overall manufacturing efficiency.

How to Evaluate Reliable Corner Radius End Mill Suppliers

In hardened tool steel machining, selecting a reliable corner radius end mill supplier is critical to ensuring consistent tool performance and machining efficiency. High-quality suppliers must provide not only durable HRC65 corner radius end mills but also demonstrate strong capabilities in material selection, heat treatment control, coating technology, and batch consistency. A systematic evaluation of supplier capabilities helps ensure stable tool performance, long service life, and consistent machining quality in high-volume production.

When assessing suppliers, attention should be given to tool material hardness and toughness, heat treatment uniformity, and geometric accuracy of the corner radius. Stable manufacturing processes ensure that corner radius end mills experience uniform stress distribution and reliable wear resistance during hardened steel machining, reducing chipping, microcracks, and unexpected tool failure.

Key Capabilities of Corner Radius End Mill Suppliers in Materials and Heat Treatment

Machining high-hardness tool steel requires cutting tools with excellent wear resistance and thermal stability. Reliable suppliers must be capable of selecting high-quality carbide or advanced tool materials and maintaining strict control over heat treatment processes, including quenching, tempering, and coating application. This ensures that HRC65 corner radius end mills achieve the intended hardness, toughness, and wear resistance.

Equally important is the control of tool geometry. Consistency in edge radius, helix angle, and flute count directly affects cutting force distribution, vibration control, and chip evacuation. Strong material and process control enable stable tool performance in interrupted cutting, deep grooves, and complex contour machining.

Consistency and Batch Stability Assessment of HRC65 Corner Radius End Mills

In mass production and long-term machining, tool consistency and batch stability have a direct impact on machining accuracy and productivity. Supplier capability can be evaluated by comparing tool wear patterns, chipping frequency, and machined surface quality across different batches of HRC65 corner radius end mills used under similar cutting conditions.

Stable batch production ensures consistent cutting forces in cavity machining, deep grooves, and complex contours, minimizing uneven wear and surface quality variation. By tracking tool life and machining performance data, the supplier’s level of process control, material management, and heat treatment consistency can be accurately assessed.

Judging Supplier Technical Capability through Machining Results

Actual machining performance is one of the most reliable indicators of a supplier’s technical capability. By evaluating wear behavior, chipping resistance, and surface finish produced by HRC65 corner radius end mills during hardened steel machining, users can determine whether tool materials, heat treatment processes, and geometric accuracy meet application requirements.

Uniform wear patterns and high surface quality indicate mature control over material selection, radius design, and heat treatment. Conversely, frequent edge chipping, uneven wear, or surface tearing often point to deficiencies in material quality or process control. Combining machining efficiency data with tool life results provides a comprehensive basis for selecting reliable suppliers capable of supporting stable, large-scale hardened steel machining.

Cost Efficiency of Using Corner Radius End Mill Cutters in Tool Steel

In hardened tool steel machining, selecting stable and durable HRC65 corner radius end mills not only ensures machining accuracy and surface quality but also significantly reduces cost per part and improves overall production efficiency. By optimizing tool geometry, corner radius size, helix angle, flute count, cutting parameters, and toolpath strategies, tool life can be maximized while vibration and chipping are minimized.

Cost efficiency depends on a balanced combination of tool performance, machining process optimization, and supplier reliability. High-quality suppliers provide consistent material properties, controlled heat treatment, and precise geometry, enabling stable performance in deep grooves, cavity machining, radius transitions, and complex contours. Matching cutting parameters to tool characteristics reduces tool changes, improves machining efficiency, and lowers total manufacturing costs.

Single-Part Cost Control in High-Hardness Machining with Corner Radius End Mills

In hardened tool steel machining, single-part cost is influenced not only by material and labor but also by tool life and process stability. HRC65 corner radius end mills distribute cutting forces through their rounded edge design, reducing chipping and microcracks while promoting uniform wear and longer service life.

In deep groove, cavity, and complex contour machining, optimized cutting parameters and toolpath strategies help maintain stable machining conditions, reducing rework and scrap rates. Consistent tool performance lowers cost per part while ensuring surface finish and dimensional accuracy, achieving an effective balance between productivity and cost control.

The Impact of Tool Life and Tool Change Frequency on Overall Machining Efficiency

Tool life directly affects tool change frequency and overall production cycle time. High-wear-resistant HRC65 corner radius end mills maintain stable cutting performance for extended periods in hardened steel machining, reducing downtime caused by frequent tool changes.

Proper corner radius selection, combined with optimized flute count and helix angle, ensures even force distribution, low vibration, and efficient chip evacuation during high-load or interrupted cutting. Extended tool life improves machining efficiency, shortens cycle time, and helps control total production costs.

The Value of Choosing the Right Corner Radius End Mills for Production Efficiency

Selecting the right HRC65 corner radius end mill is essential for maintaining production continuity while achieving consistent accuracy and surface quality. High-quality corner radius end mills from reliable suppliers deliver stable material properties, uniform heat treatment, and precise geometry, resulting in balanced cutting forces, reduced vibration, and uniform wear.

When combined with appropriate cutting parameters, toolpath strategies, and cooling methods, corner radius end mills perform reliably in complex cavities, filleted structures, and high-precision components. This shortens production cycles, improves yield, and reduces scrap and rework. Ultimately, the correct selection and application of HRC65 corner radius end mill cutters play a critical role in maximizing both economic efficiency and machining performance in hardened tool steel applications.