Top Hard Milling End Mill Suppliers in 2026

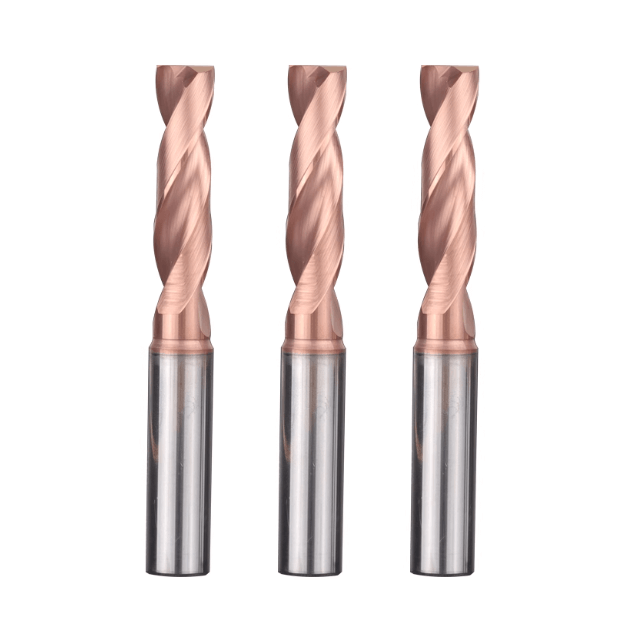

In the field of high-hardness material machining, selecting the right hard milling end mill is essential for both efficiency and precision. The market offers a wide variety of products, with different materials, coatings, and cutting edge geometries performing differently in practical applications. For factories or manufacturers working with high-hardness steel, high-quality end mills for hard […]

Top Hard Milling End Mill Suppliers in 2026 Read More »