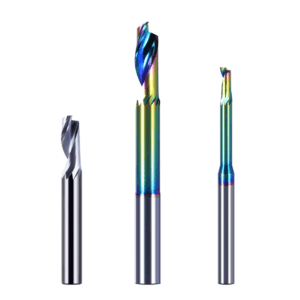

In our daily projects, we frequently encounter a recurring issue: customers use supposedly high-quality single flute end mills, yet machining results remain inconsistent. Surface burrs appear, and tool life is often far below expectations. Through years of field experience, we’ve found that these problems are rarely caused by the machine tool or operator. Instead, they typically result from insufficient attention to tool selection, material compatibility, geometry parameters, and chip removal efficiency.

For example, when machining aluminum, the geometry of a single flute end mill for aluminum—including cutting edge angles and flute polishing—directly affects cutting smoothness and surface finish. In plastic machining, the cutting edge treatment and optimized parameters of a single flute end mill for plastic are key to avoiding weld edges and stringing. For high-precision customers, we often tailor machining strategies for different aluminum alloys or engineering plastics, considering the carbide end mill single flute material and coating properties.

We also have extensive experience evaluating tool suppliers. In the Chinese single flute end mill manufacturing industry, tool consistency, batch stability, and engineering support capabilities are often more important than price alone. Only by understanding these factors can we ensure stable machining, reduce scrap rates, and improve overall production efficiency.

So, in your own machining projects, have you encountered situations where, despite seemingly appropriate tool parameters, you still can’t achieve the expected results?

In What Machining Scenarios Do We Prioritize Single Flute End Mills?

Not all materials or workpieces are suitable for multi-flute end mills. We typically prioritize single flute end mills in high-feed machining or when chip evacuation space is limited. A single flute offers a large cutting edge area and ample chip evacuation space, reducing the risk of surface scratches or premature tool wear caused by chip accumulation. This is particularly important when machining aluminum parts and certain engineering plastics at high feed rates.

We also consider machine and fixture rigidity when recommending tools. Factors like spindle power, fixture type, and machining depth influence whether a single flute end mill is optimal. Often, our goal is not to achieve theoretical cutting efficiency but to ensure repeatable and stable machining results under constrained space and material conditions. This approach is especially valuable for customers who have tried multi-flute end mills but still encounter chatter or burrs.

Actual Machining Situation with High Feed Rate but Limited Chip Removal Space

A European customer once requested complex contour machining of aluminum profiles at high feed rates, but the machining cavity was very tight. Using multi-flute end mills led to chip accumulation, surface scratches, and dimensional drift. We recommended a single flute end mill for aluminum, slightly adjusting the helical flute and cutting edge angle.

The results were significant: even at the same cutting speed, chip removal improved, surface finish was smoother, and tool life increased by roughly 30%. This case shows that, under high-feed, limited-space conditions, flute width and chip volume are often more critical than tool hardness. If you are facing similar conditions, you can prioritize single-flute tools and, based on carbide end mill single flute characteristics, perform proper edge treatment for aluminum or plastic parts instead of blindly pursuing high-speed, multi-flute options.

Typical Working Conditions Where Chips Stick or Stretch

In plastic and soft aluminum machining, we often see chips sticking to the tool and stretching excessively. Customers may initially reduce feed or increase cooling, but the problem persists. Field tests show that single flute end mills for plastic reduce cutting heat and sticking. The larger chip space, shorter contact time, and smoother chip evacuation are essential when machining fusible plastics like acrylic or POM.

We optimize performance with proper cutting edge treatment and coating selection. For instance, using an aluminum end mill to machine plastics often results in wire drawing or surface burrs, despite similar material hardness. If you are machining plastics, you can select a dedicated single flute end mill and adjust depth of cut and feed rate based on material, rather than relying solely on tool material or spindle speed.

Situations Where Multi-Flute End Mills Fail to Achieve Stability

Many customers initially use multi-flute end mills to maximize efficiency but experience vibration, surface ripples, or burrs—especially with thin-walled or complex workpieces. Our tests show that single flute end mills distribute cutting force more evenly, reducing errors caused by vibration. Combined with the wear resistance of carbide end mills with single flutes, tools maintain stable performance over extended machining.

We explain to customers that the problem often lies not in the tool itself but in the balance between cutting force, chip evacuation, and workpiece rigidity. If you are facing similar issues, you can compare single-flute tools with your current multi-flute setup to evaluate improvements in stability and surface quality.

From Real-World Experience, the Most Crucial Factor Isn’t the Number of Cutting Edges

Customers often assume “more cutting edges = higher efficiency,” but results tell a different story. In aluminum and plastic machining, cutting stability, chip removal, and tool rigidity outweigh the number of flutes. For example, mismatching effective cutting edge length with actual depth of cut can concentrate forces on a few edges, causing surface ripples, burrs, or premature wear.

Similarly, in plastics, increasing spindle speed without considering chip removal leads to welded edges or streaking. Matching cutting edge length with depth of cut ensures better stability and surface quality than simply adding flutes. If you are optimizing machining, focus on edge load, chip evacuation, and workpiece rigidity before assuming more flutes will help.

Problems from Mismatched Cutting Edge Length and Depth of Cut

We often see carbide single flute end mills cutting thin-walled aluminum with a depth exceeding half the effective edge length. This causes tool tip vibration and uneven scratches. On-site, we advise reselecting tool length, adjusting feed and depth, and ensuring even edge load.

In plastics like POM or acrylic, too short an effective edge length reduces chip evacuation and may overheat the cutting edge. By considering material type and depth of cut, each cutting edge operates within the proper load range, improving tool life and machining stability.

Impact of Tool Groove Polishing on Chip Removal and Surface Quality

Many customers overlook groove polishing. Rough grooves lead to chip sticking, especially in high-speed aluminum or low-melting plastics, causing surface scratches or clogging. We demonstrate the effects of different polishing treatments, showing that proper groove design and finish often influence machining stability more than flute count.

A well-polished groove also optimizes cutting force distribution. For complex contours, polished single flute end mills for aluminum reduce vibration and improve surface finish. For plastics, they prevent edge melting and stringing.

Spindle Requirements at High Speeds

Single flute end mills concentrate cutting forces, imposing strong loads on the spindle. At high speeds, inadequate spindle rigidity causes vibration. We advise adjusting spindle speed according to machine power and fixture method rather than reducing feed as a sole solution.

For plastics, smooth chip removal helps, but cutting forces still require proper diameter, depth, and spindle speed matching. If you are planning high-speed machining, ensure the interaction between tool, workpiece, and machine is well understood—this is often more critical than flute count.

The Trade-off Logic of Carbide End Mill Single Flute in Practical Applications

In our daily machining support, we often encounter customers confused about tool material selection, especially in high-speed machining of aluminum and engineering plastics. Many assume that harder carbide tools are always better. In practice, however, we’ve found that this choice is not always optimal. We evaluate whether a carbide end mill single flute truly addresses vibration, tool wear, and chip removal challenges, considering material properties, machine tool rigidity, and cutting depth. Typically, carbide single-flute tools only show a clear advantage under high-speed, high-feed, and strict surface quality requirements.

We also consider the customer’s machine tool and fixture conditions. For example, some low-rigidity machines may experience micro-vibrations when using overly hard tools, negatively affecting the surface finish. Choosing a tool material is not just about hardness—it’s about ensuring overall machining stability. If you are unsure whether a carbide end mill single flute is worth the investment, performing test cuts under actual conditions can confirm whether it improves efficiency without introducing scrap risk.

What Problems Does Carbide Truly Solve in Aluminum and Plastic Machining?

For aluminum, the most significant advantages of carbide single-flute tools are wear resistance and cutting consistency. In high-speed machining of thin-walled aluminum parts, uniform tool edge wear directly affects surface finish and contour accuracy. Using these tools for aluminum significantly reduces chip buildup and burr formation, while extending tool life.

In plastics, carbide tools help control edge heat and prevent melted edges. For instance, when machining POM workpieces, ordinary high-speed steel single-flute tools caused chipping. Switching to a carbide single-flute end mill resulted in smoother chip evacuation, stable cutting forces, and fewer surface burrs. Our experience shows that carbide’s value lies in high-frequency cutting and demanding surface quality situations, not simply in its hardness.

Case Study of Abnormal Tool Life Due to Incorrect Base Material

A customer reported that their single-flute tool life was one-third below expectations on certain aluminum alloys. On-site analysis revealed that using high-speed steel instead of carbide was the cause. Edge wear occurred too quickly, leading to uneven forces and premature tip breakage. After switching to carbide and fine-tuning the depth of cut and feed rate, tool life returned to expected levels.

Similar issues arose in plastics. Some clients used low-hardness steel to save costs, resulting in severe edge wear and burrs. Demonstrating carbide single-flute application on-site highlighted the importance of material matching for machining stability. This confirms that tool material selection impacts not only tool life but also surface finish and repeatability.

Applications Where We Do Not Recommend Blindly Pursuing High Hardness

Carbide single-flute tools are not always necessary. Low-speed machining or soft materials with low cutting forces may experience tip chipping or surface unevenness if the tool is too hard. We once processed thin-walled aluminum profiles with high-hardness tools on low-rigidity fixtures. Micro-vibrations caused surface ripples. Switching to medium-hardness carbide single-flute tools produced more stable results.

Similarly, in plastics, small depths of cut and feed rates make high hardness unnecessary. We advise balancing tool hardness with wear resistance, considering machine rigidity, cutting parameters, and material properties. The key is not to pursue hardness blindly but to maximize carbide effectiveness in true high-load, high-demand scenarios.

Real-World Selection Experience with Single Flute End Mills for Aluminum

From years of experience machining aluminum for European and American clients, we’ve learned that cutting edge count is not the only determinant of stability. Multi-flute tools may increase efficiency but often cause vibrations and burrs on thin-walled or complex parts. Single flute end mills provide more stable cutting forces, smoother chip removal, and maintain surface finish and dimensional accuracy at high feeds and speeds.

Tool material, helix angle, and flute polishing also directly impact results. Even with the same diameter carbide single-flute end mill, poor flute finish or an improper helix angle can cause chip buildup and scratches. We adjust selection and geometry based on machine rigidity, fixture type, and cutting depth to ensure optimal edge load, extend tool life, and stabilize quality.

Why a Single-Flute End Mill Is More Stable Than a Multi-Flute End Mill in Aluminum

Multi-flute end mills often vibrate on thin-walled aluminum or complex contours, producing surface ripples. In a 6061 aluminum profile case, high-speed multi-flutes caused fine scratches. Switching to a single flute end mill for aluminum delivered concentrated cutting force, smoother chip removal, and reduced vibration.

Single-flute tools maintain consistent cutting force at high feeds without overload from chip buildup. For clients seeking high surface quality, these tools are generally more reliable than multi-flute options. We recommend prioritizing single-flute end mills for aluminum in thin-walled or complex parts, adjusting feed and speed to match actual workpieces.

Differences in Tool Geometry Requirements for Different Aluminum Alloys (6061 / 7075)

6061 aluminum is softer and generates lower cutting temperatures, requiring sharp edges and a slightly larger helix angle for chip evacuation. 7075 is harder with higher cutting forces. Using a single-flute tool with an excessively large helix or sharp edge may cause tip chipping and micro-burrs.

We once machined parts in both alloys using the same diameter and material tool. Results varied drastically. Adjusting helix and edge angles avoided 7075 chipping while maintaining 6061 surface quality. Geometry adjustment based on material properties is a key operational method developed through field experience, not theory.

Reducing Built-Up Edge Through Tool Details, Not Just Parameters

Built-up edge is common in aluminum machining. Reducing feed or speed alone often fails. We start with tool details: flute polishing, helix angle, cutting edge sharpening, and coating selection. Optimized details ensure smooth chip evacuation, even edge load, and less built-up edge without sacrificing efficiency.

We validate tool performance on-site before each batch. By adjusting cutting edge and helix angles according to part thickness, material, and depth, customers achieve better surface finish and dimensional consistency than by merely changing parameters. This empirical approach is more reliable than increasing speed or feed rate alone.

Common Pitfalls in Single Flute End Mills for Plastics

In our long-term on-site customer support, we frequently find that many problems encountered by customers in plastic processing do not stem from machine tool or operational errors. Instead, they often result from a lack of understanding of material properties and the cutting behavior of single-edged tools. This is especially true for engineering plastics such as acrylic, POM, or ABS. If cutting conditions or tool edge selection are not optimized, weld edges and burrs can form easily. Many customers only realize after the first batch of scrapped parts that the problem was not excessive spindle speed, but rather poor chip removal and uneven cutting force distribution.

Our experience has shown that selecting the right single flute end mill for plastics, and properly treating the cutting edge, is crucial for stable processing. Tool geometry, edge sharpness, helix angle, and material hardness all affect heat accumulation and chip removal efficiency. We typically combine material type and part geometry to fine-tune the tool edge angle and coating on-site, ensuring smooth chip evacuation while controlling cutting heat. This approach reduces weld edges and burrs and comes from years of field experience rather than theoretical formulas.

Plastic Edge Melting and Burrs: More Than Just Spindle Speed Issues

When machining POM sheets, we frequently see surface streaking and edge melting. Many operators initially try reducing spindle speed, but we have found that this addresses only part of the problem. The primary issue is chips remaining in the tool groove too long, combined with an improper cutting edge angle, causing localized heat accumulation. By adjusting the edge geometry and helix angle of these single-flute tools, we significantly improve chip removal efficiency and reduce thermal contact with the workpiece, noticeably alleviating edge melting.

Similarly, in acrylic machining, tools with dull edges or insufficient groove polishing are prone to burrs and scratches even at low speeds. We verify edge sharpness and groove finish on-site to identify the optimal match, ensuring a smooth surface rather than merely reducing spindle speed or feed rate. Our experience shows that solving edge melting and burr issues requires attention to tool geometry and chip control, not just parameter adjustments.

Performance of Single-Flute End Mills in Acrylic, POM, and ABS

In our field tests, we observed significant differences in the performance of single-flute end mills across different plastics. Acrylic requires sharp edges to prevent cracks or melted surfaces; POM cutting is gentler, but edge dulling may cause stringing; ABS is prone to burrs, but smooth chip removal yields high surface finish. We select tool material and edge design for carbide single-flute end mills based on material characteristics to ensure proper machining conditions for each plastic type.

We also adjust tooling strategies based on workpiece geometry and machining depth. For thick plates or complex contours, we may reduce depth of cut or perform segmented machining rather than blindly increasing feed rates. This empirical approach extends tool life, reduces scrap, and maintains machining stability and surface quality.

How We Improve Plastic Surface Quality Through Tool Edge Treatment

Tool edge treatment is critical in plastic machining. We perform micro-grinding and coating optimization on single-flute end mills to ensure sharp edges and smooth chip removal, preventing localized heat buildup that leads to melted edges. In transparent acrylic parts, we once virtually eliminated surface burrs by polishing the edges and fine-tuning the helix angle, extending tool life by approximately 25%.

We combine cutting parameters with edge geometry optimization to ensure each edge operates within a reasonable load range, rather than relying on spindle speed reduction. This approach consistently achieves high surface quality and dimensional accuracy for plastics like POM and ABS. We have found that detailed edge treatment often has a greater impact on final part quality than simple parameter adjustments.

Common Misconceptions Customers Make When Selecting Single Flute End Mills

Customers often focus only on diameter and length when selecting tools, overlooking the actual rigidity of the machine tool and fixture. Many aluminum or plastic projects experience vibration, burrs, or premature tool wear, often not because the tool is inadequate, but because the cutting load exceeds the system’s capacity. We advise that tool stability depends on flutes, length, diameter, and clamping rigidity—especially in high-speed or thin-walled machining.

Another misconception is that single-flute tools are inherently inefficient. Some customers assume multi-flute tools always cut faster, but single-flute tools often offer higher chip removal efficiency and cutting stability, improving production consistency and part quality. Assessing efficiency requires considering material, workpiece structure, and machine rigidity, not just ideal feed rates.

Focusing Solely on Diameter and Length While Ignoring Rigidity

We often see clients select a single-flute end mill with appropriate diameter and length but still experience vibration and ripples on thin-walled aluminum. On-site analysis shows tool rigidity depends on spindle rigidity and fixture method. Ignoring this leads to uneven edge loading, accelerated wear, or tip breakage. We advise adjusting tool length based on machine conditions or using a shorter, stiffer tool, along with feed rate and depth of cut optimization.

In plastics, excessively long or flexible tools can cause chip buildup, melted edges, or burrs. We evaluate cutting edge design and helix angle to ensure each cut occurs within a reasonable load, rather than relying on theoretical parameters.

Using Aluminum Cutting Tools to Machine Plastics Often Produces Worse Results

Clients sometimes use aluminum cutting tools for POM or acrylic, assuming materials are interchangeable. This often causes stringing and burrs. On-site tests show that edge geometry and chip removal design are highly material-dependent. Aluminum tools in plastics may have overly sharp edges or large cutting angles, causing localized heat and severe melting.

We recommend dedicated single-flute end mills for plastics, optimizing cutting performance through edge treatment and coating adjustment. On-site adjustments reduce burrs and extend tool life. This demonstrates that tool material and edge design must match the workpiece material; otherwise, high hardness or sharpness can be counterproductive.

Treating “Single-Flute = Low Efficiency” as a Fixed Conclusion

Many customers initially think single-flute end mills are inefficient. Repeated on-site demonstrations show this is often based on theory, ignoring real machining conditions. For aluminum or plastic, single-flute cutters concentrate cutting forces and improve chip evacuation. Even if apparent feed rates seem lower, downtime for cleaning and scrap is reduced, improving overall production efficiency.

We illustrate actual differences based on machine type, workpiece thickness, and depth of cut. Adjusting spindle speed, feed rate, and edge geometry demonstrates that single-flute cutters can match or exceed multi-flute performance in high-precision machining, while ensuring surface quality and consistency. Efficiency cannot be judged solely by flutes; cutting stability and chip removal must be considered.

From an Engineer’s Perspective: How to Evaluate a Chinese Single Flute End Mill Manufacturer

Based on our experience in supplying and providing technical support, selecting a end mill manufacturer is not just about price. It also involves machining stability and long-term production efficiency. Many customers initially focus on the sharpness of a single tool pass, but for high-precision aluminum or plastic parts, batch consistency is critical. We evaluate manufacturers based on material uniformity, cutting edge tolerances, and flute polishing to ensure that each carbide single-flute end mill delivers consistent performance under identical conditions.

In addition, we consider customer feedback from on-site machining to assess a manufacturer’s engineering support capabilities. Simply delivering sharp tools does not solve real-world machining problems. We value manufacturers who provide guidance on cutting edge fine-tuning, geometry optimization, and coating selection. These capabilities directly impact the stability and tool life of single-flute end mills for aluminum or plastic in customer production and are the primary factors in selecting partners.

Why Tool Consistency is More Important Than Single-Batch Sharpness

We often receive feedback that the first tool performs well, but subsequent batches produce inconsistent results. On-site analysis typically shows that the problem is not the machine tool or operator error but poor batch consistency.

The cutting performance of a single-flute end mill depends not only on edge sharpness but also on flute accuracy, helix angle tolerance, tool diameter, and cutting length consistency. Even small deviations can create uneven cutting forces, impacting surface finish and dimensional accuracy.

When advising customers, we emphasize verifying batch consistency through test cuts of multiple tool batches, rather than relying solely on promotional data or single-batch results. High single-batch sharpness alone cannot ensure stable performance.

Key Manufacturing Details That Affect Batch Stability

Critical factors for batch stability include the uniformity of the tool body material, precision of cutting edge grinding, quality of spiral groove machining, and consistency of coating adhesion. We once addressed a customer’s aluminum machining issue caused by slight differences in groove polishing across batches, which led to uneven chip removal and minor surface scratches. The problem was resolved through communication with the manufacturer and process improvements.

Additionally, tool heat treatment and material hardness control are essential. Single-edged tools experience significant impact and wear at high speeds; uneven hardness or insufficient toughness can cause chipping or shortened tool life. On-site testing under continuous high-load machining allows us to evaluate whether a manufacturer can consistently deliver stable performance.

Why European and American Customers Value Engineering Support

Our experience shows that European and American clients increasingly prioritize engineering support when selecting Chinese single-flute end mill manufacturers, rather than focusing solely on price or factory sharpness. Customers often require tool geometry fine-tuning, edge optimization, and cutting parameter recommendations for specific materials, including 6061 and 7075 aluminum, as well as POM and ABS plastics.

Manufacturers capable of on-site commissioning, parameter optimization, and cutting strategy guidance are more likely to ensure part quality and tool life during actual production. Engineer-level technical support can shorten troubleshooting cycles and reduce scrap rates. In our technical support work, we emphasize that this capability has a greater long-term impact than simply pursuing tool hardness or the number of flutes.

Our Actual Methods for Providing Technical Support for Single-Flute End Mills

Clients often understand single-flute end mills only through parameter manuals or theoretical formulas, while real-world machining problems are more complex. We begin by evaluating material type, machine tool rigidity, and fixture method, then combine this with workpiece geometry to determine if a single-flute end mill is suitable. This method extends tool life, improves surface quality, and ensures smooth chip removal and stable cutting forces.

If you are machining aluminum or plastic and experience burrs, weld edges, or vibration, consider evaluating the tool diameter, helix angle, and depth of cut relative to the workpiece material and machine conditions, rather than simply adjusting spindle speed or feed. Providing drawings, material specifications, and machining details allows us to make targeted tool selections and optimize cutting edges based on actual data.

How to Determine Tool Parameters Based on Material and Machine Tool

Material hardness, cutting temperature, and chip characteristics directly affect tool geometry selection. We adjust the helix angle and cutting edge sharpness of carbide single-flute end mills based on customer materials, such as 6061 or 7075 aluminum, POM, and ABS, to ensure uniform cutting forces and smooth chip removal. Machine rigidity and spindle power also determine tolerable depth of cut and feed rates.

For thin-walled parts or complex contours, we first assess workpiece material and machine tool rigidity, then adjust cutting edge length, tool diameter, and depth of cut based on cutting load and chip removal efficiency. This ensures better machining stability than blindly applying parameter tables.

Prioritizing Tool-Material Matching Over Parameter Adjustments

When machining results in scratches, burrs, or tool chipping, our first step is not adjusting feed or spindle speed. Instead, we analyze whether the tool matches the workpiece material, depth of cut, and machine rigidity. Many scrapped parts are caused by excessive tool load or poor chip removal, not incorrect parameters.

Before fine-tuning feed or depth, check the edge load and chip removal of the single-flute end mill. Providing specific working conditions or drawings allows us to offer more accurate adjustments based on real materials and machines rather than relying solely on experience or parameter tables.

Long-Term Clients Prioritize Stability Over Lowest Price

Long-term European and American clients focus on machining stability and tool life, rather than simply the lowest cost. They care whether carbide single-flute end mills maintain surface finish, dimensional accuracy, and chip removal efficiency at high speeds and feeds.

In our technical support, we combine the client’s actual machining situation to provide edge optimization, depth of cut recommendations, and parameter fine-tuning, ensuring tool consistency in mass production. Customers should evaluate supply options based on the performance indicators that matter most to their production: surface quality, tool life, or single-pass efficiency. Providing material type, machine rigidity, and machining depth allows for optimal tool selection while ensuring machining stability, not just price.