Troubleshooting Common Flat Bottom Drilling Problems

In mechanical processing and precision manufacturing, the quality of hole machining directly affects product performance and service life. Flat bottom drills are widely applied because they produce bottoms with consistent flatness, but in actual operation, common issues such as diameter deviation, uneven hole bottoms, and burr formation still occur frequently. These problems not only lower […]

Troubleshooting Common Flat Bottom Drilling Problems Read More »

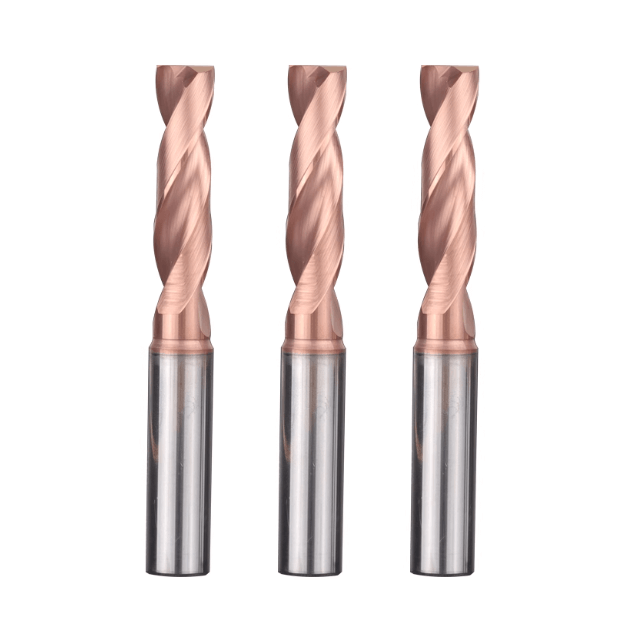

白底-主图2.jpg)

-白底主图5.jpg)

-白底主图1.jpg)